High-temperature-resistant anti-corrosion air inlet manifold sealing ring material

An intake manifold and anti-corrosion technology, which is applied in the field of polymer materials, can solve the problems of unstable idle speed of the engine, unstable idle speed, and reduced low-speed performance of the engine, and achieves a wide range of raw material sources, a simple preparation method, and excellent tolerance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

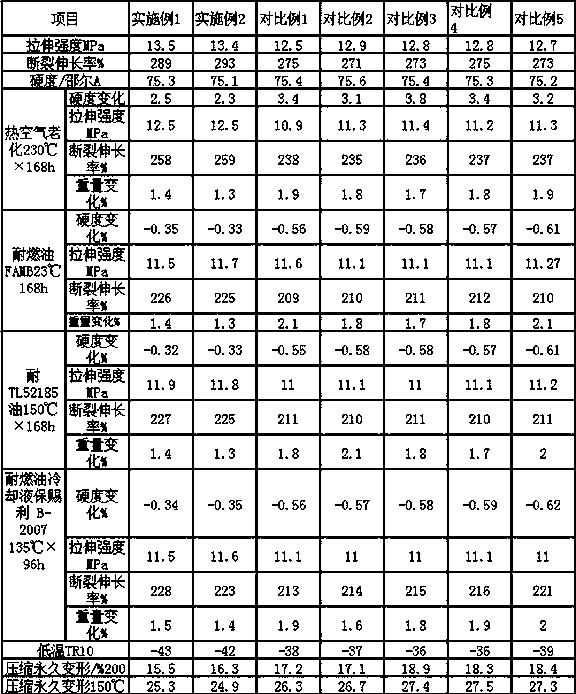

Examples

Embodiment 1

[0020] A high-temperature-resistant and anti-corrosion intake manifold sealing ring material is made of the following raw materials in parts by weight: 46 parts of polyarylether nitrile resin, 34 parts of ceramic powder, 23 parts of fluoroether rubber, 2 parts of flame retardant, poly 11 parts of phosphazene, 0.05 parts of surfactant, 0.5 parts of regulator, 0.05 parts of catalyst, 0.5 parts of vulcanization accelerator, 0.5 parts of cross-linking agent, 0.5 parts of stabilizer, 2.1 parts of black boy gum, 2.1 parts of tung oil rosin calcium, transparent 6.5 parts of amphibole asbestos, 4.7 parts of barium sulfate, 4.7 parts of serpentine powder, 1 part of nano zinc oxide, 3 parts of konjac glucomannan, ~4.1 parts of phthalocyanine resin.

[0021] Further, the polyarylether nitrile is polyarylether nitrile is phenolphthalein type polyarylether nitrile.

[0022] Further, the preparation method of the polyphosphazene is to remove the air in the reactor with dry nitrogen, add 100...

Embodiment 2

[0030] A high-temperature-resistant and anti-corrosion intake manifold sealing ring material is made of the following raw materials in parts by weight: 59 parts of polyarylether nitrile resin, 39 parts of ceramic powder, 37 parts of fluoroether rubber, 2 parts of flame retardant, polystyrene 11 parts of phosphazene, 00.05 parts of surfactant, 1.4 parts of conditioner, 0.05 parts of catalyst, 1 part of vulcanization accelerator, 1 part of crosslinking agent, 1 part of stabilizer, 2.1 parts of black gum, 2.1 parts of tung oil rosin calcium, transparent 6.5 parts of amphibole asbestos, 4.7 parts of barium sulfate, 4.7 parts of serpentine powder, 1 part of nano-zinc oxide, 3 parts of konjac glucomannan, and 4.1 parts of phthalocyanine resin.

[0031] Further, the polyarylether nitrile is a phenolphthalein type polyarylether nitrile, and the phthalocyanine resin is a bisphenol A phthalocyanine resin.

[0032] Further, the preparation method of the polyphosphazene is to remove the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com