Chip resistor and manufacturing method thereof

A manufacturing method and technology of resistors, applied in the direction of resistors, resistor parts, non-adjustable metal resistors, etc., can solve the problem of reducing the service life of resistors and safety and reliability, and the large size of metal plate resistors affects the service life of products And other problems, to achieve the effect of excellent heat dissipation, excellent mechanical properties, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

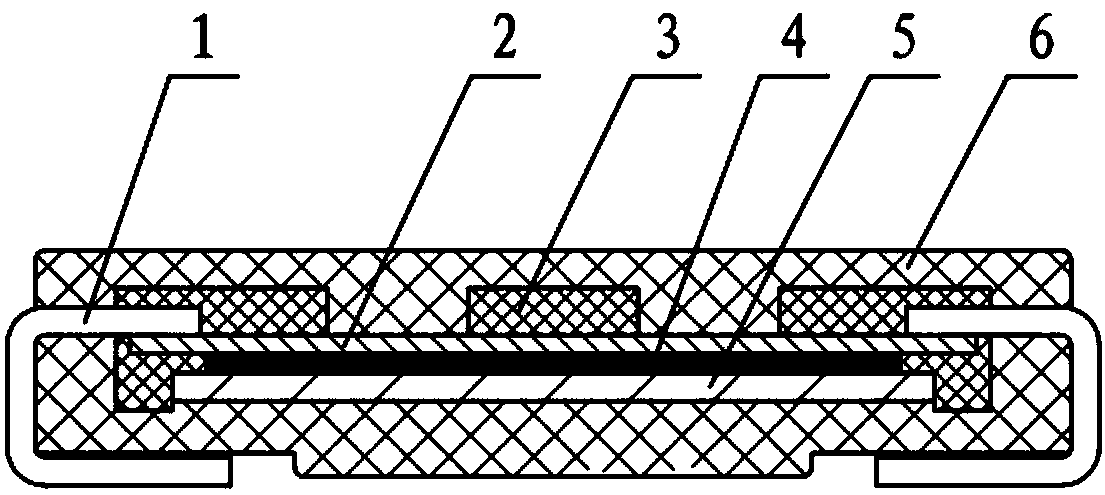

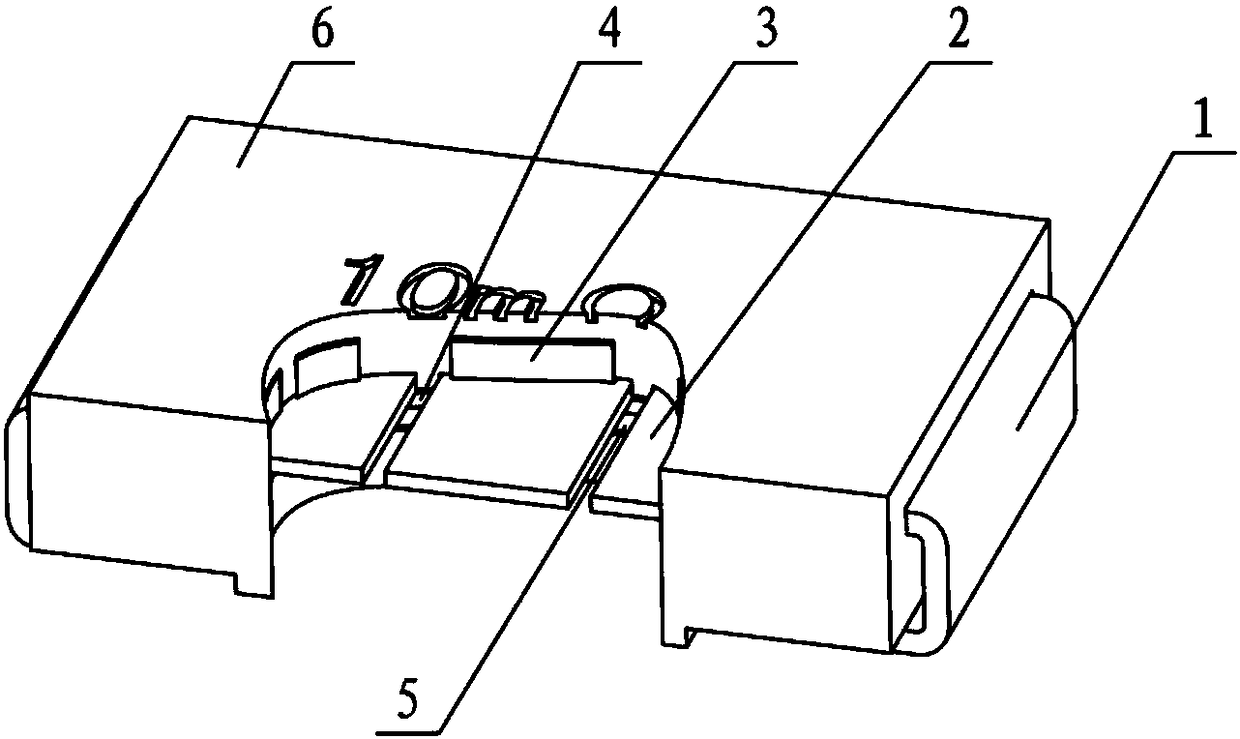

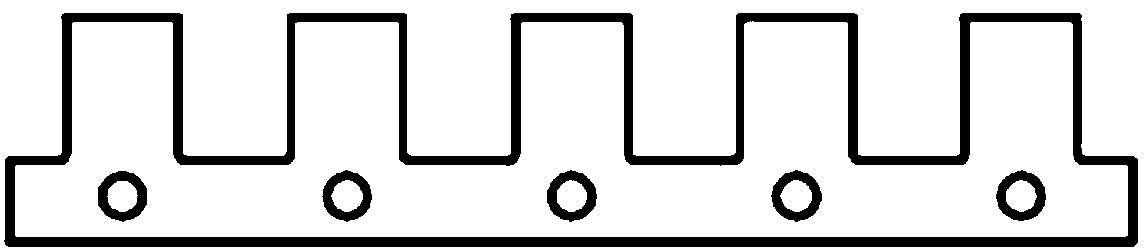

[0054] Such as Figure 1-2 As shown, the present invention provides a chip resistor, including a resistor chip 2, an inner shell 3 wrapped on the surface of the resistor chip 2, a heat sink 5 bonded to the surface of the resistor chip 2 through an insulating heat-conducting glue 4, and an outermost layer The shell 6 is connected to the two ends of the resistance sheet 2 and the electrode pin 1 is outside the shell 6. The inner shell 3 has a hollow part for coating the insulating heat-conducting glue 4.

[0055] According to the present invention, the hollow part of the inner shell 3 is smaller than the size of the heat sink 5, and the two ends of the inner shell 3 are also provided with steps to support the heat sink 5, so as to ensure that the heat sink 5 does not contact the resistor plate 2, and ensure the high precision of the equipment and instruments. Data Accuracy.

[0056] The resistance sheet 2 of the present invention is an alloy material, and the alloy material is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com