Impact-resistant flat bottom type ultra-high molecular weight polyethylene escape pipeline

An ultra-high molecular weight and escape pipe technology, applied in the field of flat-bottom ultra-high molecular weight polyethylene escape pipes, can solve the problems of high price of steel pipes, difficult construction process, slow construction progress, etc., to improve the escape probability, convenient and ingenious use , The effect of anti-aging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

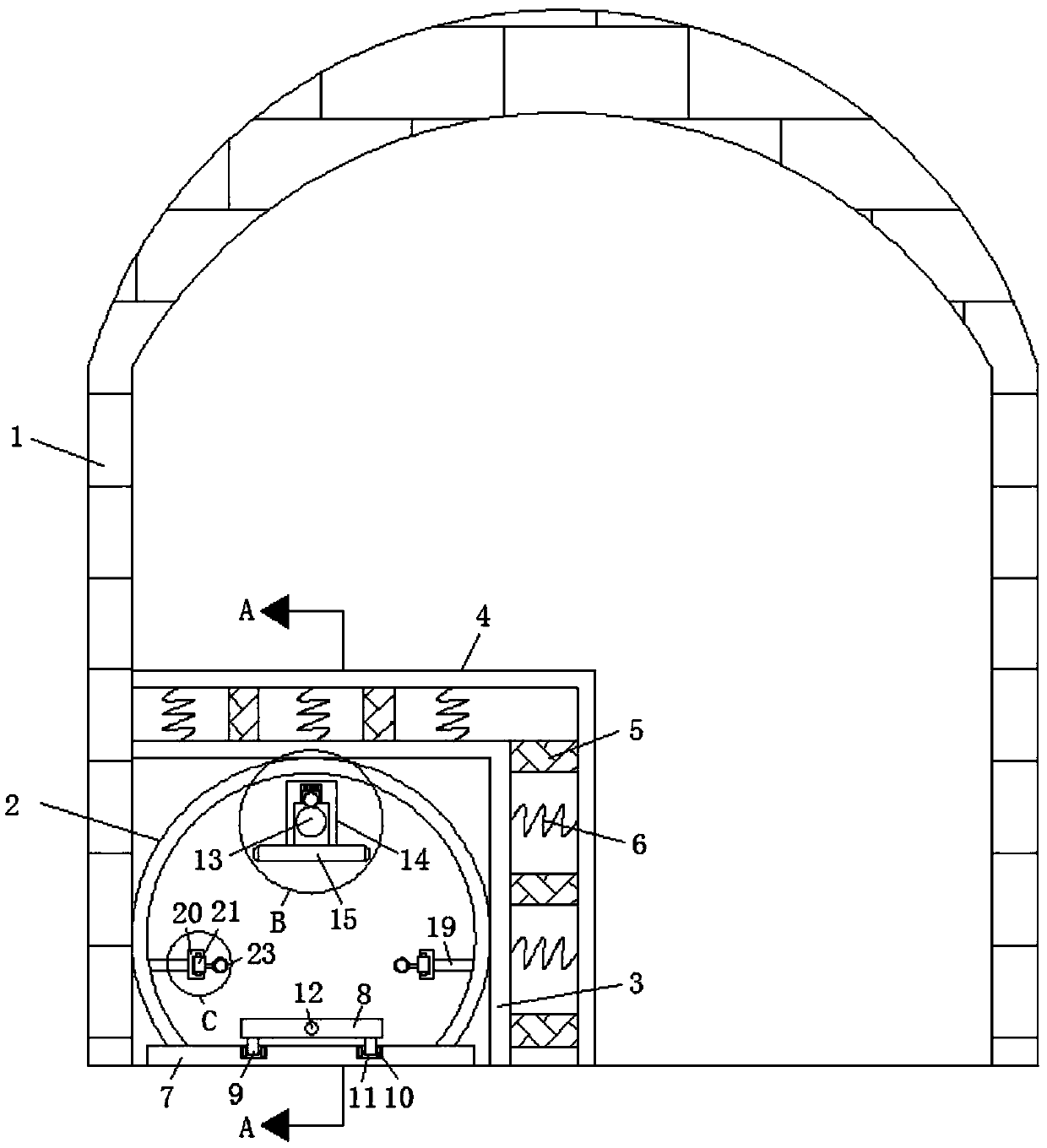

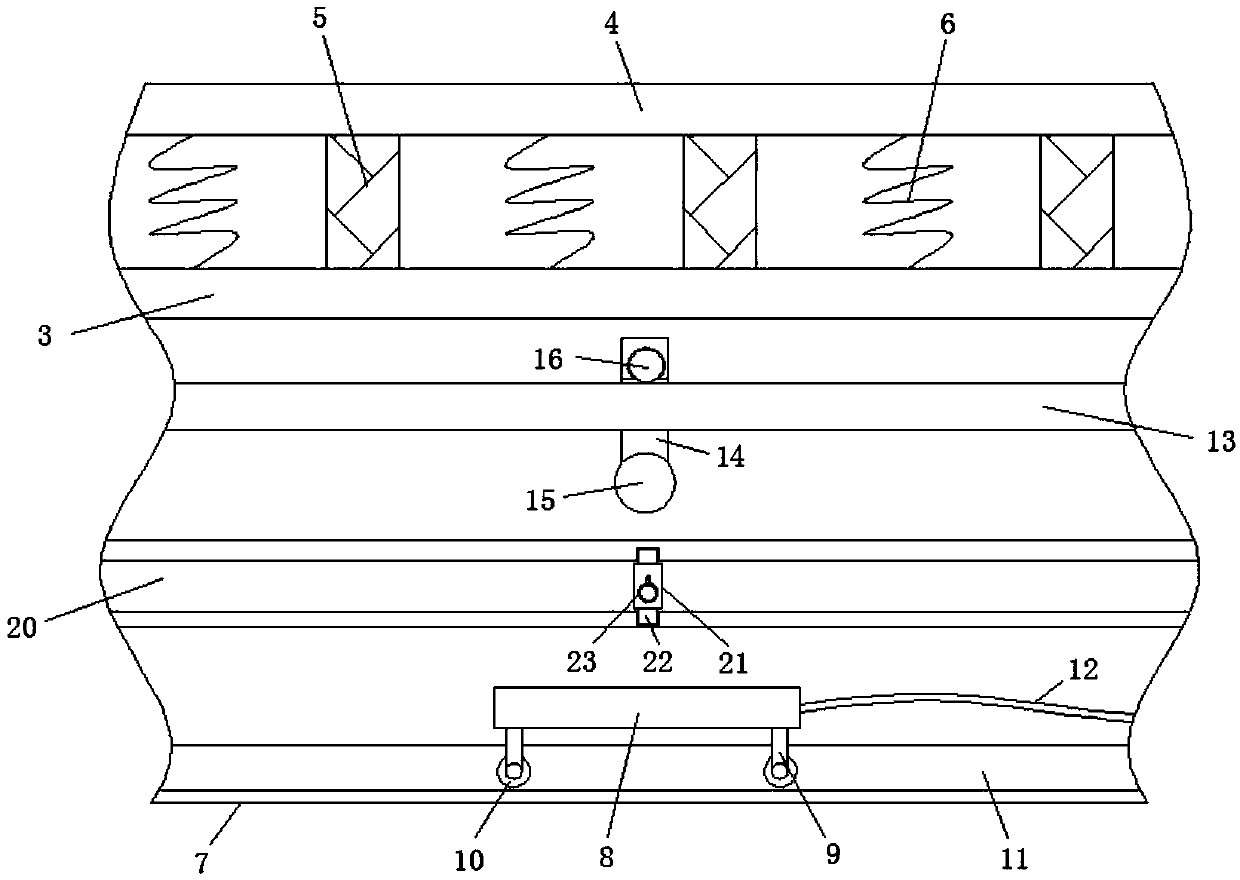

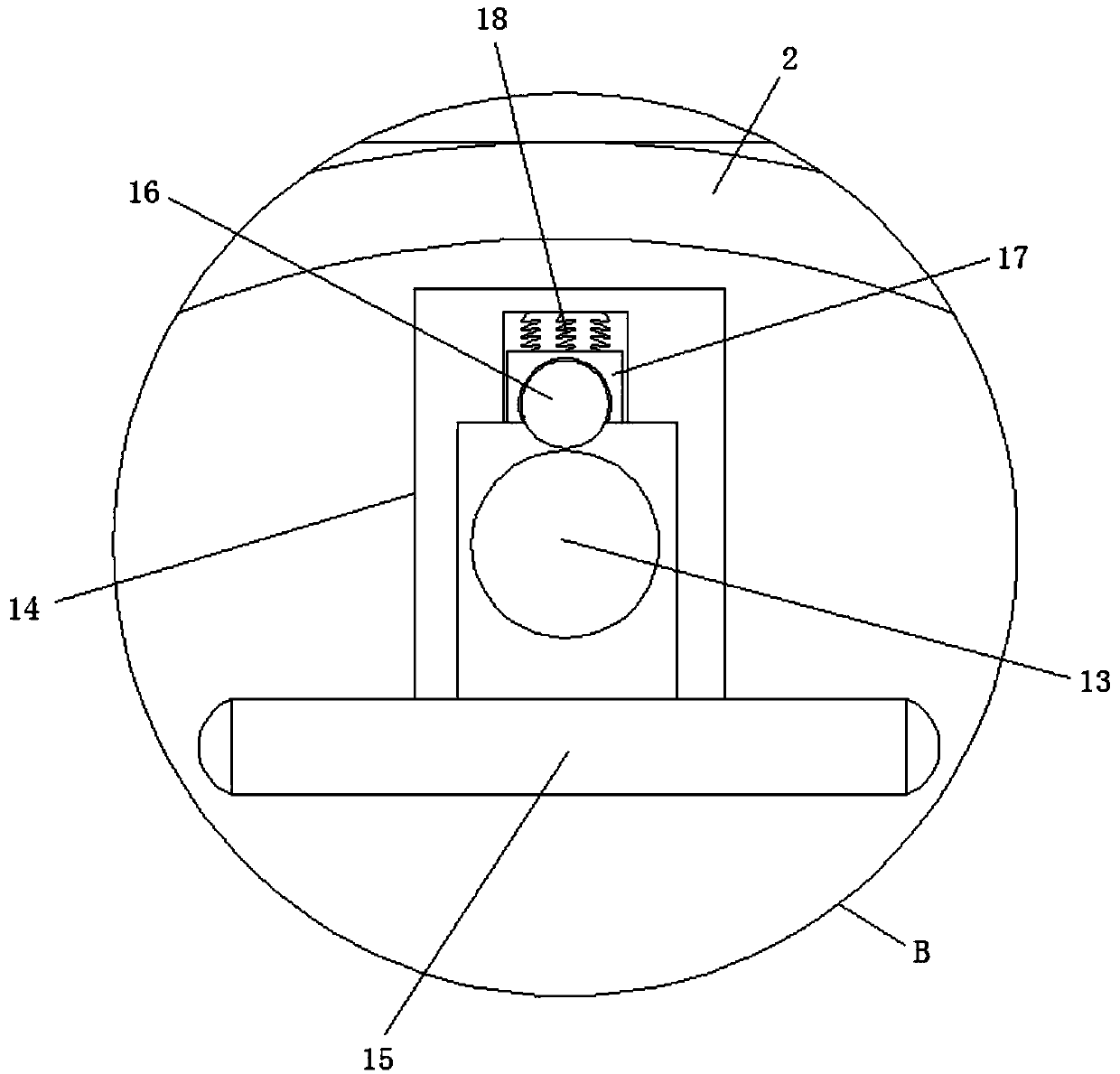

[0018] refer to Figure 1-4 , an impact-resistant flat-bottomed ultra-high molecular weight polyethylene escape pipe, comprising a tunnel 1 and an escape pipe 2, the escape pipe 2 is fixed on one side of the ground plane inside the tunnel 1, the bottom of the escape pipe 2 is provided with a flat bottom plate 7, and The upper end of the flat bottom plate 7 is provided with an escape slide 8, and the lower end of the escape slide 8 is fixedly connected with a support 9 around, and the bottom of the support 9 is provided with a pulley 10, and the escape pipe 2 is provided with an escape rope 13, and the two ends of the escape rope 13 The ends are fixed on the two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com