De-icing and/or Anti-icing of a wind turbine component by vibrating a piezoelectric material

a piezoelectric material and wind turbine technology, applied in the field of wind turbines, can solve the problems of excessive mechanical loads, increased vibration problems, and reduced performance of wind turbines, so as to reduce the probability of ice falling from a large height and increase safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

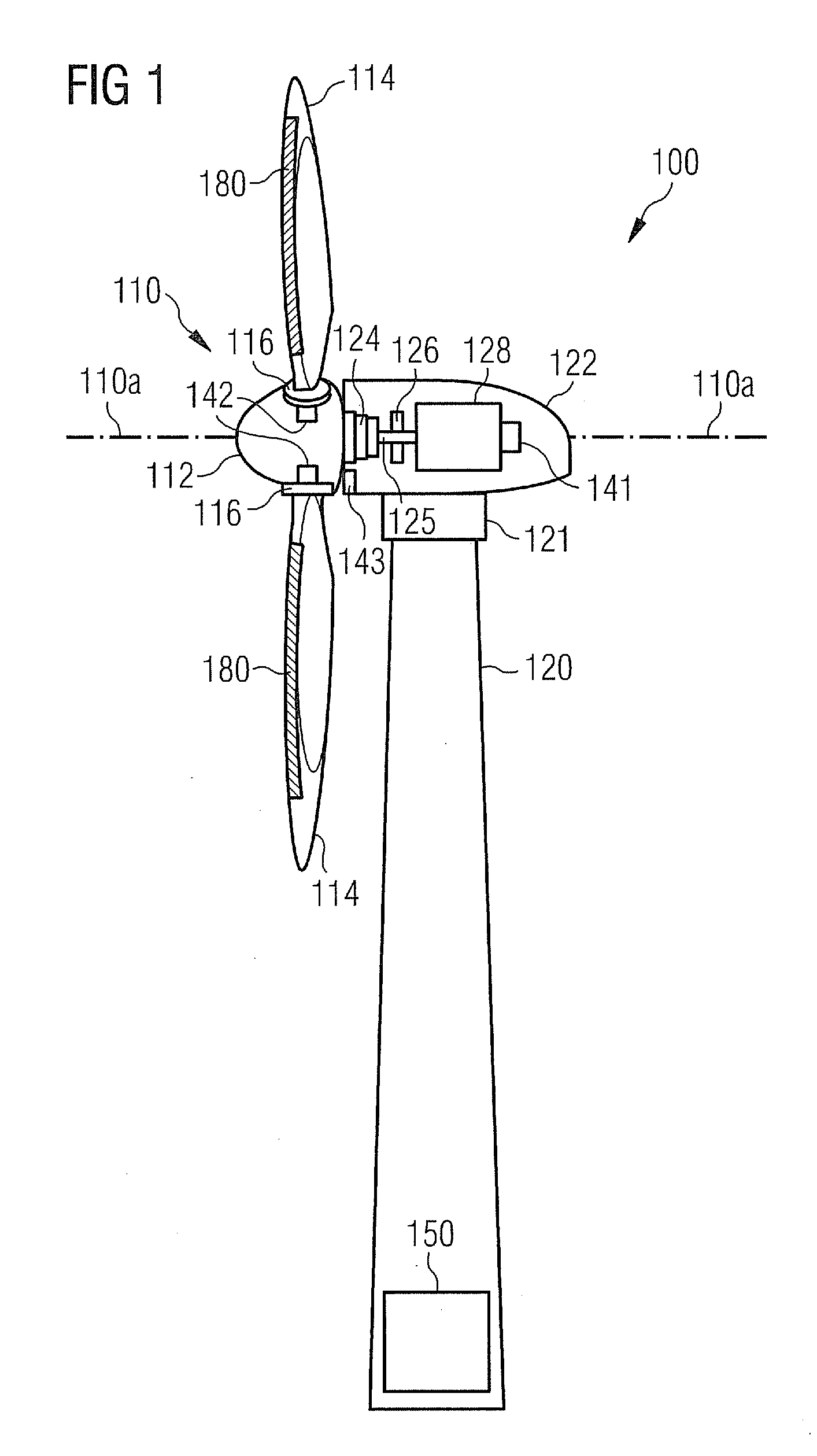

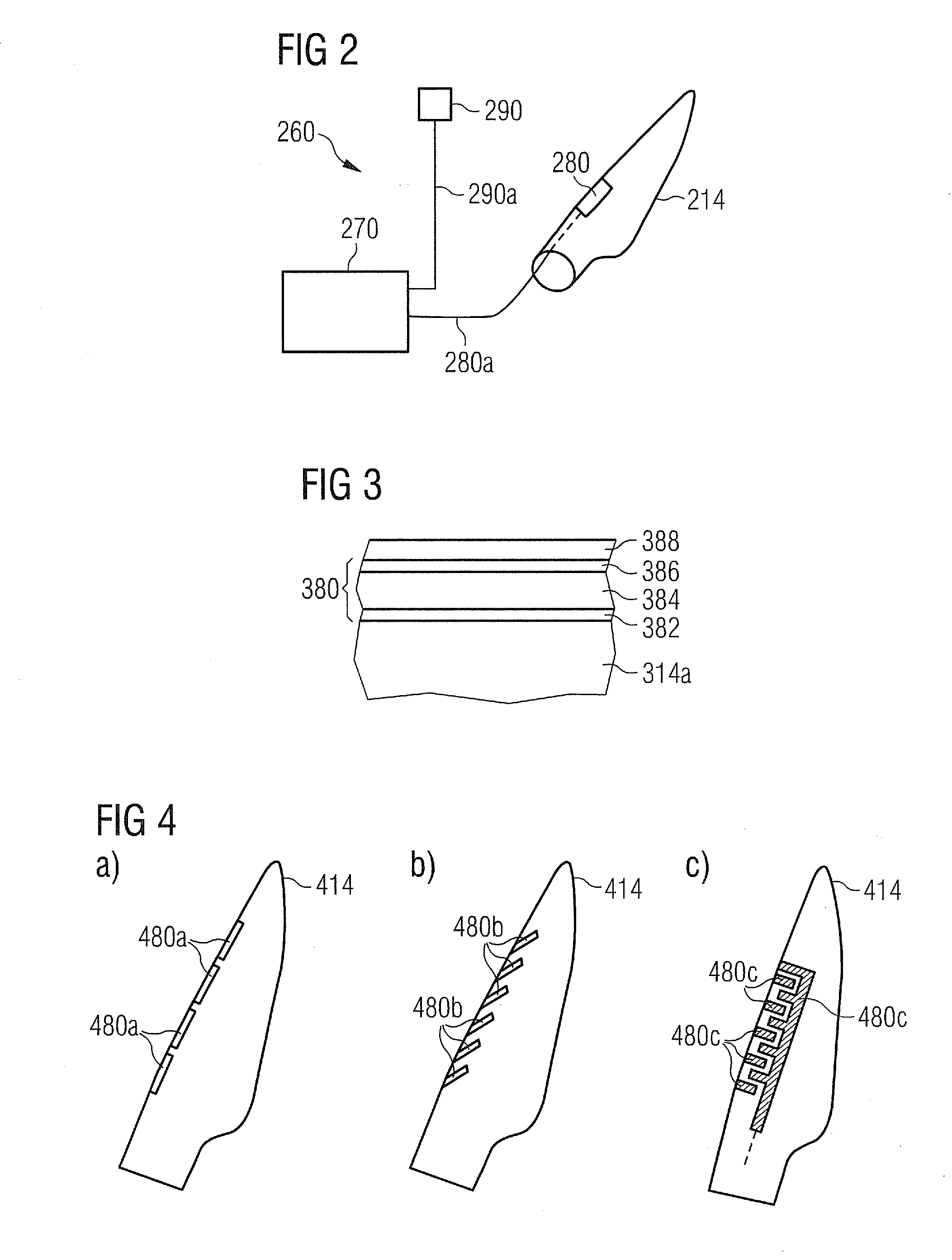

[0056]The illustration in the drawing is schematically. It is noted that in different figures, similar or identical elements are provided with the same reference signs or with reference signs, which are different from the corresponding reference signs only within the first digit.

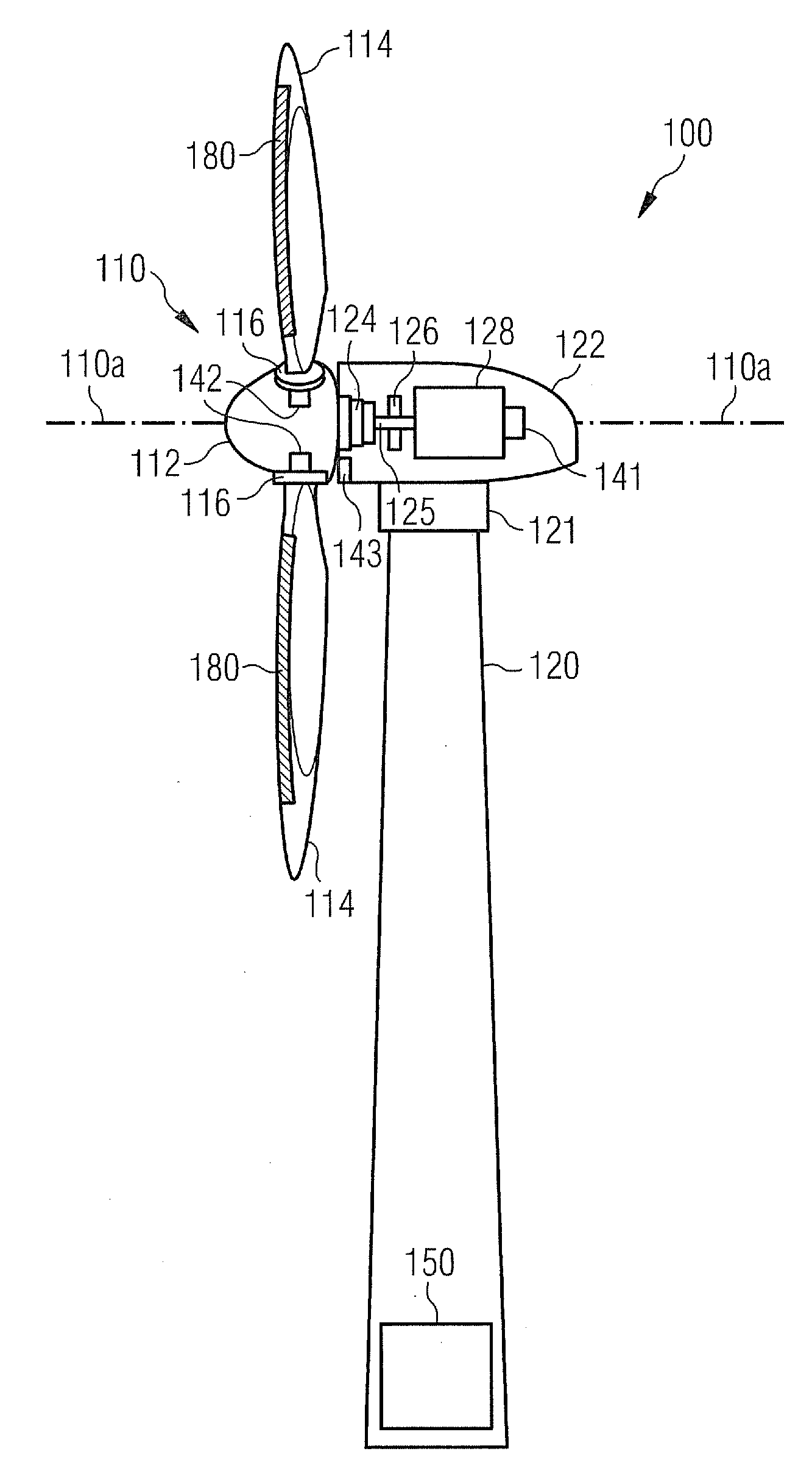

[0057]FIG. 1 shows a wind turbine 100 according to an embodiment of the invention. The wind turbine 100 comprises a tower 120, which is mounted on a non-depicted fundament. On top of the tower 120 there is arranged a nacelle 122. In between the tower 120 and the nacelle 122 there is provided a yaw angle adjustment device 121, which is capable of rotating the nacelle 122 around a non depicted vertical axis, which is aligned with the longitudinal extension of the tower 120. By controlling the yaw angle adjustment device 121 in an appropriate manner it can be made sure, that during a normal operation of the wind turbine 100 the nacelle 122 is always properly aligned with the current wind direction.

[0058]The win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com