Method for controlling symmetry of machining keyway and center of tooth or tooth space

A centrosymmetric and cogged technology, which is applied in the direction of program control, computer control, general control system, etc., can solve the problems of unguaranteed processing quality and assembly accuracy, unable to guarantee drawing requirements, extended processing cycle, etc., to achieve quality accuracy Fully guarantee, improve work efficiency and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] The method for controlling the symmetry between the processing keyway and the tooth or tooth groove center of the present invention comprises the following steps:

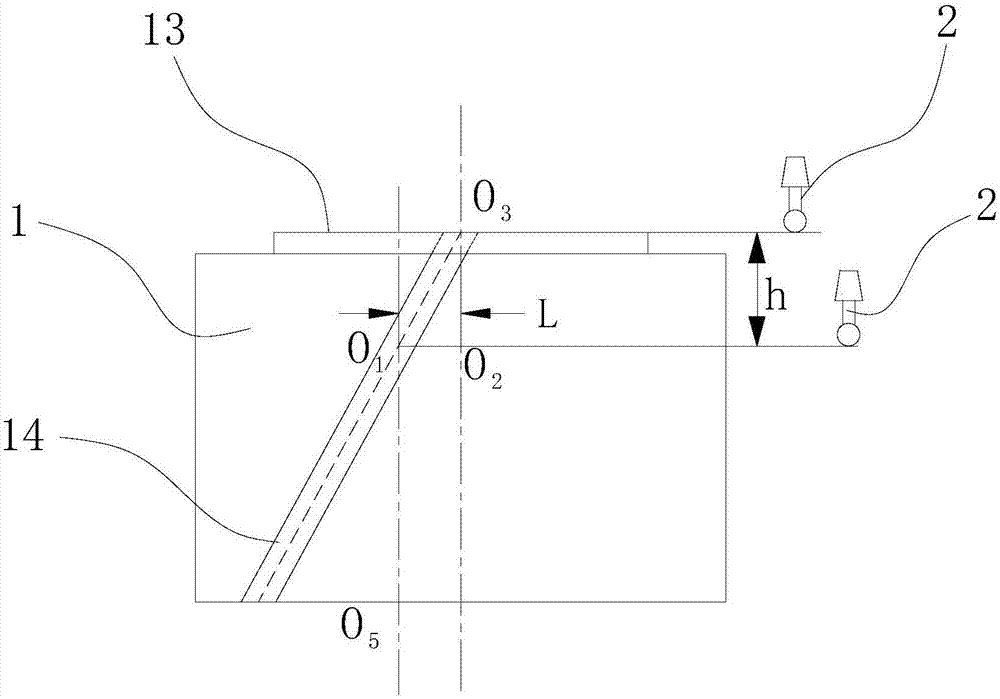

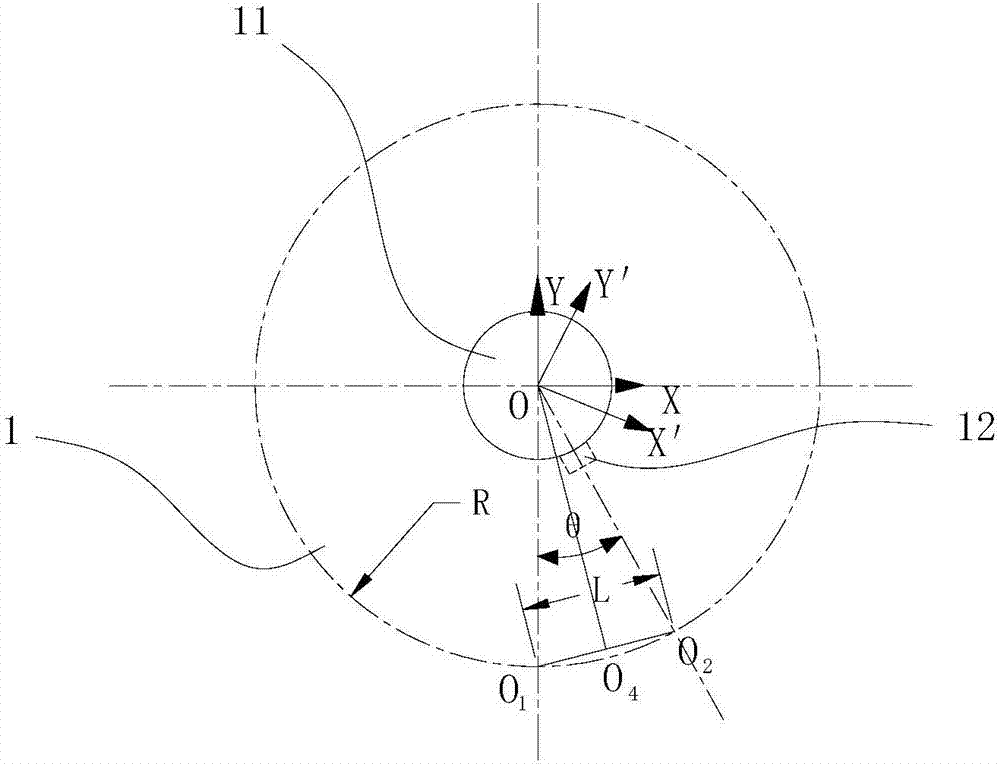

[0020] 1) Select a cross-section of the single helical gear 1 in the single helical gear 1, the height of the cross section from the base surface 13 is h; select any tooth groove or tooth on the single helical gear 1, and use the three-dimensional measuring head 2 to print The center O of the alveolar or tooth on the cross-section 1 , with O 1 The connection line with the center O of the cross section is the Y axis, and a rectangular coordinate system XOY is established on the base surface 13;

[0021] 2) Calculate the intersection point O of the helix rise of the gear indexing circle and the base surface on the cross section 3 and the alveolar or tooth center O in this cross-secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com