A kind of exterior wall inorganic coating for tropical island and reef buildings

A technology for building exterior walls and inorganic coatings, used in antifouling/underwater coatings, coatings, and biocide-containing paints, etc. It can meet the needs of long-term use of the exterior walls of tropical islands and reefs, and achieve the effect of excellent photocatalytic effect and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

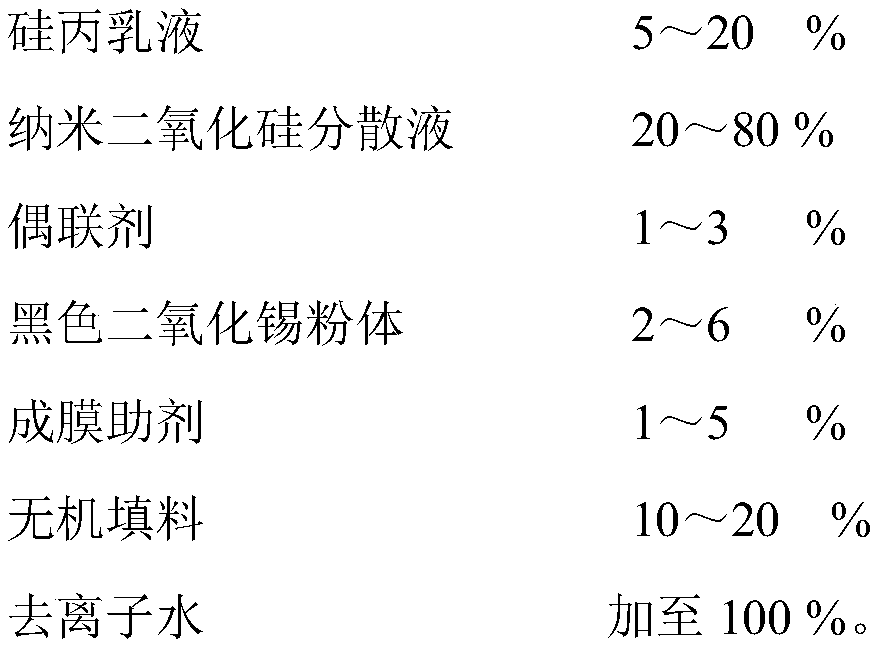

[0016] Its basic composition includes the following components by mass percentage:

[0017]

[0018] The silicon-acrylic emulsion and nano-silica dispersion are commercially available products without special requirements.

[0019] The film-forming aids (AMP-95 multifunctional additive, defoamer, leveling agent, thickener, antifreeze and dispersant) are all commercially available products without special requirements.

[0020] Nano-silica dispersion, black tin dioxide powder and vinyltrimethoxysilane, ultrasonic dispersion for 10 minutes, adding silicon acrylic emulsion and stirring for 20 minutes, adding film-forming aids and stirring for 20 minutes; finally adding calcium carbonate and making up moisture, and grind for 20 minutes to obtain an inorganic coating for the exterior walls of tropical island and reef buildings.

Embodiment 2

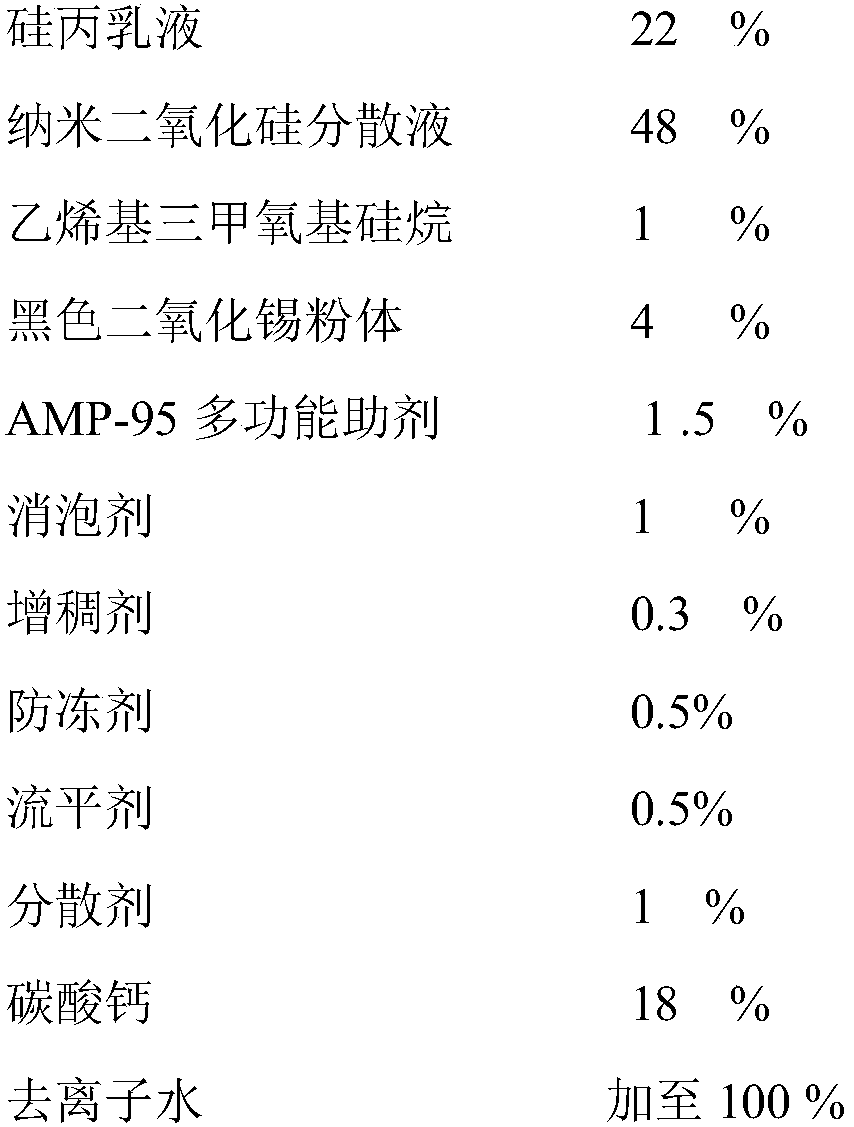

[0022] Its basic composition includes the following components by mass percentage:

[0023]

[0024] The silicon-acrylic emulsion and nano-silica dispersion are commercially available products without special requirements.

[0025] The film-forming aids (AMP-95 multifunctional additive, defoamer, leveling agent, thickener, antifreeze and dispersant) are all commercially available products without special requirements.

[0026] Nano-silica dispersion, black tin dioxide powder and vinyltrimethoxysilane, ultrasonic dispersion for 10 minutes, adding silicon acrylic emulsion and stirring for 20 minutes, adding film-forming aids and stirring for 20 minutes; finally adding calcium carbonate and making up moisture, and grind for 20 minutes to obtain an inorganic coating for the exterior walls of tropical island and reef buildings.

Embodiment 3

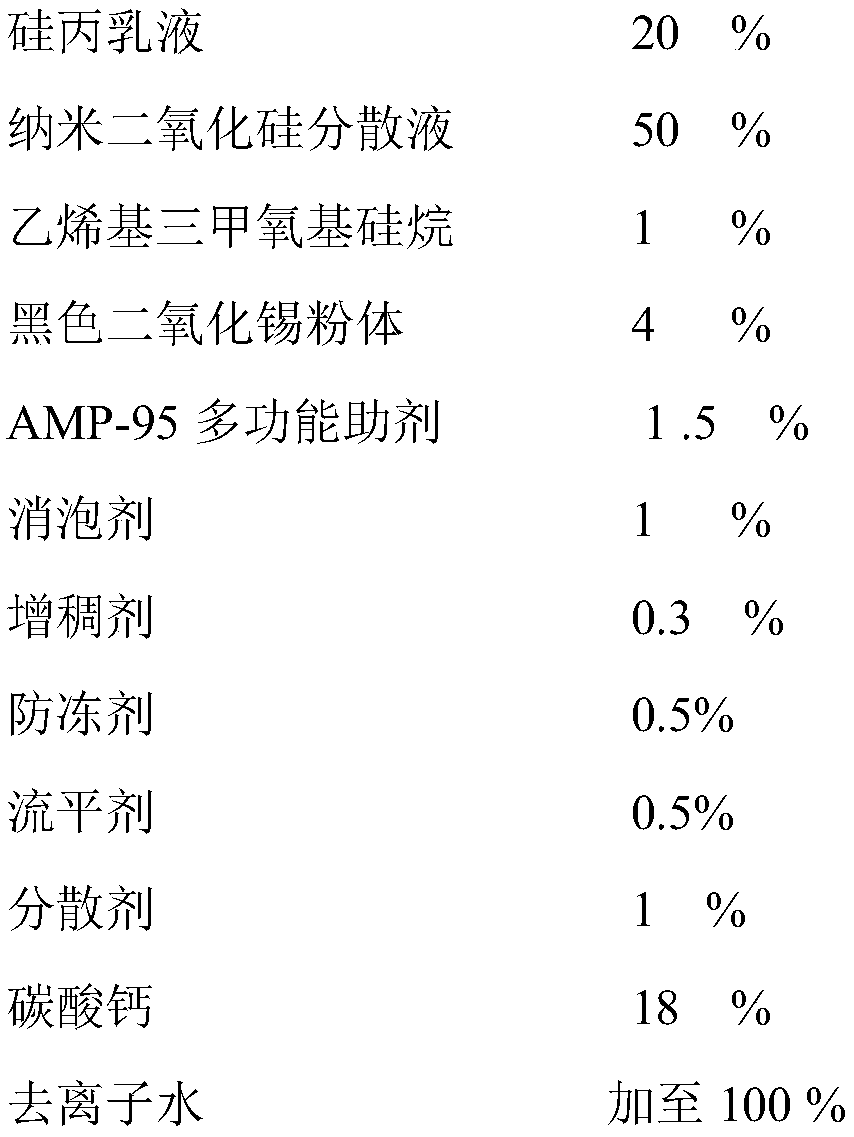

[0028] Its basic composition includes the following components by mass percentage:

[0029]

[0030]

[0031] The silicon-acrylic emulsion and nano-silica dispersion are commercially available products without special requirements.

[0032] The film-forming aids (AMP-95 multifunctional additive, defoamer, leveling agent, thickener, antifreeze and dispersant) are all commercially available products without special requirements.

[0033] Nano-silica dispersion, black tin dioxide powder and vinyltrimethoxysilane, ultrasonic dispersion for 10 minutes, adding silicon acrylic emulsion and stirring for 20 minutes, adding film-forming aids and stirring for 20 minutes; finally adding calcium carbonate and making up moisture, and grind for 20 minutes to obtain an inorganic coating for the exterior walls of tropical island and reef buildings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com