Air cathode of microbial fuel cell and preparation method of air cathode

A fuel cell and air cathode technology, applied in biochemical fuel cells, fuel cell parts, fuel cells, etc., can solve the problems of complicated manufacturing process and high cost of air cathode, and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

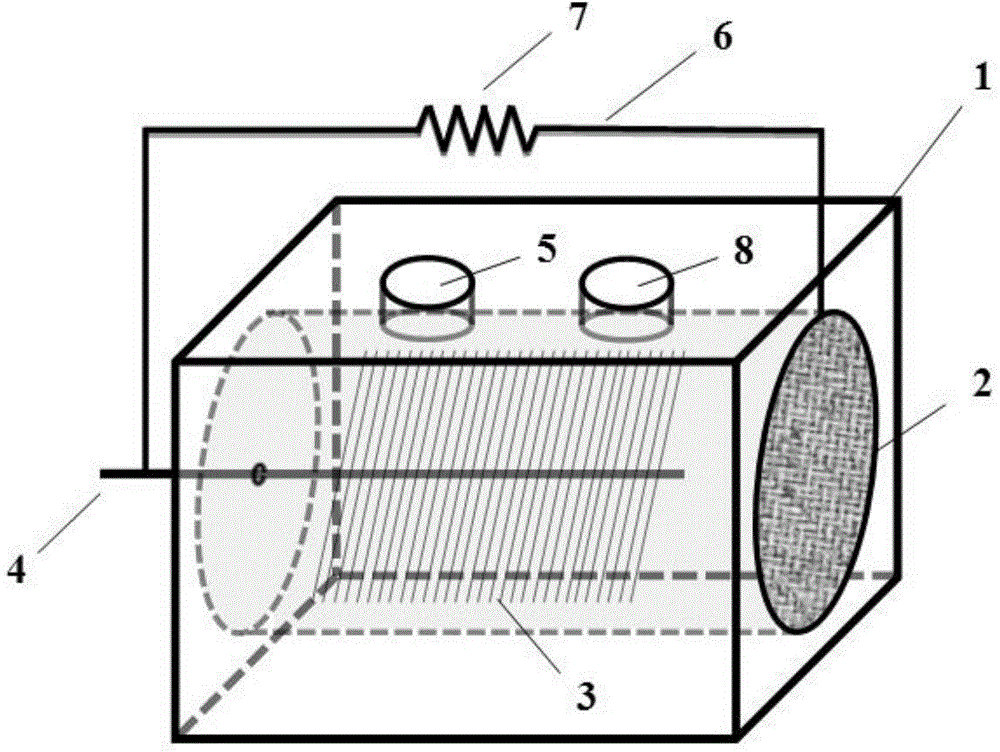

Image

Examples

specific Embodiment approach 1

[0014] Embodiment 1: The air cathode of the microbial fuel cell in this embodiment is composed of a liquid catalyst, a waterproof breathable membrane and a stainless steel mesh. The liquid catalyst is applied on the waterproof breathable membrane, and the stainless steel mesh is stacked on the side of the waterproof breathable membrane loaded with the liquid catalyst. , wherein the liquid catalyst is made by mixing catalyst, isopropanol, Nafion and deionized water, and the catalyst is a platinum carbon catalyst with a platinum mass content of 10% to 20%, carbon powder, tetramethoxyphenyl porphyrin cobalt or manganese dioxide.

[0015] The preparation cost of the air cathode of the microbial fuel cell described in this embodiment is low relative to the traditional air cathode, and the existing air cathode generally includes a carbon black / polytetrafluoroethylene layer (1 layer), a polytetrafluoroethylene air diffusion layer (3~4 layers) and catalyst layer, and the base material...

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment differs from Embodiment 1 in that the thickness of the waterproof and gas-permeable membrane is 0.05-0.15 mm.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the water vapor transmission rate of the waterproof breathable membrane is 1000~2500g / (m 2 ·24h), the impermeability is 1500~3000mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com