Ultraviolet-curing organosilicon liquefied optical adhesive composition, preparation method and application thereof

A technology of silicone and optical glue, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of widespread application obstacles, complex use process and failure of two-component glue, and achieve high yield, High bonding reliability and low volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

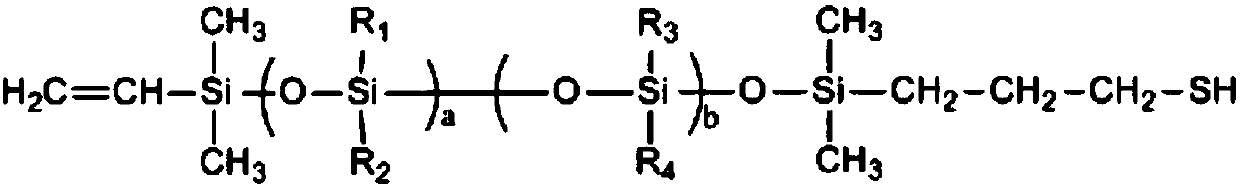

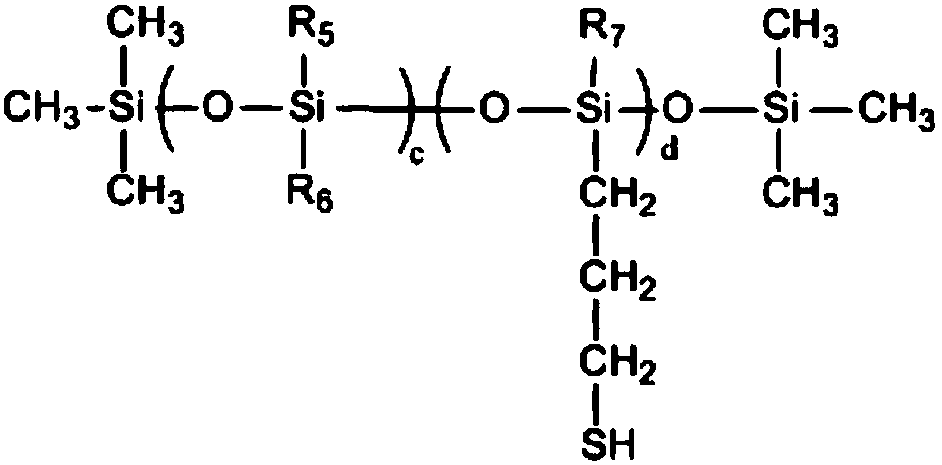

Method used

Image

Examples

Embodiment 1

[0064]A UV-curable silicone liquid optical adhesive composition, consisting of the following raw materials: 70g VA1, 25g TB1, 5.0g SC1, 0.2g 1-hydroxycyclohexyl phenyl ketone (photoinitiator 184), 0.1g 2- Chlorthioxanth-9-one, 0.5g E1, 0.01g tricresyl phosphate.

[0065] Prepare according to the following method: add the photoinitiator, tackifier, flame retardant and TB1 of the above weight into the planetary mixer, heat to 45-55, stir and dissolve at ℃; then add the remaining raw materials above, and add to Disperse at 45-55°C at high speed, filter and pack to obtain a UV-curable silicone liquid optical adhesive composition.

[0066] The formulated UV-curable silicone liquid optical adhesive composition has a viscosity of 2000 mPa.s at 25° C. and a refractive index of 1.41. Test performance, as shown in Table 1.

Embodiment 2

[0068] A UV-curable silicone liquid optical adhesive composition, consisting of the following raw materials: 70g VA1, 25g TB1, 5.0g SC1, 0.1g 2,4,6-trimethylbenzoylphenylphosphonic acid ethyl ester (TPO -L), 0.1 g 2-chlorothioxanth-9-one, 0.5 g E1, 0.05 g tricresyl phosphate.

[0069] Prepare according to the following method: add the photoinitiator, tackifier, flame retardant and TB1 of the above weight into the planetary mixer, heat to 45-55, stir and dissolve at ℃; then add the remaining raw materials above, and add to Disperse at 45-55°C at high speed, filter and pack to obtain a UV-curable silicone liquid optical adhesive composition.

[0070] The formulated UV-curable silicone liquid optical adhesive composition has a viscosity of 2000 mPa.s at 25° C. and a refractive index of 1.41. Test performance, as shown in Table 1.

Embodiment 3

[0072] A UV-curable silicone liquid optical adhesive composition, consisting of the following raw materials: 70g VA1, 25g TB1, 5.0g SC1, 0.2g methyl o-benzoylbenzoate (OMBB), 0.1g 2-chlorothioxanthene- 9-keto, 1.0 g El, 0.05 g tricresyl phosphate.

[0073] Prepare according to the following method: add the photoinitiator, tackifier, flame retardant and TB1 of the above weight into the planetary mixer, heat to 45-55, stir and dissolve at ℃; then add the remaining raw materials above, and add to Disperse at 45-55°C at high speed, filter and pack to obtain a UV-curable silicone liquid optical adhesive composition.

[0074] The formulated UV-curable silicone liquid optical adhesive composition has a viscosity of 2000 mPa.s at 25° C. and a refractive index of 1.41. Test performance, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com