Electric welding rod suitable for welding various steel types and application and preparation method thereof

A technology for welding electrodes and steel grades, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve problems such as equipment fracture and welding, incorrect application of welding electrodes, loss, etc., to enhance tensile strength and yield. Strength, the effect of improving tensile strength and yield strength, and good work hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

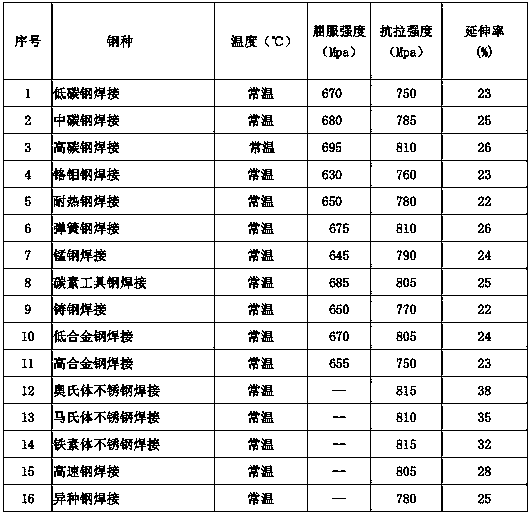

Image

Examples

Embodiment 1

[0032] 1) Selection of welding core: based on the total weight of the welding core, calculated according to the percentage, the components of the welding core are as follows:

[0033] C:0.06%, Mn:1.3%, Si:0.35%, Cr:28%, Ni:8.0%, N:0.03% S:0.015%, P:0.010%, Ti:0.15%, Nb:0.055%, Mo : 0.9%, Cu: 0.20%, balance: Fe. Preheat the solder core at 150°C for 1 hour, then cool slowly to 30°C and take it out. The coating accounts for 45% of the total weight of the electrode.

[0034] 2) Selection of coating materials: based on the total weight of the coating, the components of the coating are as follows: rutile: 20% (60-80 mesh particle size), potassium feldspar: 16% (60 -80 mesh particle size), titanium dioxide: 3% (90-120 mesh particle size), ferrosilicon: 3% (40-80 mesh particle size), metal chromium: 7% (90-100 mesh particle size), electrolysis Manganese: 5% (110-130 mesh particle size), iron oxide: 10% (120-130 mesh particle size), mica: 5% (flaky), titanium alloy: 0.5% (100-120 me...

Embodiment 2

[0039] 1) Selection of welding core: based on the total weight of the welding core, calculated according to the percentage, the components of the welding core are as follows:

[0040] C:0.06%, Mn:1.3%, Si:0.35%, Cr:28%, Ni:8.0%, N:0.03% S:0.015%, P:0.010%, Ti:0.15%, Nb:0.055%, Mo : 0.9%, Cu: 0.20%, balance: Fe. Preheat the solder core at 150°C for 1 hour, then cool slowly to 30°C and take it out. The coating accounts for 44% of the total weight of the electrode.

[0041] 2) Selection of coating materials: based on the total weight of the coating, the components of the coating are as follows: rutile: 20% (60-80 mesh particle size), potassium feldspar: 16% (60 -80 mesh particle size), titanium dioxide: 3% (90-120 mesh particle size), ferrosilicon: 3% (40-80 mesh particle size), metal chromium: 7% (90-100 mesh particle size), electrolysis Manganese: 5% (110-130 mesh particle size), iron oxide: 10% (120-130 mesh particle size), mica: 5% (flaky), titanium alloy: 0.5% (100-120 me...

Embodiment 3

[0046] An electric welding electrode suitable for welding various steel types, including a welding core and a coating, the coating is coated on the outer wall of the welding core, and the coating accounts for 40% of the total weight of the electrode;

[0047] 1) Based on the total weight of the welding core, calculated according to the mass percentage, the welding core includes the following components:

[0048] C:0.03%, Mn:1.0%, Si:0.3%, Cr:25%, Ni:8%, N:0.03%, S:0.01%-0.02%, P:0.01%, Ti:0.1%, Nb: 0.05%, Mo: 0.8%, Cu: 0.25%, and the balance is Fe.

[0049] 2) Based on the total weight of the coating and calculated by mass percentage, the coating includes the following components: rutile: 20%, potassium feldspar: 16%, titanium dioxide: 1%, ferrosilicon: 1.0%, Metal chromium: 5%, electrolytic manganese: 1%, iron oxide: 3.5%, mica: 5%, titanium alloy: 0.5%, iron oxide yellow: 3%, reduced iron powder: 2%, rare earth silicon: 0.5%, firefly Stone: 10%, marble 11%. The drug skin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com