Anti-leakage bulletproof oil tank

A bulletproof fuel tank and anti-leakage technology, applied in the direction of protective equipment, the structure of armor plate, and the arrangement combined with the fuel supply of internal combustion engines, etc., can solve the problems of unfavorable personnel safety, easy fire of fuel, fuel leakage, etc., to protect personnel Safety, prevent fire and explosion, prevent cracking and oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

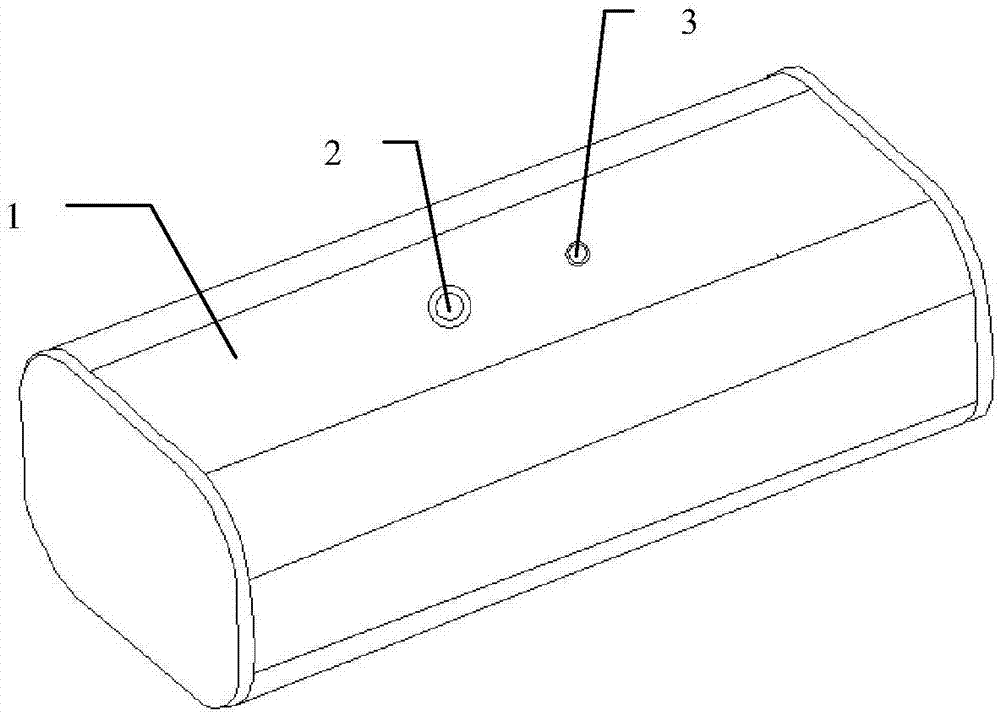

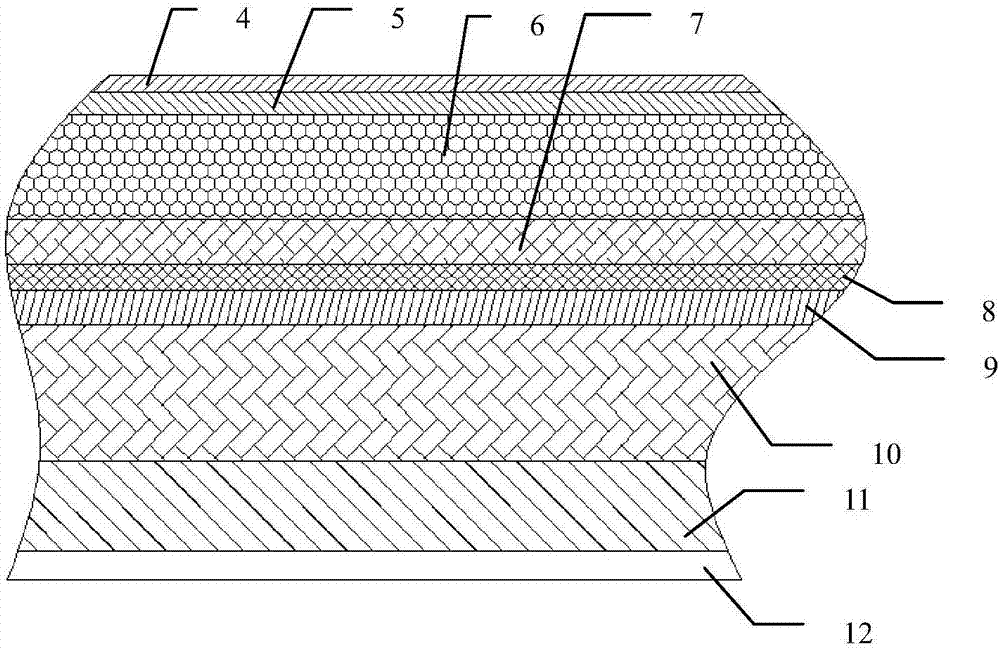

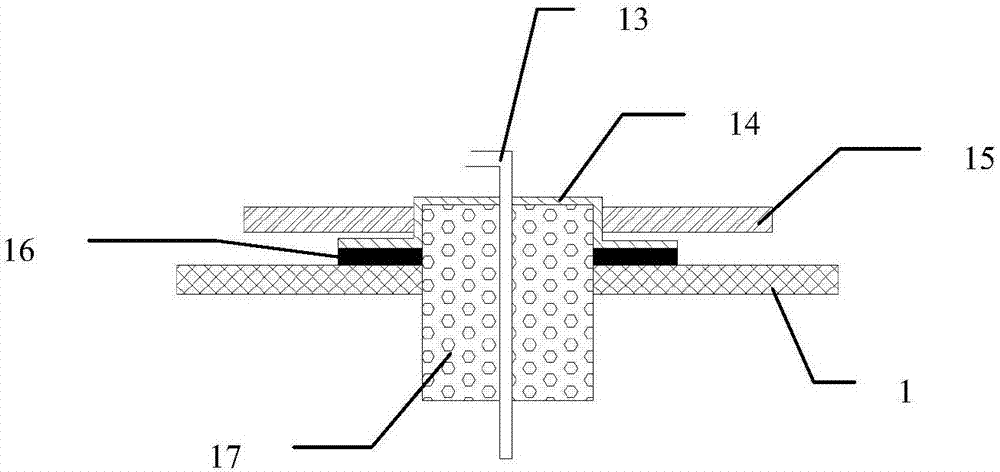

[0019] refer to Figure 1 to Figure 4 A preferred embodiment of the present invention provides a leak-proof bulletproof fuel tank, comprising a fuel tank body 1 and an oil suction pipe mechanism 2, the fuel tank body includes an anti-corrosion coating 4, a formed metal layer 5, a first Foam metal buffer layer 6, rubber layer 7, first fireproof layer 8, inner steel sheet layer 9, second foam metal buffer layer 10, fiber fabric bulletproof layer 11 and outer steel sheet layer 12, the oil suction pipe mechanism includes oil suction pipe 13 and a sealing cover 14, the sealing cover 14 protrudes from the outer surface of the fuel tank body 1, the inside of the sealing cover 14 is provided with a perforated metal cylinder 17 extending into the interior of the fuel tank body, and the outer side of the sealing cover is provided with a heat dissipatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com