Hot rolled strip steel with yield strength higher than 600MPa for mine rescue capsule and preparation method of hot rolled strip steel

A yield strength, hot-rolled strip technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of complex industrial environment, high temperature strength and corrosion resistance difficult to meet the use requirements of rescue cabins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033](1) According to the set chemical composition: weight percentage C: 0.05%, Si: 0.2%, Mn: 1.5%, Al: 0.01%, Mo: 0.4%, Cr: 0.5%, Nb: 0.04%, Ti: 0.05 %, Cu: 0.2%, P ≤0.01%, S ≤0.01%, the balance is Fe, the molten steel is smelted on a 200-ton converter and cast into a billet of 180 mm×1300 mm×10020 mm;

[0034] (2) Heat the cast slab to 1200°C, keep it warm for 1 h, and roll it on a 2050 mm hot rolling mill for 3 rough rolling passes. the intermediate billet;

[0035] (3) The intermediate slab was finished rolling for 6 passes. The starting temperature of the finish rolling was 950 °C, and the final rolling temperature was 780 °C. Water cooling is adopted between the strip steel and the finishing stand;

[0036] (4) The strip steel after finishing rolling is cooled to 450 °C at a rate of 40 °C / s, and then coiled. The thickness of the final hot-rolled strip product obtained is 4 mm.

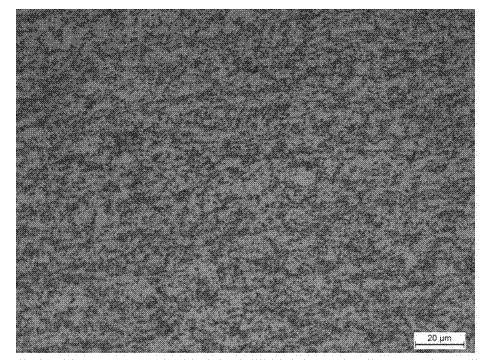

[0037] Its metallographic structure is as figure 1 As shown, all are granular bainite st...

Embodiment 2

[0040] (1) According to the set chemical composition: weight percentage C: 0.06%, Si: 0.3%, Mn: 1.6%, Al: 0.04%, Mo: 0.45%, Cr: 0.6%, Nb: 0.05%, Ti: 0.02 %, Cu: 0.25%, P ≤0.01%, S ≤0.01%, and the balance is Fe. The molten steel is smelted on a 200-ton converter and cast into a billet of 200 mm×1300 mm×10020 mm;

[0041] (2) Heat the cast slab to 1230°C, hold it for 1 h, and roll rough rolling on a 2050 mm hot rolling mill for 4 passes. mm intermediate billet;

[0042] (3) Seven passes of finish rolling were carried out on the intermediate slab, the start temperature of finish rolling was 1000 °C, the temperature of finish rolling was 820 °C, the reduction of each pass of finish rolling was controlled at 15-40%, and the thickness of 8 mm was obtained. Water cooling is adopted between the strip steel and the finishing stand;

[0043] (4) The strip after finishing rolling is cooled to 610°C at a rate of 28°C / s, and then coiled. The thickness of the final hot-rolled strip produc...

Embodiment 3

[0047] (1) According to the set chemical composition: weight percentage C: 0.08%, Si: 0.1%, Mn: 1.7%, Al: 0.05%, Mo: 0.5%, Cr: 0.4%, Nb: 0.06%, Ti: 0.04 %, Cu: 0.35%, P ≤ 0.01%, S ≤ 0.01%, the balance is Fe, the molten steel is smelted on a 200-ton converter and cast into a billet of 250 mm×1300 mm×10020 mm;

[0048] (2) Heat the cast slab to 1250 °C, keep it warm for 1 h, and roll rough rolling on a 2050 mm hot rolling mill for 5 passes. mm intermediate billet;

[0049] (3) The intermediate slab was finished rolling for 5 passes, the starting temperature of the finish rolling was 1030 °C, and the final rolling temperature was 860 °C. Water cooling is adopted between the strip steel and the finishing stand;

[0050] (4) The finished strip is cooled to 700°C at a rate of 10°C / s, and then coiled, and the thickness of the final hot-rolled strip product obtained is 14 mm.

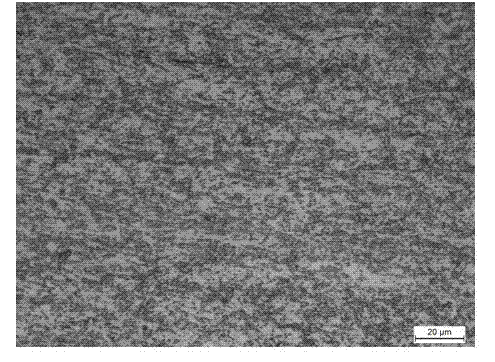

[0051] Its metallographic structure is as image 3 As shown, it is mainly granular bainite, mixed with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com