Acrylic resin mainly used for container topcoat coating material, and preparation process thereof

An acrylic resin, container technology, applied in the coating and other directions, can solve the problem that it is difficult to meet the physical properties and construction requirements of the container finish, and achieve the effect of excellent color dispersion and high fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An acrylic resin mainly used for container finish paint, including the following components:

[0023] Methyl methacrylate 160Kg,

[0024] n-Butyl methacrylate 320Kg,

[0025] Methacrylic acid 5Kg,

[0026] Acrylic 2Kg,

[0027] Hydroxyethyl methacrylate 12Kg,

[0028] Dibenzoyl peroxide 9Kg,

[0029] Toluene 500Kg.

[0030] A preparation process of acrylic resin mainly used for container finish paint, comprising the following process flow:

[0031] A. The toluene of described 400Kg is added in the reactor, and feed nitrogen and be heated to reflux state;

[0032] b. The methyl methacrylate of 160KG, the n-butyl methacrylate of 320KG, the methacrylic acid of 5KG, the acrylic acid of 2KG, the hydroxyethyl methacrylate of 12KG and the dibenzoyl peroxide of 3KG are dropped into dropwise addition tank, and mix well;

[0033] c. Under the condition that the toluene in the reaction kettle of step a is in a reflux state, the mixed raw materials obtained in the dropping ...

Embodiment 2

[0037] An acrylic resin mainly used for container finish paint, including the following components:

[0038] Methyl methacrylate 200Kg,

[0039] n-Butyl methacrylate 300Kg,

[0040] Methacrylic acid 2Kg,

[0041] Acrylic 2Kg,

[0042] Hydroxyethyl methacrylate 10Kg,

[0043] Di-tert-butyl peroxide 10Kg,

[0044] Xylene 510Kg.

[0045] A preparation process of acrylic resin mainly used for container finish paint, comprising the following process flow:

[0046] A. the xylene of described 320Kg is added in the reactor, and feed nitrogen and be heated to reflux state;

[0047] b. The methyl methacrylate of 200KG, the n-butyl methacrylate of 300KG, the methacrylic acid of 2KG, the acrylic acid of 2KG, the hydroxyethyl methacrylate of 10KG and the di-tert-butyl peroxide of 4KG are put into dropwise addition tank, and mix evenly;

[0048] c. When the toluene in the reaction kettle of step a is in a reflux state, the mixed raw materials obtained in the dripping tank of step b ...

Embodiment 3

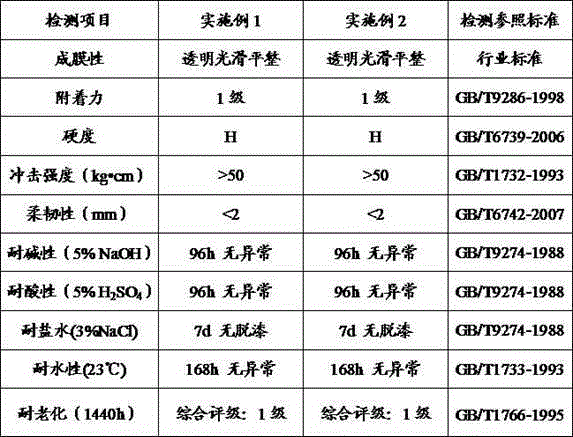

[0052] After the acrylic resin obtained in Example 1 and Example 2 is made into a paint film according to the corresponding national and industry standards, the corresponding performance test is carried out, and the test results can all meet the corresponding standard requirements. The test results are shown in Table 1 below.

[0053] Table 1.

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com