Patents

Literature

35results about How to "High temperature and high humidity resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Highly wearable vacuum coating ultraviolet curing coatings

ActiveCN101157808AImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsWear resistantLacquer

The invention relates to the electronic application-coating field, in particular to uv-curing coating with high wearing resistance and vacuum coating. The compositions and contents of the invention are: 10 wt percent to 30 wt percent of difunctional group polyurethane acrylate, 10 wt percent to 40 wt percent of high functional group polyurethane acrylate, 5 wt percent to 20 wt percent of high functional group acrylate monomer, 0 wt percent to 15 wt percent of monofunctional group acrylate monomer, 1 wt percent to 10 wt percent of acid adhesive promoter, 1 wt percent to 6 wt percent of photoinitiator, 0 wt percent to 5 wt percent of nano wearing resistance materials, 0.1 wt percent to 2 wt percent of additive and 10 wt percent to 50 wt percent of solvent. The invention is designed for providing surface protection for vacuum coating parts of electric products such as mobile phone, MP3, and digital camera, etc., and is characterized by good surface effect, good performances of ultrawear-resistance, high temperature and humidity resistance, anti-cold thermal cycling and anti-yellowing, etc., wherein, RCA wear can be up to more than 1500 times, which can effectively improve the service life of electric products. The invention effectively enhances the adhesion and wearing resistant performance of the uv-curing and vacuum coating dope, solves the matching problem of the bottom and surface lacquer of the uv-curing and vacuum coating dope, and has broad university.

Owner:HUNAN SOKAN NEW MATERIAL

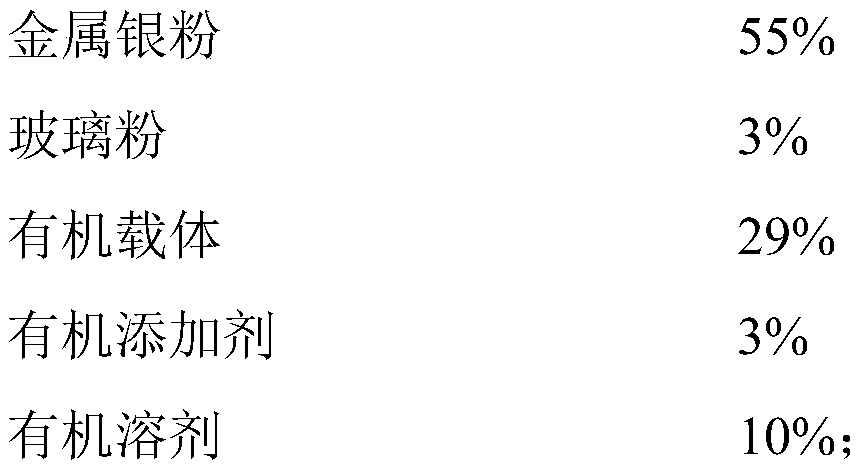

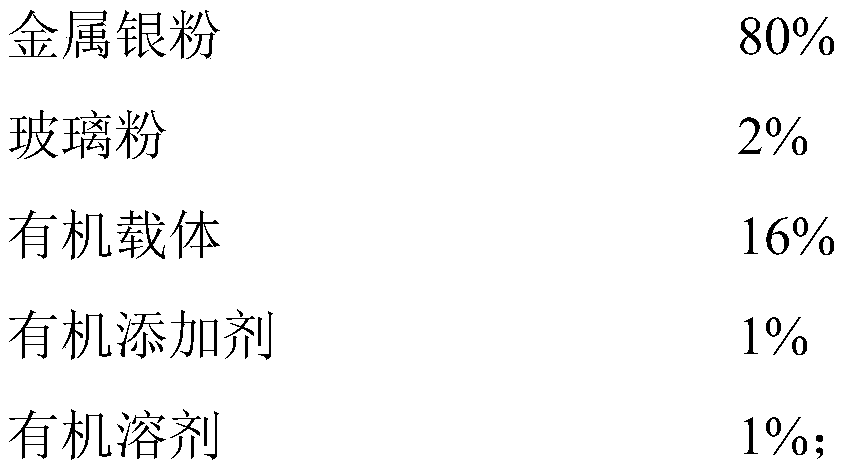

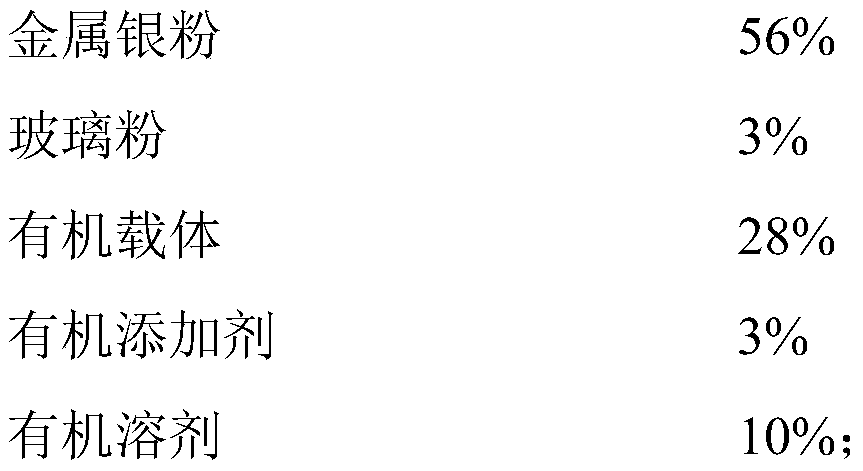

Conductive silver paste for ceramic filter and preparation method thereof

PendingCN111489848ASolve conductivity problemsSolve solder performanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteThermal dilatation

The invention relates to conductive silver paste for a ceramic filter and a preparation method of the conductive silver paste. The conductive silver paste comprises the following components in parts by weight: 50-80 parts of metal silver powder, 2-5 parts of glass powder, 10-30 parts of an organic carrier, 1-3 parts of an organic additive and 1-10 parts of an organic solvent, wherein the glass powder is lead-free glass powder, the coefficient of thermal expansion is 110-120*10<-7> / DEG C, and the sintering temperature is 550-750 DEG C. The preparation method comprises the following steps: adding the organic carrier and the organic solvent into a mixer, adding the metal silver powder, the glass powder and the organic additive, fully mixing, transferring a mixture into a high-speed dispersionmachine, and uniformly dispersing at a high speed to obtain a conductive silver paste; and grinding the prepared conductive silver paste in a three-roller mill, and finely adjusting a roller to enable the fineness of the conductive silver paste to be less than 10mu m and the viscosity to be 30-50Pa.S, thereby obtaining the conductive silver paste for the ceramic filter. The conductive silver paste for the filter can form a conductive silver layer which is high in compactness, high in adhesive force, high in conductivity, good in weldability and stable in performance.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

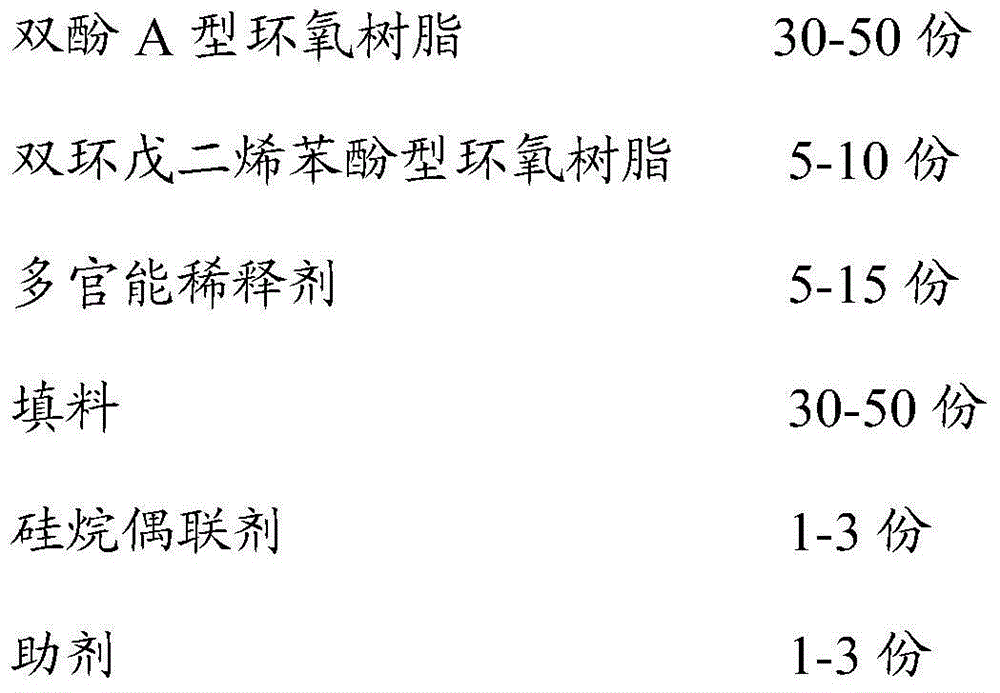

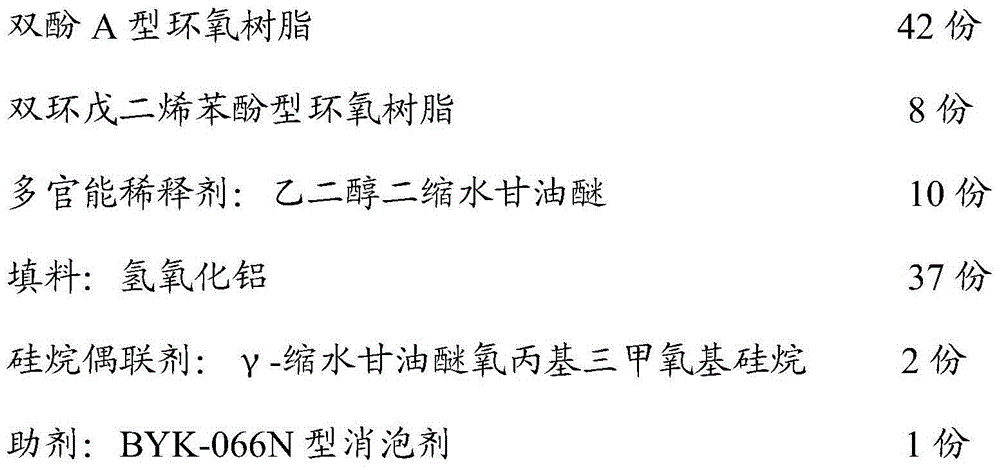

Epoxy resin encapsulating material as well as preparation method and application thereof

ActiveCN104531027AGood heat resistanceHeat resistance Very low moisture absorptionNon-macromolecular adhesive additivesEpoxy resin adhesivesChemistryElectronic materials

The invention discloses an epoxy resin encapsulating material as well as a preparation method and application thereof, and belongs to the technical field of electronic materials. The epoxy resin encapsulating material is prepared from the following raw materials: a resin part, namely a bisphenol A epoxy resin, a dicyclopentadiene phenol-type epoxy resin, a multifunctional diluent, a filler, a silane coupling agent and auxiliaries, and a curing agent part, namely methyl nadic anhydride and / or methyl tetrahydrophthalic anhydride, a cycloaliphatic epoxy resin and an accelerant; the resin part is mixed with the curing part to obtain the epoxy resin encapsulating material. According to the encapsulating material, the dicyclopentadiene phenol-type epoxy resin is added to the resin part, the silane coupling agent is applied to activating the filler in combination with the multifunctional diluent, and the cycloaliphatic epoxy resin is added to the curing part, and therefore, the finally obtained encapsulating material has the characteristics of high temperature resistance and high humidity resistance. The encapsulating material is used for preparing a capacitor, and consequently, the capacitor is enabled to be stable in capacity, small in change tolerance and longer in service life under the conditions of a high temperature, high humidity, and running with load after being powered on.

Owner:GUANGZHOU POCHELY NEW MATERIAL TECH CO LTD

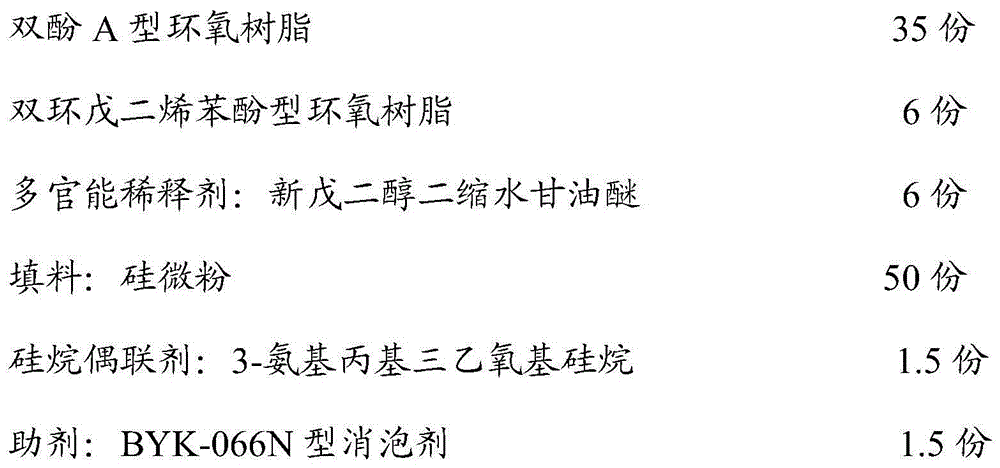

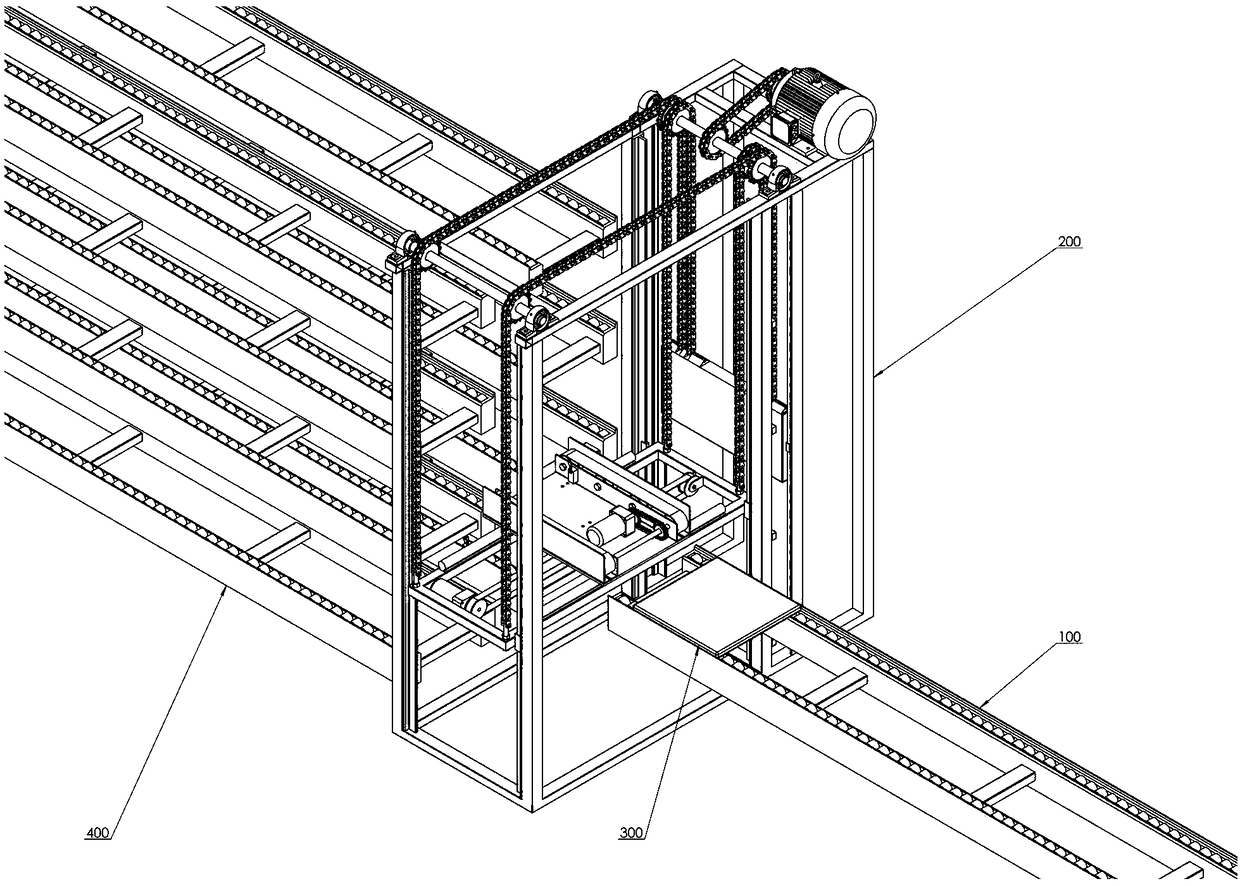

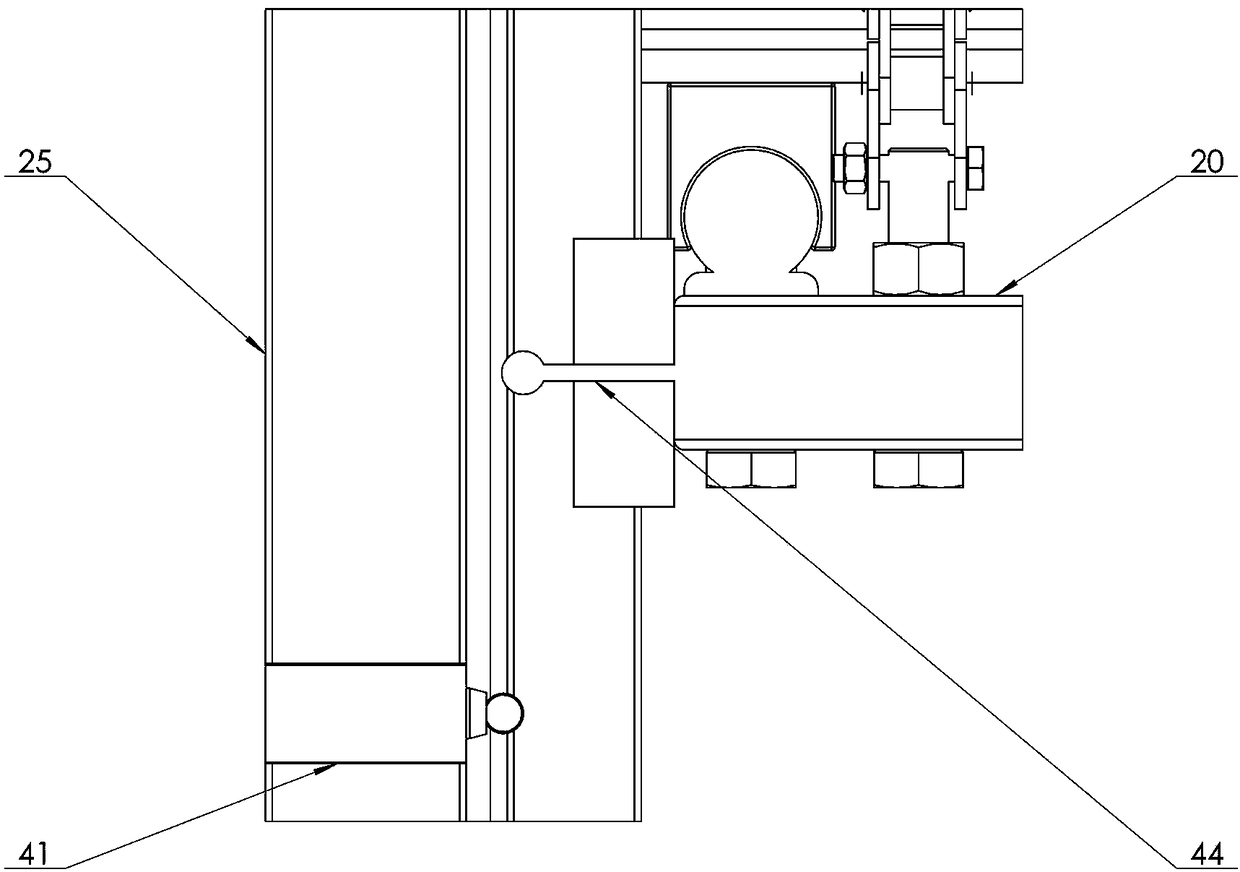

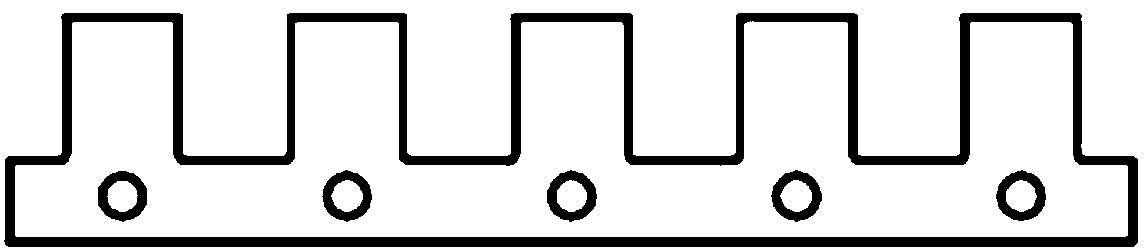

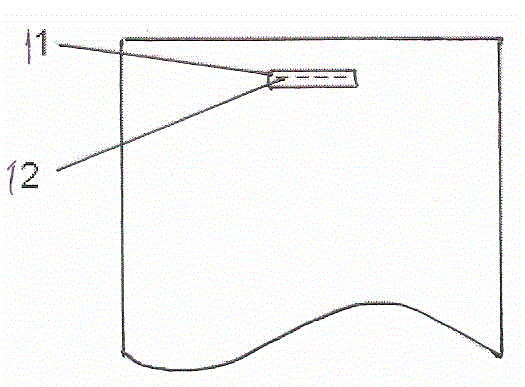

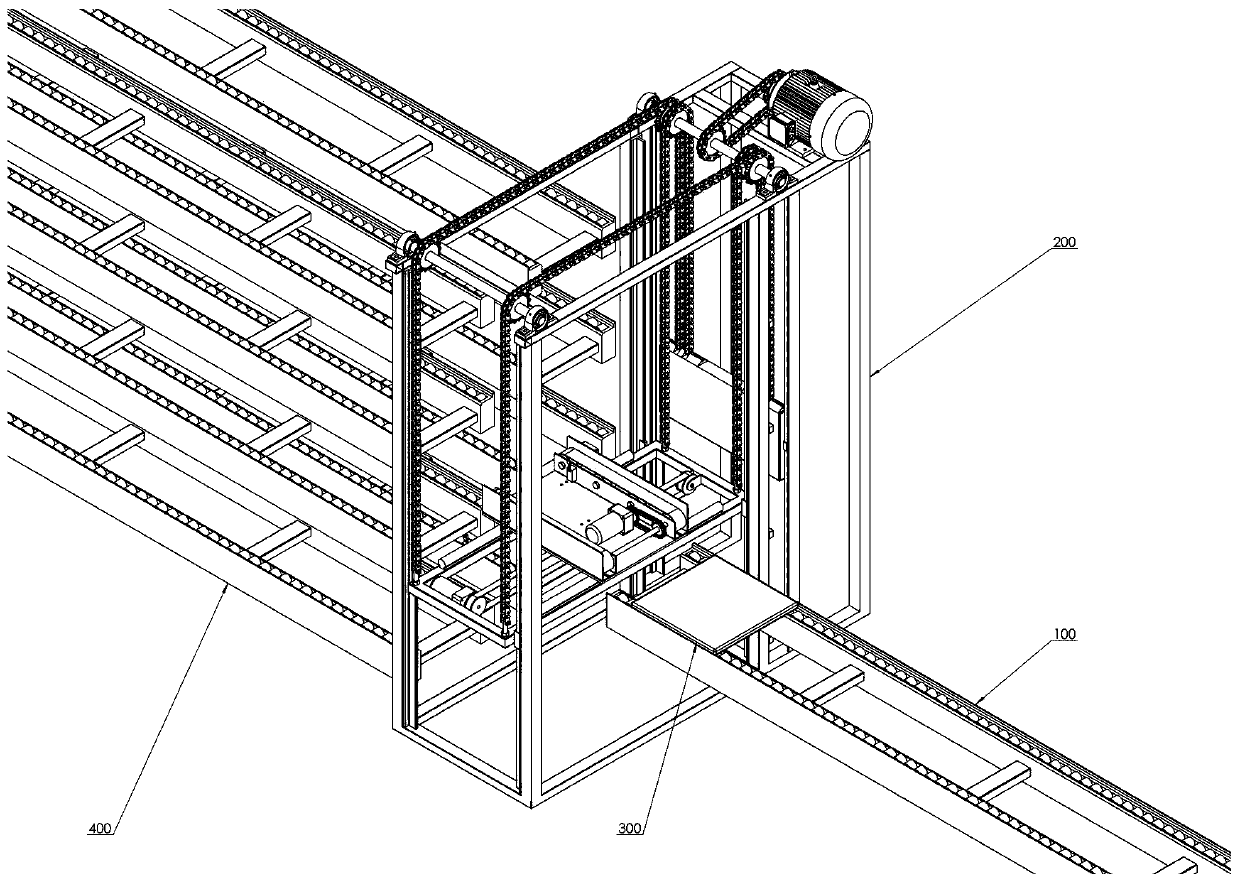

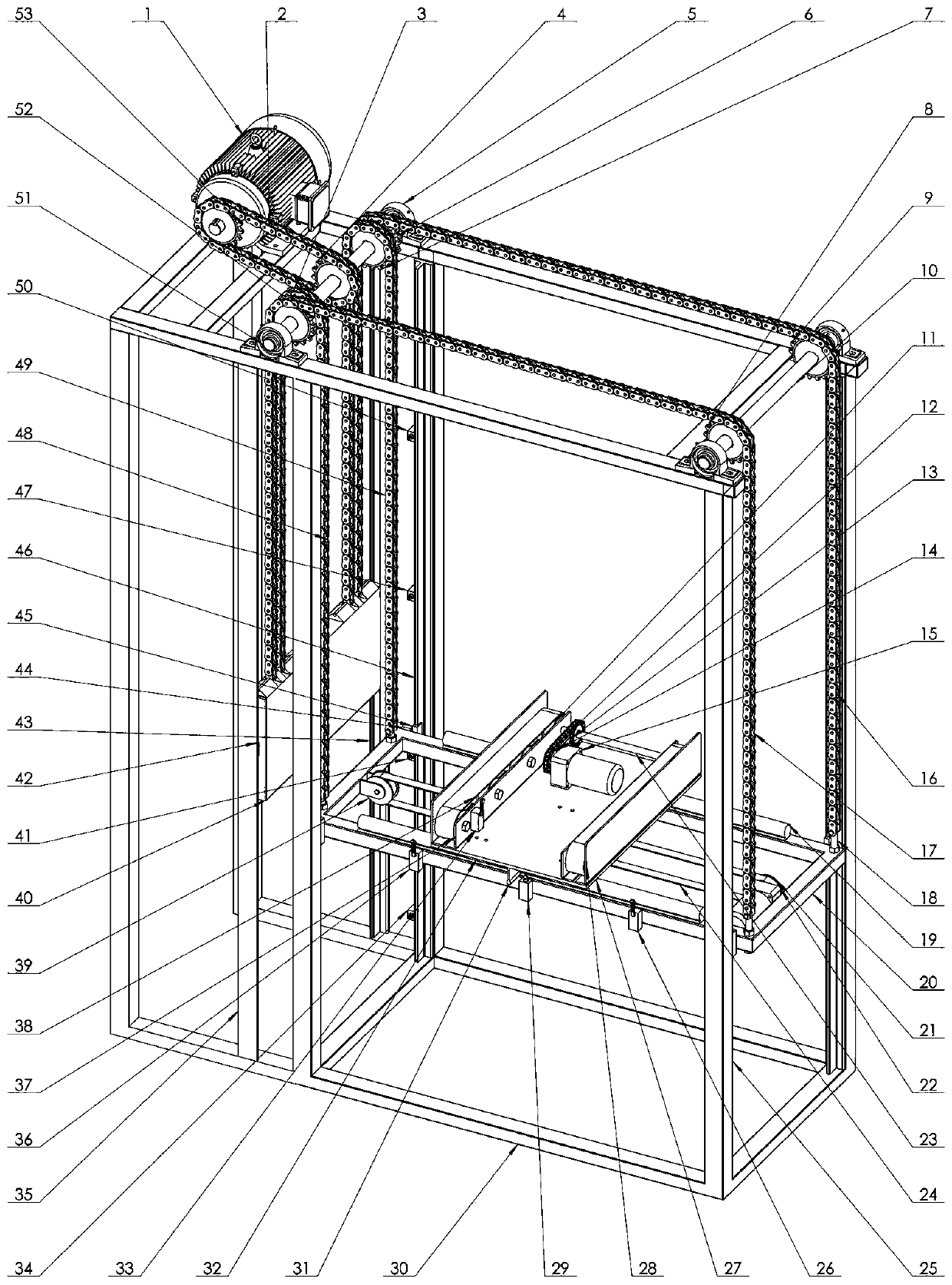

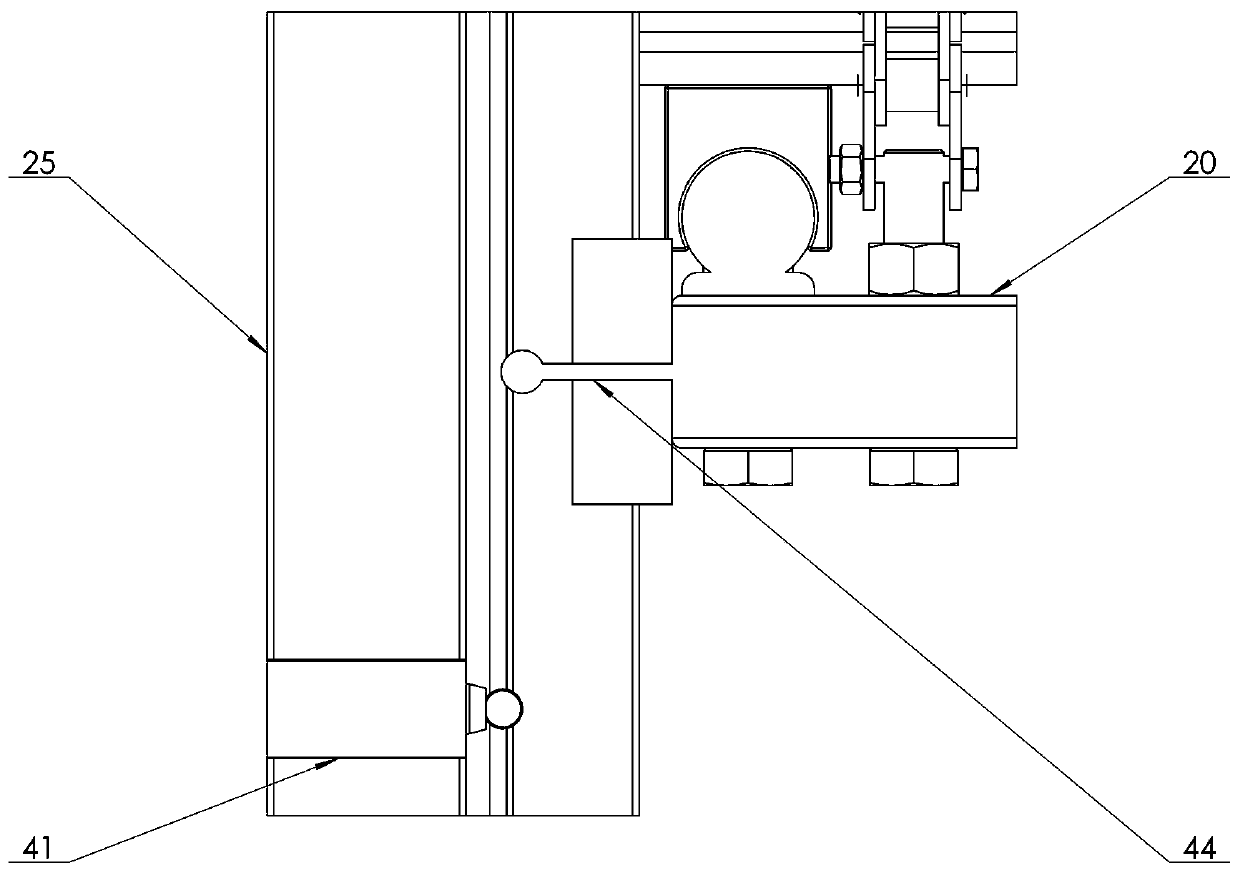

Rising and falling horizontal transferring machine

ActiveCN108516307AReduce loadSimple control circuitControl devices for conveyorsMechanical conveyorsMotor driveEngineering

The invention belongs to the technical field of transferring machines and discloses a rising and falling horizontal transferring machine which comprises a transferring machine support, a rising and falling moving assembly and a horizontal moving and plate conveying assembly. A layer limit switch is arranged on the transferring machine support. The rising and falling moving assembly drives a risingand falling moving framework through a three-phase asynchronous band-type brake motor. The rising and falling moving framework is dragged through a chain. The horizontal moving and plate conveying assembly comprises a horizontal moving device and a plate conveying device. The horizontal moving device is provided with a horizontal limit switch, and a horizontal moving direct-current speed reducingmotor drives a horizontal moving bottom plate. The plate conveying device is provided with a plate in-place switch, and a plate conveying direct-current speed reducing motor drives a pattern conveying belt to drive a tool plate. The rising and falling horizontal transferring machine is simple in structure and reliable in performance, and the problem of connection between single triple speed chains of an inlet and an outlet of an aging house and multi-layer triple speed chain in the aging house can be solved.

Owner:WUHAN UNIV OF TECH

Bulbil konjak artificial induced flowering asexual breeding method

InactiveCN1775002ARealize sowing and reproductionStrong disease resistancePlant phenotype modificationHorticulture methodsGrowth plantBud

The present invention relates to an artificial inductive flowering asexual breeding method of bulbil konjak. Said method includes the following steps: making the bulbil konjak bulb undergo the process of flowering induction, inhibiting germination of lateral bud on the bulb and making the root tip grown out on the bulb be perished, promoting differentiation of top bud of konjak bulb to form flower bud, after the bulb is transplanted, artificially inhibiting flowered leafing plant growth, making flower bract can be matured and seeded so as to obtain lots of seeds capable of reproducing konjak.

Owner:云南耕耘魔芋资源开发有限责任公司

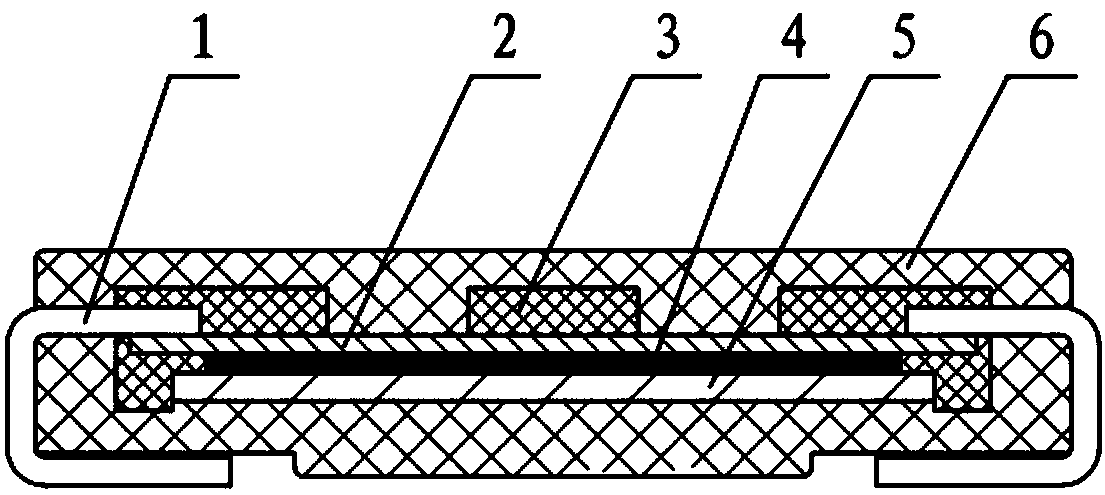

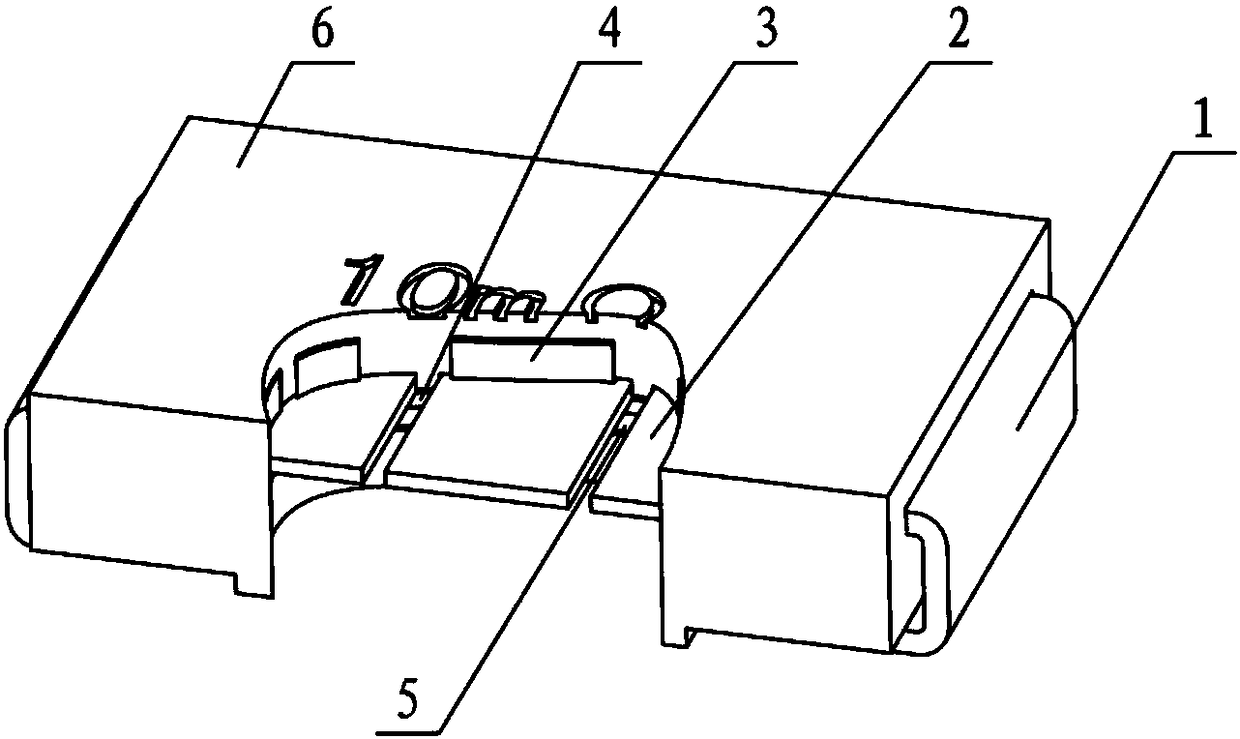

Chip resistor and manufacturing method thereof

PendingCN108538527AImprove insulation performanceHigh temperature and high humidity resistanceEnvelope/housing resistor manufactureResistor cooling/heating/ventillationAdhesiveHeat sink

The invention provides a chip resistor. The chip resistor comprises a resistor sheet, an inner shell which wraps the surface of the resistor sheet, a heat sink bonded to the surface of the resistor sheet through an insulating thermal conductive adhesive, an outer shell at the outermost layer and electrode pins connected with the two ends of the resistor sheet and located outside the outer shell, and the inner shell is provided with a hollowed-out part for coating the insulating thermal conductive adhesive. A manufacturing method of the chip resistor includes the steps of blanking the resistorsheet and the electrode pins, then processing and connecting the resistor sheet and the electrode pins to form a resistor body, conducting rough adjustment and fine adjustment on a resistance value ofthe resistor body, packaging for the first time to form the inner shell, blanking the heat sink, bonding the heat sink to the resistor sheet through the insulating thermal conductive adhesive, packaging for the second time, cutting and bending the electrode pins to form a side U shape, and finally conducting post-processing to obtain the chip resistor. According to the chip resistor, after roughadjustment and fine adjustment are conducted on the resistance value of the resistor body, packaging is conducted for the first time, a layer of inner shell wraps the resistor body to ensure that theheat sink is not contact with the resistor sheet, and the obtained chip resistor has high precision, fast heat dissipation, long service life, safety and reliability, and high product yield.

Owner:常德思高技术有限公司

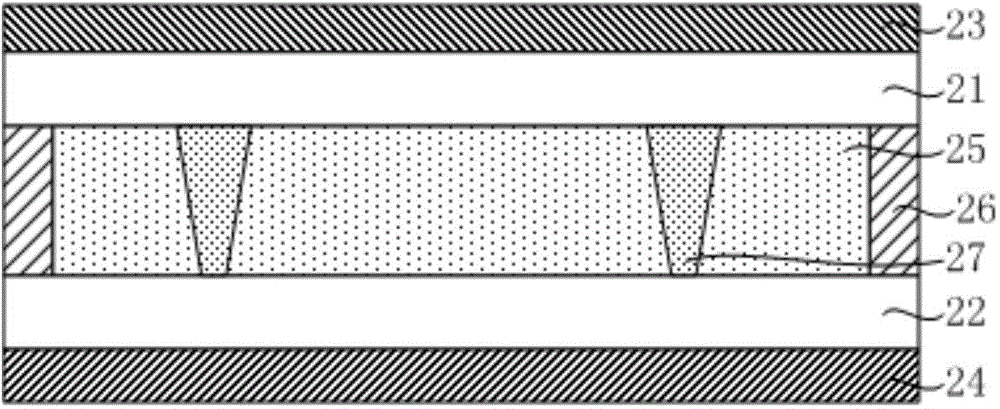

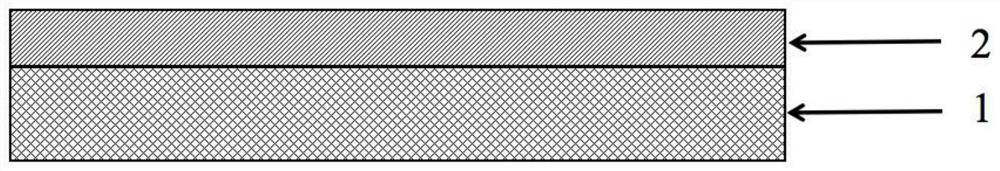

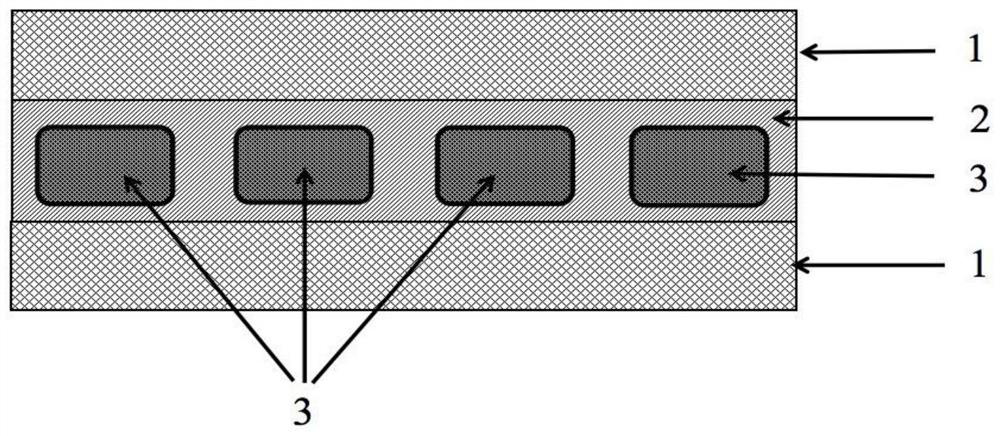

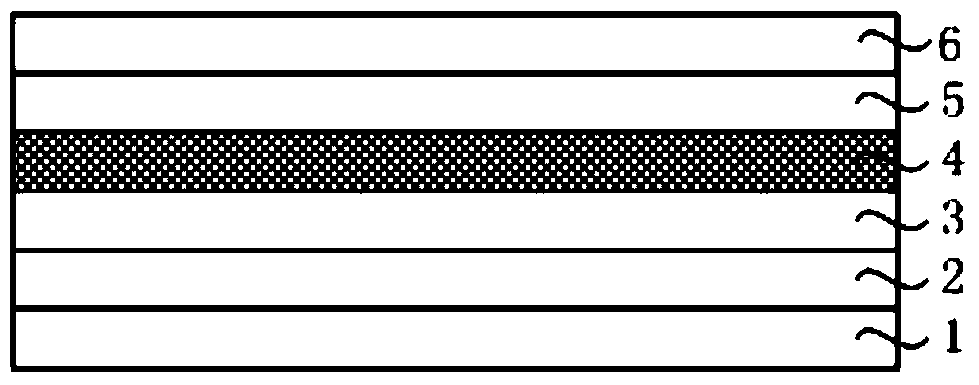

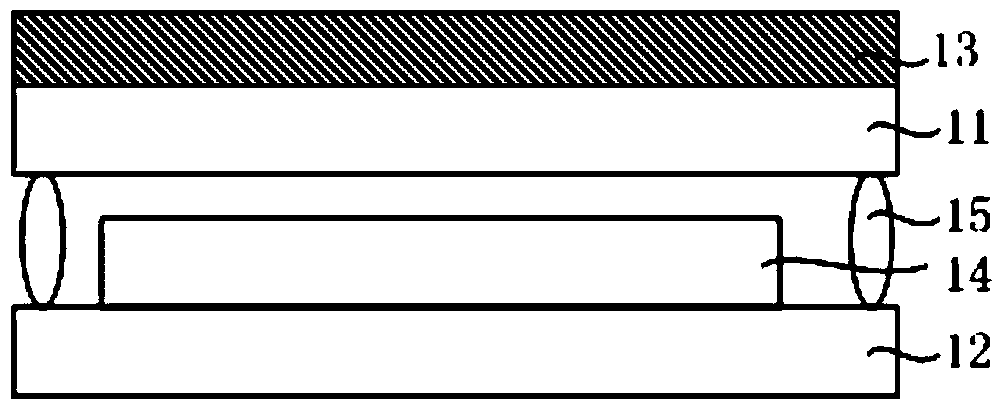

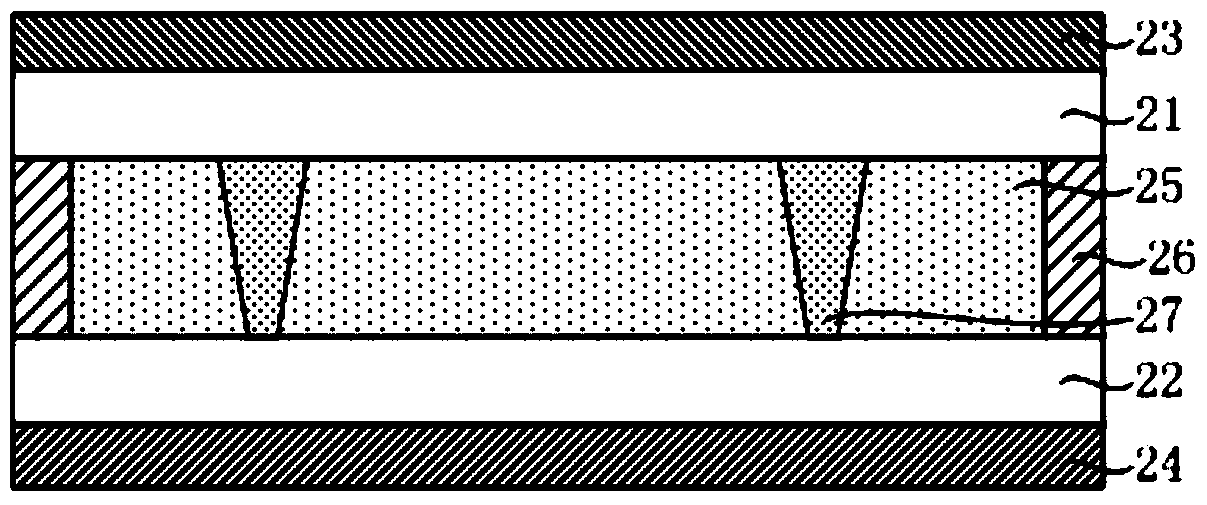

Display panel, manufacturing method thereof and display device

ActiveCN105807472AHigh temperature and high humidity resistanceReduce thicknessNon-linear opticsOrganic filmDisplay device

The invention discloses a display panel, a manufacturing method thereof and a display device. The display panel comprises a first substrate, a second substrate opposite to the first substrate, a first organic film layer arranged on the first substrate and / or a second organic film layer arranged on the second substrate, wherein the first organic film layer and / or the second organic film layer are the organic film layers doped with dichroism organic dyestuff polyimide. Alignment can be achieved conveniently without stretching, so that no protective film or an adhesive layer is needed, the thickness of a polarizing film can be decreased, the reliability of the polarizing film is improved, and the warping phenomenon of the polarizing film can be improved, and the durability is good.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

Feed additive capable of enhancing production capacity and anti-disease capacities of animals

InactiveCN101595945AHigh purityHigh purity high purityAnimal feeding stuffAccessory food factorsAnimal scienceSide effect

A feed additive capable of enhancing the production capacity and the anti-disease capacities of animals relates to the feeds which prevent diseases of animals, in particular to the feed additive capable of enhancing the production capacity and the anti-disease capacities of animals and a preparation method thereof. The feed additive is prepared by mixing the following raw materials based on parts by weight: 1-5 of bacillus coagulans and 30-50 of grifola frondosa polysaccharide. The feed additive is characterized by reasonable mixing of various active ingredients, wide sources of raw materials and simple preparation process, and can safely and effectively prevent frequent infectious diseases and syndromes of the diseases of animals. The feed additive is environment-friendly, leaves no drug residues during use, has no toxic side effect, has little irritation on organisms, is uneasy to have drug resistance, accords with the idea of being green and healthy and completely solves the trouble of export restriction. The feed additive features high cure rate, low production cost and broad application range.

Owner:涂晓华

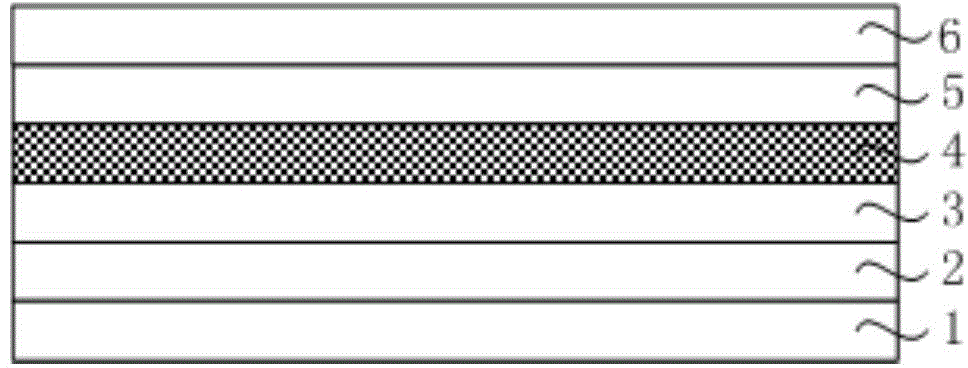

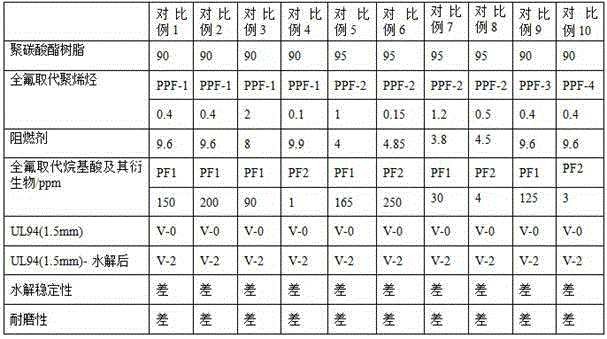

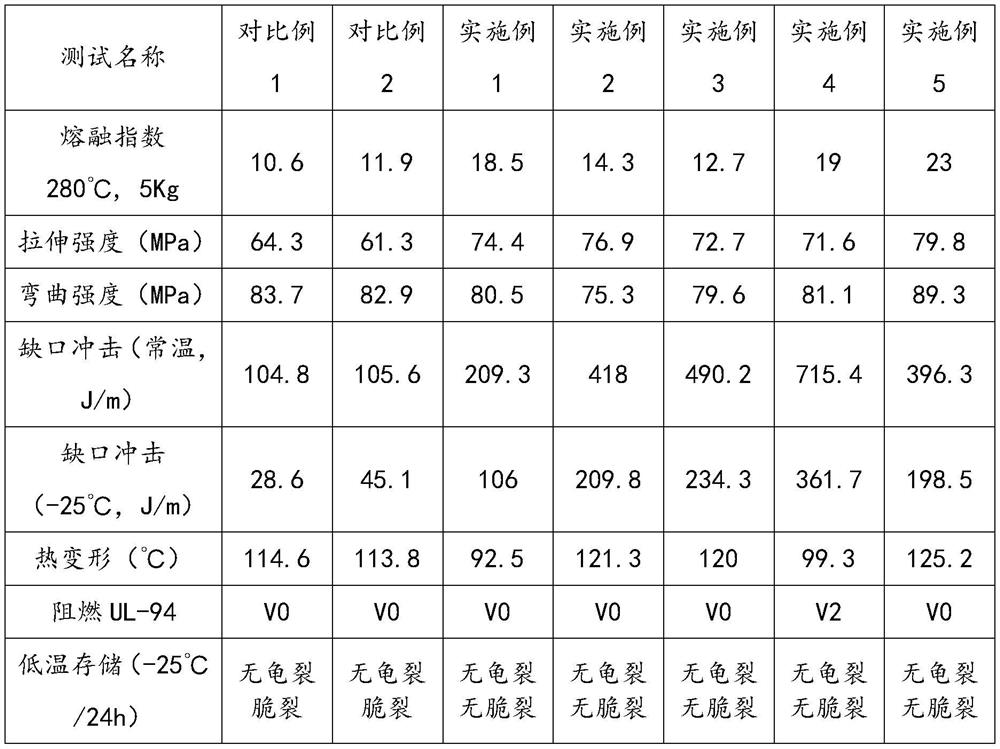

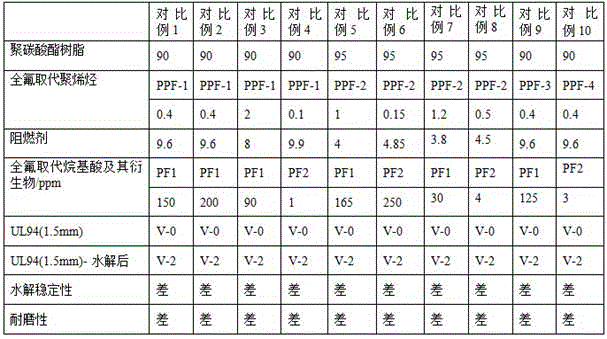

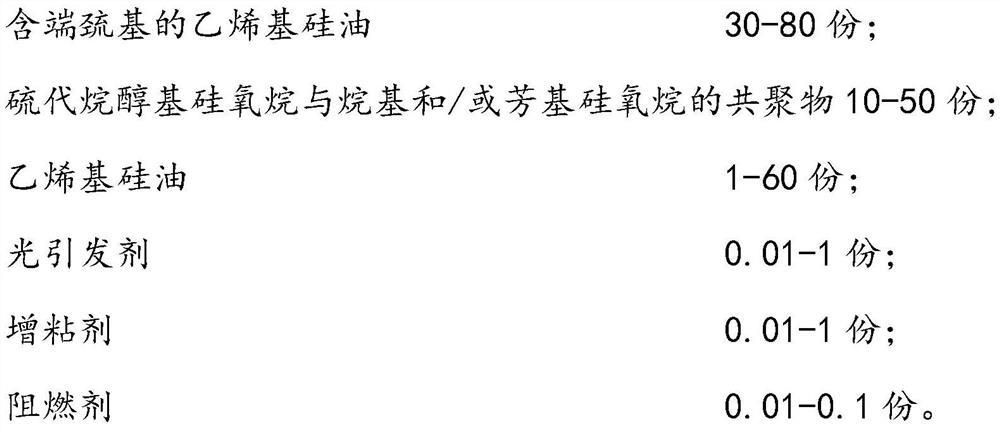

Polycarbonate composition, method for preparing same and application of polycarbonate composition

The invention discloses a polycarbonate composition. The polycarbonate composition comprises, by weight, 86-99.5 parts of polycarbonate, 0.2-0.7 part of total-fluorine substituted polyolefin and 0.3-13.8 parts of flame retardant. The sum of the weights of the polycarbonate, the total-fluorine substituted polyolefin and the flame retardants is 100 parts. The polycarbonate composition has the advantages that specific quantities of the total-fluorine substituted polyolefin, total-fluorine substituted alkyl acid and derivatives of the total-fluorine substituted alkyl acid are selectively added into the polycarbonate composition in a formula, the total-fluorine substituted alkyl acid and the derivatives are based on the polycarbonate composition, the total weight of the total-fluorine substituted alkyl acid and the derivatives is 5ppm-100ppm, and accordingly, the hydrolysis stability, the abrasion resistance and the flame retardancy of the polycarbonate composition can be obviously improved; the polycarbonate composition is particularly applicable to the field of electronic and electrical appliances.

Owner:KINGFA SCI & TECH CO LTD

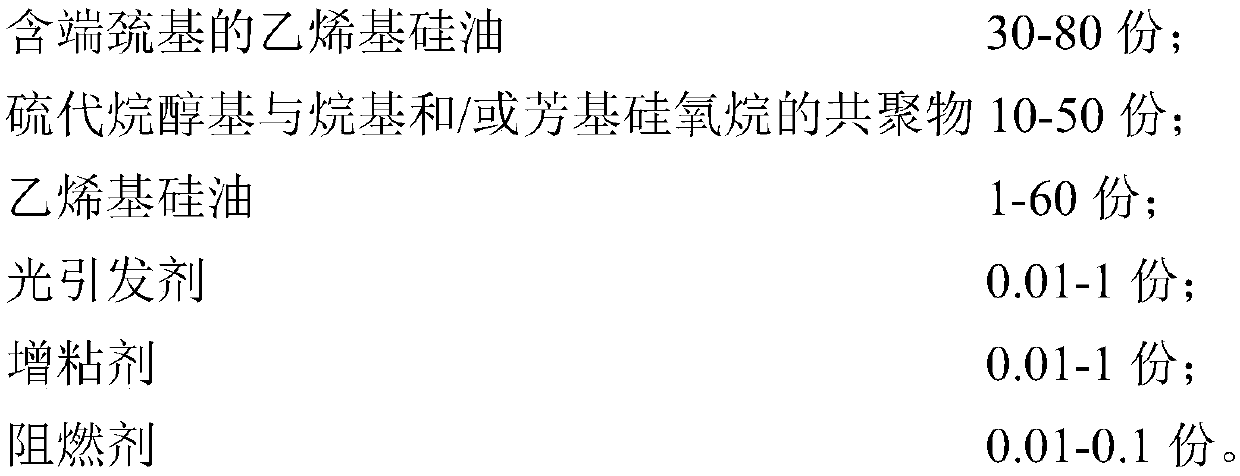

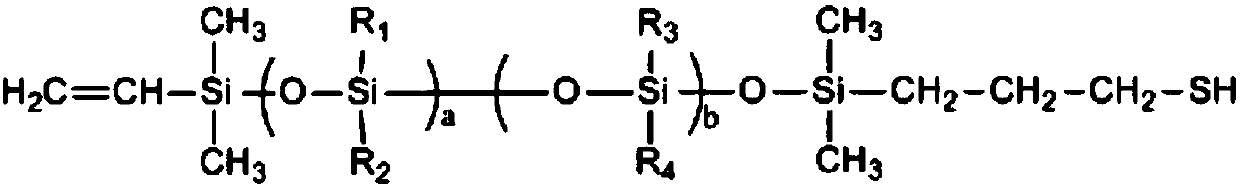

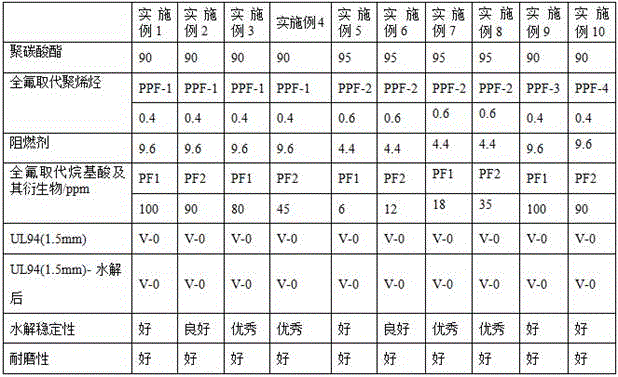

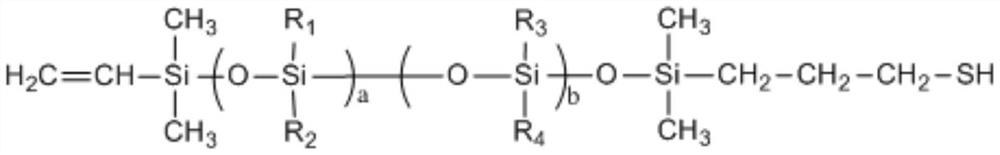

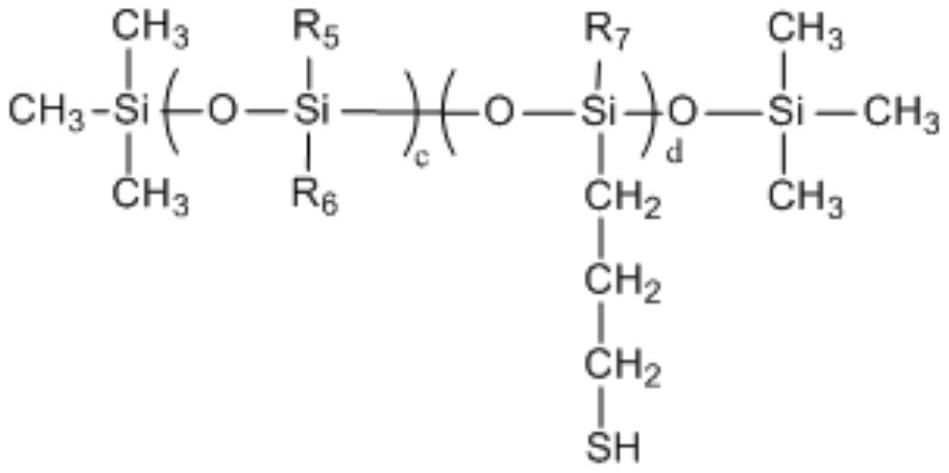

Ultraviolet-curing organosilicon liquefied optical adhesive composition, preparation method and application thereof

ActiveCN109517574AHigh temperature and high humidity resistanceWith thermal shockNon-macromolecular adhesive additivesMacromolecular adhesive additivesGlass coverUltraviolet

The invention discloses an ultraviolet-curing organosilicon liquefied optical adhesive composition, a preparation method and an application thereof. The ultraviolet-curing organosilicon liquefied optical adhesive composition comprises the following components in parts by weight: 30-80 parts of vinyl silicone oil containing end-sulfydryl group, 10-50 parts of thioalkyl and alkyl group and / or aryl siloxane copolymer, 1-60 parts of vinyl silicone oil, 0.01-1 part of photoinitiator, 0.01-1 part of viscosifier and 0.01-0.1 part of flame retardant. The ultraviolet-curing organosilicon liquefied optical adhesive composition provided by the invention has the properties of liquid-state self-leveling bubble removal, rapid curing and low volume shrinkage rate and the like, can form good attachment with a glass cover plate and an LCD (Liquid Crystal Display) screen, and can be used for whole attachment with a touch screen; the light transmittance reaches more than 99%, and simultaneously the ultraviolet-curing organosilicon liquefied optical adhesive composition has the advantages of high-temperature and high-humidity resistance and cold-heat impact resistance and the like, is high in attachment reliability and finished-product rate and is suitable for continuous production.

Owner:东莞市贝特利新材料有限公司

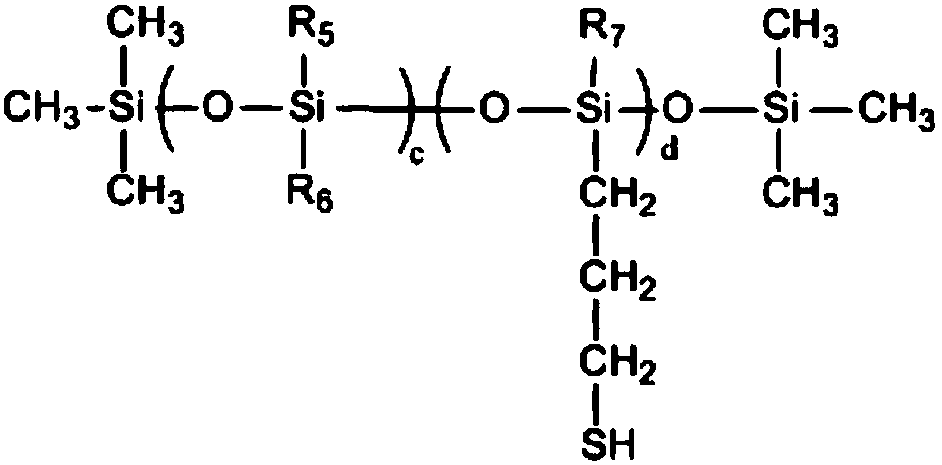

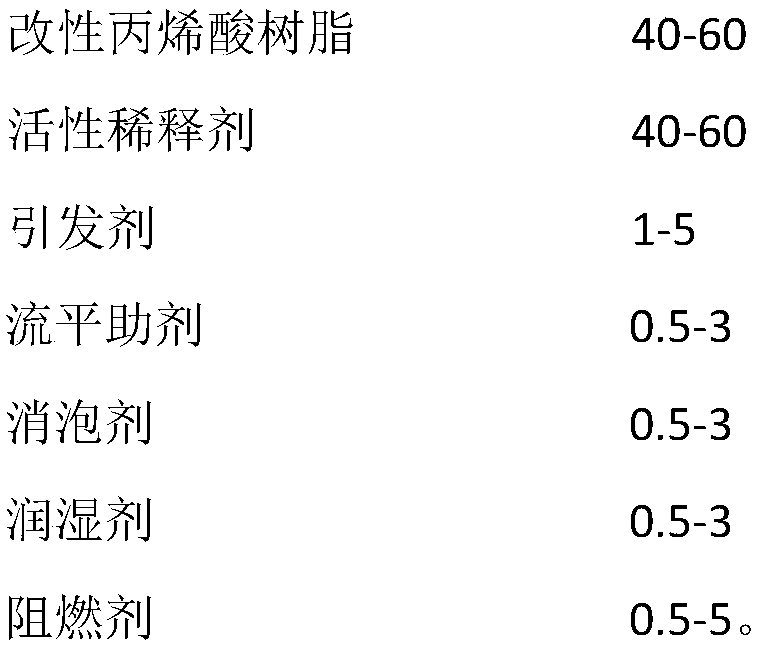

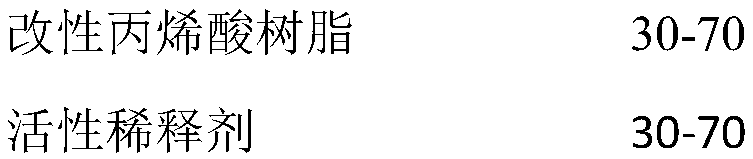

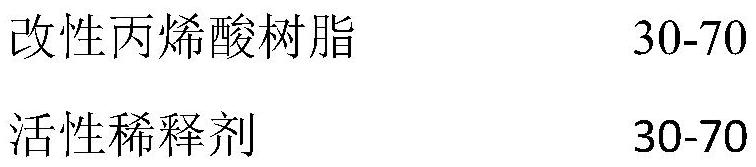

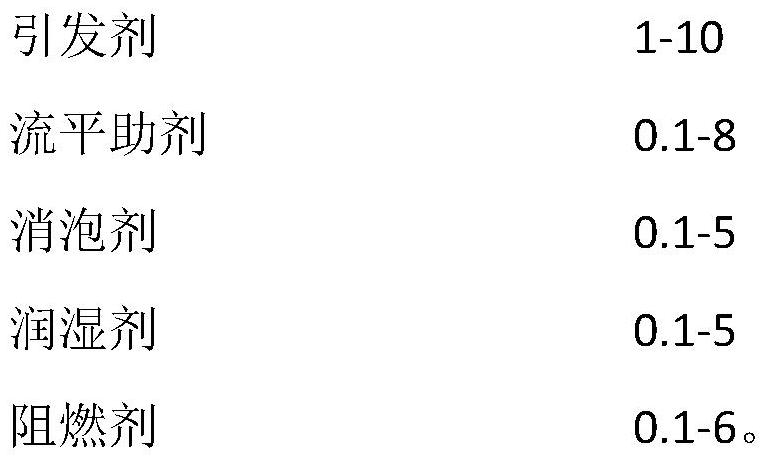

High-efficiency environment-friendly UV-moisture double-cured three-proofing paint for flexible circuit board

ActiveCN109608919AHigh temperature and high humidity resistanceStrong adhesionFireproof paintsAnti-corrosive paintsAcrylic resinFlexible circuits

The invention relates to the technical field of flexible circuit board protection, and particularly relates to high-efficiency environment-friendly ultraviolet (UV)-moisture double-cured three-proofing paint for a flexible circuit board. The three-proofing paint is prepared from the following raw materials in parts by weight: 30-70 parts of modified acrylic resin, 30-70 parts of a reactive diluents, 1-10 parts of an initiator, 0.1-8 parts of a leveling aid, 0.1-5 parts of a defoaming agent, 0.1-5 parts of a wetting agent and 0.1-6 parts of a flame retardant.

Owner:YIK SHING TAT INDUSTRIALCO LTD

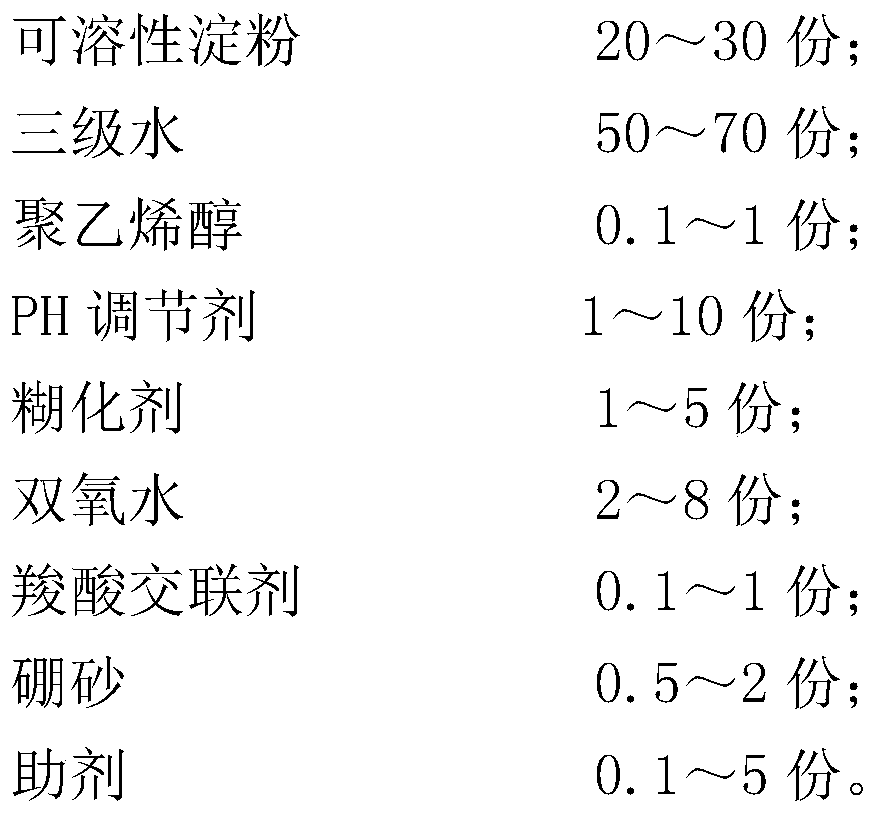

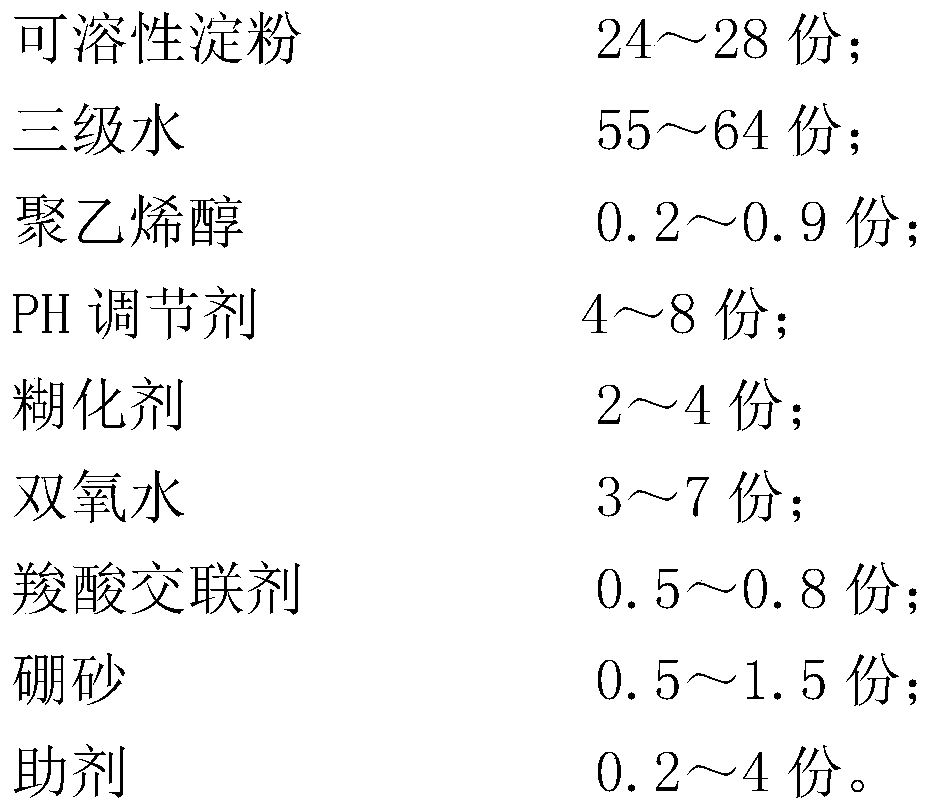

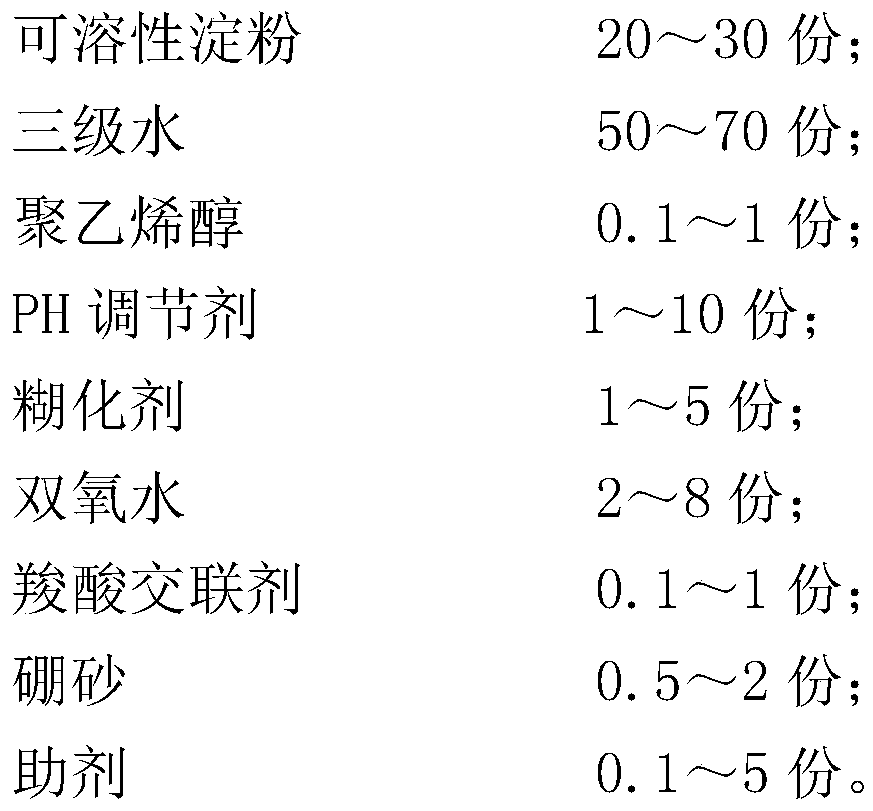

Environment-friendly, high-viscosity and weather-resistant modified starch adhesive and preparation method thereof

InactiveCN110551462AHigh temperature resistantStable network structureStarch derivtive adhesivesMacromolecular adhesive additivesPolyvinyl alcoholAdhesive

The invention discloses an environment-friendly, high-viscosity and weather-resistant modified starch adhesive and a preparation method thereof.The environmentally friendly, high-viscosity and weather-resistant modified starch adhesive is prepared from the following components in parts by weight: 20 to 30 parts of soluble starch, 50 to 70 parts of tertiary water; 0.1 to 1 part of vinyl alcohol, 1to 10 parts of a PH regulator, 1 to 5 parts of a gelatinizer, 2 to 8 parts of hydrogen peroxide, 0.1 to 1 part of a carboxylic acid crosslinking agent, 0.5 to 2 parts of borax and 0.1 to 5 parts of anadditives. According to the environmentally friendly, high-viscosity and weather-resistant modified starch adhesive, the polyvinyl alcohol, the starch and the tertiary water are mixed, then the hydrogen peroxide is added in an alkaline environment for oxidization to destroy the hydrogen bond of the starch for modification, the carboxylic acid crosslinking agent is added to form a stable network structure,and then gelatinization, complexationand dispersion are conducted to prepare the environment-friendly and highly-viscosity modified starch adhesive with the abilities to withstand high temperature and high humidity, low temperature and high and low temperature cycling impact.

Owner:永发印务(东莞)有限公司

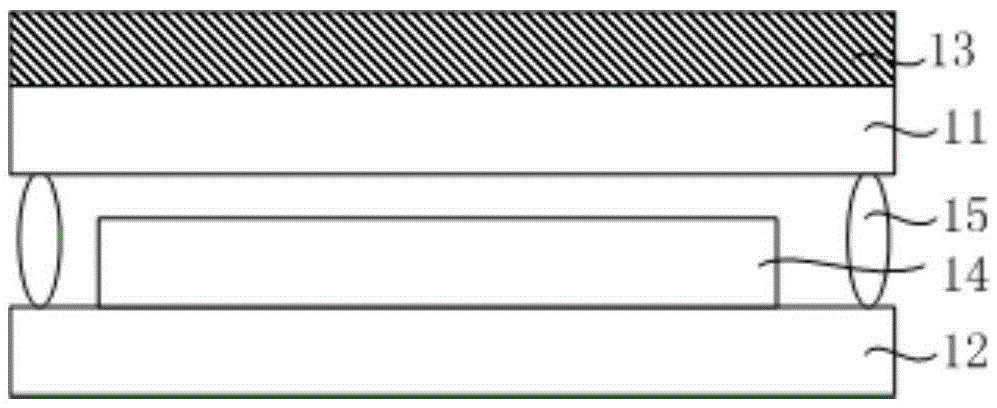

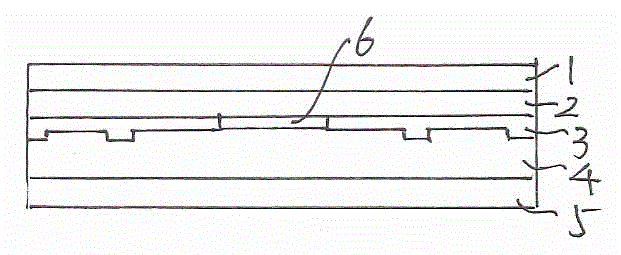

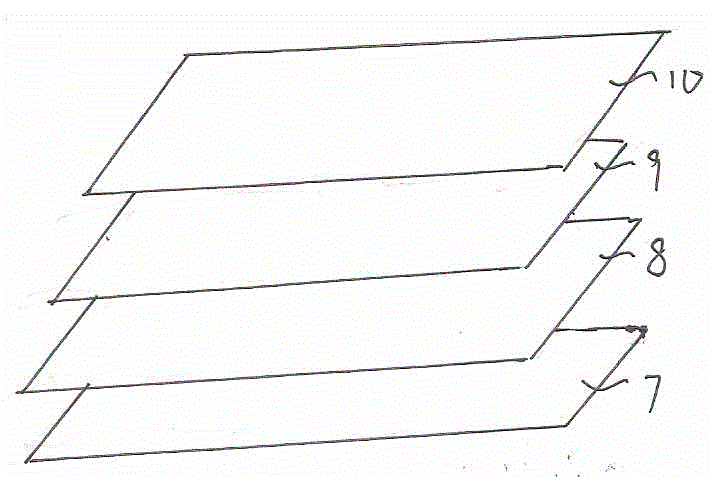

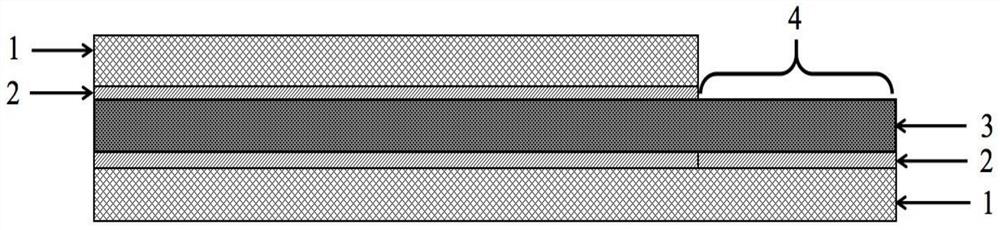

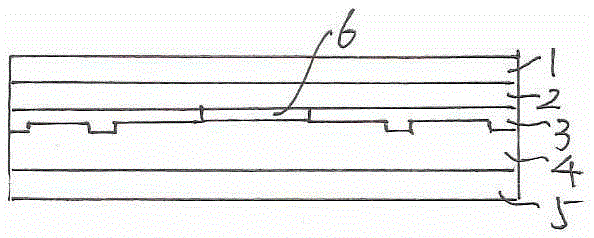

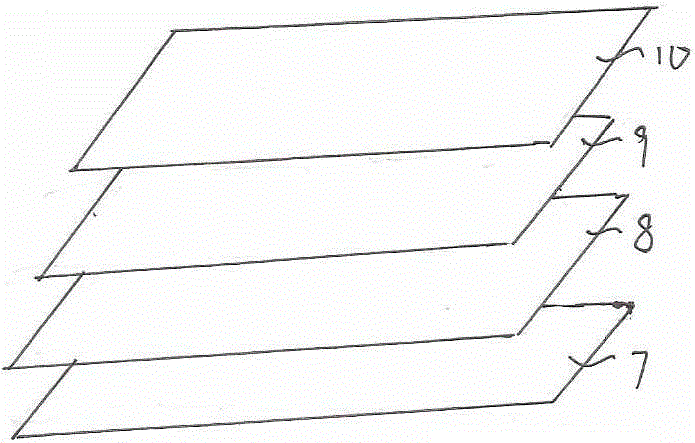

Photovoltaic module applied to desert areas and tropical areas

ActiveCN103956398AGuaranteed to workImprove strength propertiesPhotovoltaic energy generationSemiconductor devicesCompound aAluminum foil

The invention discloses a photovoltaic module applied to desert areas and tropical areas. The photovoltaic module is formed by overlaying a piece of tempered glass, a first UV cut-off EVA layer, a battery piece, a second UV cut-off EVA layer, an aluminum backboard, a junction box and an aluminum frame in sequence. According to the photovoltaic module, the aluminum backboard is formed by sequentially compounding a first backboard film, a PET layer, an aluminum foil and a second backboard film. The photovoltaic module is reasonable in structure and can be used not only in the desert areas and the tropical areas but also in various areas with severe conditions, the high-performance EVA layers and the aluminum backboard of a novel structure are used, the performance of the photovoltaic module is improved, the power of the photovoltaic module is improved, and the service life of the photovoltaic module is prolonged.

Owner:HANWHA SOLARONE QIDONG

Hot-pressed insulating film and flexible flat cable comprising same

ActiveCN112877006AGood adhesionGood weather resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceFirming agent

The invention discloses a hot-pressed insulating film and a flexible flat cable comprising the same. The invention provides the hot-pressed insulating film. The hot-pressed insulating film comprises a base material layer and an adhesive layer formed on the surface of the base material layer, the adhesive layer comprises the following raw materials in percentage by mass: 30-50% of saturated polyester resin A, 5-20% of saturated polyester resin B, 25-45% of a flame retardant, 5-10% of a curing agent, 0.01-0.1% of a curing accelerator, 0.1-1% of a dispersing aid, and 0.1-1% of a hydrolysis-resistant auxiliary agent. The glass transition temperature Tg of the saturated polyester resin A is 0-30 DEG C, and the acid value of the resin A is less than 3 KOHmg / g; the glass transition temperature Tg of the saturated polyester resin B is 40-120 DEG C; and the number-average molecular weight Mn of the saturated polyester resin A and the saturated polyester resin B is 5000-40000. The hot-pressed insulating film provided by the invention can meet long-term outdoor use requirements.

Owner:CYBRID TECHNOLOGIES INC

Bulbil konjak artificial induced flowering asexual breeding method

InactiveCN100421547CRealize sowing and reproductionStrong disease resistancePlant phenotype modificationHorticulture methodsGrowth plantBud

The present invention relates to an artificial inductive flowering asexual breeding method of bulbil konjak. Said method includes the following steps: making the bulbil konjak bulb undergo the process of flowering induction, inhibiting germination of lateral bud on the bulb and making the root tip grown out on the bulb be perished, promoting differentiation of top bud of konjak bulb to form flower bud, after the bulb is transplanted, artificially inhibiting flowered leafing plant growth, making flower bract can be matured and seeded so as to obtain lots of seeds capable of reproducing konjak.

Owner:云南耕耘魔芋资源开发有限责任公司

A lifting and horizontal transfer machine

ActiveCN108516307BReduce loadSimple control circuitControl devices for conveyorsMechanical conveyorsMotor driveThree-phase

The invention belongs to the technical field of transferring machines and discloses a rising and falling horizontal transferring machine which comprises a transferring machine support, a rising and falling moving assembly and a horizontal moving and plate conveying assembly. A layer limit switch is arranged on the transferring machine support. The rising and falling moving assembly drives a risingand falling moving framework through a three-phase asynchronous band-type brake motor. The rising and falling moving framework is dragged through a chain. The horizontal moving and plate conveying assembly comprises a horizontal moving device and a plate conveying device. The horizontal moving device is provided with a horizontal limit switch, and a horizontal moving direct-current speed reducingmotor drives a horizontal moving bottom plate. The plate conveying device is provided with a plate in-place switch, and a plate conveying direct-current speed reducing motor drives a pattern conveying belt to drive a tool plate. The rising and falling horizontal transferring machine is simple in structure and reliable in performance, and the problem of connection between single triple speed chains of an inlet and an outlet of an aging house and multi-layer triple speed chain in the aging house can be solved.

Owner:WUHAN UNIV OF TECH

Hot-pressing adhesive tape capable of insulating heat and retarding flame in blade battery and preparation method of hot-pressing adhesive tape

PendingCN114836151AReduce storage requirementsExcellent heat insulation performanceNon-macromolecular adhesive additivesEster polymer adhesivesSilica coatingFirming agent

The invention discloses a heat-insulating and flame-retardant hot-pressing adhesive tape in a blade battery and a preparation method thereof, and belongs to the technical field of adhesive tapes. The adhesive tape disclosed by the invention is prepared by mixing polyester, epoxy resin, acrylate copolymer resin, flame retardant, butanone and curing agent, coating, drying and curing, and the adhesive tape is convenient in production process and high in automatic production efficiency. The aerogel wrapped by the adhesive tape can be completely bonded within 8 seconds through hot pressing, the product performance requirement is met, when a combustion experiment is applied to the aerogel, the surface silicon dioxide coating can slowly form powder silicon attached to the surface of the aerogel, the powder silicon and the aerogel resist high temperature together without damaging the aerogel, and the heat insulation performance of the aerogel is improved by 20 degrees or above. The adhesive tape can be subjected to adhesive-to-adhesive hot pressing and opposite pasting after being heated, has super-strong adhesion with ceramics, rubber and silica gel, has excellent high-temperature and high-humidity resistance, high and low temperature impact resistance and electrochemical resistance, and is good in flame retardance, heat insulation and insulation performance and low in storage requirement.

Owner:东莞市胜昊新材料科技有限公司

Highly wearable vacuum coating ultraviolet curing coatings

ActiveCN100567413CImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsHigh humidityWear resistant

The invention relates to the field of electronic application coatings, in particular to high wear-resistant vacuum coating ultraviolet light curing coatings. The composition and content of the high wear-resistant vacuum coating UV-curable coating are: 10-30wt% of difunctional urethane acrylate, 10-40wt% of high-functional urethane acrylate, 5-20wt% of high-functional acrylate monomer, single Functional acrylate monomer 0-15wt%, acid adhesion promotion 1-10wt%, photoinitiator 1-6wt%, nano wear-resistant material 0-5wt%, additive 0.1-2wt%, solvent 10-50wt%. The invention is aimed at protecting the surface of vacuum coating workpieces of electronic products such as mobile phones, MP3s, and digital cameras, and has the characteristics of good surface effect, super wear resistance, high temperature and high humidity resistance, cold and heat cycle resistance, and excellent yellowing resistance, among which RCA has the highest wear resistance It can reach more than 1500 times, effectively improving the service life of electronic products. The invention effectively solves the adhesive force and wear resistance of the UV-cured vacuum coating paint, solves the matching problem of the primer and top paint of the UV-cured vacuum coating paint, and has wide versatility.

Owner:HUNAN SOKAN NEW MATERIAL

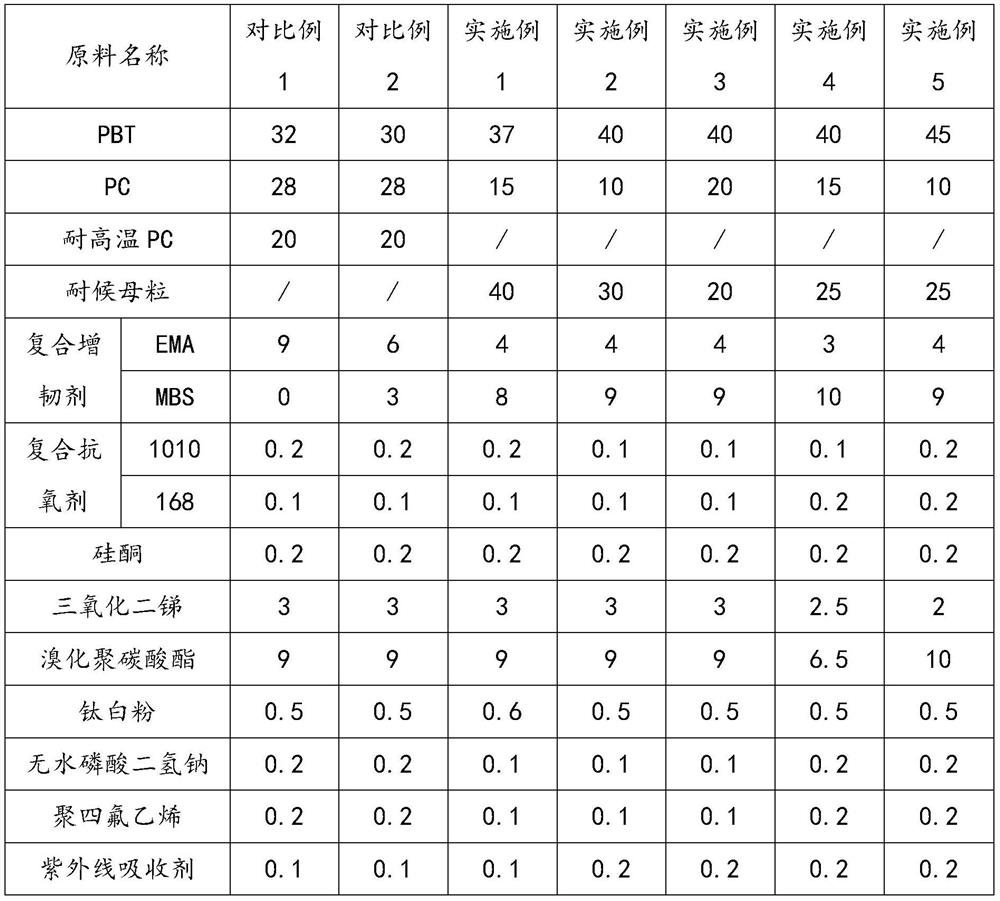

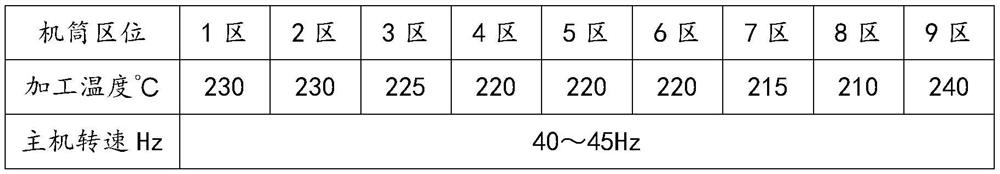

High-impact high-flame-retardant weather-resistant PBT/PC alloy material

ActiveCN113817297AGood compatibilityGood high and low temperature resistancePolytetramethylene terephthalateUltraviolet lights

The invention discloses a weather-resistant PBT / PC alloy material with high impact resistance and high flame retardance and a preparation method thereof, and relates to the technical field of polymer composite material processing. The material is prepared from the following raw materials in parts by weight: 30 to 70 parts of polybutylene terephthalate, 10 to 28 parts of polycarbonate, 10 to 20 parts of weather-resistant master batch, 5 to 16 parts of a composite toughening agent, 0.1 to 1.0 part of a composite antioxidant, 0.3 to 3 parts of a lubricant, 2 to 8 parts of antimony trioxide, 5 to 15 parts of a flame retardant, 0.5 to 5 parts of titanium dioxide, 0.1 to 0.5 part of anhydrous sodium dihydrogen phosphate, 0.1 to 0.5 part of polytetrafluoroethylene and 0.1 to 3 parts of an ultraviolet light absorber. The environment-friendly PBT / PC alloy material provided by the invention can be suitable for outdoor weather conditions, that is, under the conditions of strong ultraviolet rays, high temperature and high humidity or low-temperature freezing, the environment-friendly PBT / PC alloy material still has long anti-aging time, high flowability, high impact resistance and high flame retardance, and can meet product requirements under any weather conditions.

Owner:湖南恒屹新材料有限公司 +1

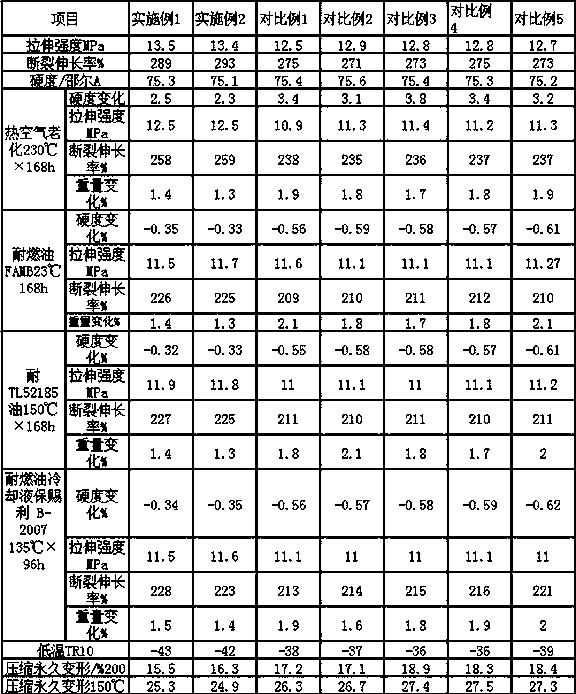

High-temperature-resistant anti-corrosion air inlet manifold sealing ring material

Owner:蚌埠创特新材料科技有限公司

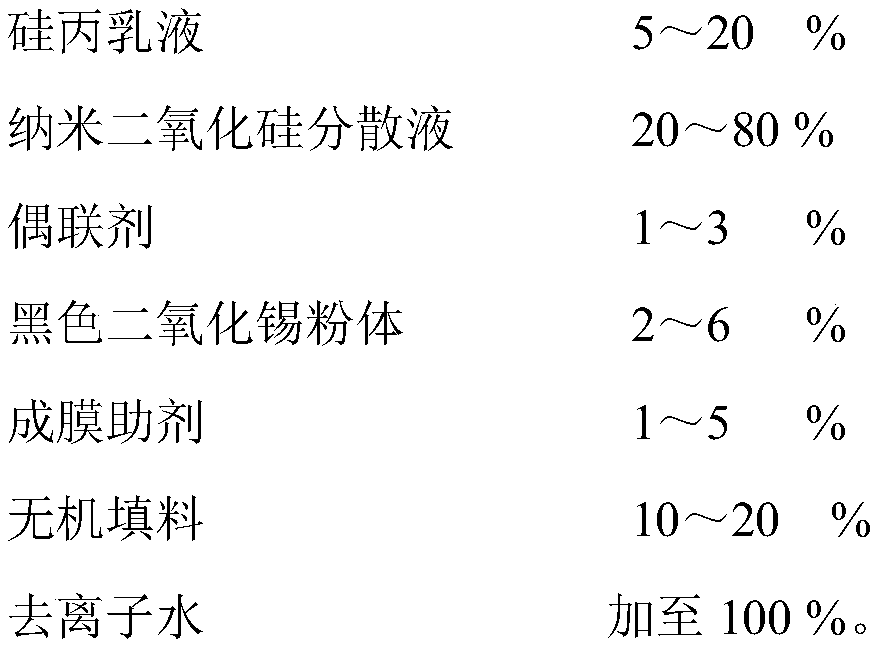

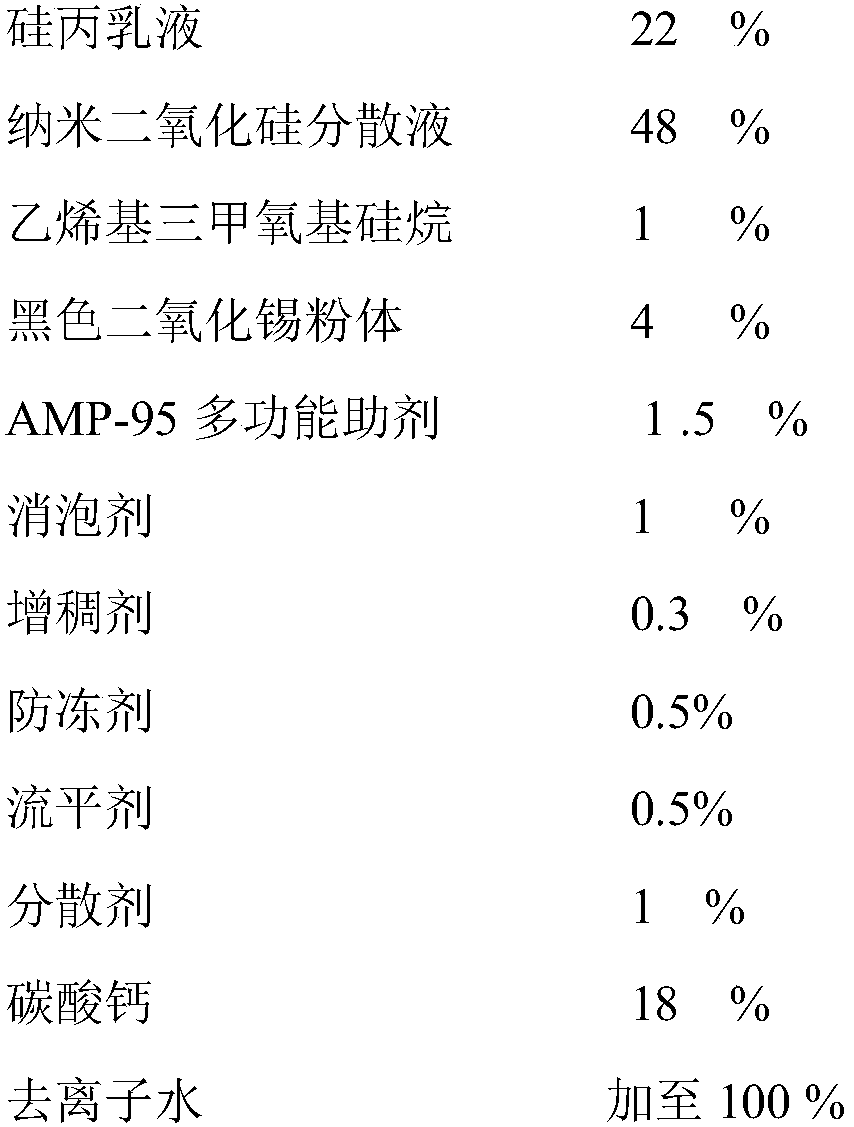

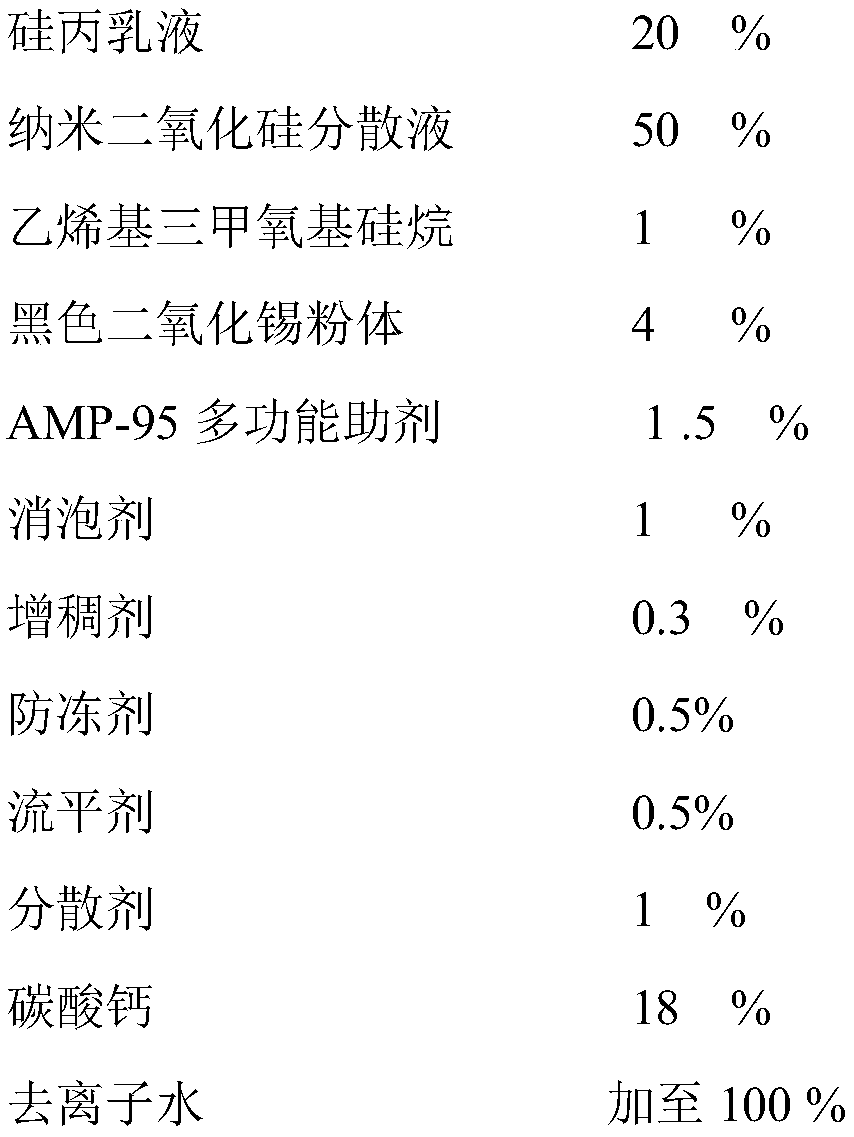

A kind of exterior wall inorganic coating for tropical island and reef buildings

ActiveCN105802419BHigh temperature and high humidity resistanceUV aging resistantAntifouling/underwater paintsPaints with biocidesTin dioxideTropical islands

The invention discloses an outer wall inorganic coating for tropical island buildings. The outer wall inorganic coating basically comprises, by weight percentage, 5-20% of silicone acrylic emulsion, 20-80% of nano-silica dispersing liquid, 1-3% of coupling agent, 2-6% of black tin dioxide powder, 1-5% of film-forming auxiliary, 10-20% of inorganic filler and the balance of deionized water, wherein the weight percentage of the outer wall inorganic coating is 100%. The outer wall inorganic coating has the advantages that the main film-forming substance of the outer wall inorganic coating is the nano-silica dispersing liquid, and the outer wall inorganic coating has the high temperature resistance, high humidity resistance, salt mist resistance and ultraviolet aging resistance of common inorganic coating; meanwhile, the silicone acrylic emulsion is mixed with the nano-silica dispersing liquid to allow organic polymer to be evenly distributed in the gaps between inorganic coating layers, the shrinkage of a coating film is buffered when the coating film is subjected to alternated cooling and heating, the coating film has certain elasticity, the formed coating film has the features of inorganic and organic coating, and the defects of the inorganic and organic coating are overcome; the added black tin dioxide powder has good photocatalytic activity and can generate an oxidation effect under the effect of sunlight, and effects of sterilizing, self-cleaning and mildew preventing are achieved.

Owner:YANCHENG INST OF TECH

A kind of polycarbonate composition and its preparation method and application

Owner:KINGFA SCI & TECH CO LTD

Ultraviolet light-curable silicone liquid optical adhesive composition, preparation method and application thereof

ActiveCN109517574BHigh temperature and high humidity resistanceWith thermal shockNon-macromolecular adhesive additivesMacromolecular adhesive additivesGlass coverUltraviolet lights

The invention discloses an ultraviolet light-curable silicone liquid optical adhesive composition, a preparation method and an application thereof. The ultraviolet light-curable organic silicon liquid optical adhesive composition comprises the following components in parts by weight: vinyl silicone oil 30 containing terminal mercapto groups ‑80 parts; 10‑50 parts of copolymer of thioalkanol siloxane and alkyl and / or aryl siloxane; 1‑60 parts of vinyl silicone oil; 0.01‑1 part of photoinitiator; tackifier 0.01-1 part; flame retardant 0.01-0.1 part. The UV-curable organic silicon liquid optical adhesive composition provided by the present invention has the properties of self-leveling and defoaming in a liquid state, fast curing, and low volume shrinkage, and can form a good fit with glass cover plates and LCD screens, and can be used for touch screens It has the advantages of high temperature and high humidity resistance, thermal shock resistance, high bonding reliability, high yield rate, and is suitable for continuous production.

Owner:东莞市贝特利新材料有限公司

Display panel, manufacturing method thereof, and display device

ActiveCN105807472BHigh temperature and high humidity resistanceReduce thicknessNon-linear opticsOrganic filmOrganic dye

A display panel and a manufacturing method therefor are disclosed. The display panel includes a first substrate, a second substrate disposed opposite to the first substrate, and at least one of a first organic film layer disposed on the first substrate, and a second organic film layer disposed on the second substrate, where at least one of the first organic film layer or the second organic film layer is an polyimide doped with a dichromatic organic dye.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

A high-efficiency and environment-friendly UV-moisture dual-cure conformal paint for flexible circuit boards

ActiveCN109608919BHigh temperature and high humidity resistanceStrong adhesionFireproof paintsAnti-corrosive paintsAcrylic resinFlexible circuits

The invention relates to the technical field of flexible circuit board protection, and particularly relates to high-efficiency environment-friendly ultraviolet (UV)-moisture double-cured three-proofing paint for a flexible circuit board. The three-proofing paint is prepared from the following raw materials in parts by weight: 30-70 parts of modified acrylic resin, 30-70 parts of a reactive diluents, 1-10 parts of an initiator, 0.1-8 parts of a leveling aid, 0.1-5 parts of a defoaming agent, 0.1-5 parts of a wetting agent and 0.1-6 parts of a flame retardant.

Owner:YIK SHING TAT INDUSTRIALCO LTD

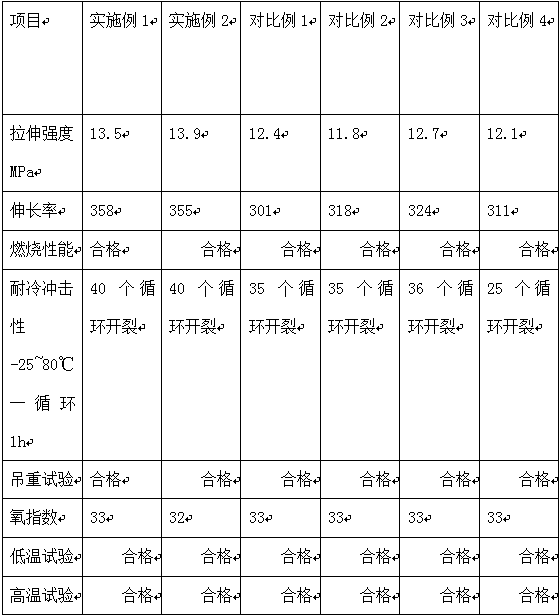

Heat-resistant flame-retardant tablet computer charger wire sheath material

InactiveCN109294210AImprove potting toughnessImprove adhesionPlastic/resin/waxes insulatorsTablet computerPolymer science

The invention discloses a heat-resistant flame-retardant tablet computer charger wire sheath material, and belongs to the technical field of polymer materials. The heat-resistant flame-retardant tablet computer charger wire sheath material is mainly prepared from the following raw materials: rectorite powder, wollastonite powder, serpentine powder, kaolin powder, pyrophyllite powder, pitchstone powder, organic silicone modified vinyl ester resin, thermoplastic polyurethane, 3-glycidyloxypropyltrimethylsilane, p-tert-butylphenol formaldehyde resin, aromatic hyperbranched polyester, a flame retardant, thermoplastic polyurethane and an antioxidant. The wire sheath material has heat-resistant and flame-retardant characteristics. When the material is used for preparing the wire sheath, the wiresheath can have stable performance when operating with power on and load at high temperature and high humidity and has longer service life, and safety of the changer is improved.

Owner:蚌埠心里程教育科技有限公司

A method for cultivating high-yield foliage corms of bulbil-like konjac underground corms

InactiveCN105393788BHigh reproductive coefficientStrong resistancePlant cultivationCultivating equipmentsMeristem growthCataphyll

Owner:KUNMING HANYUBAILIN AGRI TECH CO LTD

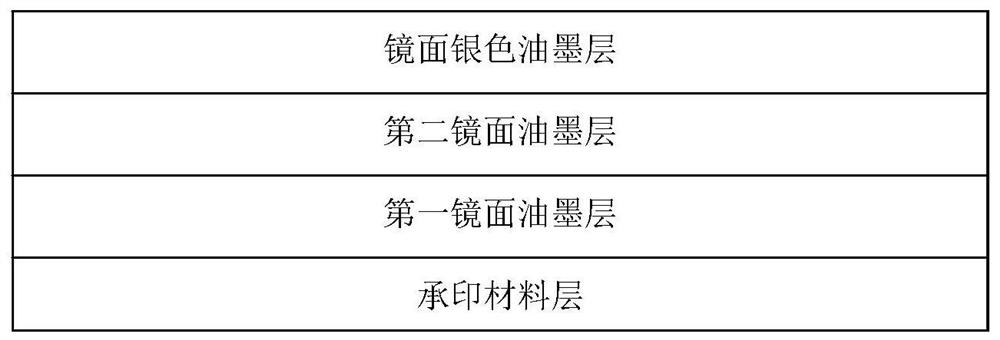

A kind of anti-static discharge high-brightness mirror ink and its preparation and use method

The invention discloses anti-static discharge high-brightness mirror ink which comprises the following components in parts by weight: 80-90 parts of high-transparency resin, 10-20 parts of polyester resin, 0.3-0.6 part of aluminum powder, 4-22 parts of a hardener, 2-6 parts of additives and 0-20 parts of a solvent The invention also discloses preparation and use methods of the mirror ink, wherein the use method comprises steps of primary printing, secondary printing and silver embossing. The mirror ink provided by the invention adopts a novel formula in which the content of aluminum powder is reduced and a layered printing process is innovated, so that the printed products have high brightness and ESD resisting function, have no failure even if a human body operates a screen with static electricity, and have strong adhesion, high temperature and humidity resistance, high leveling, ultrasonic cleaning resistance, rich color and other excellent properties after being suffered to specific drying conditions.

Owner:精工油墨(四会)有限公司

Photovoltaic modules for desert and tropical regions

ActiveCN103956398BConvenience guaranteedGuaranteed to workPhotovoltaic energy generationSemiconductor devicesCompound aUltraviolet

Disclosed is a photovoltaic module applied to desert areas and tropical areas. The photovoltaic module is formed by overlaying a piece of tempered glass (1), a first ultraviolet (UV) cut-off EVA layer (2), a battery piece (3), a second ultraviolet (UV) cut-off EVA layer (4), an aluminum backboard (5), a junction box and an aluminum frame in sequence. The aluminum backboard is formed by sequentially compounding a first backboard film (7), a PET layer (8), an aluminum foil (9) and a second backboard film (10). The photovoltaic module is proper in structure and can be used not only in desert areas and tropical areas but also in various areas with severe conditions; the high-performance EVA and the aluminum backboard of a new structure are used, the performance of the module is improved, the power of the module is improved, and the service life of the module is prolonged.

Owner:HANWHA SOLARONE QIDONG

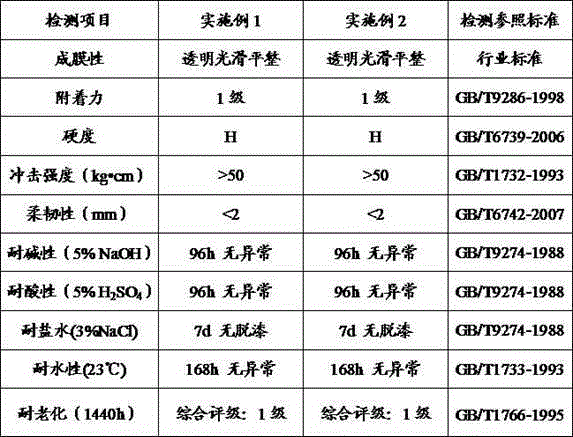

Acrylic resin mainly used for container topcoat coating material, and preparation process thereof

The present invention relates to the technical field of chemical industry, particularly to an acrylic resin mainly used for a container topcoat coating material, and a preparation process thereof. The acrylic resin comprises, by weight, 40-60 parts of an acrylic monomer, 5-15 parts of a functional acrylic monomer, 0.1-5 parts of an initiator, and 40-70 parts of a solvent, wherein the acrylic monomer is two or more than two selected from methyl acrylate, methyl methacrylate, n-butyl methacrylate, and n-butyl acrylate. According to the present invention, various physical requirements of the container topcoat are completely considered, and the appropriate acrylic monomer and the appropriate functional acrylic monomer are screened to perform the polymerization reaction of the acrylic resin, such that the acrylic resin with characteristics of corrosion resistance, wear resistance, impact resistance, high-temperature resistance, high-humidity resistance, low-temperature resistance, high salt erosion resistance, yellowing resistance and other physical properties, and with rapid drying, high fullness, thick coating, excellent color dispersion, easy repair and other coating construction characteristics is developed.

Owner:KUNSHAN SUMEI FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com