Filter apparatus

A filter equipment and filter technology, which is applied in the direction of filtration separation, membrane filter, fixed filter element filter, etc., can solve the problems of affecting fluid treatment, cost consumption, large structure, etc., and achieve the solution of stress cracks, compact layout, uniform The effect of heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

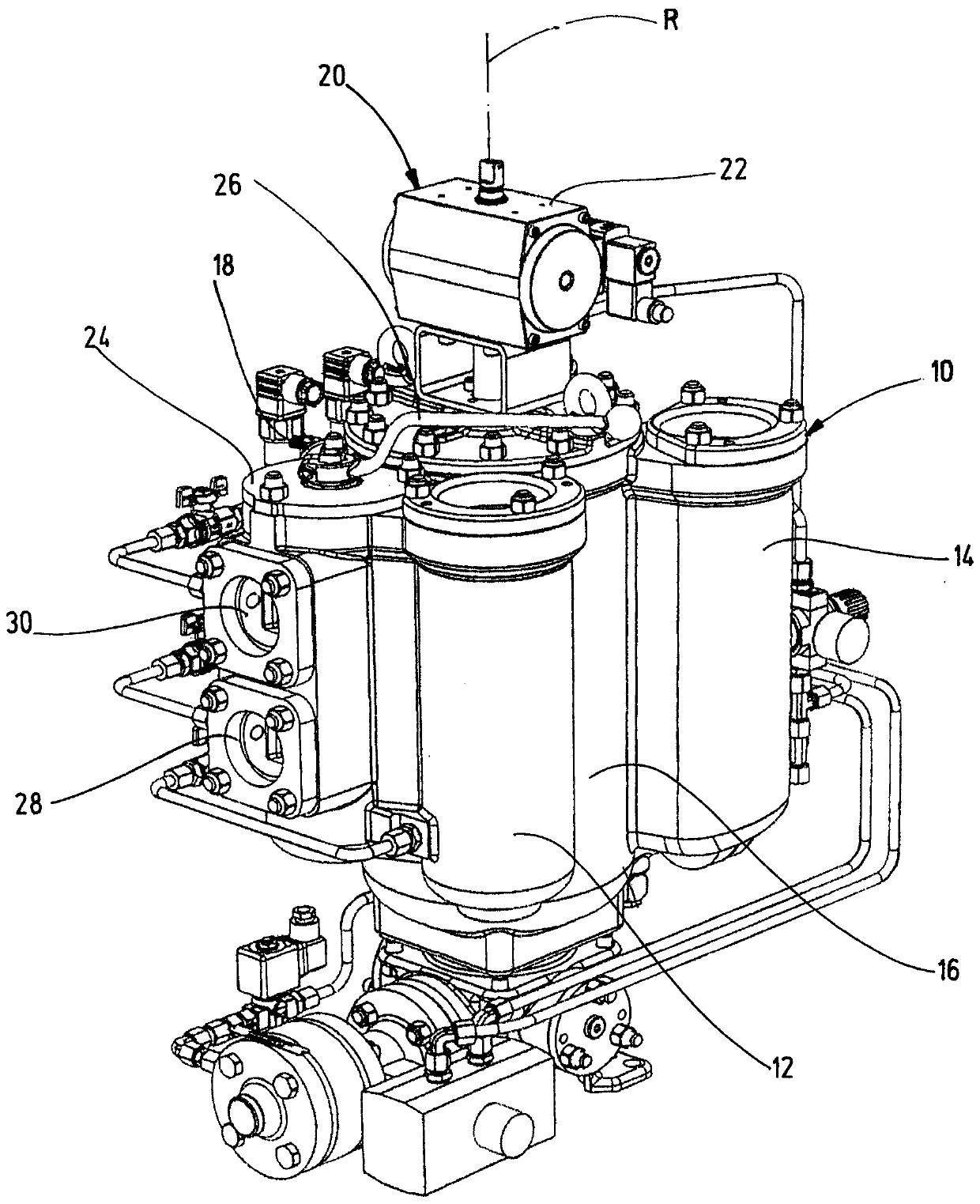

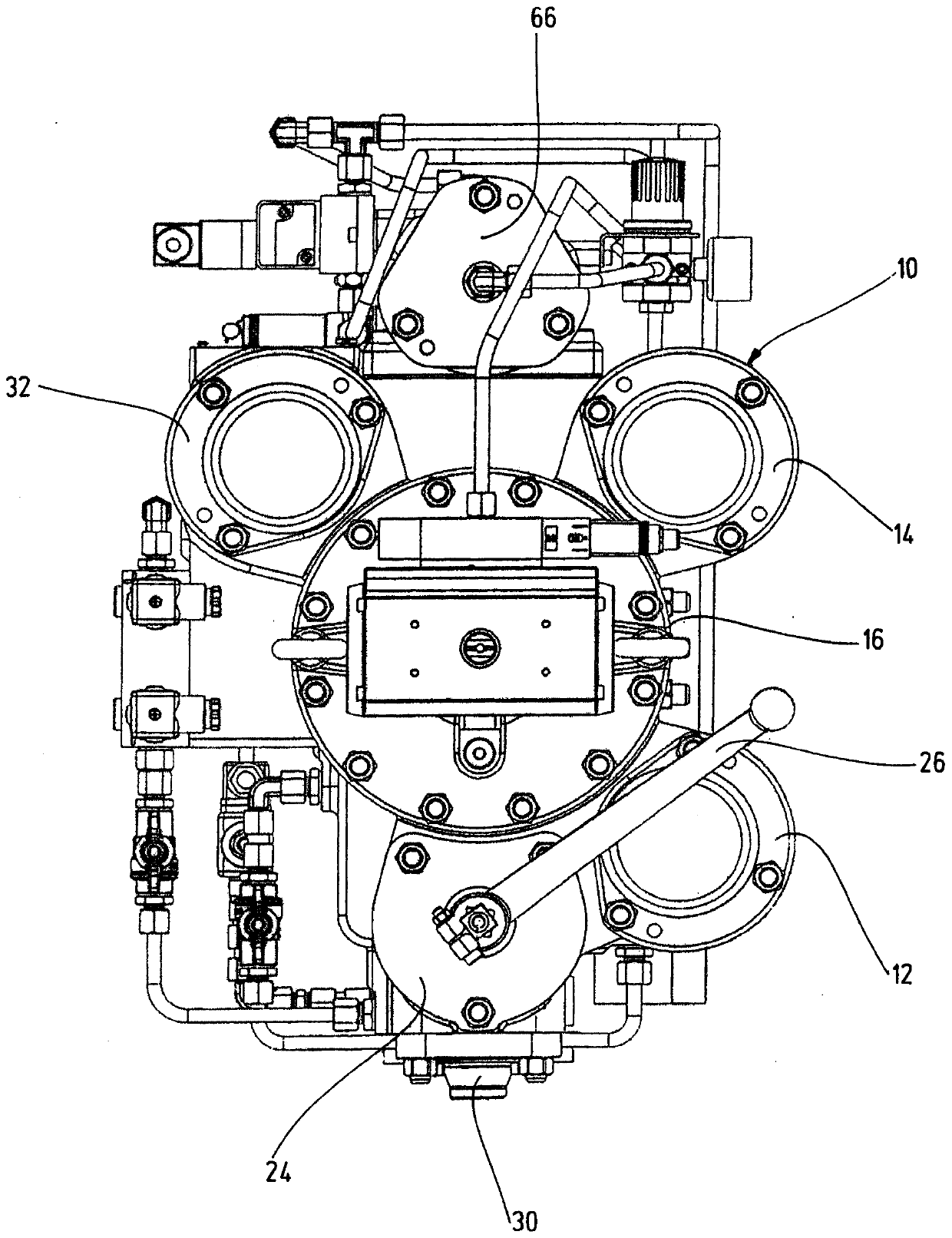

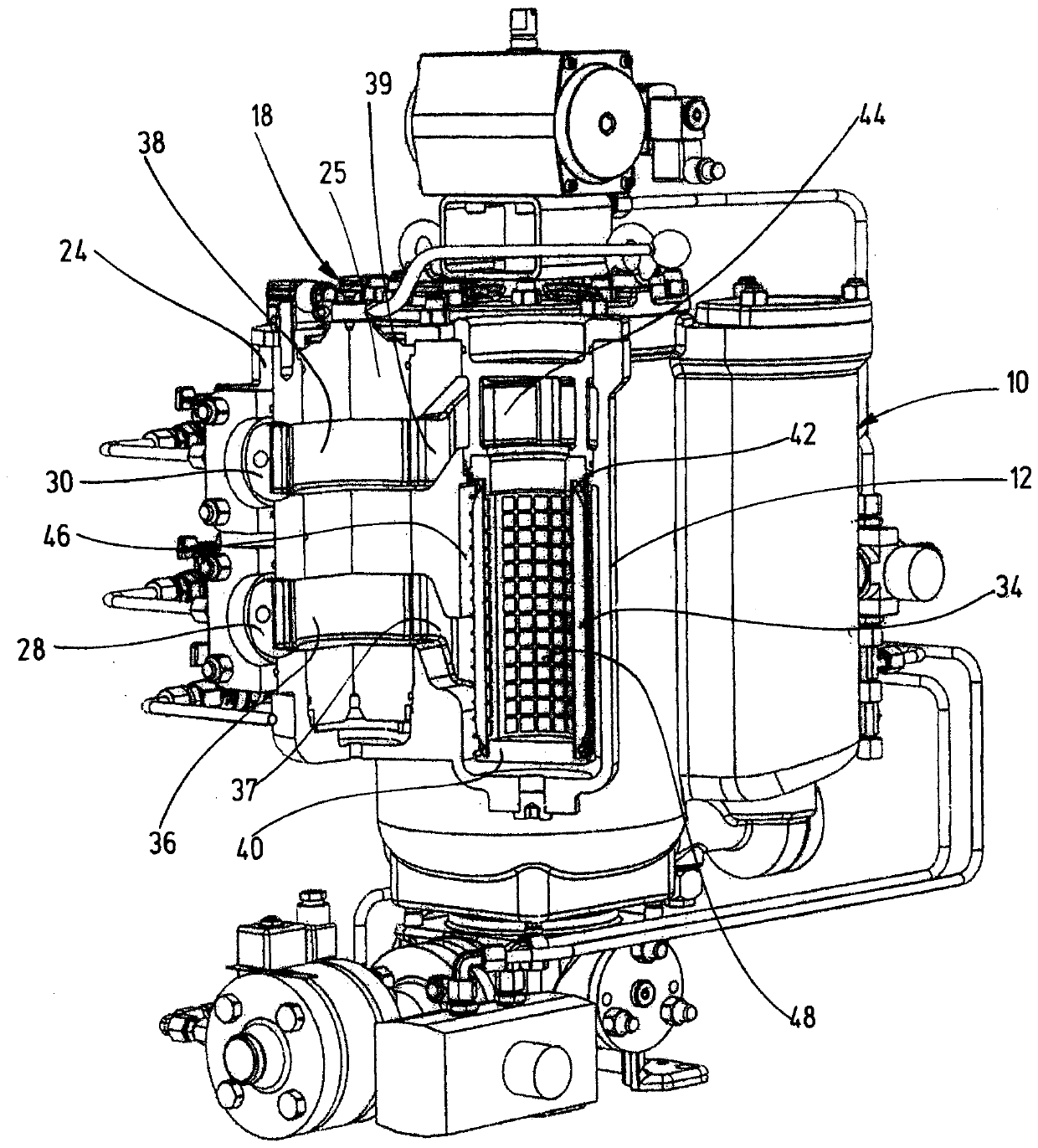

[0031] figure 1 Shows a general view of a filter device according to the invention with a filter housing 10 having three filter chambers (a first filter chamber 12, a second filter chamber 14 and a third filter chamber Filter chamber 32 (see figure 2 )), spindle housing 24, housing body 16 and drive unit 22. Provided on the spindle housing 24 is a fluid inlet indicated by 28 for supplying the fluid to be cleaned, and an outlet indicated by 30 for discharging the cleaned fluid. One filter element 34 is installed in each filter chamber 12, 14, 32 (see image 3 ), 60 (see Figure 4 ). The central component of the filter device is the conversion device 18, which is received by the main shaft housing 24 and figure 1 Only the operating device in the form of a hand lever 26 is visible in the conversion device. Furthermore, a backflushing device 20 is provided on the filter device, which is accommodated in the housing body 16 and figure 1 The drive unit 22 arranged above the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com