A kind of anti-static discharge high-brightness mirror ink and its preparation and use method

A mirror ink and high-brightness technology, applied in ink, applications, household utensils, etc., can solve the problems of easy oil scattering, poor mirror effect, low adhesion, etc., reduce the content of aluminum powder, and have a good sales prospect , high leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

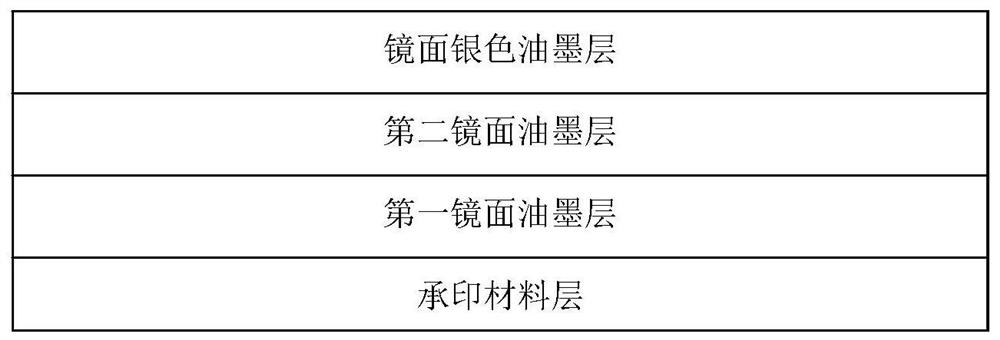

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0026] Such as figure 1 As shown, the anti-static discharge high-brightness mirror ink provided by the present invention comprises in parts by weight: 80-90 parts of high transparency resin, 10-20 parts of polyester resin, 0.3-0.6 part of aluminum powder, 4 parts of hardener -22 parts, 2-6 parts of additives, 0-20 parts of solvent; wherein, the high transparency resin is cellulose resin, and the polyester resin is mixed polyester resin, and Cas 35176-78-4 poly In the ester resin, the additive is a leveling agent and / or a defoamer, and the solvent includes naphtha and / or trimethylbenzene.

[0027] In Example 1, the specific composition of the mirror ink is: 82 parts of cellulose resin, 18 parts of polyester resin, 0.54 parts of aluminum powder, 5 parts of hardener, and 5 parts of additive; wherein the hardener includes 3.5 parts of polyisocyanate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com