A high-efficiency and environment-friendly UV-moisture dual-cure conformal paint for flexible circuit boards

A flexible circuit board, environmentally friendly technology, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problems of non-drying of the shadow area of the circuit board, induction of occupational diseases, delamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In the present invention, monomers containing C=C double bonds and -NHCOO- can be purchased from the market, for example, can be selected from ethyl [2-(vinylthio) ethyl] carbamate, ethyl ( 2-methyl-4-penten-1-yl) carbamate, naphthalene-1-yl N-prop-2-enyl carbamate, 2-methyl-2-propyl[(4E) One of -6-oxo-1,4-hexadien-3-yl] carbamate, etc. It can also be prepared by reacting diisocyanate, polyol, and hydroxyalkyl acrylate as raw materials under a solvent and a catalyst. The specific preparation method includes the following steps:

[0030] Take a certain amount of diisocyanate, hydroxyalkyl acrylate (such as hydroxyethyl (meth)acrylate) and ethylene glycol, add to the reaction kettle, in the presence of a solvent (such as acetone) and a catalyst (such as dibutyltin dilaurate) 60 ° C reflux reaction for 3 hours that is.

[0031] In the present invention, polyurethane modified acrylic resin is adopted, and isocyanate reacts with moisture in the air to realize dark curing w...

Embodiment 1

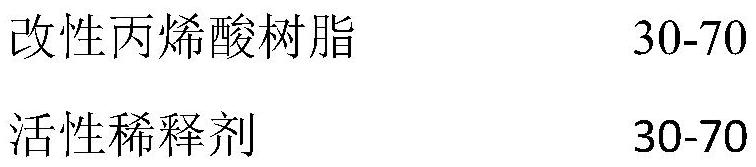

[0054] Embodiment 1 provides a high-efficiency and environment-friendly UV-moisture dual-curing conformal coating for flexible circuit boards, and the preparation raw materials of the conformal coating, in parts by weight, include:

[0055]

[0056] The modified acrylic resin is a polyurethane modified acrylic resin, and its preparation method includes the following steps:

[0057] 0.1mol acrylic acid, 0.1mol ethyl(2-methyl-4-penten-1-yl)carbamate (CAS: 112476-23-0), 0.02mol N-prop-2-enylbenzyl The amide (CAS: 10283-95-1) was added to 100 mL of acetone, stirred and mixed, heated to 60° C., then 2.7 g of potassium persulfate was added, and the reaction was continued for 2 hours under reflux, and then cooled and discharged.

[0058] The active diluent is 8-hydroxyoctyl acrylate; the leveling aid is leveling aid A; the defoaming agent is polyoxyethylene polyoxypropylene pentaerythritol ether; the wetting agent is diethylene glycol ; the flame retardant is tris(2,3-dibromoprop...

Embodiment 2

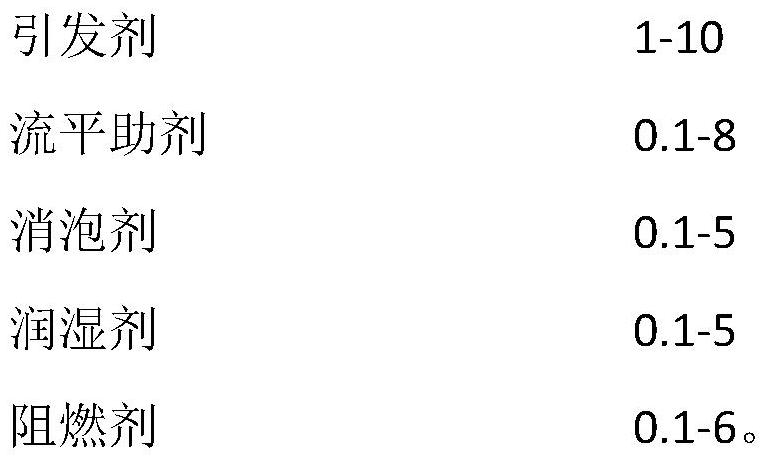

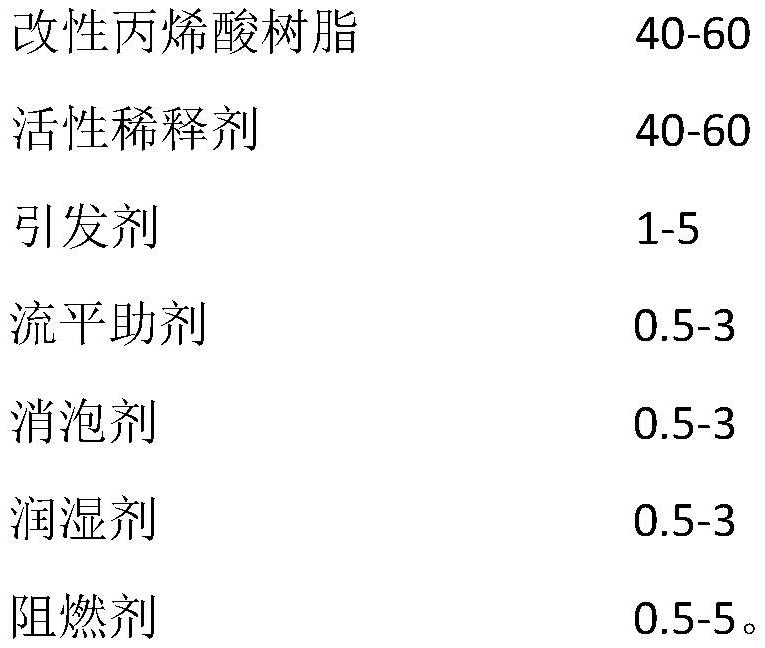

[0063] Embodiment 2 provides a high-efficiency and environment-friendly UV-moisture dual-curing conformal coating for flexible circuit boards, and the preparation raw materials of the conformal coating, in parts by weight, include:

[0064]

[0065] The modified acrylic resin is a polyurethane modified acrylic resin, and its preparation method includes the following steps:

[0066] 0.1mol acrylic acid, 0.1mol ethyl(2-methyl-4-penten-1-yl)carbamate (CAS: 112476-23-0), 0.02mol N-prop-2-enylbenzyl The amide (CAS: 10283-95-1) was added to 100 mL of acetone, stirred and mixed, heated to 60° C., then 2.7 g of potassium persulfate was added, and the reaction was continued for 2 hours under reflux, and then cooled and discharged.

[0067] The active diluent is 8-hydroxyoctyl acrylate; the leveling aid is leveling aid A; the defoaming agent is polyoxyethylene polyoxypropylene pentaerythritol ether; the wetting agent is diethylene glycol ; the flame retardant is tris(2,3-dibromoprop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com