Organsilicone modified polyurethane adhesive, preparation method and application of adhesive

A polyurethane adhesive and silicone technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of unstable performance of silicon-modified adhesives and achieve good heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

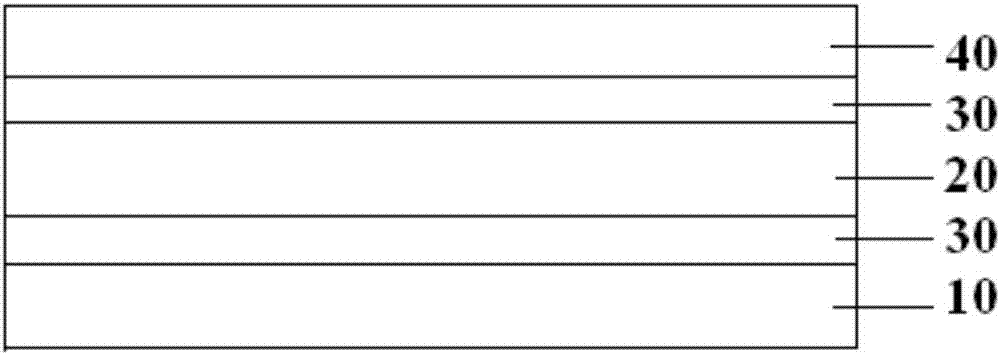

Image

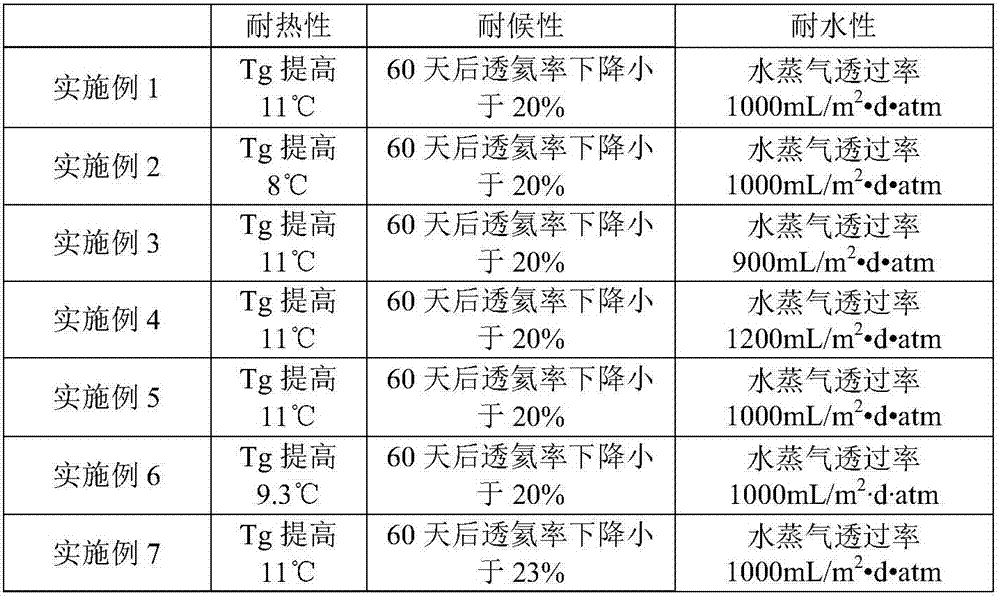

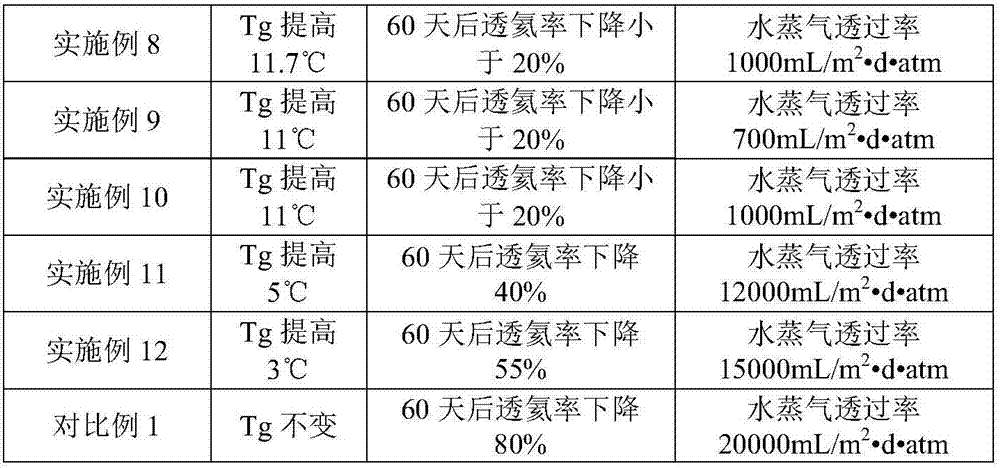

Examples

preparation example Construction

[0027] As described in the background art, the silicon-modified adhesive prepared by the existing preparation method has the problem of unstable performance. In order to solve the above technical problems, the present invention provides a method for preparing a silicone-modified polyurethane adhesive, the preparation method comprising: performing a first prepolymerization reaction on polyether polyol, a first polyisocyanate and a chain extender to obtain an isocyanate Polyurethane-based prepolymer; Polyhydroxysilane coupling agent, second polyisocyanate and polyester polyol are subjected to the second prepolymerization reaction to obtain polyester polyurethane-based silane coupling agent; and isocyanate-based polyurethane prepolymer and poly The ester-type polyurethane-based silane coupling agent undergoes a coupling reaction to obtain a silicone-modified polyurethane adhesive.

[0028] The silicone-modified polyurethane adhesive prepared by the above preparation method can be...

Embodiment 1

[0051] After vacuum dehydration at 110°C, 200g of polyether diol N210 was polymerized with excess IPDI to obtain the first intermediate product, and the reaction time was 2 hours; 200g of the first intermediate product to remove excess IPDI was expanded with 5.4g of ethylenediamine chain reaction until the NCO content reaches the theoretical value by titration analysis to obtain an isocyanate-based polyurethane prepolymer.

[0052] After dehydrating 100g of propyltrimethylolsilane in vacuum at 90°C, cool down to 70°C and slowly add hexamethylene diisocyanate dropwise for coupling reaction to obtain the second intermediate product; add polycapsene to the above second intermediate product Estertriol until (place an appropriate amount of sample in a test tube and heat, the generated isocyanate vapor is directly introduced into anhydrous acetone, and then add a drop of 10% sodium nitrite solution to the acetone, if the sample is isocyanate, the solution will appear orange To reddi...

Embodiment 2

[0055] After vacuum dehydration of 200g polyether diol N210 at 110°C, polymerize with excess IPDI to obtain the first intermediate product, the reaction time is 2h; 200g of the first intermediate product after removing excess IPDI is expanded with 6.8g ethylene glycol chain reaction until the NCO content reaches the theoretical value by titration analysis to obtain an isocyanate-based polyurethane prepolymer.

[0056] After dehydrating 100g of propyltrimethylolsilane in vacuum at 90°C, cool down to 70°C and slowly add hexamethylene diisocyanate dropwise for coupling reaction to obtain the second intermediate product; add polycapsene to the above second intermediate product ester triol until the end of the reaction to obtain a polyester polyurethane-based silane coupling agent.

[0057] Mix 100g of isocyanate-based polyurethane prepolymer and 75g of polyester-based polyurethane-based silane coupling agent evenly, and then conduct a coupling reaction to obtain the final product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com