Multifunctional alternating current capacitor

A capacitor and multi-functional technology, applied in the field of capacitors, can solve the problems of waste, overheating, capacitor fire, etc., and achieve the effects of long use time, prevention of fire and explosion, and easy replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

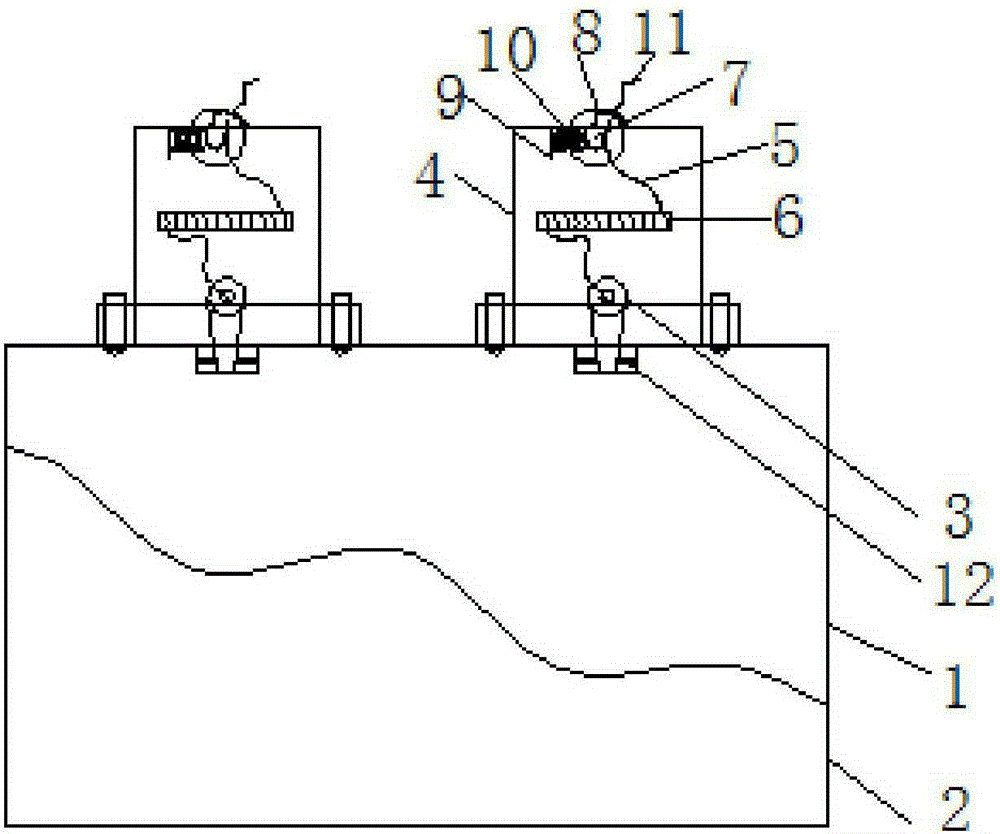

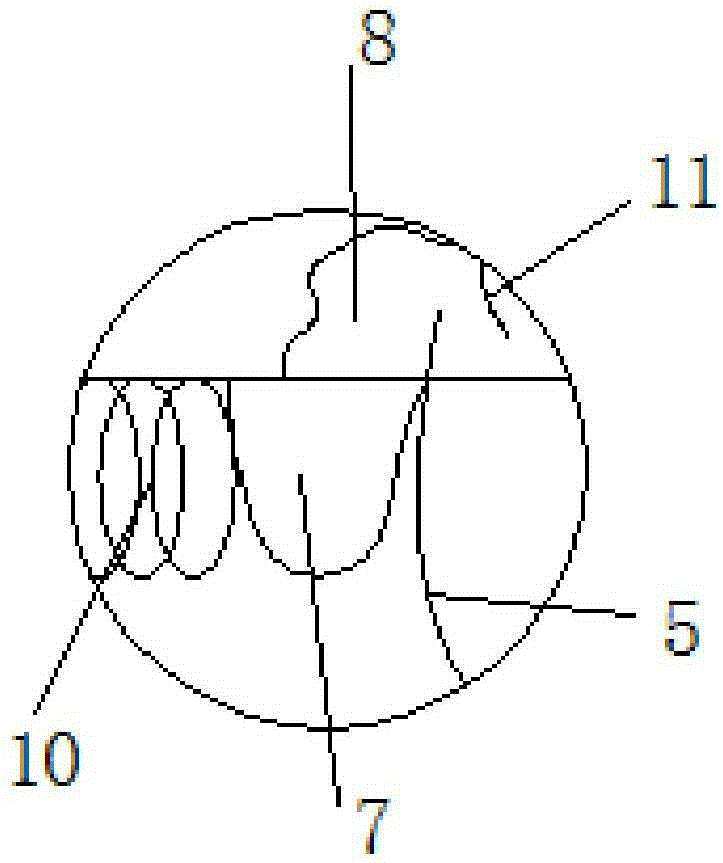

[0015] Referring to the drawings, a multifunctional AC capacitor includes a shell 1, a capacitor core 2. The capacitor core 2 is located in the shell 1, and a pin 3 is provided on the shell 1, and a protective cover is provided outside the pin 3 4. The lower part of the protective cover 4 is connected to the housing 1. A heavy rod 6 is arranged in the cavity of the protective cover 4, and an inner wire 5 is wound on the heavy rod 6, and the pin 3 is connected to the lower end of the inner wire 5, and the inner wire 5 The upper end extends out of the housing 1, the upper end of the inner wire 5 is welded to the outer wire 11 through an outer solder joint 8. The outer solder joint 8 is arranged on the upper end of the protective cover 4, and the lower end of the protective cover 4 is provided with an inner solder joint 7, and the inner solder joint One side of 7 is in contact with the inner wire 5, and the other side of the inner solder joint 7 is provided with a side plate 9, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com