Motor vehicle with height adjusting device for loading floor

A technology for motor vehicles and floor plates, applied in vehicle parts, transportation and packaging, etc., can solve problems such as laborious pulling and pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

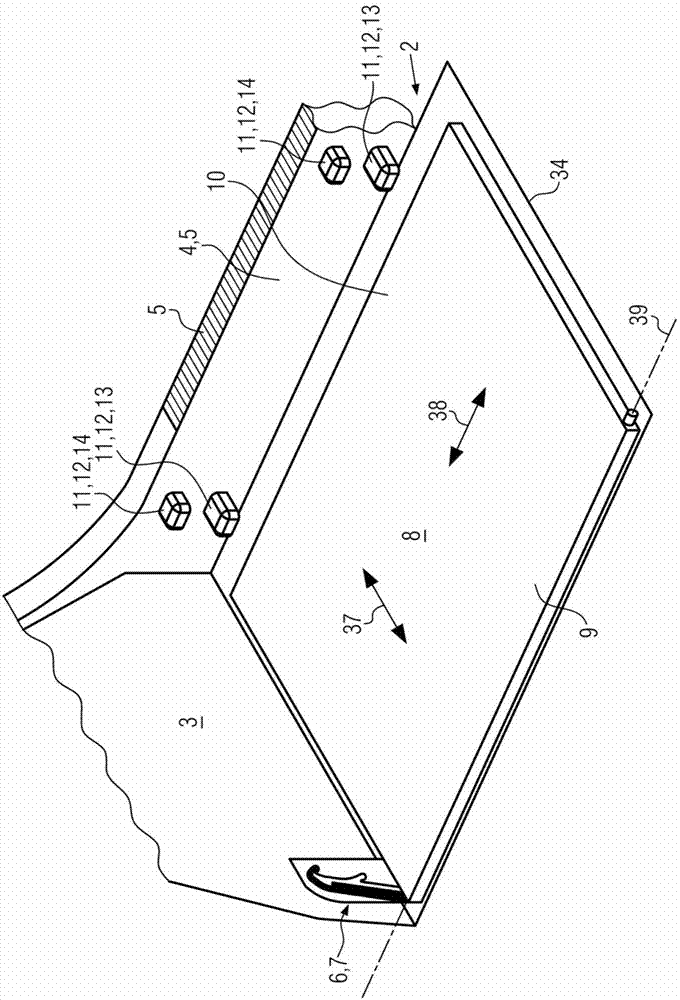

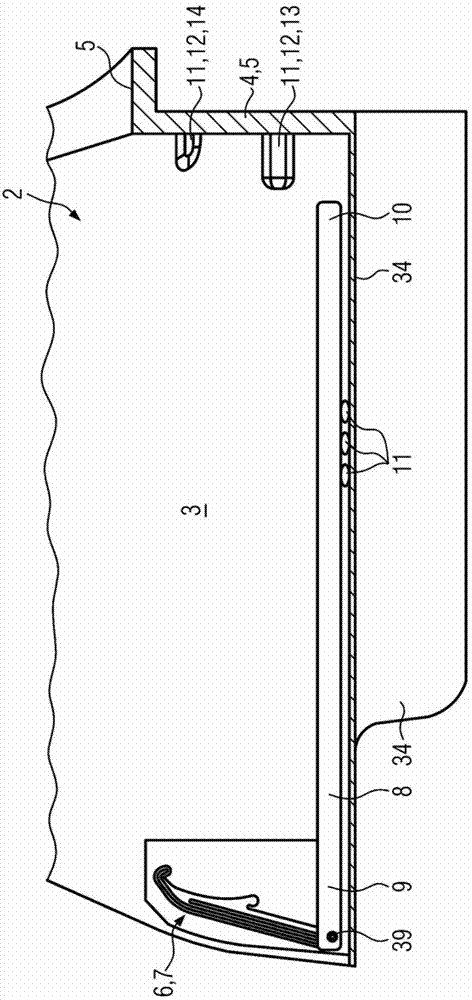

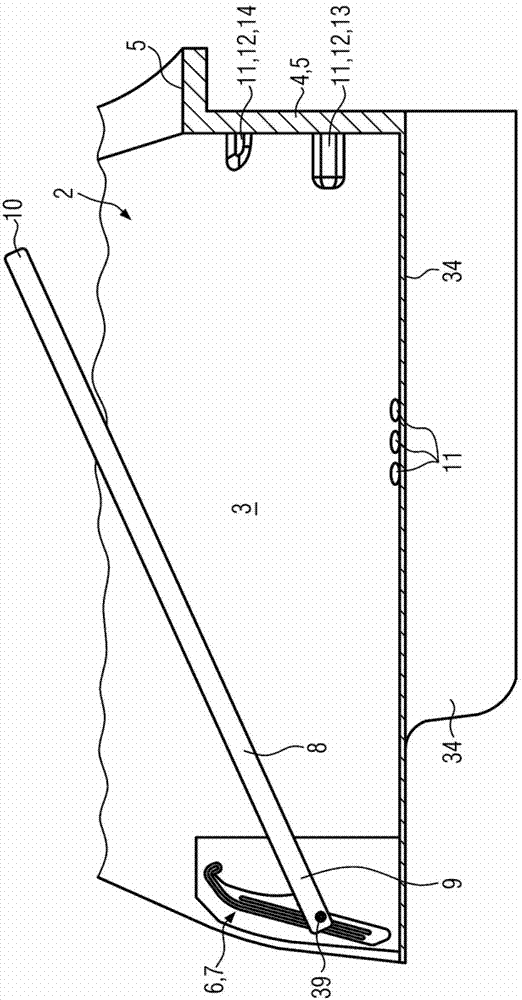

[0039] exist Figure 10 The motor vehicle 1 shown in FIG. 1 has an internal combustion engine and / or an electric motor for driving the motor vehicle. Two front seats and three rear seats are provided in the interior of the motor vehicle 1 . This is a five-door motor vehicle 1 with four side doors for getting on and off passengers and a cargo compartment 2 ( figure 1 ) for loading and unloading the rear fifth door as a tailgate. Here, the load compartment 2 is delimited rearwardly by a rear body wall 4 and an interior trim panel on the rear body wall 4 as loading edge 5 , and laterally by two body side walls 3 and an inner trim on the body side walls 3 . The plaque defines the border. Forwards, the cargo space 2 is bounded by the backrests of the three rear seats (not shown). The cargo space 2 is bounded downwards by a plate-like and substantially rectangular cargo floor 8 made of metal and / or plastic. In this case, the cargo floor 8 is oriented substantially horizontally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com