Patents

Literature

56results about How to "Low temperature resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based environment-friendly finishing paint and preparation method thereof

InactiveCN101712833AGood anti-corrosion decoration effectHigh hardnessEpoxy resin coatingsWater basedEpoxy

The invention discloses a water-based environment-friendly finishing paint, which is prepared from the following compositions in part by weight: 20 to 70 parts of water borne acrylic resin solution of which the solid content is 30 to 80 percent and / or 20 to 70 parts of water borne epoxy resin solution of which the solid content is 30 to 80 percent, 4 to 10 parts of water borne amino resin solution of which the solid content is 60 to 98 percent; 1 to 5 parts of organic amine, 0.2 to 2 parts of wetting and leveling agent, 0.2 to 2 parts of thickener, 0.1 to 0.8 part of defoaming agent, 1 to 5 parts of adhesion promoter, 0.2 to 5 parts of catalyst, 10 to 30 parts of alcohol diluting solvent and / or 1 to 5 parts of nontoxic ether diluting solvent, and 20 to 50 parts of deionized water, wherein the catalyst is one or more of ammonias, alcohols and benzenesulfonic acids. The water-based environment-friendly finishing paint has the advantages of wide applicable range, high hardness, good flexibility, strong adhesion, good scratchproof performance, and environmental protection. Simultaneously, the invention also discloses a method for preparing the water-based environment-friendly finishing paint.

Owner:重庆亢石新材料科技有限公司

Aqueous environment-friendly packaging steel drum paint and preparation method thereof

InactiveCN101735703AGood anti-corrosion decoration effectHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to an aqueous environment-friendly packaging steel drum paint, which is prepared by mixing the following compositions in part by weight: 20 to 70 parts of aqueous solution of acrylic resin with a solid content of 30 to 80 percent and / or aqueous solution of epoxy resin with the solid content of 30 to 80 percent, 4 to 10 parts of aqueous solution of amino resin with the solid content of 60 to 98 percent, 1 to 5 parts of organic amine, 1 to 50 parts of filling materials with the granularity of more than 2,000 meshes, 0.5 to 10 parts of color paste, 0.2 to 2 parts of wetting levelling agent, 0.2 to 2 parts of thickening agent, 0.1 to 0.8 part of antifoaming agent, 1 to 5 parts of adhesive force accelerant, 0.2 to 5 parts of catalyst, 0 to 30 parts of alcohol diluting solvent and / or 0 to 5 parts of non-toxic ether diluting solvent, and 20 to 50 parts of deionized water. The aqueous environment-friendly packaging steel drum paint has the advantages of wide application range, high rigidity, good flexibility, strong adhesive force and good anti-scraping and anti-collision properties and environmental protection; and meanwhile, the invention discloses a preparation method for the aqueous environment-friendly packaging steel drum paint.

Owner:重庆亢石新材料科技有限公司

Reinforced toughening flame-proof polyolefin resin composition and its preparation method

The invention discloses a flame-proof polyolefin resin component and preparing method in the resin flame resistant modifying domain, which comprises the following parts: a. 9-20% bromine fire retardant with decabran diphenyl ethane or octabromobium ether and heat-stability hexabromide cyclododecane with weight rate at 2: 1-1: 2, b. 3-8% synergic fire retardant with antimony trioxide, c. 3-12% melt resistant melt drip agent with one or more of organic montmorillonite, kaolin and clay.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Sheet laminating preparation method for sisal fiber reinforced polypropylene composite material

The present invention adopts the sisal hemp fiber as fiber raw material, and uses the nonwoven fabric of thermoplastic resin PP, film, powder material and its fiber as resin base body, and adopts thefollowing steps: pretreating sisal hemp fiber and making it into fiber felt, hot-pressing and forming, selecting and using a certain number of fiber felts, delaminating and sand wiching pp nonwoven fabric or film, under the condition of a certain temp. and pressure hot-pressing and forming or mixing PP fiber (PP powder) directly with sisal hemp fibre, making them into fiber felt and then hot-pressing and forming so as to obtain the invented sisal hemp fiber reinforced polypropylene composite material.

Owner:SUN YAT SEN UNIV

Engineering fibre manufacturing technique for polyester reclaiming material road

InactiveCN101265611AReduce manufacturing costSave resourcesFilament manufactureHeating/cooling textile fabricsPolyesterCircular economy

The invention discloses a polyester recycled material road used technical fiber production process, which includes the following steps: dosing, batch charging, vibratory screening, feeding, pre-drying, drying or tackifying drying, adding nucleator, screw extrusion, melt filtrating, spinning, tow cooling, rolling and oiling, reciprocating tank falling, bunching, drafting, tension-setting, passing through a crimping machine, and shrink-setting. The invention improves the prior polyester recycled material technical fiber production process, and can adopt the polyester recycled material to produce the eligible road used technical fiber with low cost, environmental protection, and saved resource; which accords with the present nation called circulating economic developing ideology. The product quality completely achieves the quality standard of the road used technical fiber at home and abroad.

Owner:谭亦武 +1

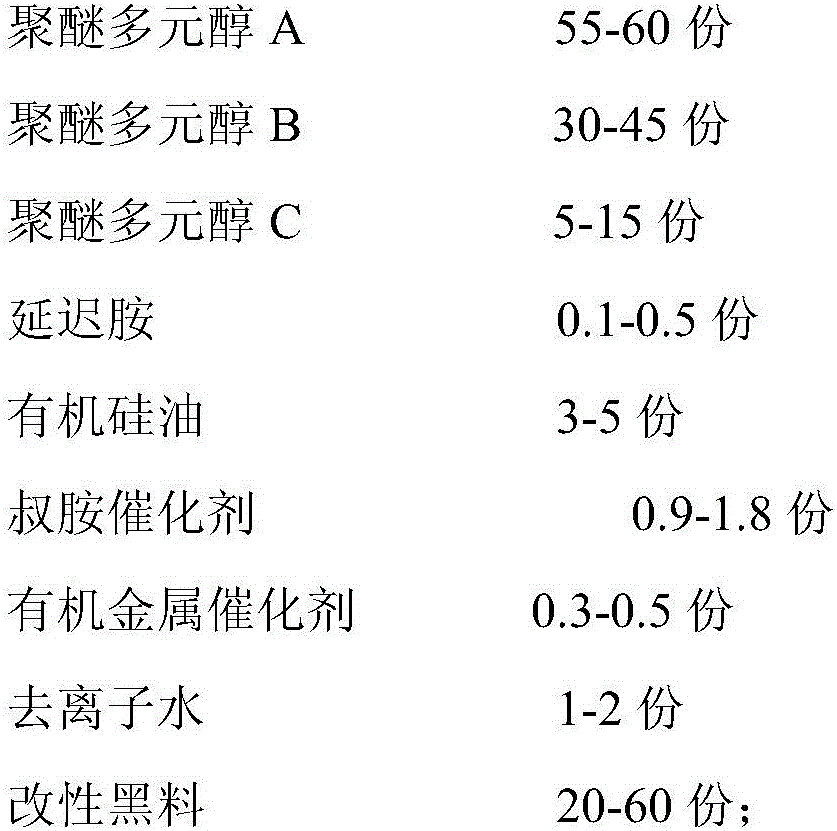

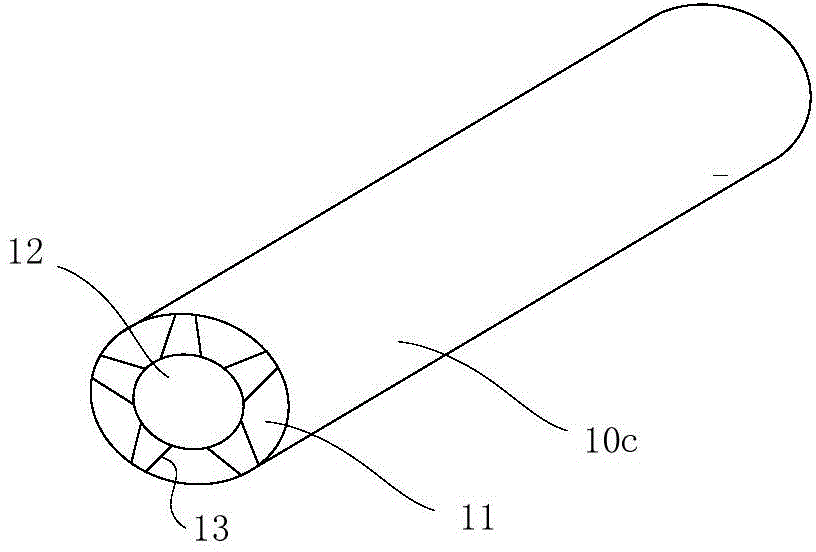

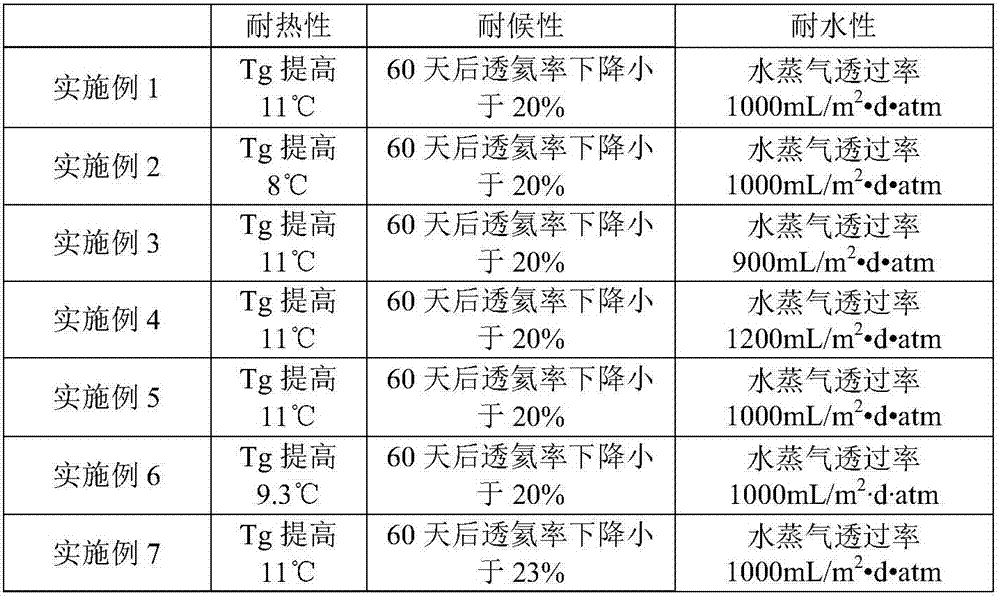

Slow-recovery foam with low temperature resistance and high density as well as preparation method thereof

The invention belongs to the field of organic polymer synthesis technology, and concretely relates to slow-recovery foam with low temperature resistance and high density as well as a preparation method thereof. The slow-recovery foam is prepared by the following raw materials: polyether polyol A (hydroxyl value is 30-50, and functionality is 2.5-4.5), polyether polyol B (hydroxyl value is 45-65 and functionality is 2.5-4.5), polyether polyol C (hydroxyl value is 340-400, and functionality is 2.5-3.5), a delayed action polyurethane catalyst, silicone oil, a tertiary amine catalyst, an organo-metallic catalyst, deionized water, and modified diphenylmethane-4,4'-diisocyanate. A pore forming agent is not added, and the pore forming effects are good; special slow-recovery silicone oil is not used, flexible form silicone oil can be directly used, and cost is saved. recovery time is 3-5 seconds which is the optimal recovery time for the slow-recovery foam; the slow-recovery foam has low temperature resisting effects, and the bearing capacity of the slow-recovery foam is one time higher than the bearing capacity of slow-recovery foam on the market. The invention also provides a preparation method of the slow-recovery foam.

Owner:ZIBO DEXIN LIANBANG CHEM IND

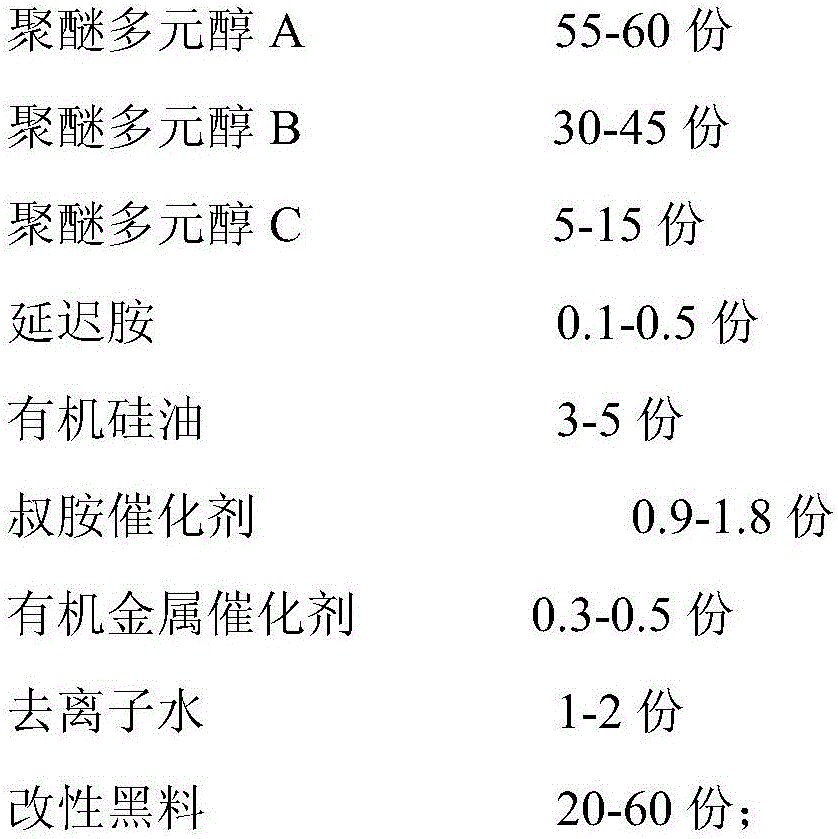

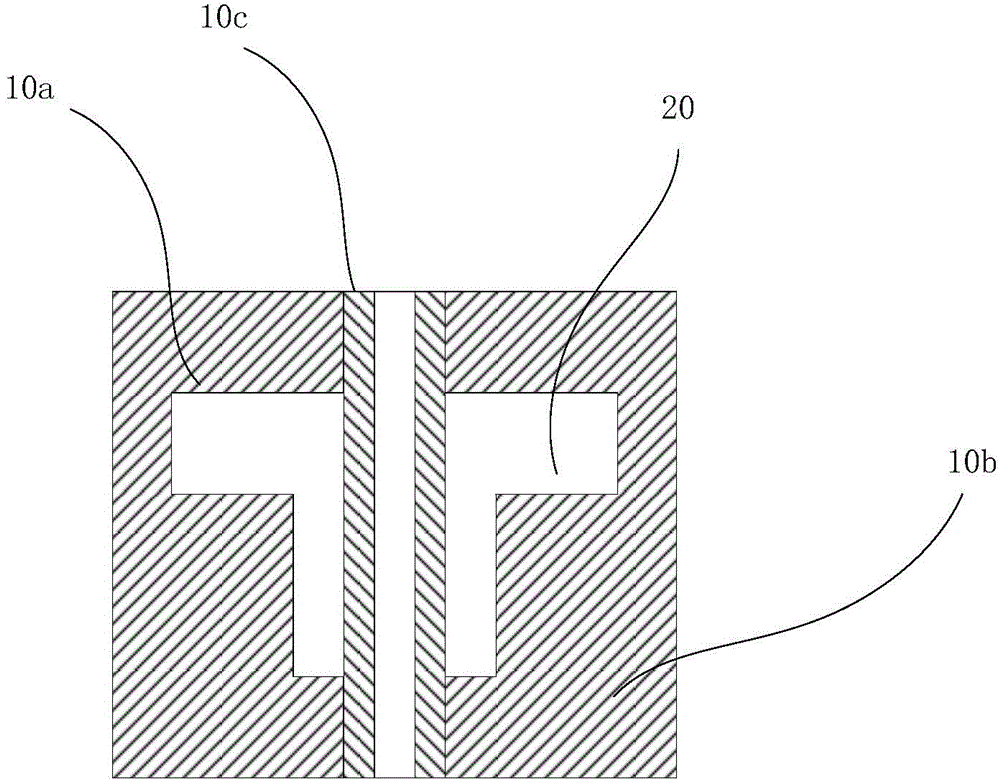

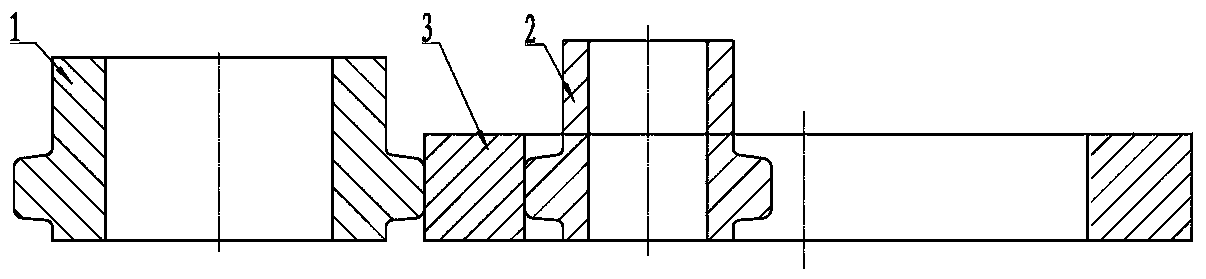

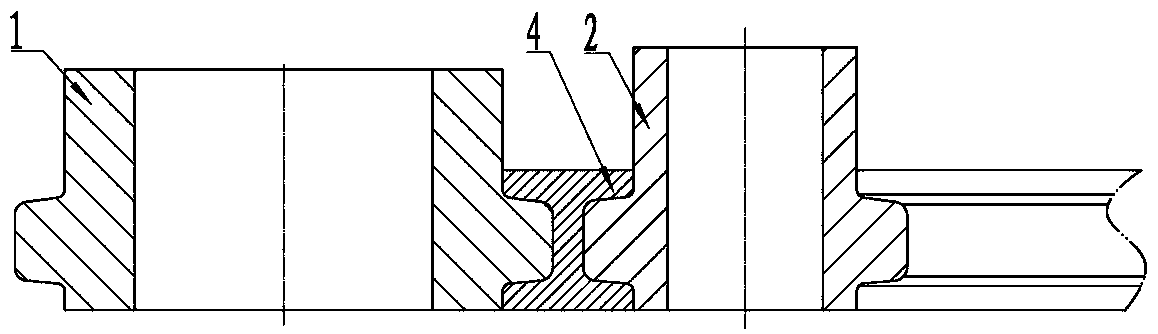

Casting mold used in casting molding process of metal casting and casting

ActiveCN104439081AInhibit aggregationLow temperature resistantFoundry mouldsFoundry coresCasting moldMetal

The invention discloses a casting mold used in a casting molding process of metal casting and a casting cast with the casting mold. The casting mold comprises a shell and a core, wherein a cavity is formed in the shell; the core is arranged in the cavity in a predetermined manner; the shape of the casting to be formed is defined by both the outline of the core and the inner wall of the cavity; the shell is made of a ceramic material; at least part of the core is made of a ceramic material; a yielding structure used for shrinkage yielding and / or withdrawal yielding of the core is also arranged on the core. The casting mold provided by the invention not only can be used repeatedly, but also has the corresponding characteristic of a sand shell; as the core of the casting mold comprises the yielding structure, convenience is brought for withdrawal during use.

Owner:SUS LAB FOR IND SCI & TECH

Air cathode of microbial fuel cell and preparation method of air cathode

ActiveCN104091955AStable structureLow costCell electrodesFinal product manufactureFuel cellsManufacturing technology

The invention provides an air cathode of a microbial fuel cell and a preparation method of the air cathode, relates to an air cathode of a single-chamber air cathode microbial fuel cell and a preparation method of the single-chamber air cathode microbial fuel cell, and aims at solving the problems that the air cathode in an existing microbial fuel cell is high in manufacturing cost and complicated in manufacturing technology. The air cathode comprises a liquid catalyst, a waterproof and breathable film and a stainless steel net, wherein the liquid catalyst coats the waterproof and breathable film; the stainless steel net is arranged on the side, loaded with the liquid catalyst is loaded, of the waterproof and breathable film in a stacking manner. The preparation method comprises the steps of 1, mixing a catalyst, isopropanol, Nafion and deionized water to prepare the liquid catalyst; 2, coating the waterproof and breathable film with the liquid catalyst; and 3, stacking the stainless steel net on the side, loaded with the liquid catalyst, of the waterproof and breathable film. The air cathode of the microbial fuel cell is low in manufacturing cost, simple in manufacturing technology, and short in consumed time, and the expanded production of the air cathode can be facilitated.

Owner:HARBIN INST OF TECH

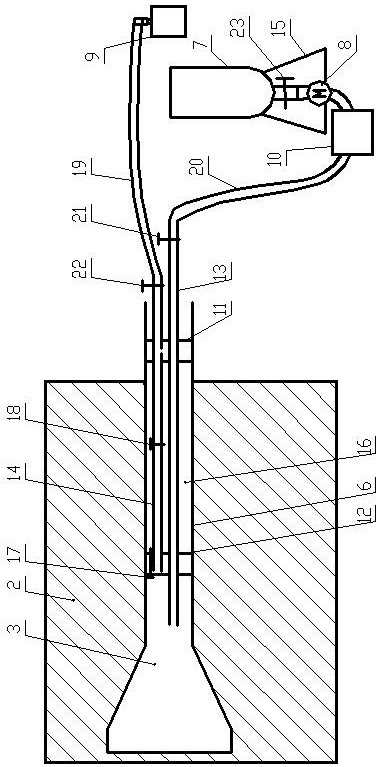

Method for enhancing permeability and promoting drainage by combining hydraulic hole making and hole drilling heat injection in mining-coal bed

ActiveCN112412417ANo pollution in the processImprove thermal stressInsulationLiquid/gas jet drillingThermodynamicsPunching

The invention provides a method for enhancing permeability and promoting drainage by combining hydraulic hole making and hole drilling heat injection in a mining-coal bed. The method comprises the following steps that crossheading drilling is carried out on a working face crossheading, wherein the distance between every two adjacent drill holes is 7-10m, and any two adjacent drill holes are namedas a heat injection hole and a drainage hole respectively; drainage pipes are arranged in the drill holes, and a special hole packer is sent into the second drainage pipe for hole sealing; high-temperature and high-pressure nitrogen is injected into the heat injection holes through the special hole packer, the adjacent drainage holes are always in normal gas drainage, and gas escaping from heatedcoal is pumped away in time; the drainage pipes in the heat injection holes are connected with a drainage system for gas drainage work, and the gas drainage effect is further enhanced. In conclusion,the method is scientific in principle, tight in hole sealing, safe and reliable, the heat injection improving drainage promoting effect is greatly enhanced by combining hydraulic punching; and the method can be widely applied to rock cross-cut coal uncovering, fault crossing, permeability enhancement and drainage promotion of excavation working faces, enhanced gas drainage and other work and is wide in application prospect.

Owner:HENAN POLYTECHNIC UNIV

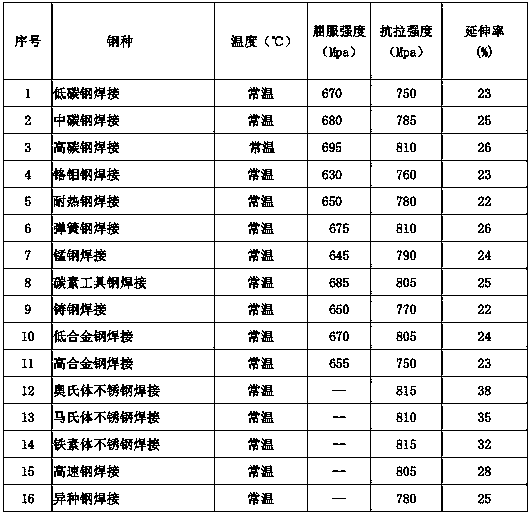

Electric welding rod suitable for welding various steel types and application and preparation method thereof

ActiveCN110142530AImprove work hardening abilityNo change in weld strengthWelding/cutting media/materialsSoldering mediaMartensitic stainless steelEngineering

The invention provides an electric welding rod suitable for welding various steel types and application and preparation method of the electric welding rod suitable for welding various steel types andrelates to the electric welding rod suitable for welding various steel types. The electric welding rod comprises a welding core and a coating. The coating is applied to the outer wall of the welding core, and the coating accounts for 40-45% of the total weight of the welding rod. The invention further relates to a preparation method of the electric welding rod suitable for welding various steel types. The preparation method comprises the steps of preparation of the welding core and the coating, forming and drying. The electric welding rod is used for welding of low carbon steel, medium carbonsteel, high carbon steel, chromium molybdenum steel, heat resistant steel, spring steel, manganese steel, carbon tool steel, hot-work alloy steel, cast steel, low alloy steel, high alloy steel, austenitic stainless steel, martensitic stainless steel, ferritic stainless steel, high-speed tool steel and dissimilar steel. The electric welding rod and the application and preparation method have the beneficial effects that the application is wide, the cost is low and the welding effect is good.

Owner:清河县联盛焊接材料有限公司

Method for preparing asphalt modifying assistant

InactiveCN104845013AImprove shrinkageImprove performanceBuilding insulationsLow speedPolymer science

The invention relates to a method for preparing an asphalt modifying assistant and belongs to the technical field of assistant preparation methods. The method comprises the steps: (1) mixing 15-21 parts by weight of SBS (Styrene Butadiene Styrene block polymer) thermoplastic rubber, 15-25 parts by weight of UPVC (Unplasticized Polyvinyl Chloride), 5-12 parts by weight of CPVC (Chlorinated PVC) and 5-10 parts by weight of solvent oil, and stirring at a low speed until the temperature of the mixture is 60 DEG C; (2) adding 5-8 parts by weight of kaolin, and stirring at a high speed until the temperature of the mixture is 80 DEG C, wherein the revolution rate of stirring is higher than 1,000 revolutions per minute; (3) adding 6-8 parts by weight of dispersant, and stirring at a high speed until the temperature of the mixture is 100-110 DEG C, wherein the revolution rate of stirring is higher than 1,000 revolutions per minute; (4) grinding, and then, filtrating, so as to enable the degree of fineness of the ingredients to be not greater than 80 microns; (5) adding 3-5 parts by weight of stabilizer, stirring at a low speed, and cooling the mixture to the temperature of 35-40 DEG C, thereby preparing the assistant. Due to the addition of UPVC, CPVC and kaolin, UPVC, CPVC and kaolin mutually generate synergistic effects, and Al and Si ions generated from the decomposition of kaolin play a role in polarizing other ions, so that the shrinking percentage of UPVC and CPVC is increased, the plasticity and viscosity of the assistant are improved, and the anti-corrosion property of the assistant is improved jointly by UPVC, CPVC and kaolin.

Owner:湖州华仑助剂科技有限公司

Environment-friendly modified-asphalt coating material and preparation method thereof

InactiveCN104845422AImprove overall performanceAnti-crack lengthAnti-corrosive paintsButadiene-styrene rubberPetroleum

The invention relates to an environment-friendly modified-asphalt coating material and a preparation method thereof and belongs to the technical field of paint and preparation processes thereof. The coating material contains the following ingredients in parts by weight: 30-42 parts of petroleum asphalt, 25-31 parts of polyethylene oxide, 19-27 parts of glycidyl methacrylate, 4-8 parts of polyvinyl chloride paste resin, 5-20 parts of dioctyl phthalate, 15-21 parts of SBS (Styrene Butadiene Styrene block polymer) thermoplastic rubber, 15-25 parts of UPVC (Unplasticized Polyvinyl Chloride) and 5-12 parts of CPVC (Chlorinated PVC). According to the scheme, volatile organic solvents are not adopted, so that the coating material is environmentally-friendly. Meanwhile, the coating material disclosed by the invention is excellent in heat resistance, integrates chemical stability and heat resistance, can still work normally below 200 DEG C and has good stability.

Owner:湖州大周高分子材料有限公司

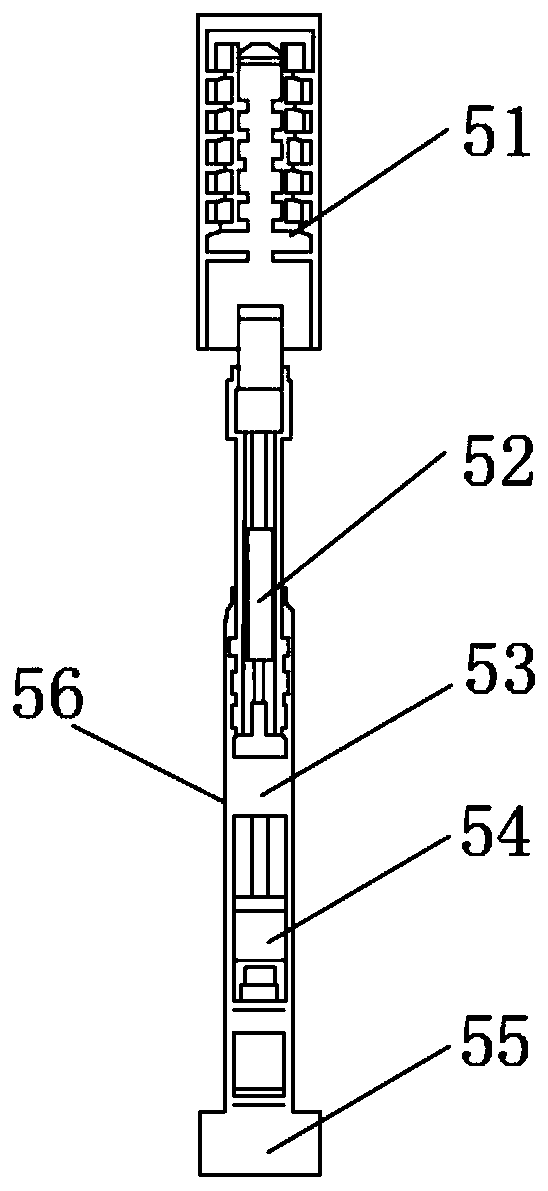

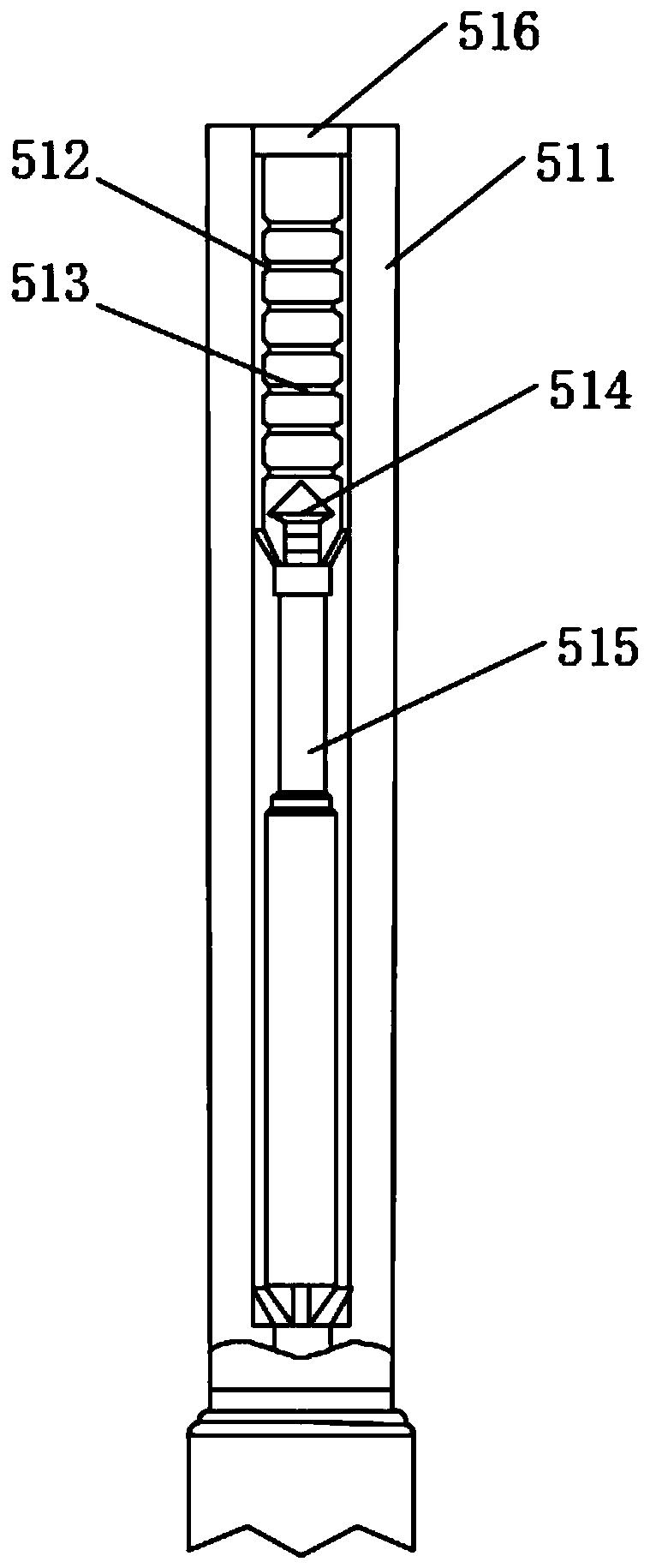

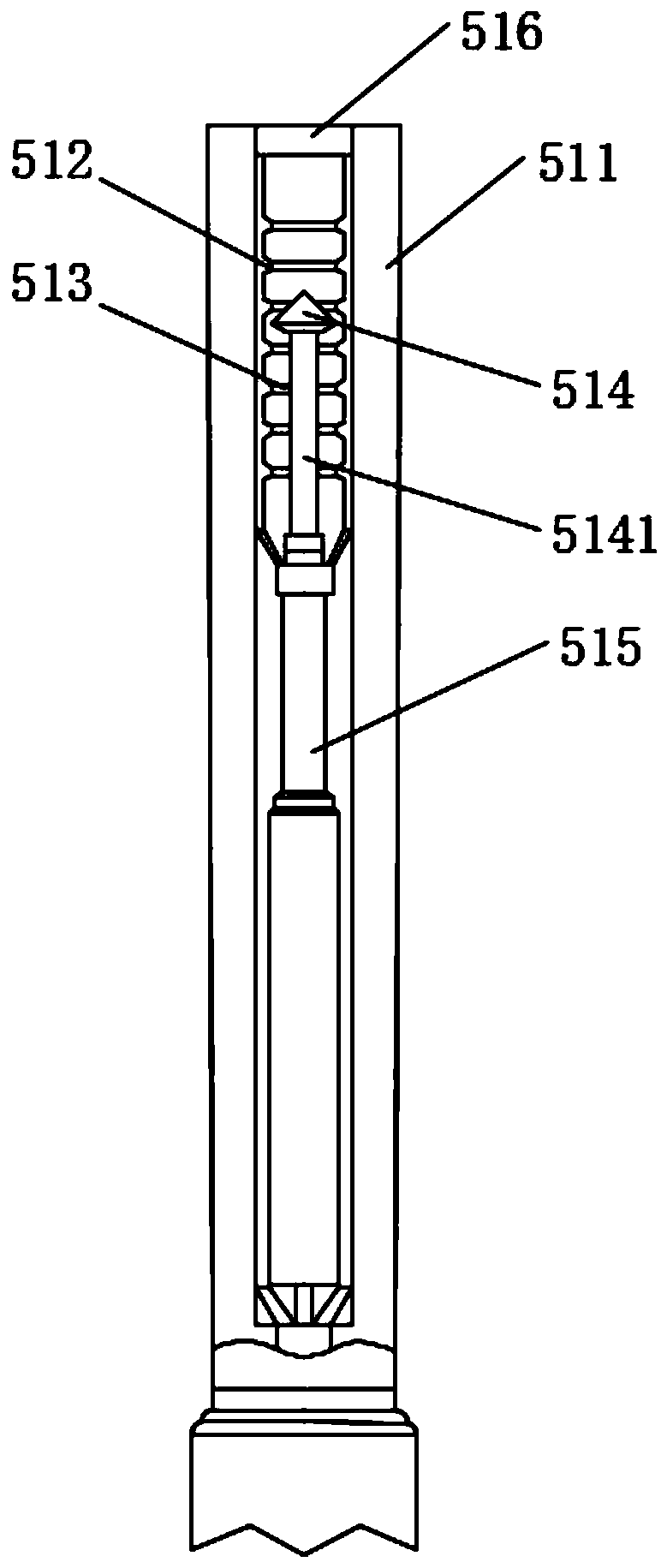

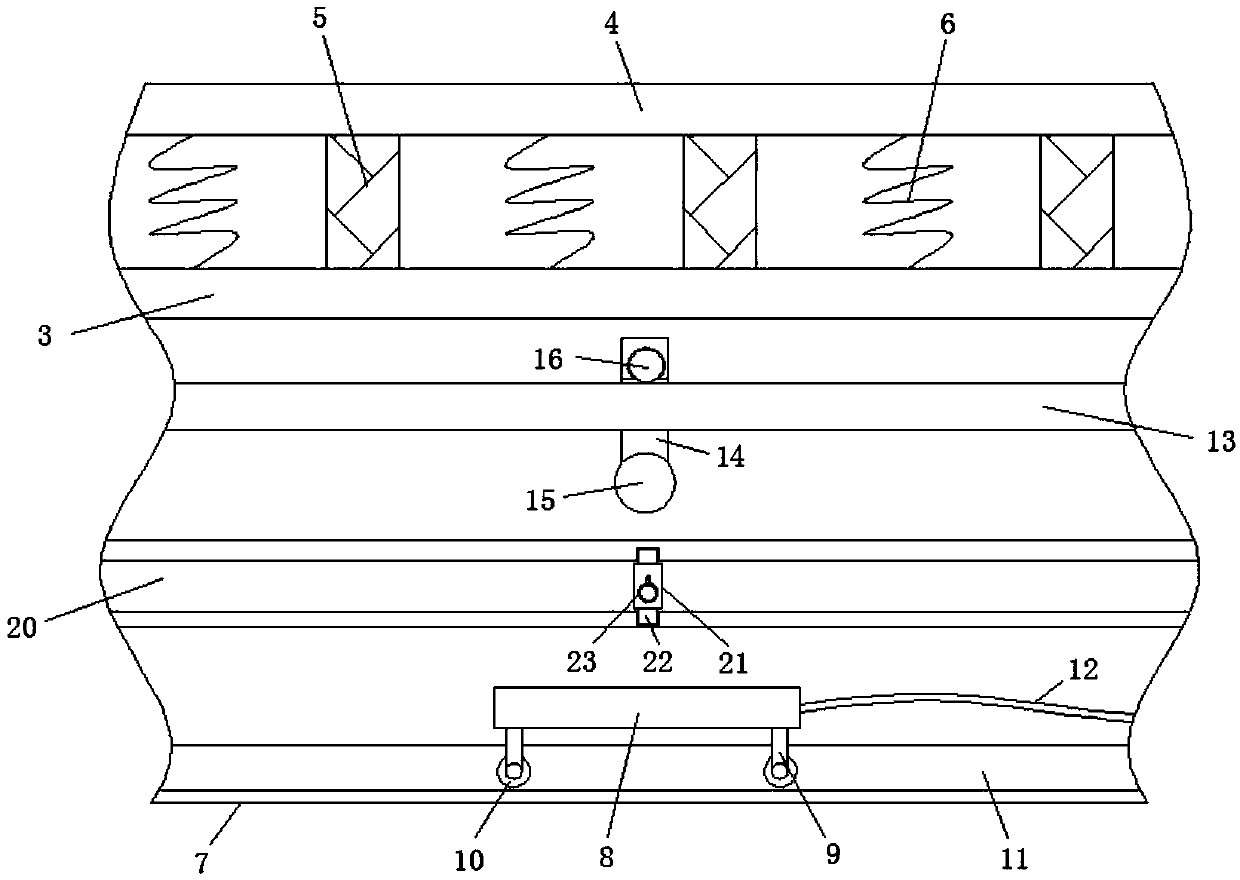

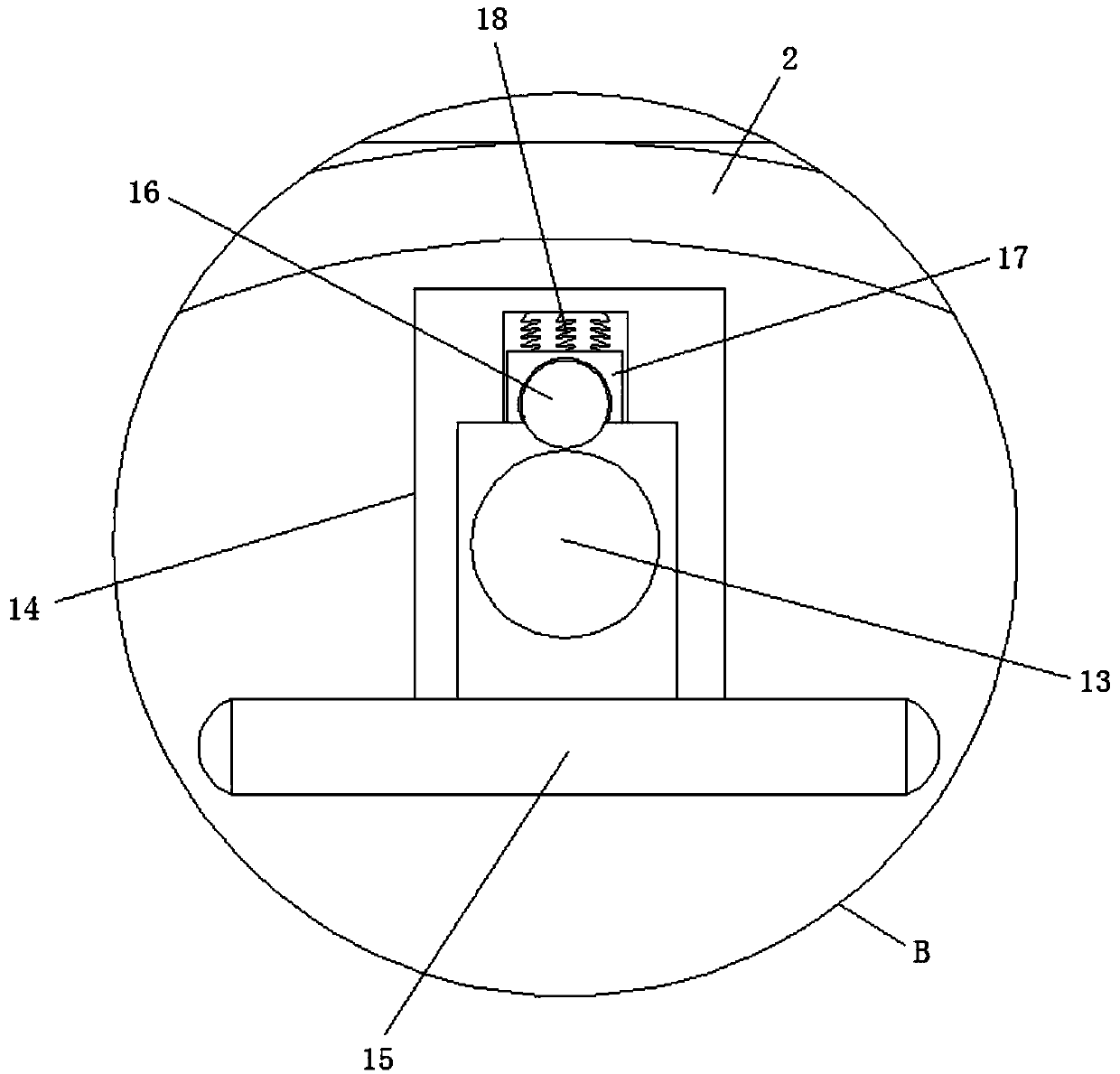

Mechanical deviation measuring instrument based on drilling fluid circulation

The invention discloses a mechanical deviation measuring instrument based on drilling fluid circulation. The mechanical deviation measuring instrument based on the drilling fluid circulation comprisesa pulse generating device, a coding control mechanism, an oblique measuring mechanism, a damping device and a base communicating with a drill bit, wherein the pulse generating device, the coding control mechanism, the oblique measuring mechanism, the damping device and the base communicate in sequence according to the flow direction of drilling fluid. A shell is arranged on the base, and the damping device, the oblique measuring mechanism and the coding control mechanism are coated with the shell. The mechanical deviation measuring instrument based on the drilling fluid circulation has the beneficial effects that according to the scheme, the function of wireless oblique measurement while drilling can be realized, measuring the parameters of drilling is realized without affecting the normal drilling, a construction error is too large due to the delay of measurement data is avoided, and the correction and processing are conveniently carried out on the error in time.

Owner:自贡中兴耐磨新材料有限公司

Medicated diet composition for enhancing immunity and preparation method thereof

PendingCN110367522AReduce resistanceIncrease the totalTripeptide ingredientsFungi medical ingredientsAgaricus blazeiBULK ACTIVE INGREDIENT

The invention provides a medicated diet composition for enhancing immunity. The medicated diet composition comprises, by weight, 60-75 parts of selenium-rich grifola frondosa, 35-45 parts of selenium-rich agaricus blazei murill, 30-40 parts of selenium-rich radix astragali, 2-10 parts of gypenoside and 2-10 parts of glutathione, wherein the selenium contents of the selenium-rich grifola frondosa,the selenium-rich agaricus blazei murill and the selenium-rich radix astragali are greater than 400 ppm. The invention further provides a preparation method of the medicated diet composition. The method is based on water extraction and repeated low-temperature extraction. The medicated diet composition has the advantages that components are reasonably compounded, the formulation is ingenious, andthe composition has the effect of regulating the balance of qi, blood, yin and yang of the human body and enhancing the body immunity. The preparation method has the advantages that through repeated low-temperature extraction, active ingredients can be extracted as many as possible on the premise of ensuring the activity of the active ingredients.

Owner:恩施硒圣植物科技有限公司

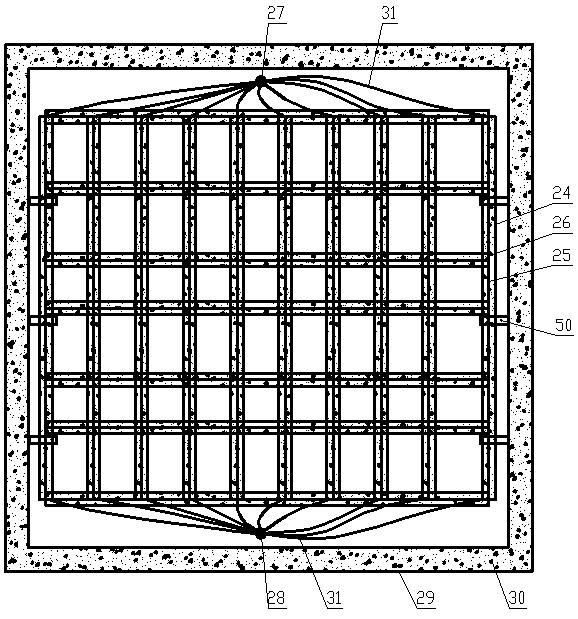

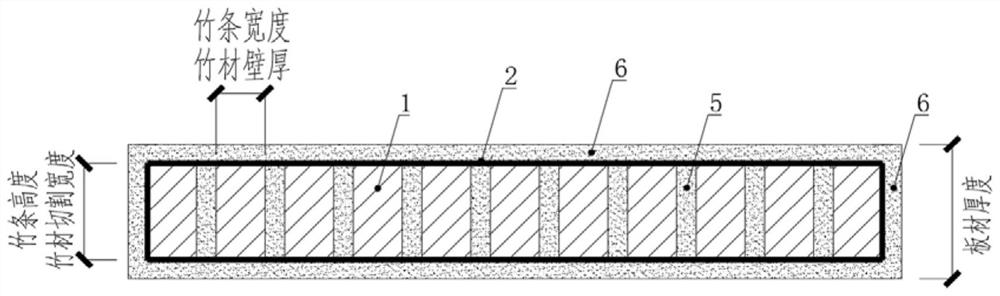

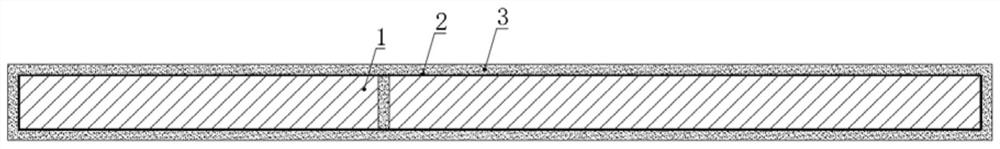

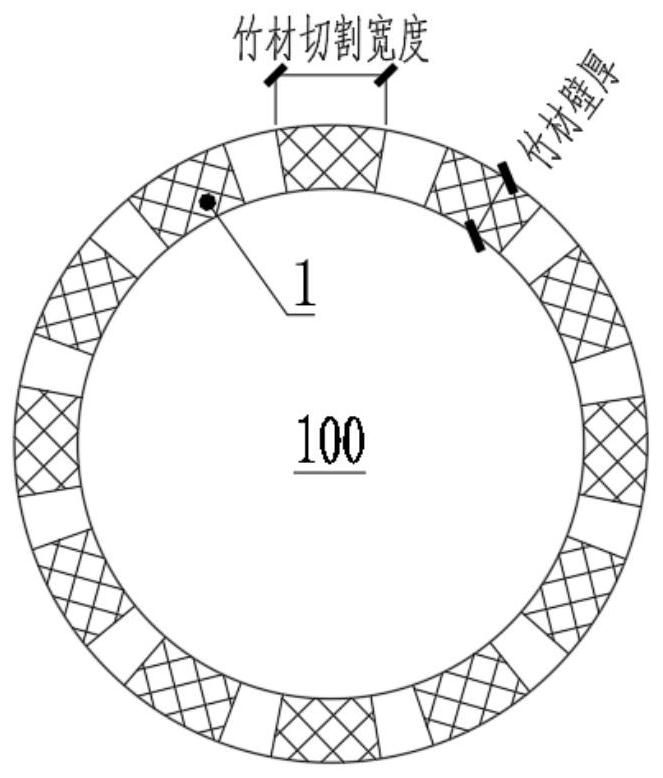

Permanent bamboo-based composite bearing plate and processing technology

The invention relates to a permanent bamboo-based composite bearing plate. The permanent bamboo-based composite bearing plate comprises assembly bamboo canes, fiber gridding cloth and a cementing material, wherein the assembly bamboo canes are formed by longitudinally cutting bamboos, the bamboo canes are vertically placed during assembly, and first gaps are formed between the adjacent bamboo canes at intervals; the fiber gridding cloth is attached to the upper surfaces and the lower surfaces of the assembly bamboo canes and completely wraps the side surfaces and the end surfaces of the assembly bamboo canes from the peripheries; the cementing material is poured into the first gaps, as well as the upper surface and the lower surface of the outer side and the peripheral side surface of thefiber gridding cloth, the cementing material in the first gaps forms thin-wall connecting supporting ribs, and the cementing material on the upper surface and the lower surface of the outer side and the peripheral side surface of the fiber gridding cloth forms a bearing protection bonding layer. The permanent bamboo-based composite bearing plate not only can give consideration to bearing strength,but also can realize the advantages of energy conservation, environmental protection, safety, low consumption, high temperature resistance, low temperature resistance, wear resistance, corrosion resistance, seepage resistance and high fire resistance.

Owner:西藏涛扬集团有限公司

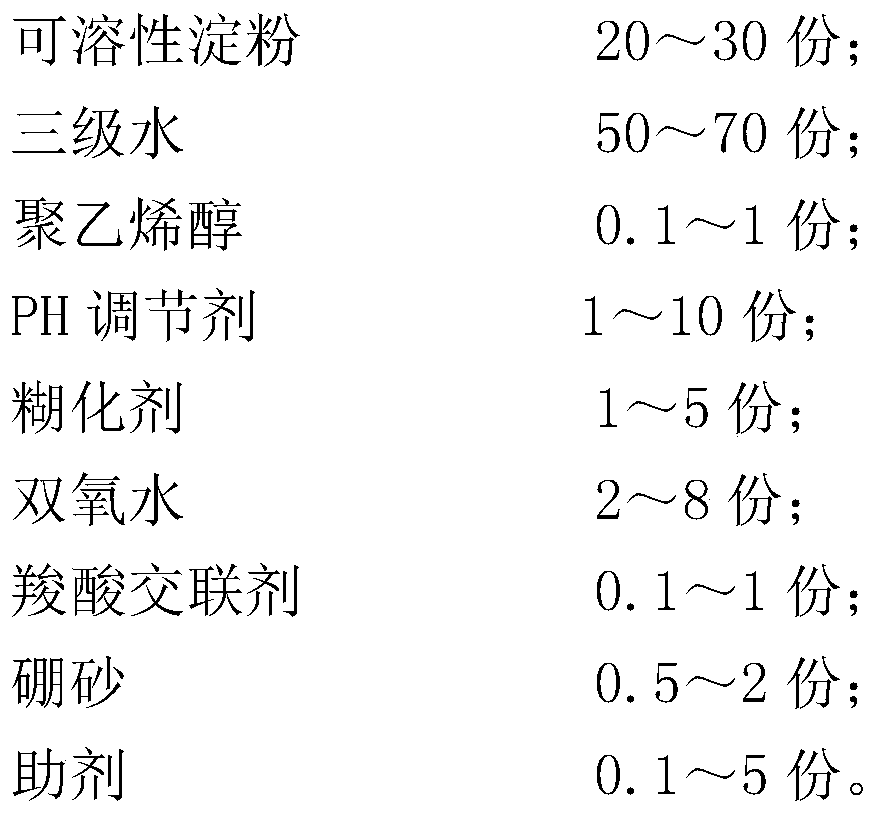

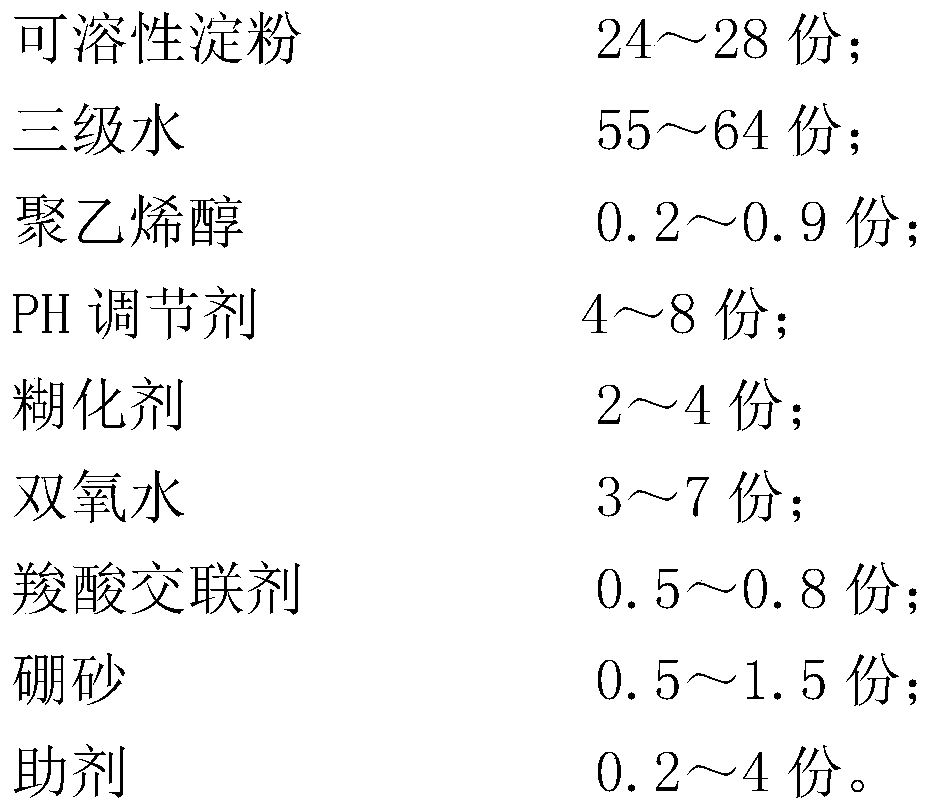

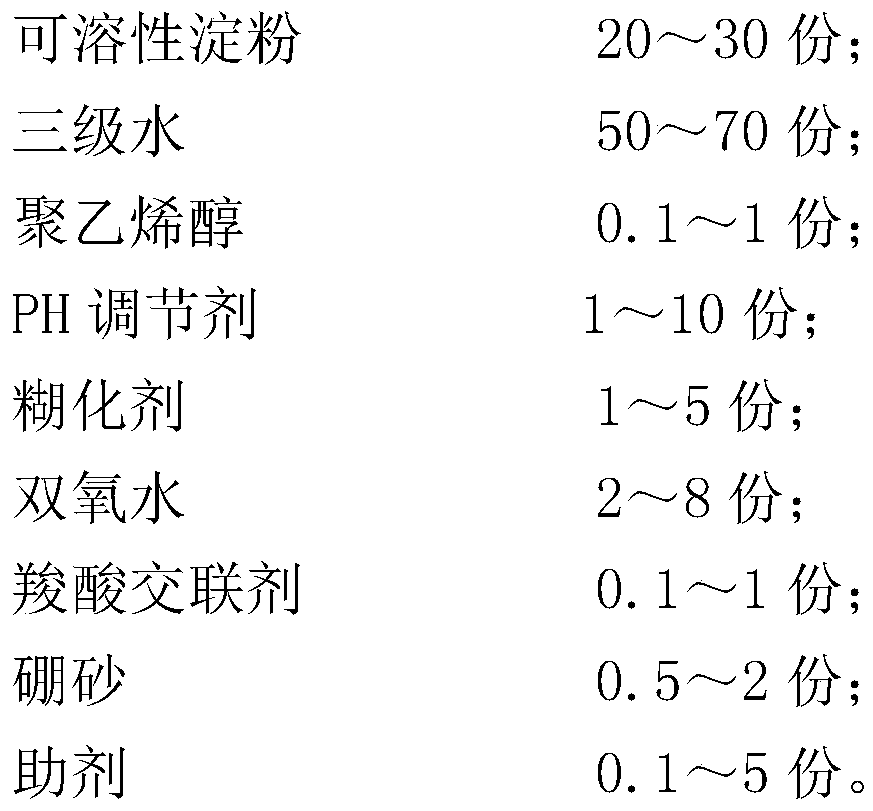

Environment-friendly, high-viscosity and weather-resistant modified starch adhesive and preparation method thereof

InactiveCN110551462AHigh temperature resistantStable network structureStarch derivtive adhesivesMacromolecular adhesive additivesPolyvinyl alcoholAdhesive

The invention discloses an environment-friendly, high-viscosity and weather-resistant modified starch adhesive and a preparation method thereof.The environmentally friendly, high-viscosity and weather-resistant modified starch adhesive is prepared from the following components in parts by weight: 20 to 30 parts of soluble starch, 50 to 70 parts of tertiary water; 0.1 to 1 part of vinyl alcohol, 1to 10 parts of a PH regulator, 1 to 5 parts of a gelatinizer, 2 to 8 parts of hydrogen peroxide, 0.1 to 1 part of a carboxylic acid crosslinking agent, 0.5 to 2 parts of borax and 0.1 to 5 parts of anadditives. According to the environmentally friendly, high-viscosity and weather-resistant modified starch adhesive, the polyvinyl alcohol, the starch and the tertiary water are mixed, then the hydrogen peroxide is added in an alkaline environment for oxidization to destroy the hydrogen bond of the starch for modification, the carboxylic acid crosslinking agent is added to form a stable network structure,and then gelatinization, complexationand dispersion are conducted to prepare the environment-friendly and highly-viscosity modified starch adhesive with the abilities to withstand high temperature and high humidity, low temperature and high and low temperature cycling impact.

Owner:永发印务(东莞)有限公司

Acrylic acid copolymerized polyvinyl chloride pipe for water supply and preparation method thereof

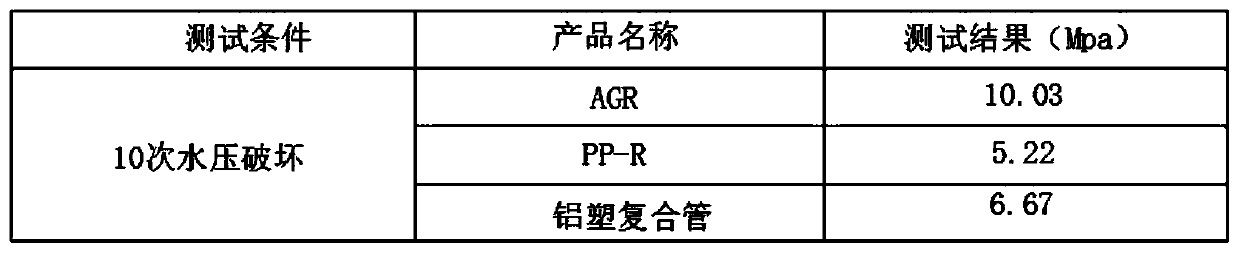

The invention discloses an acrylic acid copolymerized polyvinyl chloride pipe for water supply and a preparation method thereof. The preparation method comprises the following steps that acrylic resinand polyvinyl chloride are placed in a polymerization kettle, the acrylic resin and the polyvinyl chloride are mixed and placed in a pre-polymerization kettle, the pre-polymerization kettle is a vertical stainless steel polymerization kettle, a turbo-type flat paddle stirrer is arranged in the pre-polymerization kettle, and the; wherein the stirring speed is controlled to be 50-250 rpm, then themixed material is placed from the pre-polymerization kettle into a post-polymerization kettle, the post-polymerization kettle is a horizontal kettle and is internally provided with a stirrer which isformed by combining three helical ribbons and is used for stirring at a low speed, and the rotating speed of the horizontal kettle is 6-7 rpm; the AGR pipe manufactured through the method is simple and convenient in process, complex process steps are reduced, meanwhile, the product quality is improved, the occurrence frequency of defective products is reduced, installation and construction are convenient, the AGR pipe does not need to consider the influence of thermal expansion and cold contraction on the pipe, and construction can be conducted all the year round, in a high-temperature area and in a cold area.

Owner:CHENGDU CHUANXING TECH PLASTICS INDUSRTY CO LTD

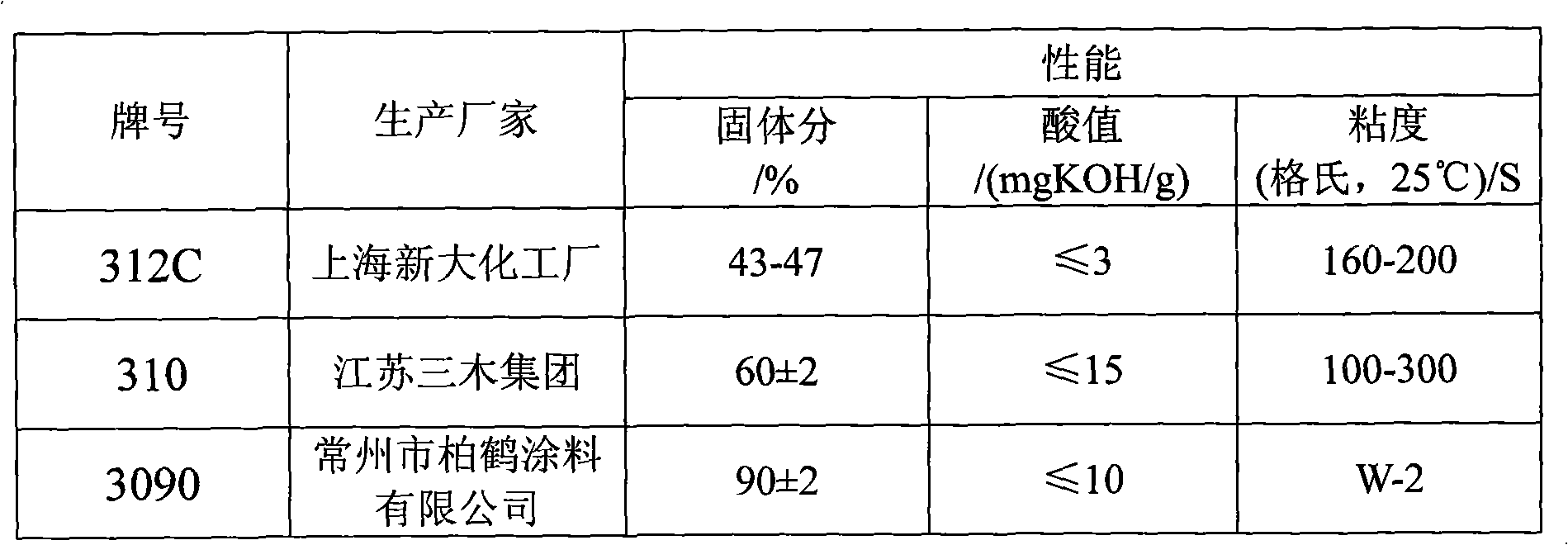

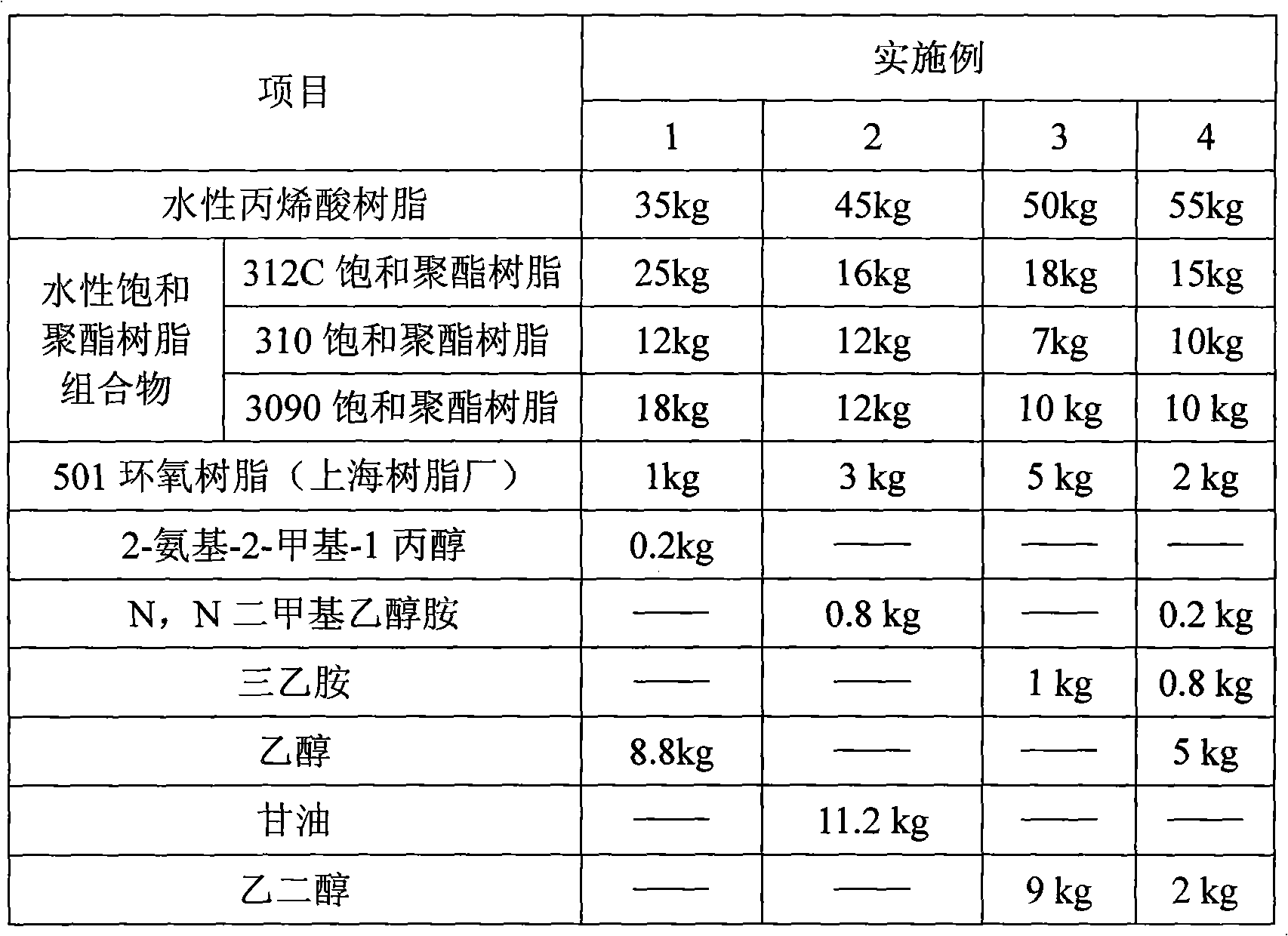

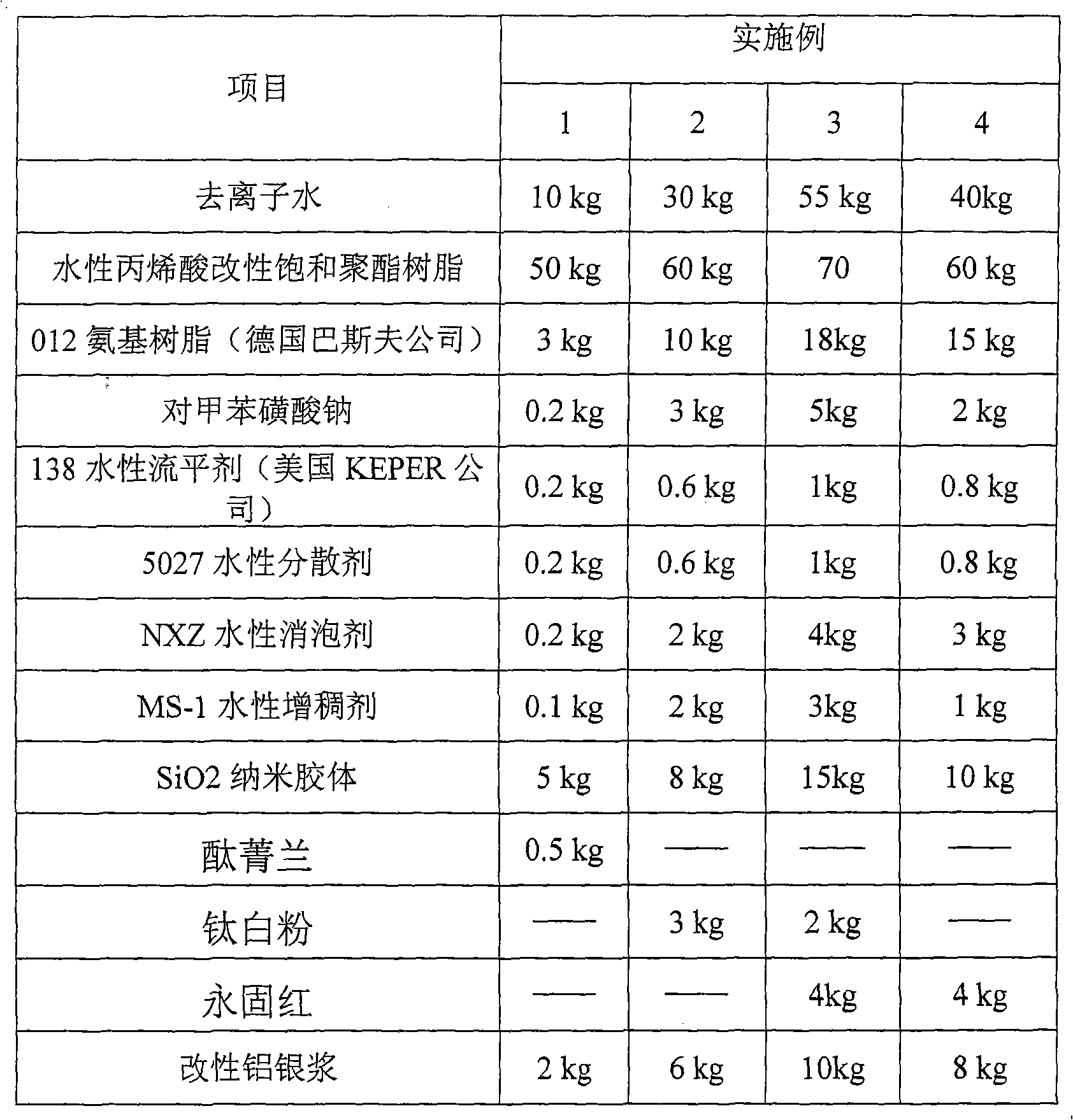

Watersoluble acrylic acid modified saturated polyester, method and watersoluble baking aluminum paint

InactiveCN101429319BHigh hardnessStrong adhesionAnti-corrosive paintsPolyester coatingsEpoxyWater based

The invention discloses a water-based acrylic modified saturated polyester, a method for preparing the same and water-based baking aluminum powder paint. Water-based acrylic resin, a water-based saturated polyester resin composition, epoxy resin and amino resin used as film forming materials and unctuous aluminum powder as a coloring material are prepared and are applied to a water-based system, so that the production cost is significantly reduced. The water-based acrylic modified saturated polyester uses water as a diluent so that the water-based acrylic modified saturated polyester is nonpoisonous, tasteless, pollution-free, non-waste, non-flammable and non-explosive, and the VOC content is smaller than 50 to ensure the environmental protection and fire safety and guarantee the health of workers; besides, the formed paint film has the advantages of high hardness, scratch resistance, strong adhesive force, salt mist resistance, salt water resistance, acid and alkali resistance, waterresistance, oil resistance, ultraviolet light resistance, aging resistance, low temperature resistance, damp heat resistance and sweat resistance, can be repeatedly used on the surface of a (water-based, oil-based) old paint film, cannot cause paint film damage, has ultra-strong paint film flexibility and the like.

Owner:北京斯耐博科技有限公司

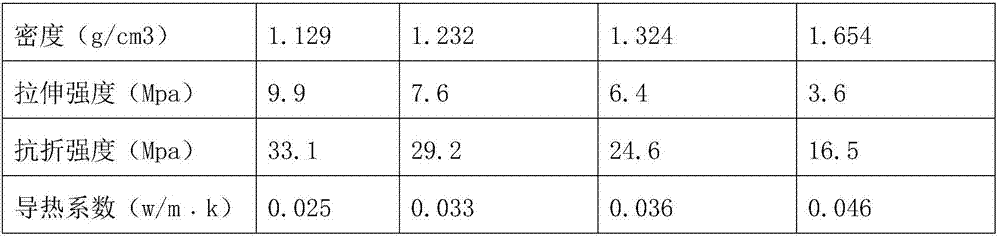

Foamed concrete and preparation method thereof

InactiveCN111620607AGood ultra-low temperature insulation performanceImprove self-resisting strengthCeramicwareFoam concreteFoaming agent

The invention discloses foamed concrete which comprises the following components in parts by mass: 80-120 parts of cement, 20-30 parts of pearlife, 20-30 parts of vitrified micro bubbles, 30-45 partsof fly ash, 12-30 parts of rock wool board particles, 8-20 parts of a foaming agent and 60-100 parts of water. The invention further discloses a preparation method of the foamed concrete. The foamed concrete has the advantages of simple components and simple preparation, has the advantages of light weight, heat insulation, sound insulation, fire resistance and good shock resistance possessed by traditional foamed concrete, also has the excellent properties of high temperature resistance and ultralow temperature resistance, has strong anti-load capacity, and is not easy to pulverize.

Owner:浙江任凯公路工程有限公司

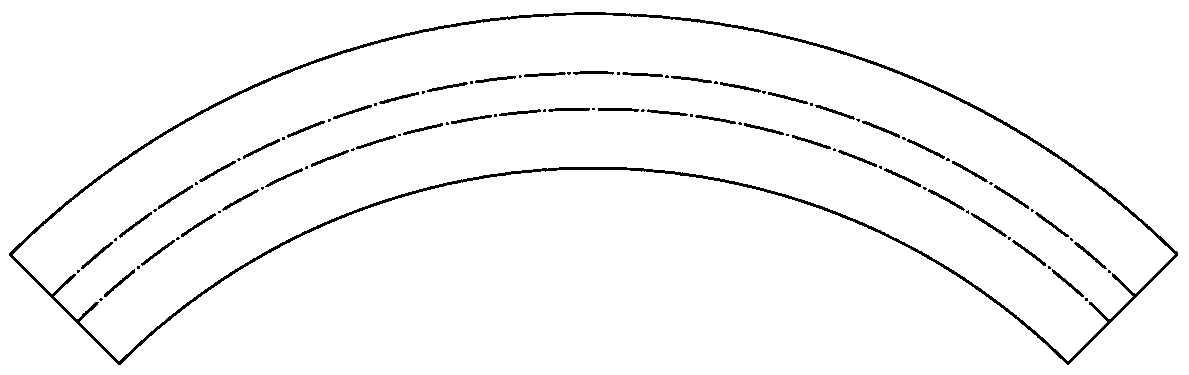

Formation method of I-shaped steel for nuclear fusion reactor magnet supporting

The invention provides a formation method of I-shaped steel for nuclear fusion reactor magnet supporting. According to the formation method, a main roller die and a core roller die are adopted; the formation method comprises the steps of (1), preparing an annular blank, wherein steel ingots are heated to 1150 DEG C to be forged and pressed, so that the texture state of the steel ingots is changed, internal defects are seamed, and the annular blank is manufactured after a punching procedure and a chambering procedure; (2) conducting ring rolling manufacturing on the I-shaped section, wherein the main roller die is arranged on a main roller of a ring rolling machine, the core roller die is arranged on a core roller of the ring rolling machine, the annular blank is heated to 1150 DEG C, thetemperature is kept for enough time, the annular blank is placed on a workbench of the ring rolling machine, the main roller of the ring rolling machine rotates and feeds until the core roller die and the main roller die feed in place, and formation ring rolling of the I-shaped section is completed; (3) conducting dividing and straightening, wherein the annular piece is divided into multiple arcsections according to arc length, the arc sections are straightened correspondingly, and then the I-shaped steel for nuclear fusion reactor magnet supporting is formed. By the adoption of the formation method of the I-shaped steel for nuclear fusion reactor magnet supporting, the formation speed is rapid, the dimension precision is high, the machining allowance is small, the manufacturing difficulty is greatly lowered, the mechanical performance is improved, the service life is prolonged, and the formed I-shaped steel has low temperature resistance, high pressure resistance and corrosion resistance and is low in machining cost.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

Sports shoes and preparation method thereof

InactiveCN107057134ASolve prone to breakageSolve quality and weightFootwearPolyvinyl alcoholStearic acid

The invention provides a pair of sports shoes and a preparation method thereof and relates to the technical field of shoes. The pair of sports shoes is prepared from, by weight, 250-280 parts of natural rubber, 100-200 parts of butadiene styrene rubber, 50-100 parts of polyurethane rubber, 600-700 parts of rock flour, 60-80 parts of zinc oxide, 3-5 parts of stearic acid, 4-8 parts of sulphur, 10-14 parts of ointment, 16-24 parts of floating beads, 16-40 parts of aerogel, 40-60 parts of formalized polyvinyl alcohol fiber, 29-35 parts of aromatic polyamide fiber, 5-9 parts of foaming agent, 3-7 parts of rubber accelerator, 3-5 parts of plasticizer, 7-9 parts of light stabilizer, 3-9 parts of heat stabilizer, 2-6 parts of lubricating agent and 4-8 parts of coupling agent. The preparation method includes the following steps that 1, raw materials are weighed; 2, the raw materials are put in a rubber mixing mill; 3, upper molds, bottom molds and shoe trees are manufactured; 4, foaming molding is performed; 5, the shoe trees, the upper molds and the bottom molds are taken out. The problem that existing sports shoes easily break and have heavy weight, poor toughness and poor heat preservation and insulation effect is solved.

Owner:合肥博创机械制造有限公司

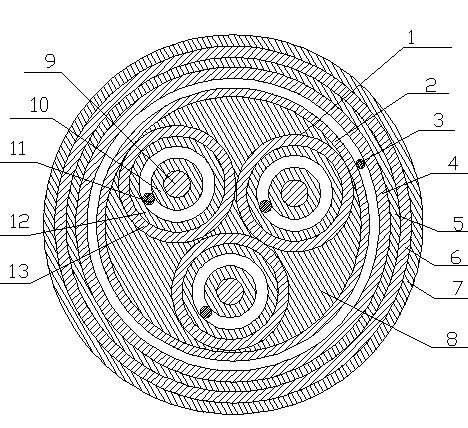

Intrinsic safety instrument flexible cable for ocean engineering

InactiveCN104078121AReduce capacitanceReduce inductanceClimate change adaptationFlexible cablesIntrinsic safetyElectrical conductor

The invention discloses an intrinsic safety instrument flexible cable for ocean engineering, and relates to the technical field of cable manufacturing, in particular to the technical field of intrinsic safety instrument flexible cable manufacturing for the ocean engineering. The flexible cable comprises three mutually stranded wire cores, wherein a total warping layer, a total shield layer, an inner protection layer, an armor layer and an outer sheath layer are sequentially arranged on the outer sides of the three stranded wire cores; an external drainage wire is arranged between the total warping layer and the total shield layer; fillers are arranged between the three wire cores and the total warping layer; each wire core comprises a tinned copper wire bunch stranded conductor; insulating layers, unit shield layers and unit warping layers are sequentially arranged on the outer sides of the tinned copper wire bunch stranded conductors; and internal drainage wires are arranged between the insulating layers and the unit shield layers. The flexible cable is scientific, novel and reasonable in structure, advanced in technology and good in use performance, has the characteristics of excellent low capacity, low inductance, intrinsic safety, high signal transmission capacity, good anti-interference performance and the like, and has flame retardance, low temperature resistance, oil sludge resistance, water resistance and the like.

Owner:YANGZHOU SHUGUANG CABLE

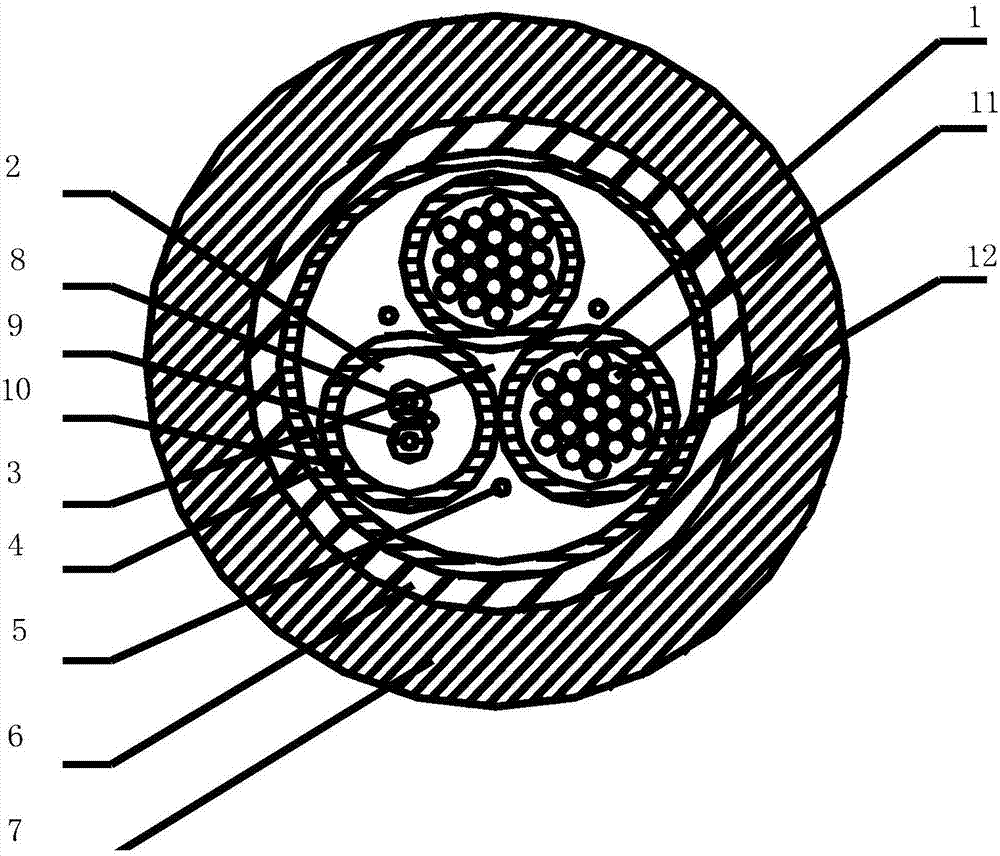

Dragging optical and electrical composite cable

InactiveCN106920587AImprove aging resistanceImproves UV resistanceNon-insulated conductorsCommunication cablesYarnSilver plate

The invention discloses a dragging optical and electrical composite cable. The dragging optical and electrical composite cable comprises two power lines and an optical cable, wherein the power lines and the optical cable are twisted into a composite cable; a waterproof layer is encapsulated outside the composite cable; a waterproof yarn knitted layer is further filled between the composite cable and the waterproof layer; an aramid yarn knitted layer is encapsulated outside the waterproof layer; a sheath layer is encapsulated outside the aramid yarn knitted layer; the cable comprises a plurality of fiber units, an internal anti-flaming layer is extruded outside the fiber units, an external anti-flaming layer is encapsulated outside the internal anti-flaming layer, and the aramid yarn knitted layer and the waterproof yarn knitted layer are further filled between the internal anti-flaming layer and the external anti-flaming layer; each power line comprises stranded silver-plated copper wires, the silver-plated copper wires are twisted into a copper wire beam, and an insulating layer is encapsulated outside the copper wire beam. Compared with the prior art, the dragging optical and electrical composite cable has the advantages of small external diameter, light weight, low cost, stretching and pressure resistance, high bending performance and the like, is green, environmentally-friendly, wearproof, oilproof and resistant to low temperature, can be safely used for a long period of time, can be applied to interior and outdoor mobile communication systems, and is convenient in construction and stable in operation.

Owner:HEFEI XINGLIAN COMM

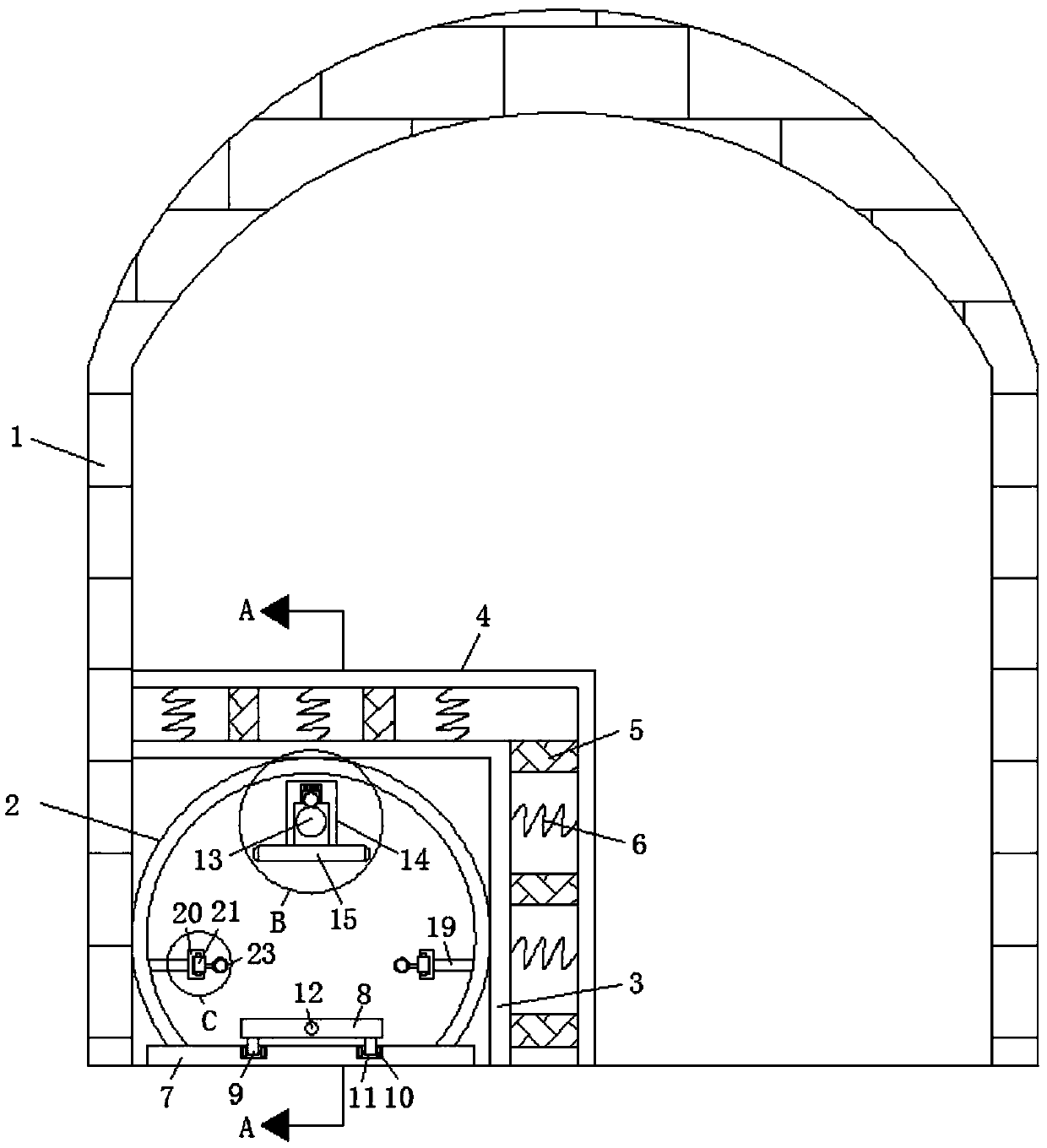

Impact-resistant flat bottom type ultra-high molecular weight polyethylene escape pipeline

The invention discloses an impact-resistant flat bottom type ultra-high molecular weight polyethylene escape pipeline. The impact-resistant flat bottom type ultra-high molecular weight polyethylene escape pipeline comprises a tunnel and an escape pipeline body; the escape pipeline body is fixed to one side of the ground plane inside the tunnel; a flat bottom plate is arranged at the bottom of theescape pipeline body, and an escape sliding plate is arranged at the upper end of the flat bottom plate; supports are fixedly connected to the periphery of the lower end of the escape sliding plate, and sliding wheels are arranged at the bottoms of the supports; an escape rope is arranged in the escape pipeline body, and the two ends of the escape rope are fixed to the two ends of the escape pipeline body through fixing pieces; a fixing frame is connected to the outer wall of the escape rope in a sleeving mode, and the bottom of the fixing frame is fixedly connected with a handle; a limiting block is arranged on the inner wall of the upper end of the fixing frame through a limiting groove, and a ball is arranged at the lower end of the limiting block; a first L-shaped protection plate anda second L-shaped protection plate are arranged outside the escape pipeline in sequence from inside to outside. The impact-resistant flat bottom type ultra-high molecular weight polyethylene escape pipeline is simple in structure, easy to operate, small in weight, convenient to mount and meanwhile capable of increasing the escape probability of escape personnel.

Owner:泰州市兴氟高分子材料有限公司

Organsilicone modified polyurethane adhesive, preparation method and application of adhesive

InactiveCN107955120AChemically stableWith wear resistancePolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention provides an organsilicone modified polyurethane adhesive, a preparation method and application of the adhesive. The preparation method comprises the following steps: carrying out a firstpre-polymerization reaction on a polyether polyol, a first polyisocyanate and a chain extender to obtain an isocyanate-based polyurethane prepolymer; carrying out a second pre-polymerization reactionon a polyhydroxy silane coupling agent, a second polyisocyanate and a polyester polyol to obtain a polyester-type polyurethane-based silane coupling agent; and carrying out a coupling reaction on theisocyanate-based polyurethane prepolymer with the polyester-type polyurethane-based silane coupling agent to obtain the organsilicone modified polyurethane adhesive. The organsilicone modified polyurethane adhesive prepared by adopting the method has the advantages of stable chemical stability, difficult occurrence of phase separation, and the like. In addition, no water participates in the preparation method, so that the problems that the reaction speed of terminal isocyanate groups with trace water in conventional wet-curing type polyurethane adhesive agent is slow, and the bonding strengthis influenced by bubbles generated by carbon dioxide are solved.

Owner:海口未来技术研究院

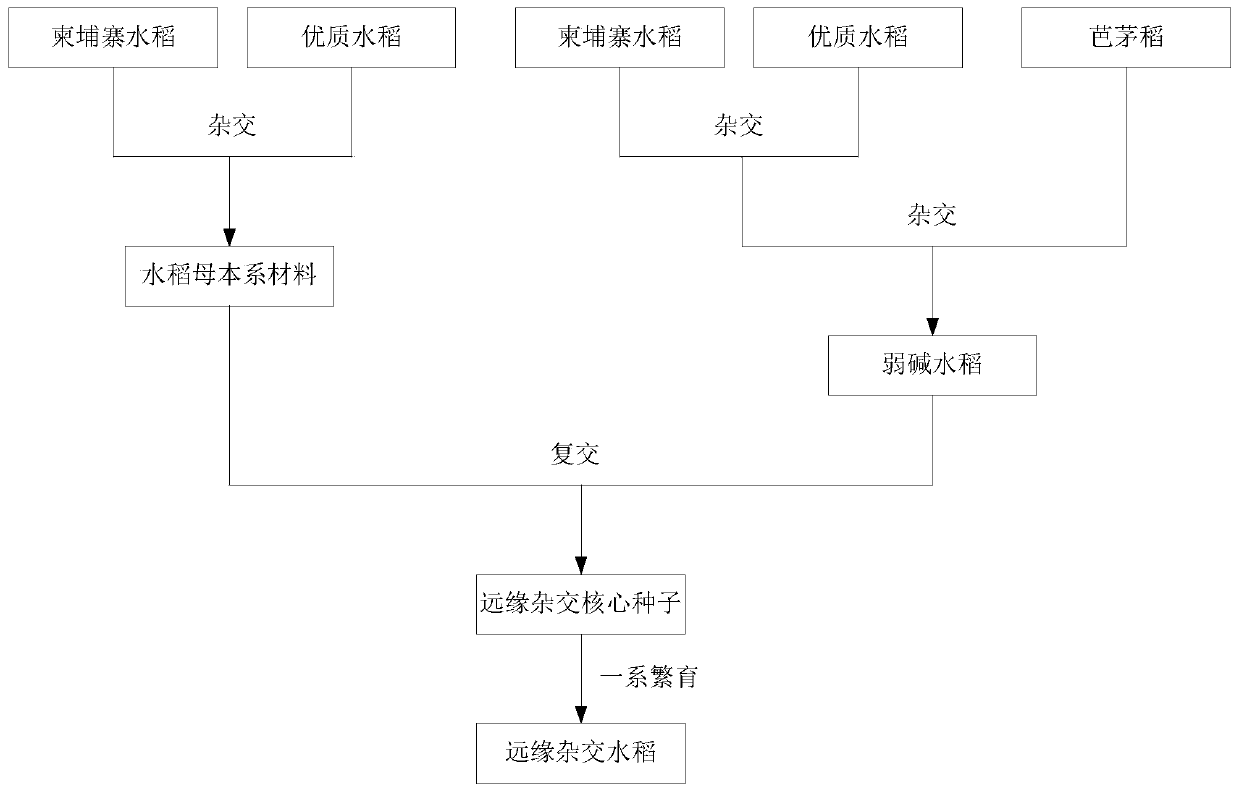

Breeding method of distant hybridization rice

InactiveCN109769689ALow temperature resistantWeakly alkalineHorticulture methodsPlant protectionDrought resistanceOryza sativa

The invention belongs to the technical field of breeding of hybrid rice, and provides a breeding method of distant hybridization rice. The breeding method includes the steps that Cambodian rice is castrated, the castrated Cambodian rice and high-quality rice with low-temperature-resistant and cold-leaching-resistant characters are hybridized, and a rice female parent material is obtained; the ricefemale part material and weak-base rice are re-hybridized, and distant hybridization core seeds are obtained; the distant hybridization core seeds are bred through a first series, and the distant hybridization rice is obtained. The Cambodian rice and the high-quality rice with the low-temperature-resistant and cold-leaching-resistant characters are hybridized, then the offspring and the weak-baserice are re-hybridized for seed production, the characters of the rice are synthesized, and the distant hybridization rice has the characteristics of low temperature resistance, cold leaching resistance, drought resistance, waterlogging resistance, lodging resistance, weak base and high yield. Meanwhile, as the produced distant hybridization rice has the characteristics, the resistance of the distant hybridization rice in the seed production and breeding process is enhanced, the requirements and conditions of seed production environments are lowered, and the seed production cost is reduced.

Owner:常德中旺农业股份有限公司

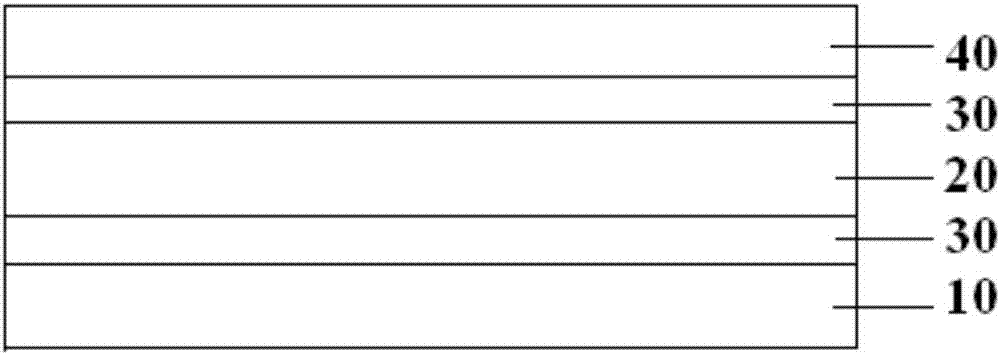

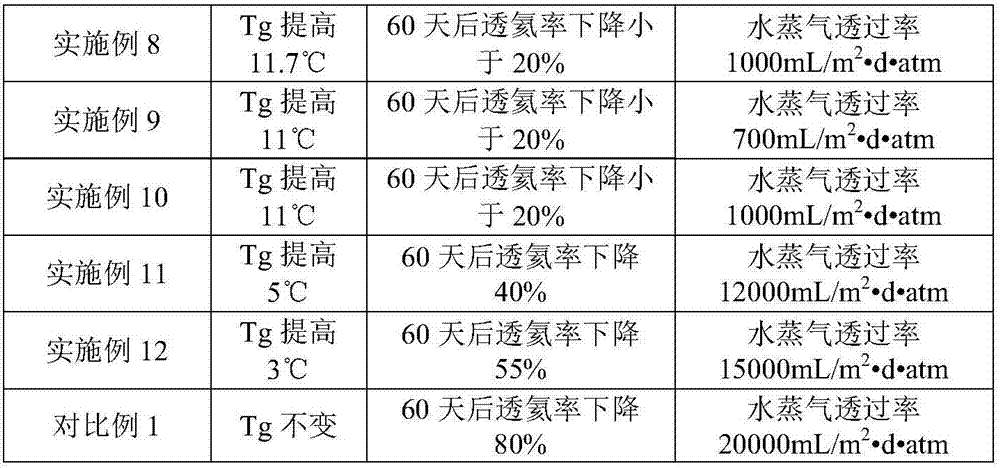

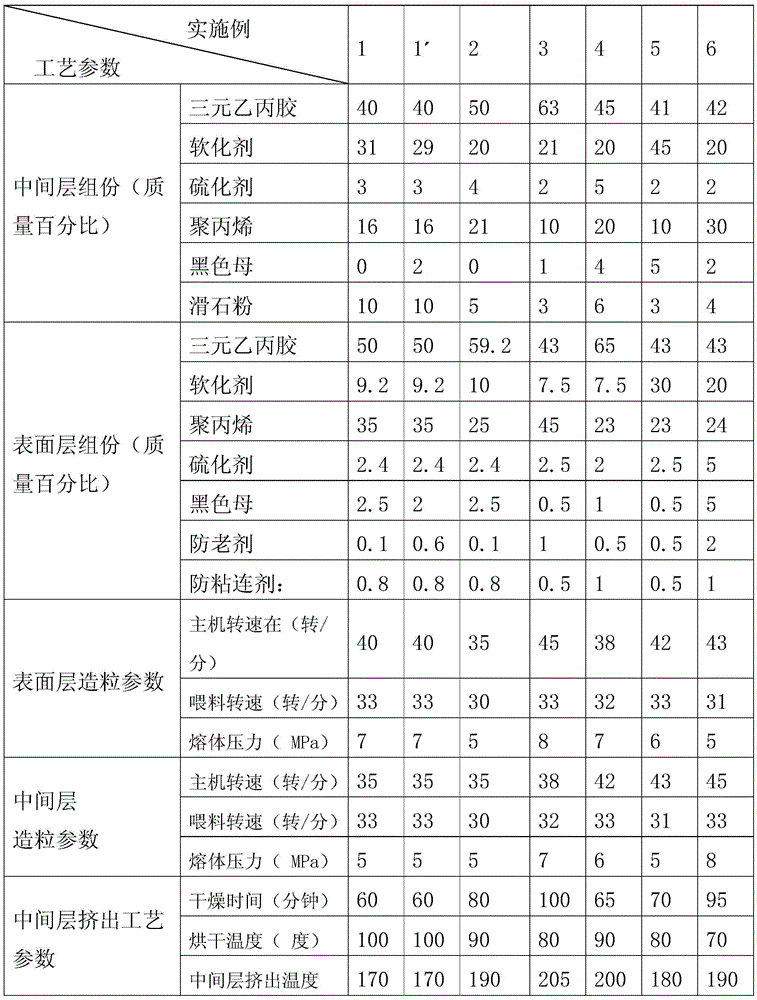

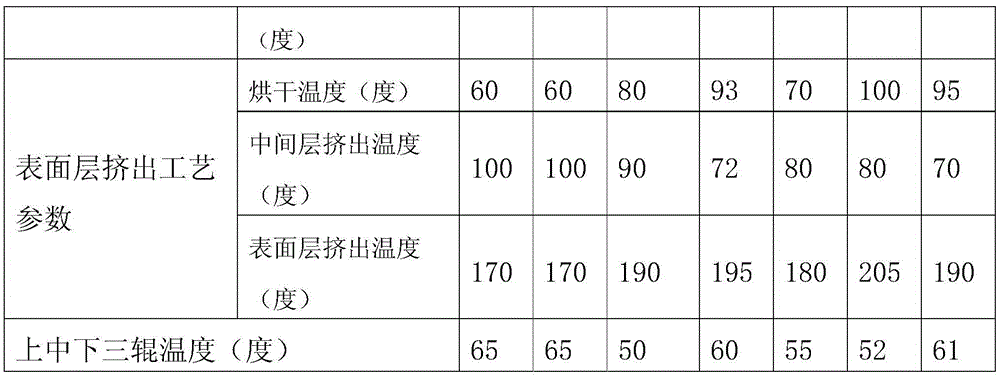

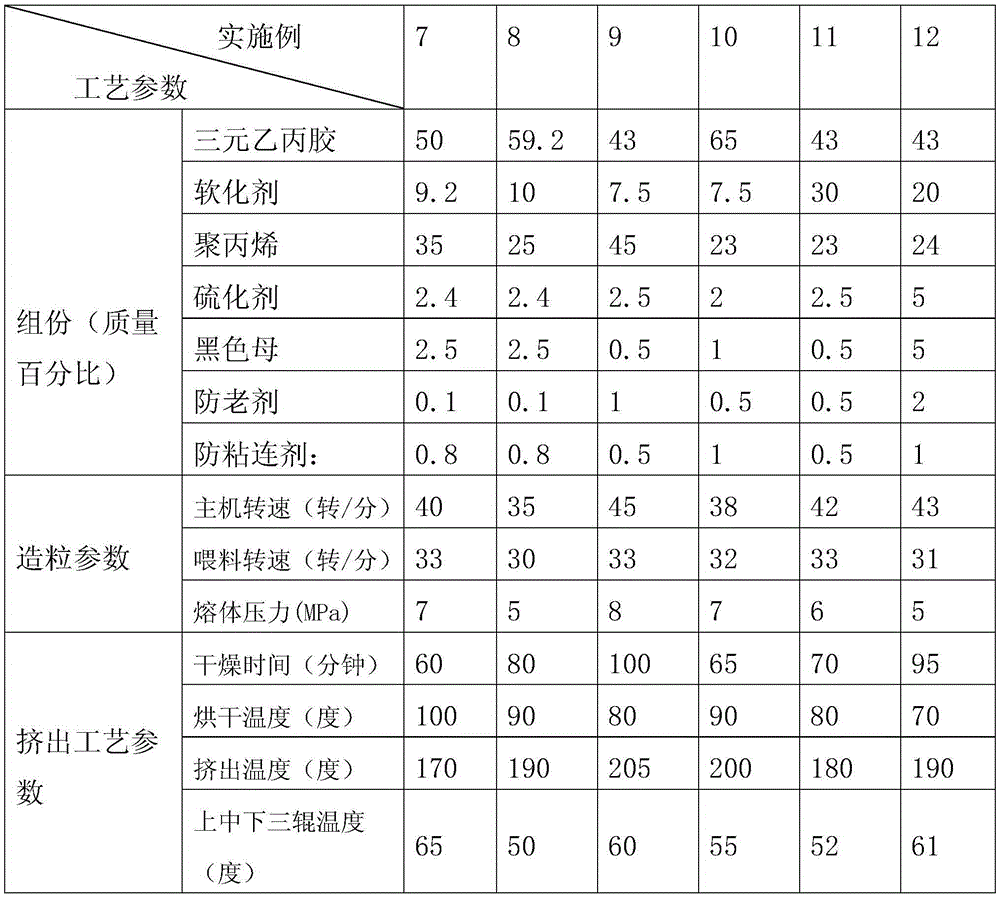

TPV (thermoplastic vulcanizate) thermoplastic elastomer composite sheet and manufacturing method thereof

ActiveCN105647027AEnvironmentally friendly and non-toxicWear-resistantSynthetic resin layered productsElectrical equipmentThermoplasticSurface layer

In order to overcome the defects of short service life of the loudspeaker and high adhesion tendency during rewinding due to the high aging tendency of the loudspeaker prepared from the material in the prior art, the invention relates to a TPV (thermoplastic vulcanizate) thermoplastic elastomer composite sheet with the advantages of low aging tendency and low adhesion tendency during rewinding and a manufacturing method thereof. In the TPV thermoplastic elastomer composite sheet, the middle layer is composed of 40-63% of ethylene propylene diene copolymer, 20-45% of softening agent, 10-30% of polypropylene, 2-5% of vulcanizing agent, 0-5% of black color master batch and 3-10% of talcum powder; the surface layer is composed of 43-65% of ethylene propylene diene copolymer, 7.5-30% of softening agent, 23-45% of polypropylene, 2-5% of vulcanizing agent, 0-5% of black color master batch, 0-2% of anti-aging agent and 0.5-1% of antiblocking agent. Due to the addition of the antiblocking agent, the composite sheet has low adhesion tendency during rewinding. The TPV adopts the surface layer raw material of the composite sheet, and thus, also has the antiblocking property.

Owner:浙江亿铭新材料科技有限公司

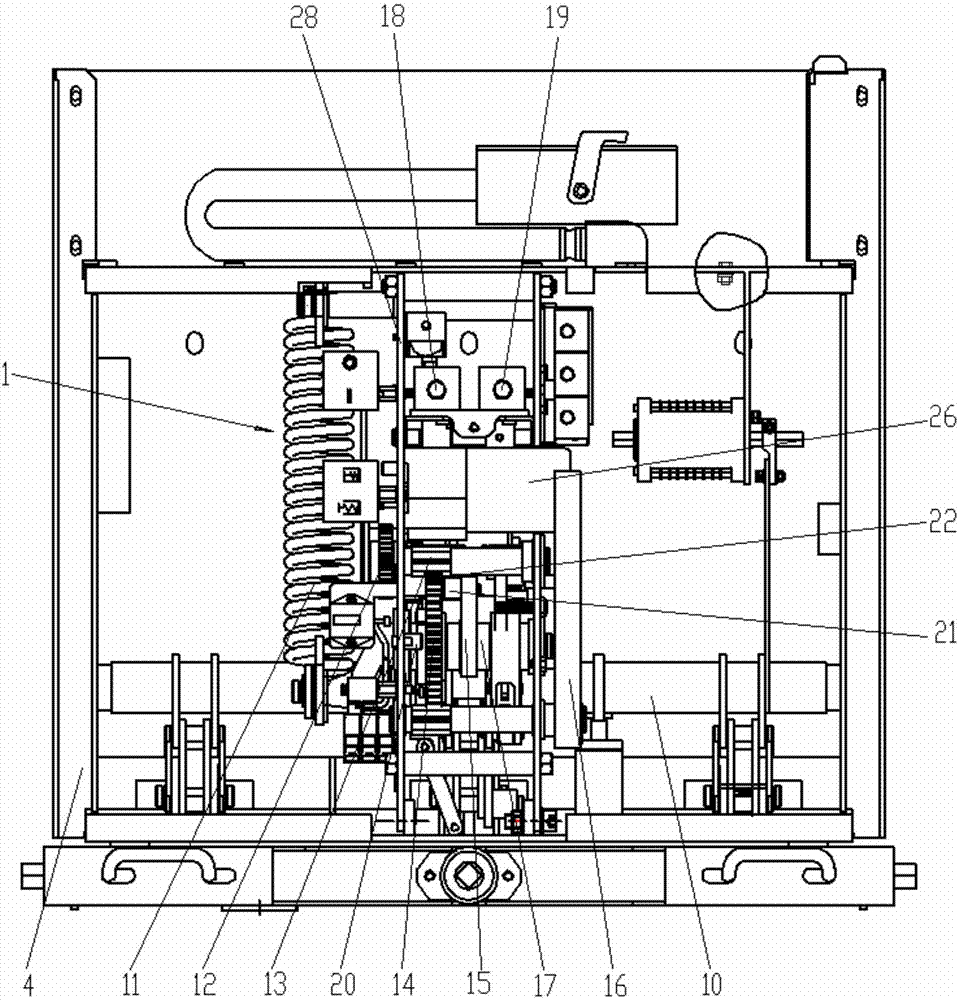

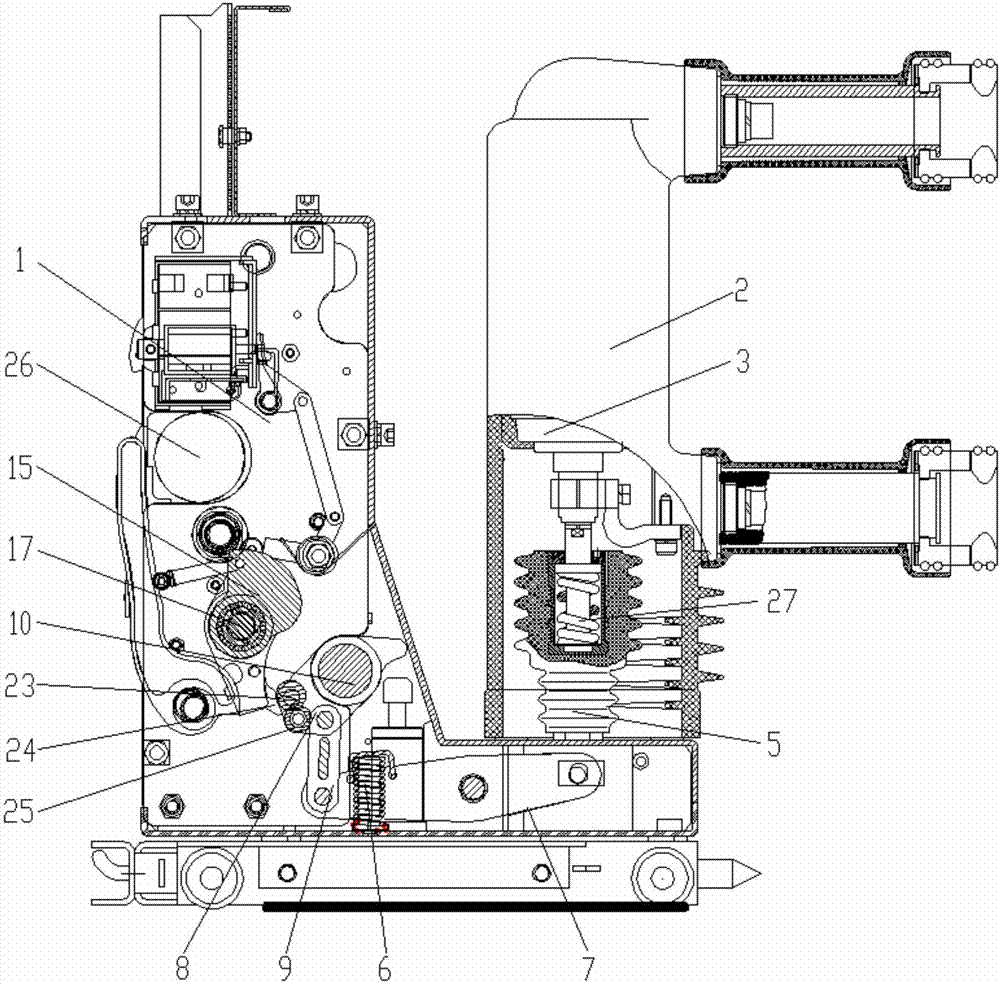

24KV vacuum high-voltage circuit breaker equipped with small modular spring operating mechanism

ActiveCN107403706ASmall footprintReduce in quantityHigh-tension/heavy-dress switchesAir-break switchesLow noiseEngineering

Provided is a 24KV vacuum high-voltage circuit breaker equipped with a small modular spring operating mechanism. The circuit breaker includes a box body. A solid-sealed polar pole and a VSH small modular spring operating mechanism are arranged inside the box body. A vacuum interrupter is arranged inside the solid-sealed polar pole. An insulated pull rod is arranged at the bottom of the vacuum interrupter. A transmission shaft in the VSH small modular spring operating mechanism is connected with the insulated pull rod through a connecting rod and crank arm structure so the VSH small modular spring operating mechanism can drive the insulated pull rod and the vacuum interrupter to realize closing and opening. The VSH small modular spring operating mechanism is applied to the 24KV vacuum high-voltage circuit breaker. The spring operating mechanism and the vacuum interrupter are arranged up and down, which is different from the plane layout mode in the prior art in which the spring operating mechanism is scattered. Compared with the original mechanism, the size is reduced by 60%, the number of parts is reduced by 50%, and the total weight is reduced by 30%. The 24KV vacuum high-voltage circuit breaker has the advantages of long service life, no need for maintenance, no pollution, no danger of explosion, low noise, and the like, and is more suitable for frequent operation and other harsh working conditions.

Owner:苏州市相城区黄桥工业园经济发展有限公司

Thermosetting fluororesin powder coating formula

InactiveCN103483886AHigh temperature resistantLow temperature resistantPowdery paintsTetrafluoroethyleneChemical corrosion

The invention provides a thermosetting fluororesin powder coating formula which comprises the following raw materials by mass: 30-40 parts of cyclohexyl vinyl ether, 30-40 parts of isobutyl vinyl ether, 60-80 parts of 4-hydroxybutyl vinyl ether, 250-350 parts of teflon vinyl ether, 20-30 parts of a catalyst and 30-40 parts of a crosslinking agent. The coating prepared according to the formula is high in dispersibility, and good in surface gloss, and has the advantages of high temperature resistance, low temperature resistance, and chemical corrosion resistance and the like.

Owner:TIANJIN CITY XINLIHUA COLOR MATERIAL

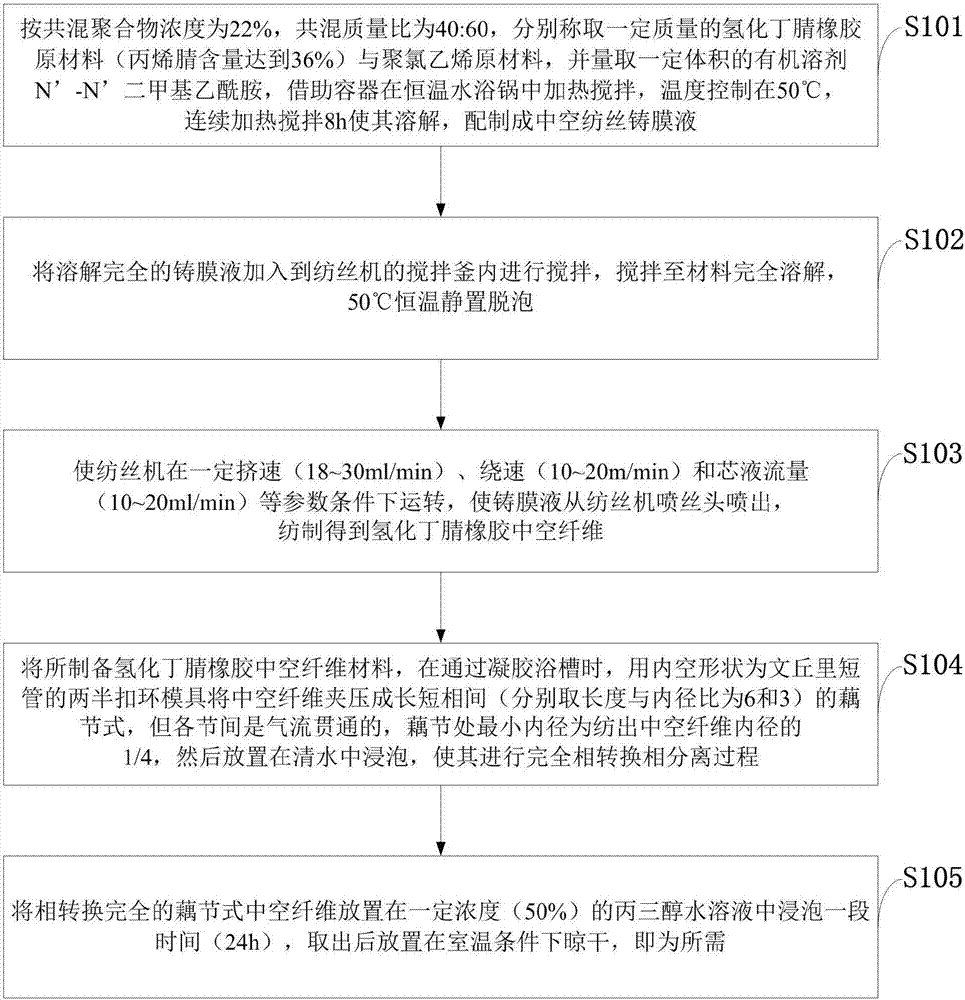

Preparation method of hollow fiber damping material with lotus root section type air bag adjustment

ActiveCN107119344ALow temperature resistantWith wear resistanceFilament/thread formingConjugated synthetic polymer artificial filamentsFiberAcrylonitrile

The invention belongs to the technical field of hollow fiber damping materials, and discloses a preparation method of a hollow fiber damping material with lotus root section type air bag adjustment. The preparation method comprises the following steps: preparing a hollow spinning film casting solution; adding the completely dissolved film casting solution into a stirring kettle of a spinning machine for stirring; spraying the film casting solution from a spinning jet of the spinning machine, thus spinning hydrogenated butadiene-acrylonitrile rubber hollow fiber; when the hollow fiber passes through a gel bath tank, clamping and pressing the hollow fiber into long and short lotus root sections through two half retaining ring dies with Venturi short tube-shaped inner cavities, and placing the lotus root sections in clean water for soaking, conversion and phase separation; standing the phase conversion-completed lotus root section type hollow fiber, taking out the hollow fiber, and drying the hollow fiber under a room temperature condition, thus obtaining the hollow fiber damping material. An adjustment method which improves the air bag damping of the hollow fiber damping material has important application value, and the problem that an air bag of the hollow fiber, of which the size is not changed along the axial direction, on the section of the hollow fiber damping material is too simple is solved.

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com