TPV (thermoplastic vulcanizate) thermoplastic elastomer composite sheet and manufacturing method thereof

A thermoplastic elastomer and composite sheet technology, applied in chemical instruments and methods, electronic equipment, synthetic resin layered products, etc., can solve the problems of low speaker life, easy aging of speakers, easy adhesion of rewinding, etc., and achieve low density , Blister molding is superior, and the effect of improving the elasticity ratio of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

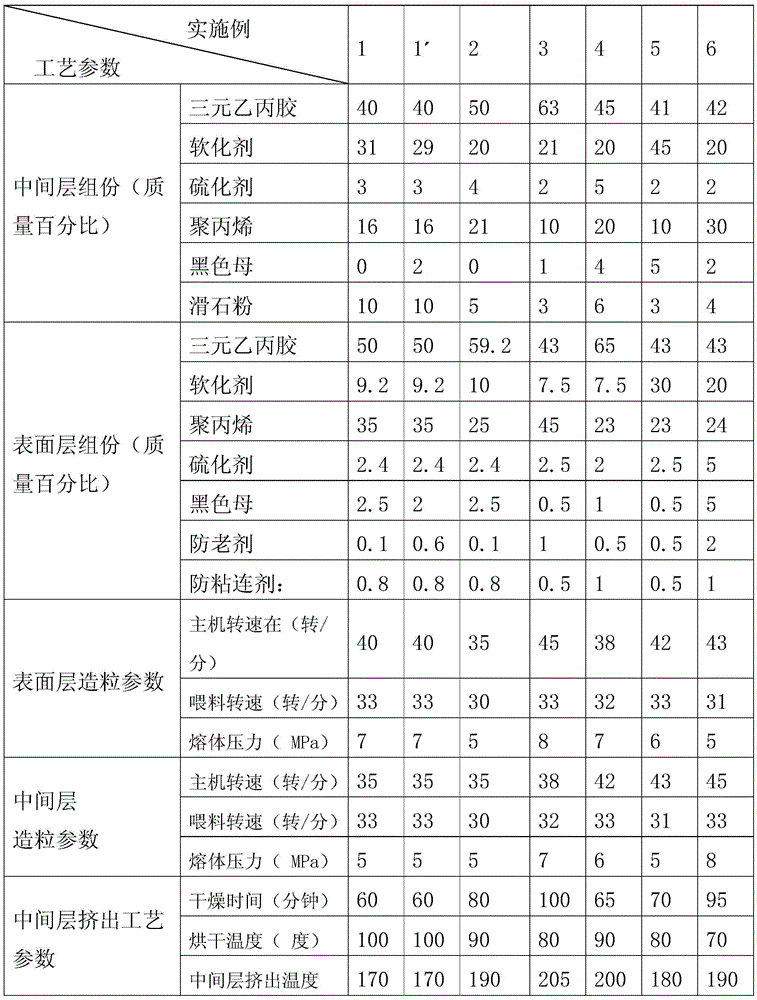

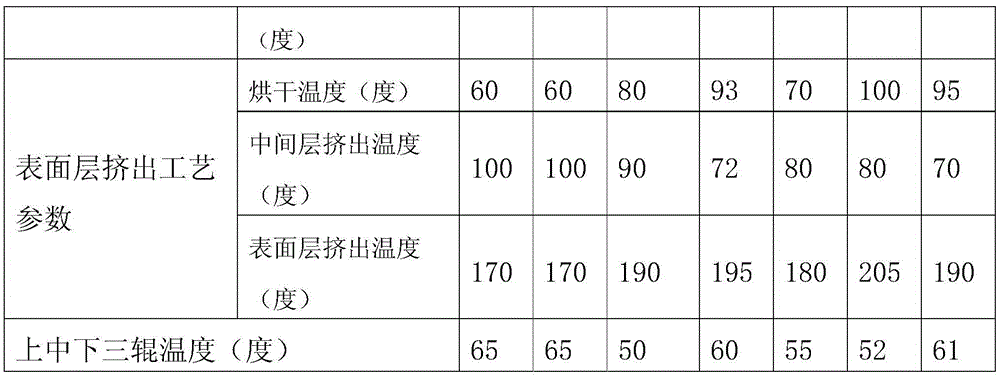

[0025] 1) The mass percentage composition of the middle layer is composed of EPDM rubber 40%, softener 31%, polypropylene 16%, vulcanizing agent 3%, black masterbatch 0%, talcum powder 10%; surface layer mass percentage composition: It is composed of 50% EPDM rubber, 9.2% softener, 35% polypropylene, 2.4% vulcanizing agent, 2.5% black masterbatch, 0.1% anti-aging agent, and 0.8% anti-blocking agent;

[0026] 2) Granulation: According to the proportion of the middle layer, first take EPDM rubber and softener for plasticizing, then add polypropylene, vulcanizing agent, black masterbatch, and talcum powder for pre-dispersion to obtain the middle layer mixture, and mix the middle layer The material is put into a twin-screw granulator for dynamic vulcanization and extruded into middle layer particles. The main engine speed of the granulator is 35 rpm, the feeding speed is 33 rpm, and the melt pressure is between 5 MPa; according to the surface layer The mass ratio is to take EPDM r...

Embodiment 2

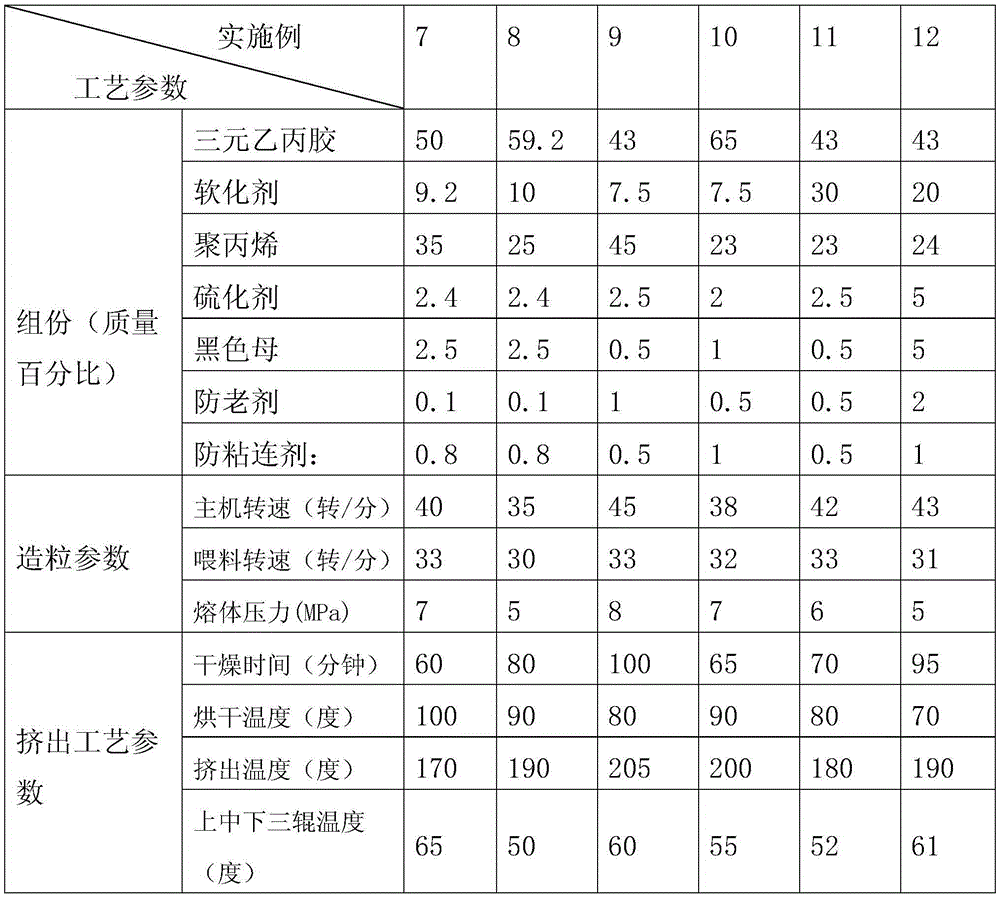

[0032] The components and process parameters of the middle layer and the surface layer are shown in Table 1. The mass percentage components of the vulcanizing agent are: bismaleimide 40%, octyl phenolic resin 35%, di-tert-butyl peroxide cumene 25. Antiblocking agent adopts the polymer of methacrylate; All the other are the same as embodiment 1. The thickness of the prepared sheet is 0.5mm

Embodiment 3

[0034] The components and process parameters of the middle layer and the surface layer are shown in Table 1. The mass percentage components of the vulcanizing agent are: bismaleimide 30%, octylphenolic resin 20%, di-tert-butyl peroxide cumene 50%, antiblocking agent adopts the polymer of methacrylate; All the other are with embodiment 1. The thickness of the prepared sheet is 0.4mm

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com