Patents

Literature

78results about How to "Compact run" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

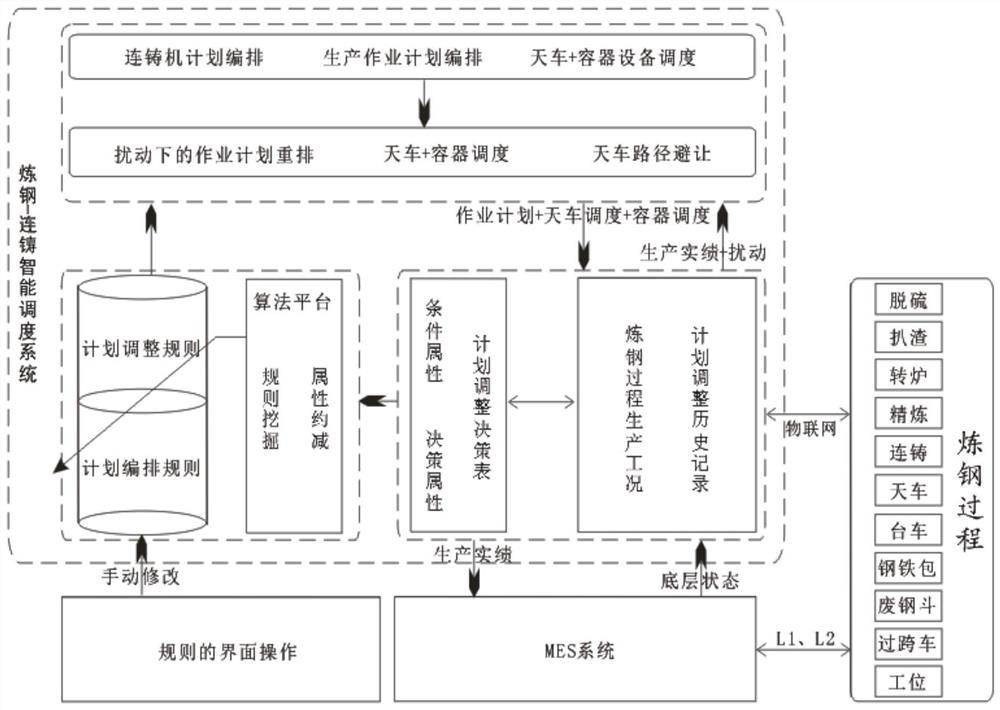

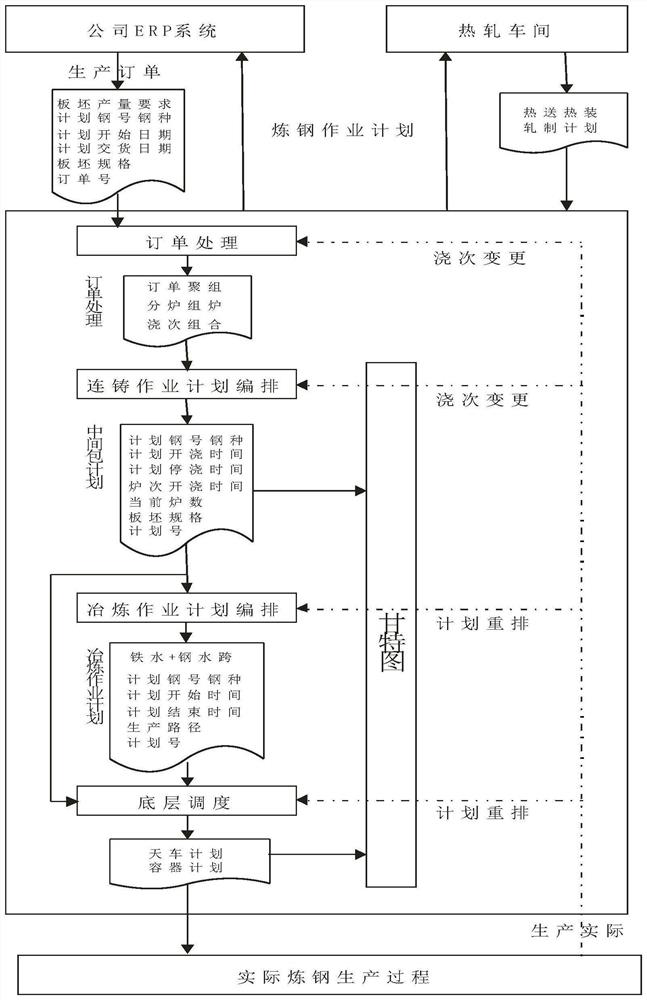

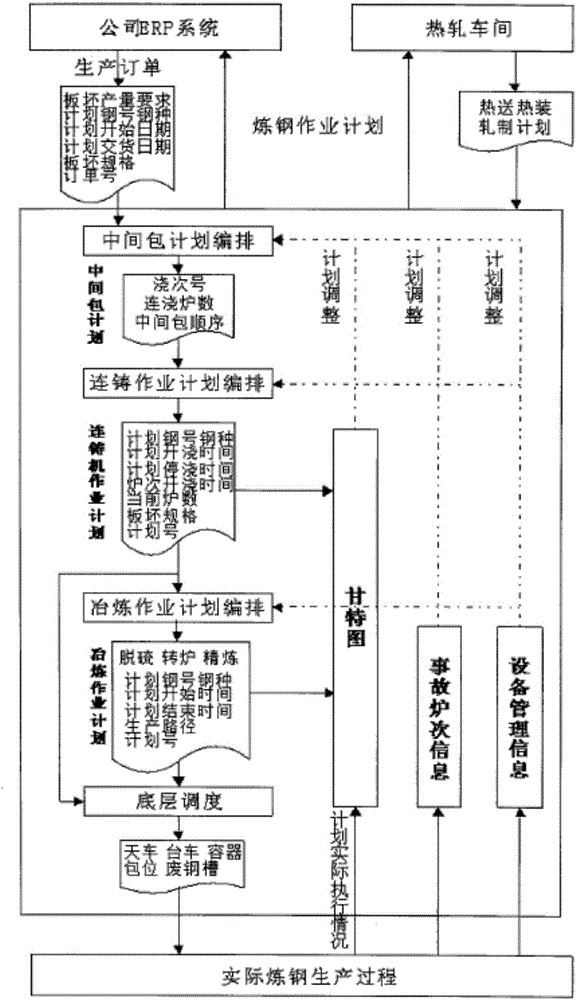

Steel-making production process intelligent scheduling method

ActiveCN105353733AOptimize runCompact runEnergy industryTotal factory controlProduction planningOperational costs

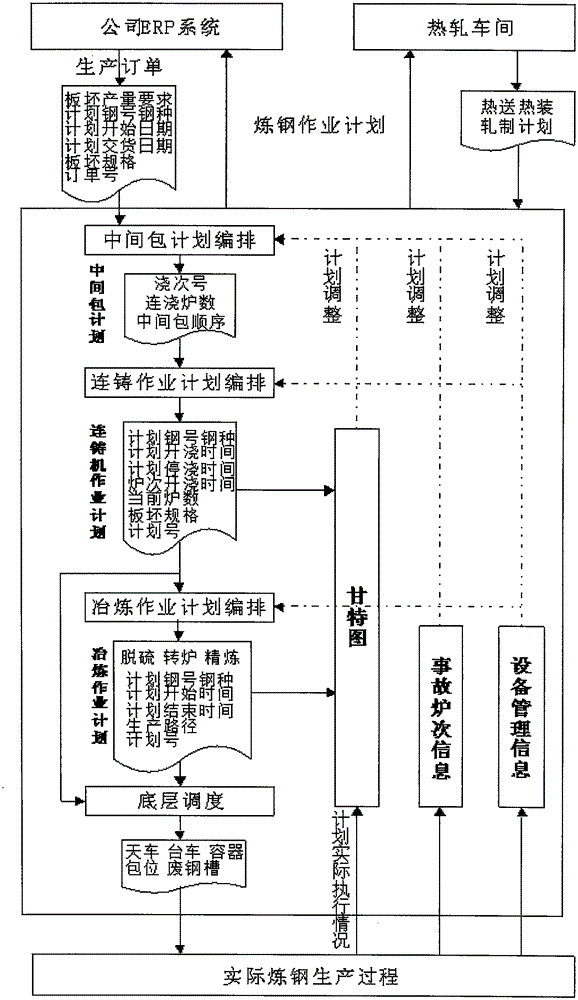

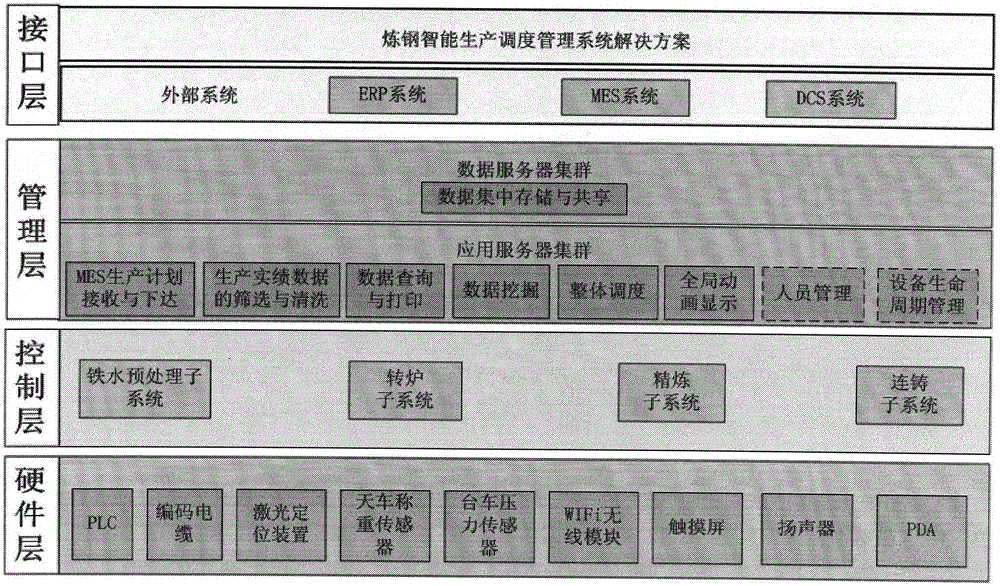

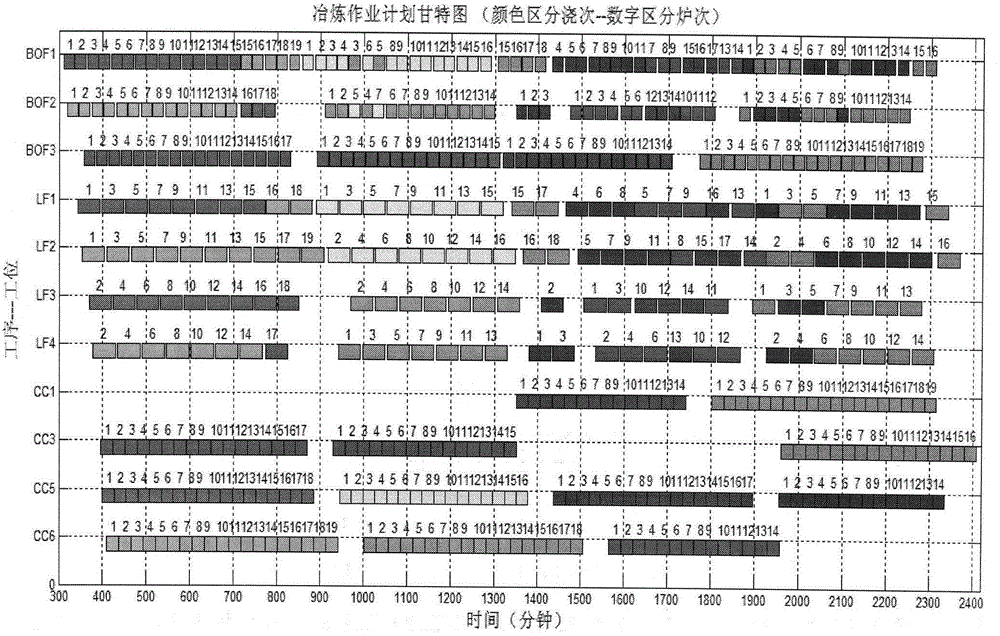

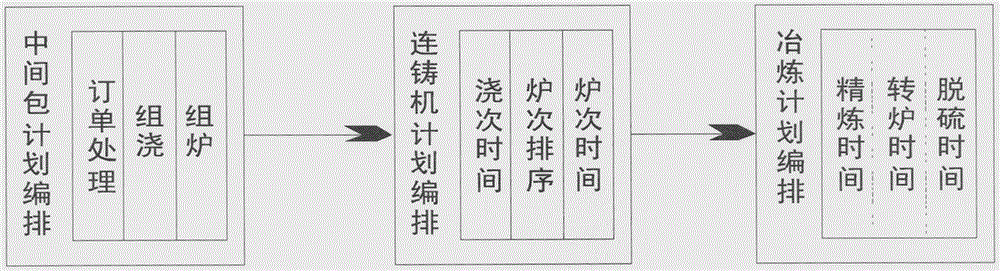

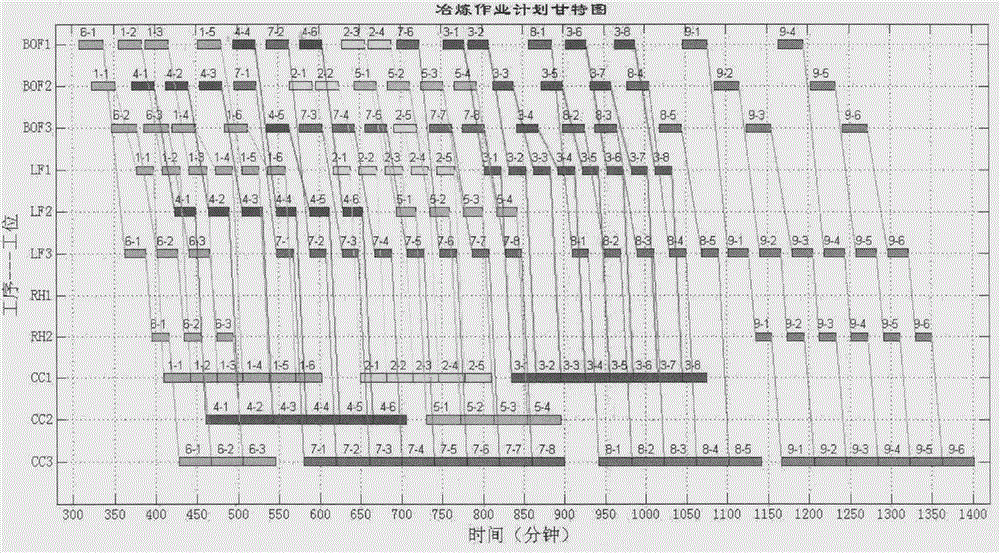

The present invention discloses a steel-making production process intelligent scheduling method which comprises the steps of (1) inputting a production plan which comprises a production order and a hot delivery and hot charging production plan given by a hot rolling workshop, (2) decompositing a working plan, calculating the number of slabs, and decompositing the order according to steel types, slab specifications and delivery dates, (3) scheduling a cast order, and scheduling each casting according to a continuous casting machine usage condition and the difference between order delivery dates, (4) collecting a characteristic signal and obtaining bottom layer equipment key position characteristic signal through a corresponding sensor, (5) executing a crane preferred algorithm, (6) switching a transport task state, (7) rearranging a plan, and (8) displaying the rearranged plan to dispatchers in the form of a Gantt diagram. According to the method, the production safety in the steel-making process is ensured, the production operating cost is reduced, the energy is saved, the enterprise management is enhanced, the production efficiency is improved, and the enterprise performance maximization is facilitated.

Owner:HUNAN CHAIRMAN IND INTELLIGENT SYST CO LTD

Dynamic scheduling method of steelmaking operation plan

Owner:HUNAN CHAIRMAN IOT INFORMATION TECH CO LTD

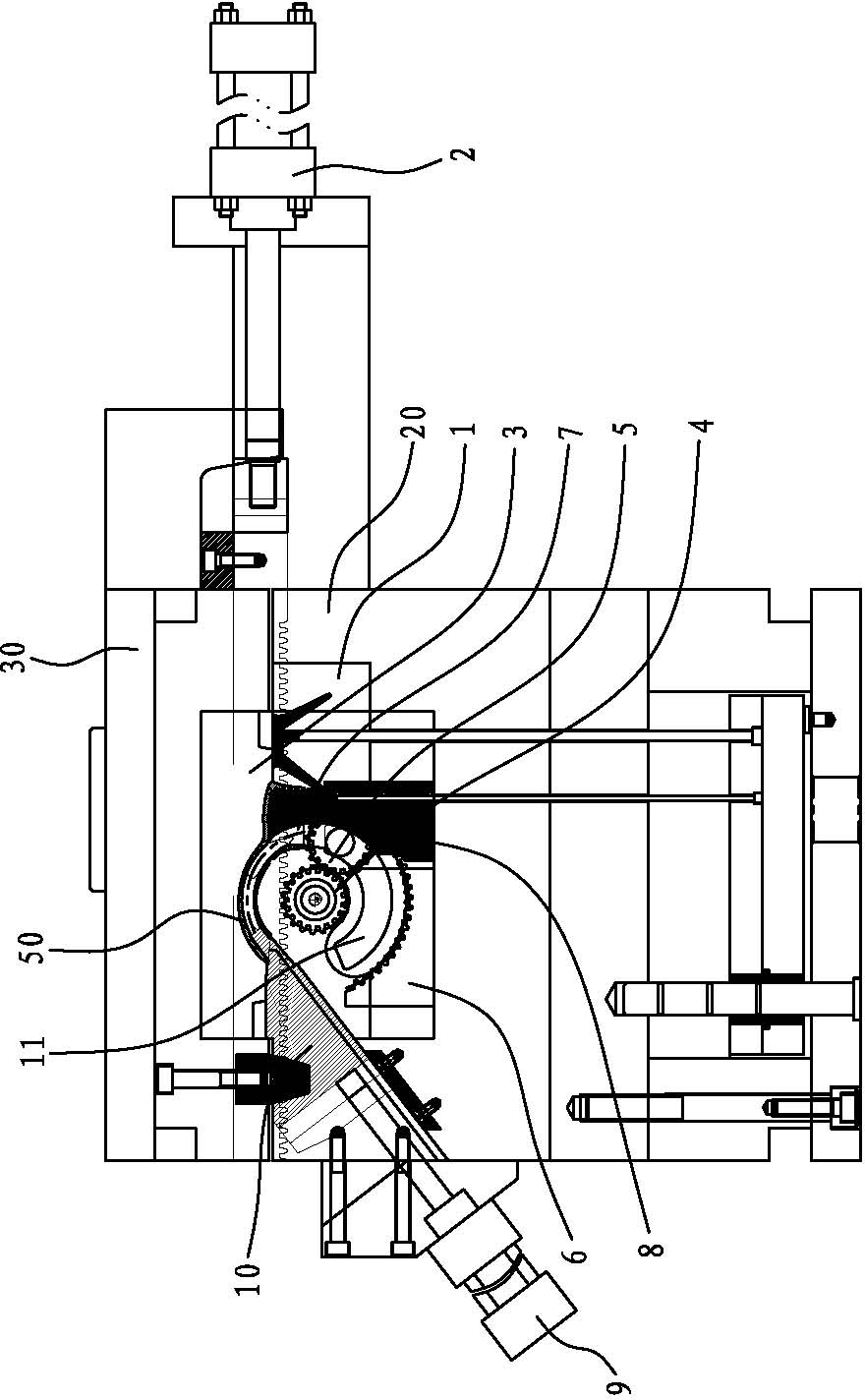

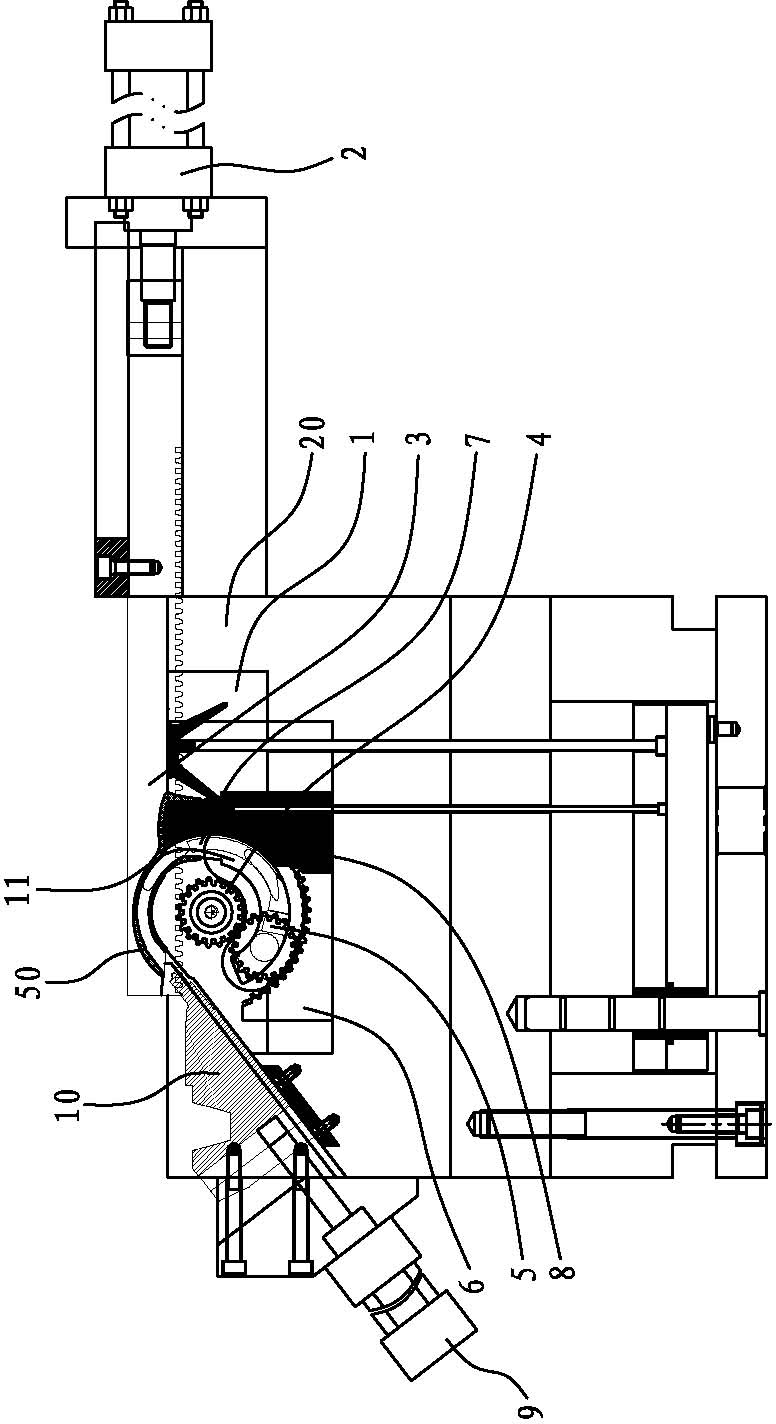

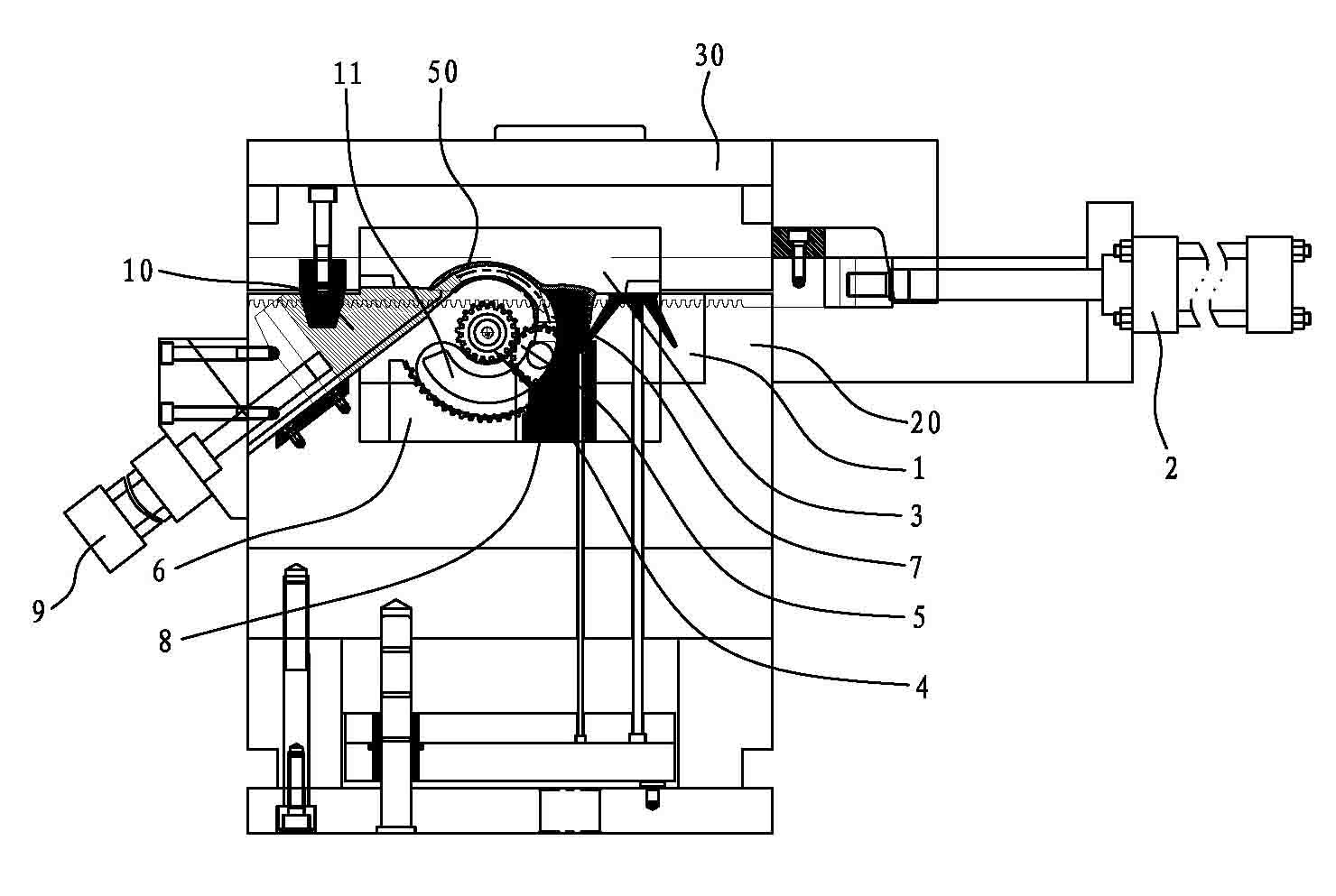

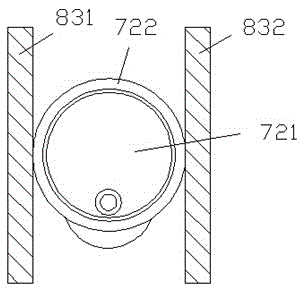

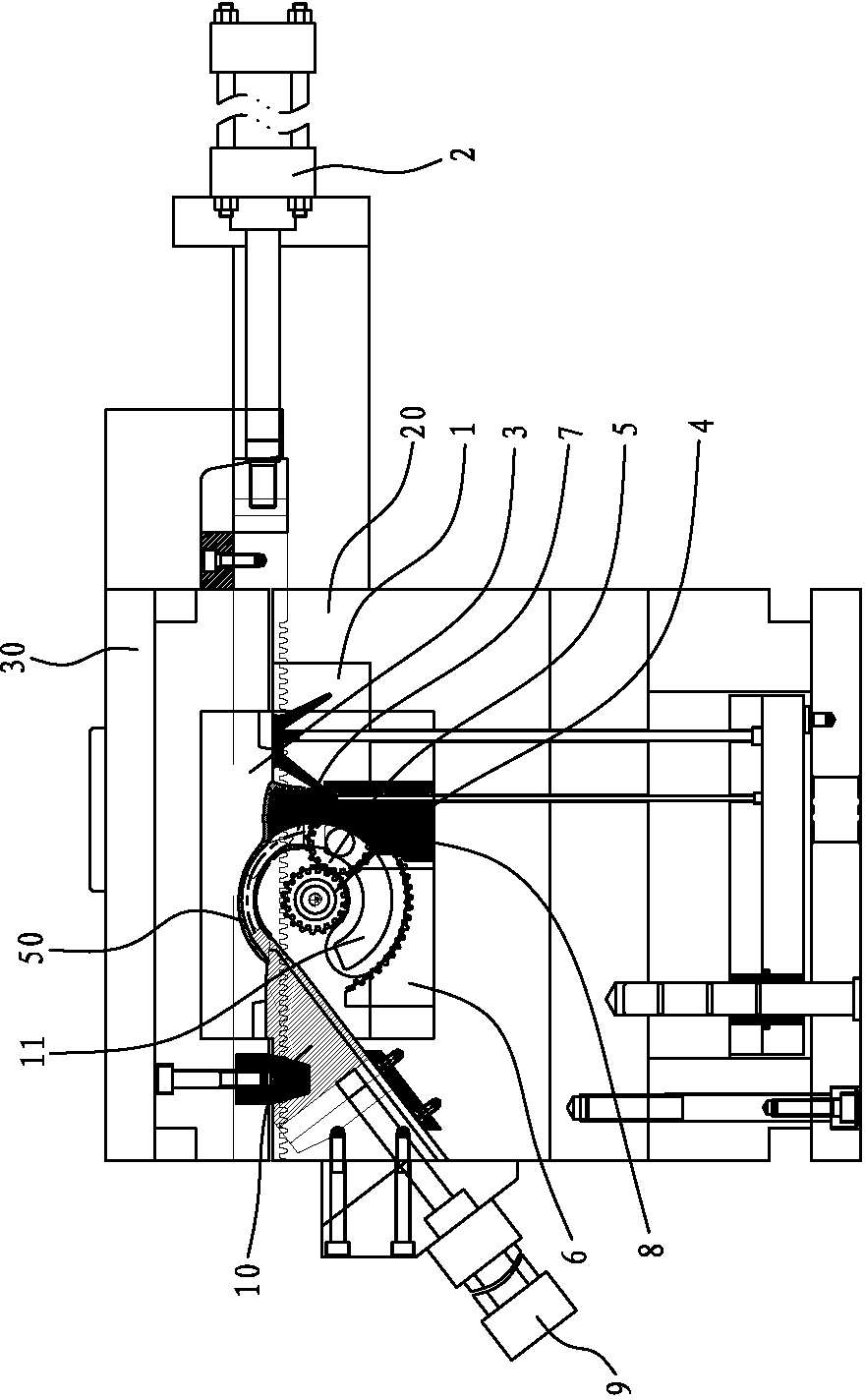

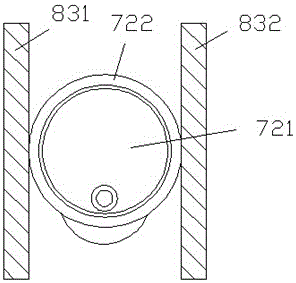

Arc core-pulling device for die

The invention discloses an arc core-pulling device for a die, which mainly comprises a movable die insert panel, a teeth row oil cylinder, a teeth row, a fixed gear, a movable gear, a U-shaped gear and a bending core, wherein the movable die insert panel is installed on a movable die, a rod end of a piston rod of the teeth row oil cylinder is connected with the teeth row, the fixed gear is rotatably installed on the movable die insert panel, and the U-shaped gear is installed in the movable die and located below the movable die insert panel; and the movable gear is rotatably connected with one end of the bending core, the outer teeth of the movable gear are respectively engaged with the outer teeth of the fixed gear and the arc inner teeth of the U-shaped gear, and the bending core is slidably connected to the interior of a bending groove of the movable die insert panel. Because the U-shaped gear is provided with the arc inner teeth, the movable gear engaged with the U-shaped gear moves along an arc inner teeth surface to drive the bending core to be stably pulled out from a die cavity. The fixed gear, the movable gear and the U-shaped gear are engaged with each other to realize power transmission as well as stable and reliable running.

Owner:厦门市方圆通模具有限公司

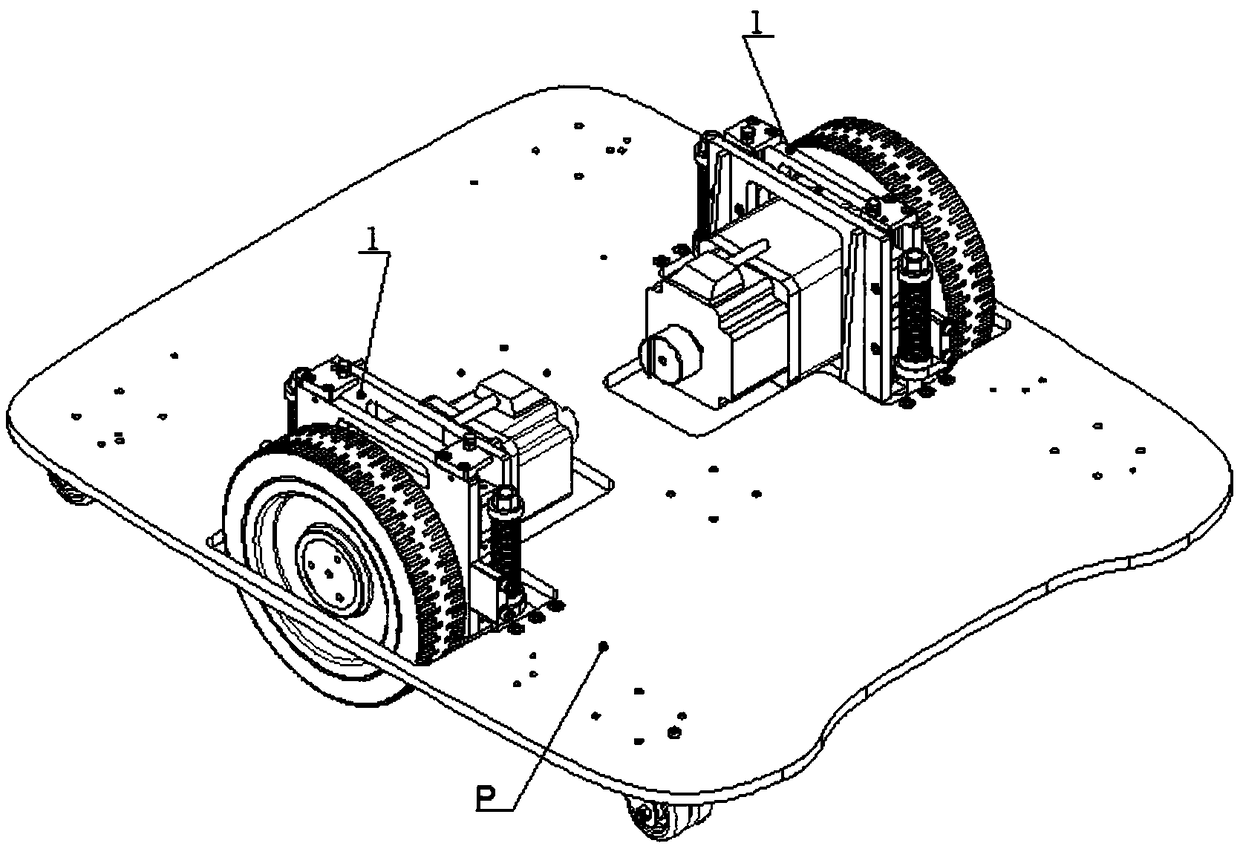

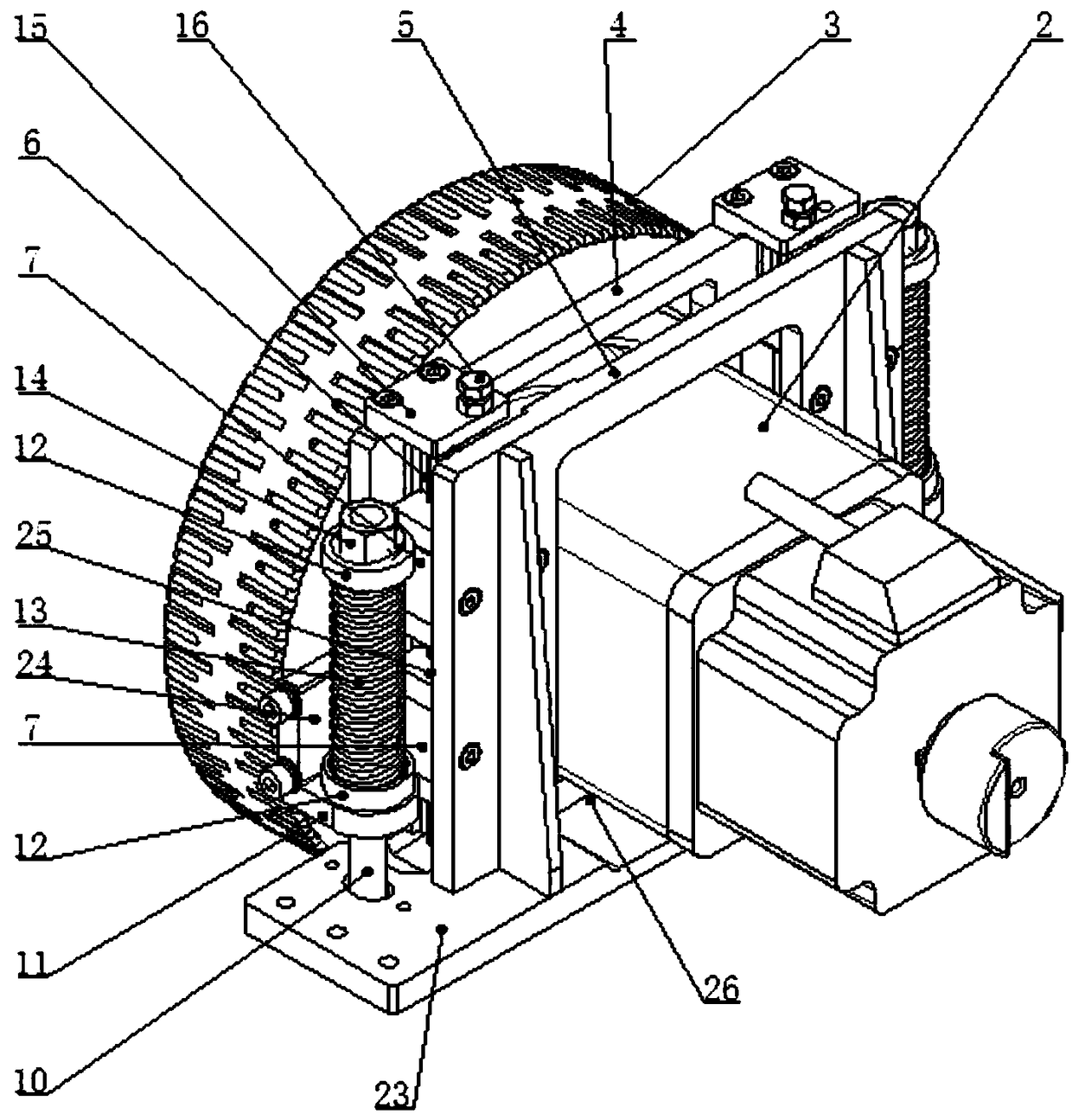

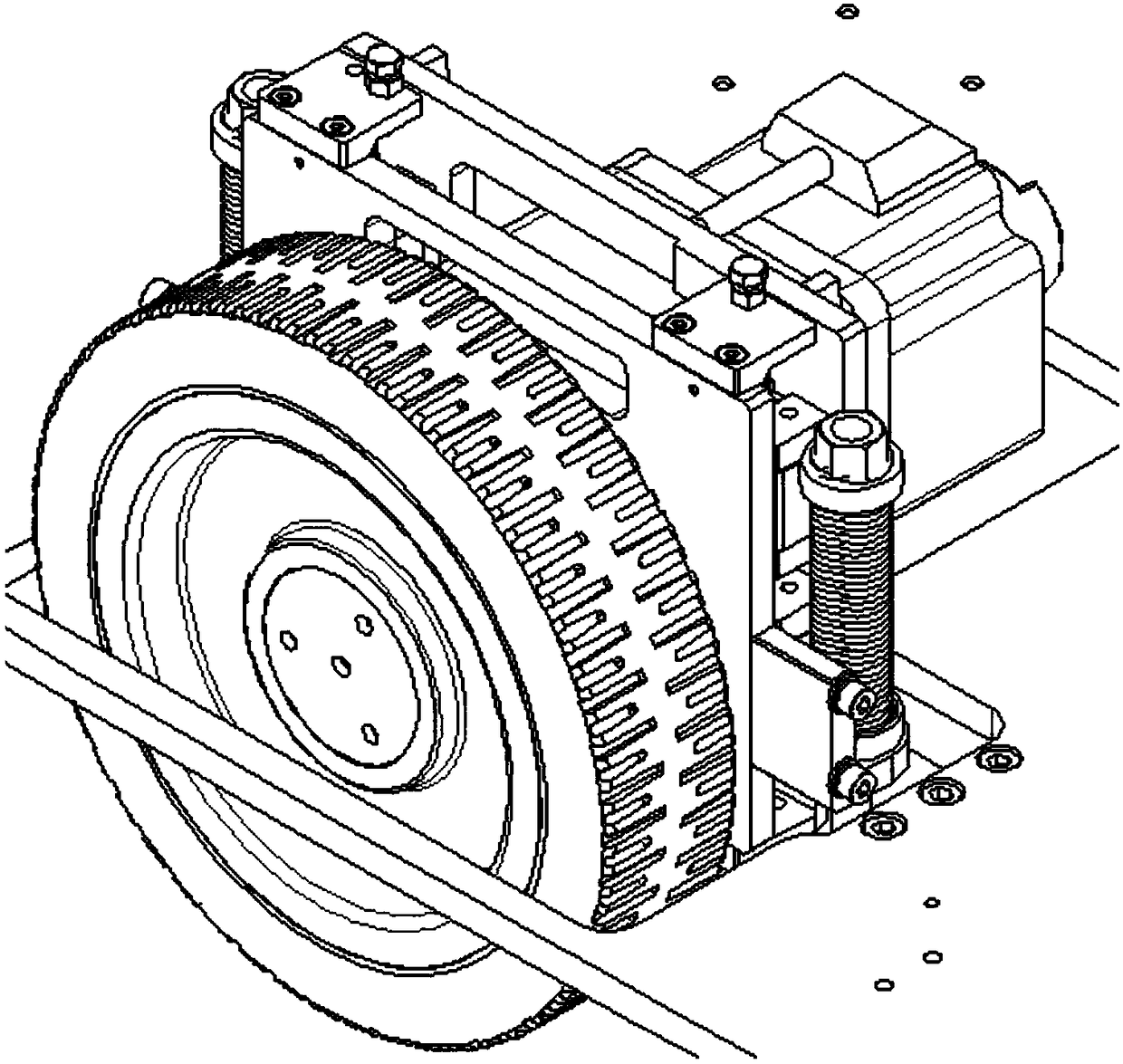

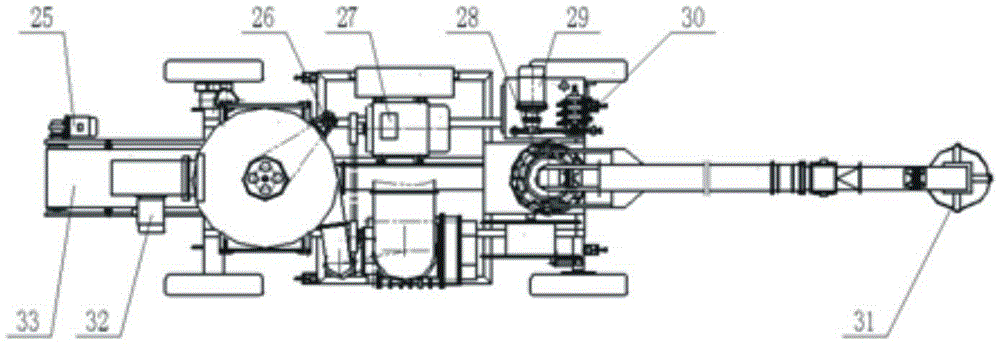

Driving wheel suspension damping mechanism for AGV, chassis and AGV

The invention discloses a driving wheel suspension damping mechanism for an AGV. The upper surface of a suspension damping mounting plate is fixedly connected with a sliding block fixing plate, and aplurality of sliding blocks are mounted on the side, close to a driving wheel, of the sliding block fixing plate. The suspension damping mounting plate is provided with two guide rods, and each of theguide rods is provided with a locknut, a first spring limiting pad, a rectangular spring, a second spring limiting pad and a spring fixing seat from top to bottom. A suspension structure adopts a structure of which a linear guide rail is matched with damping springs, the structure is simple and compact, the operation is smooth, the shock absorption effect is good, the bearing capacity is high, the adhesive force provided to the drive wheel is large, and the adaptability to a complex road surface is good.

Owner:严格科创发展(昆山)有限公司

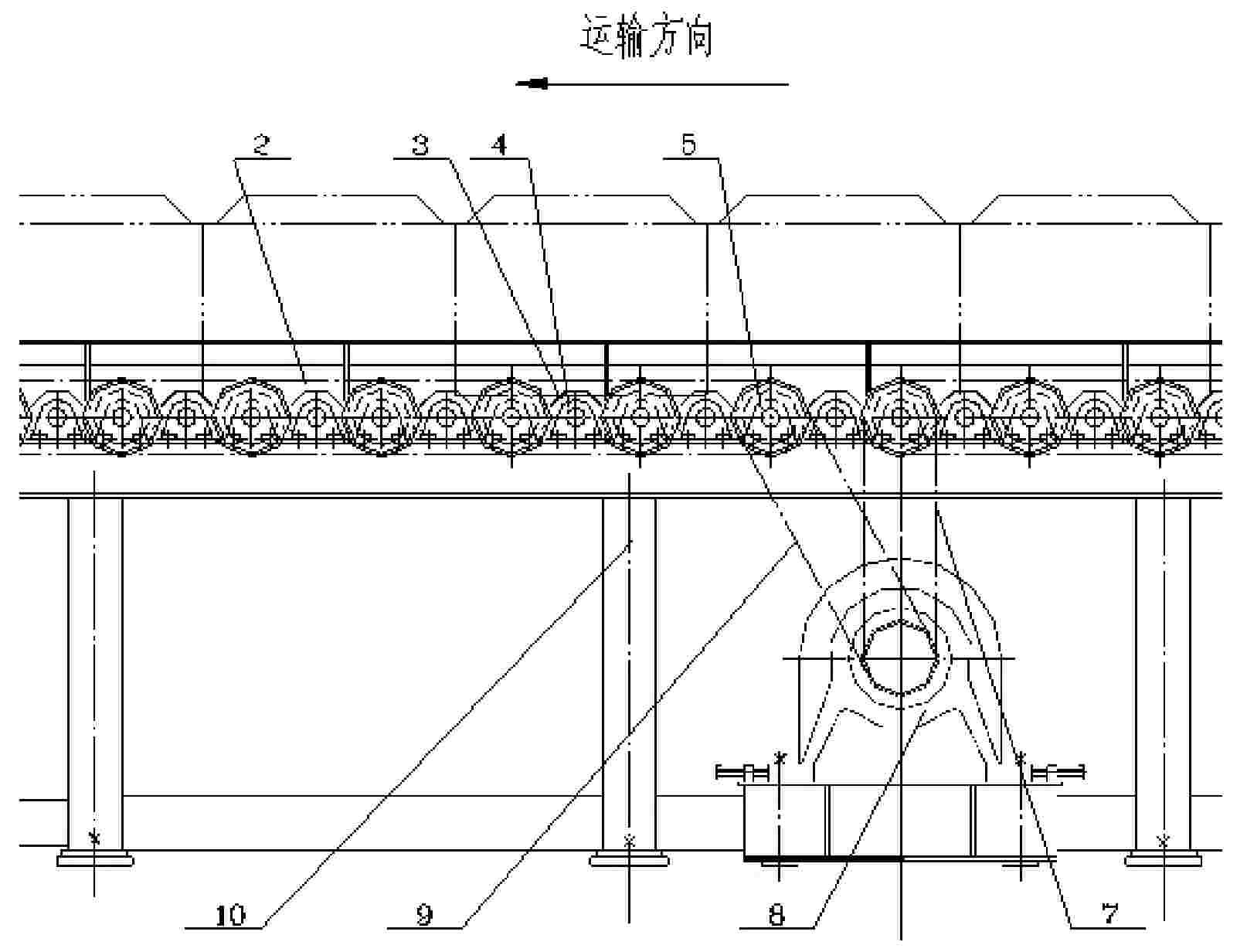

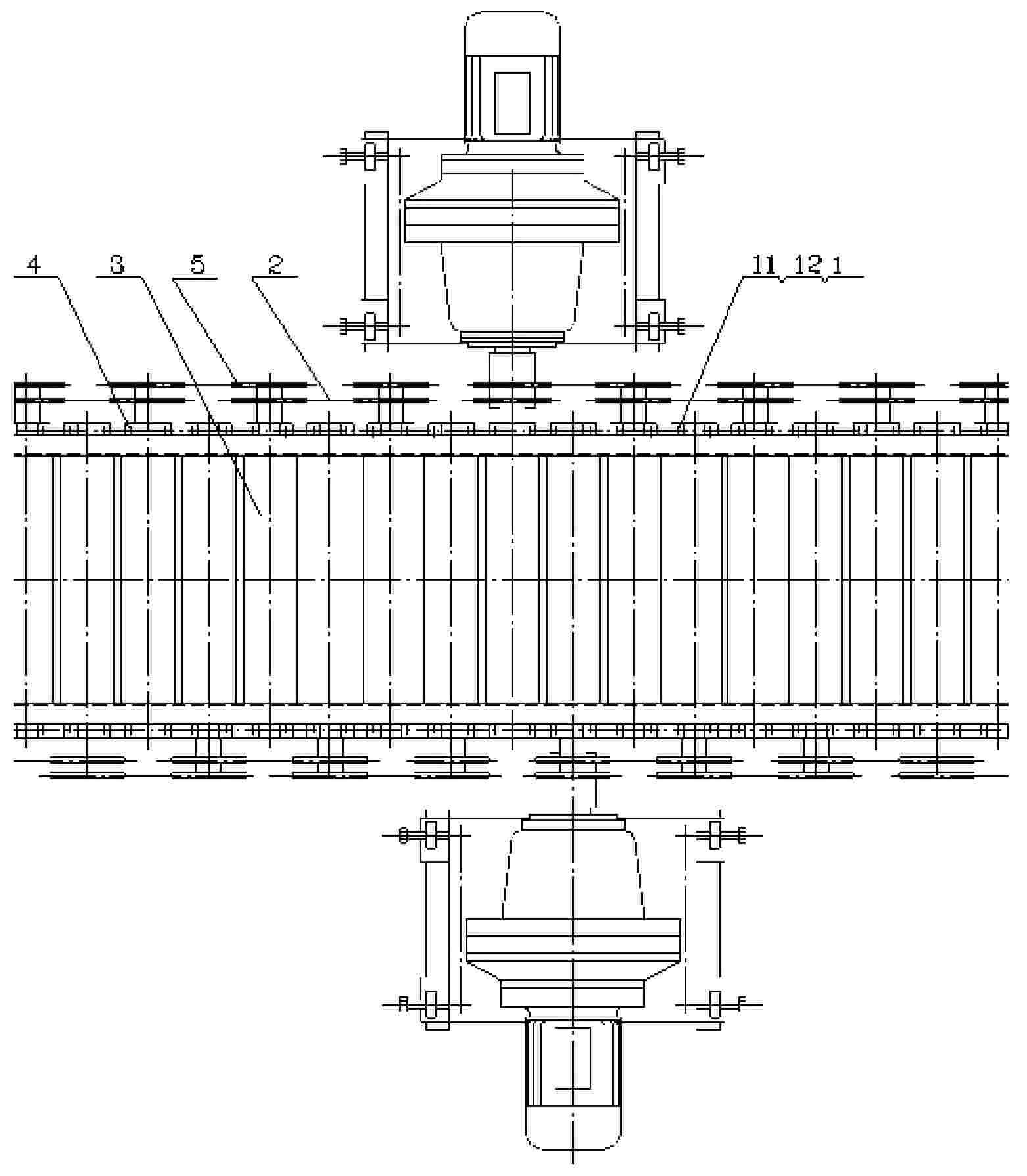

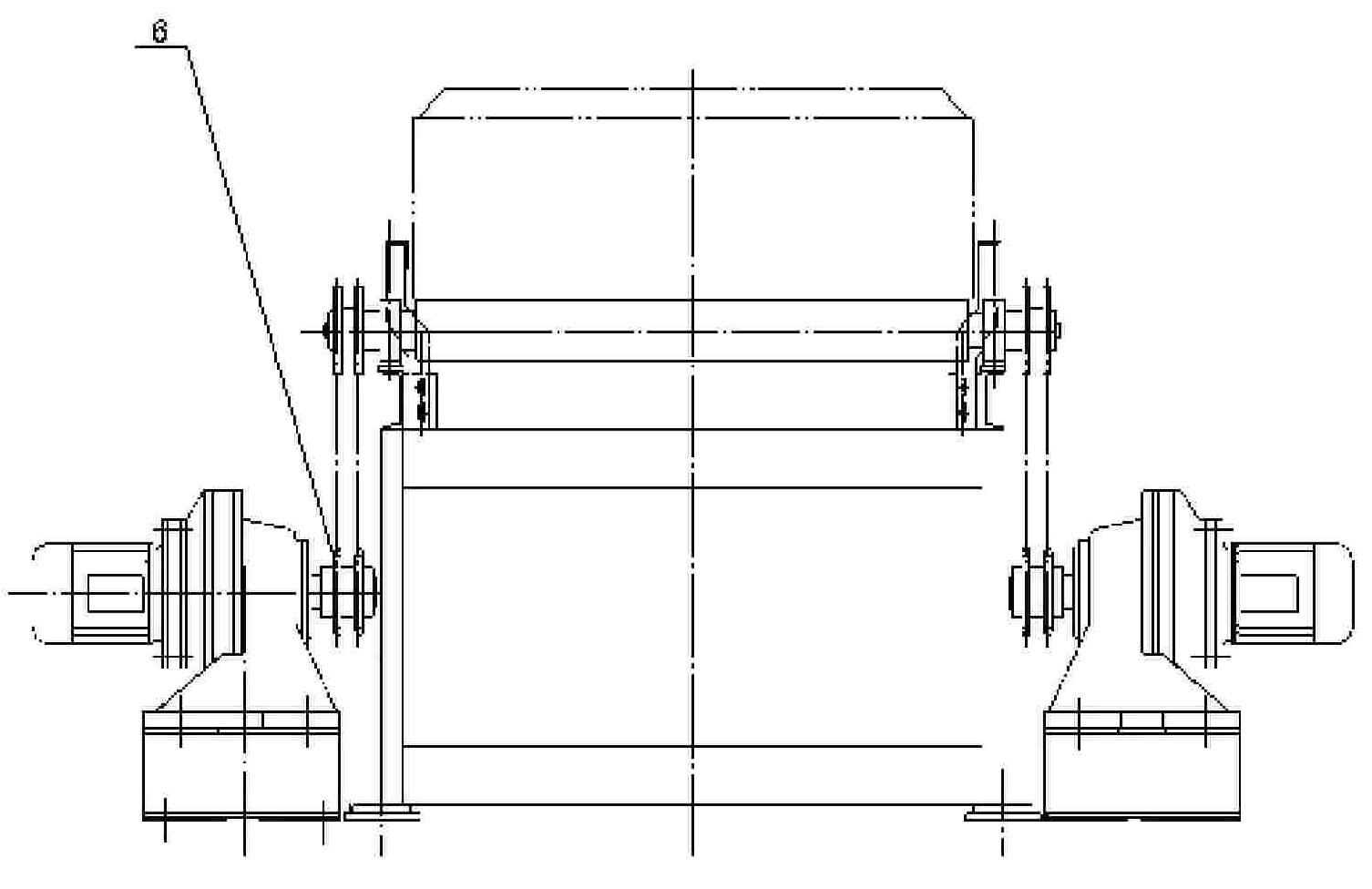

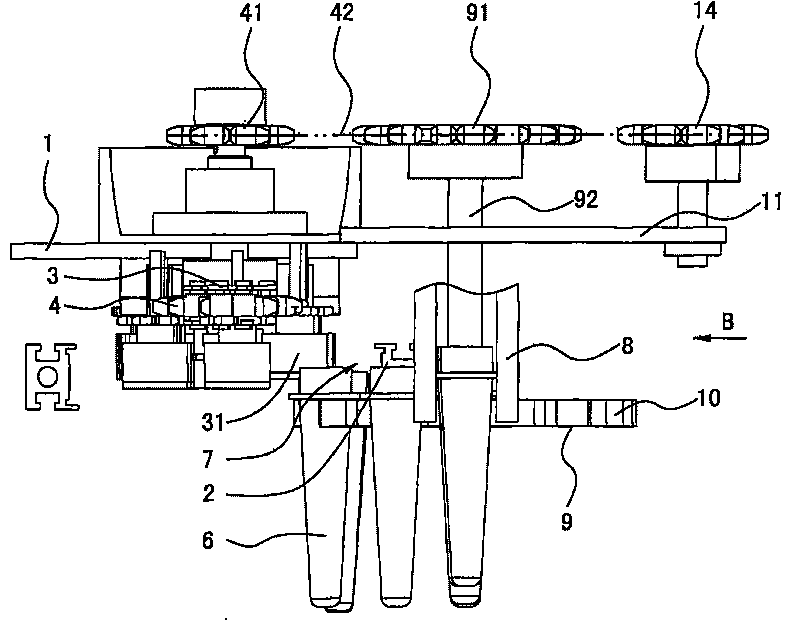

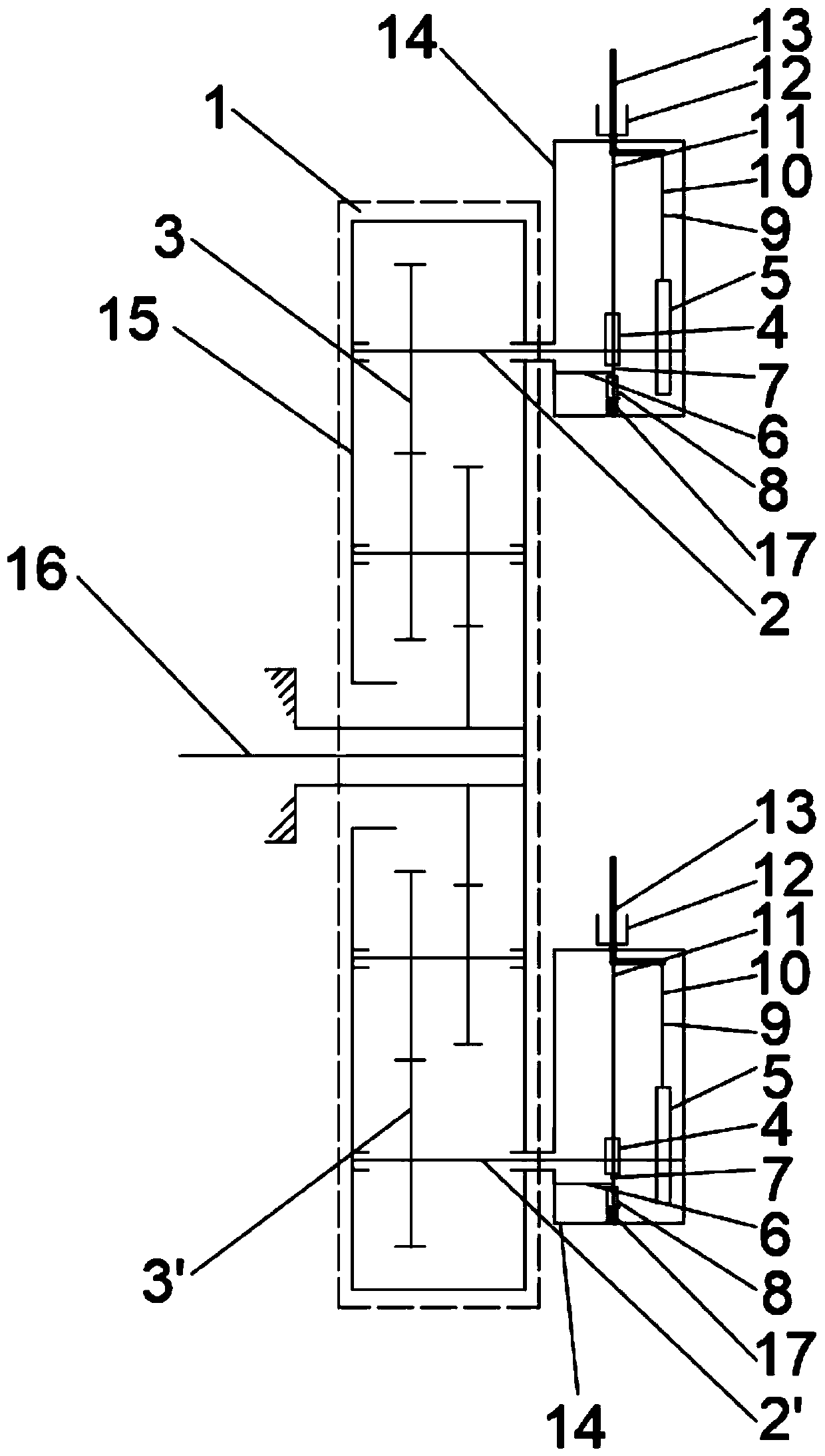

Double-roller bed conveyor device

The invention discloses a double-roller bed conveyor device used for conveying transversely running anode carbon blocks. Two reducers (8) are respectively arranged on the left and right of a frame (10) and are staggered by a space equal to that of a roller, and output shafts of the two reducers are respectively provided with a double row sprocket (6); one end of a driving roller (3) is provided with a double row sprocket (5) and a plummer block (4), while the other end is provided with only one plummer block (4); by taking the end of the driving roller (3) provided with the double row sprocket as a reference, two driving rollers are arranged on the frame (10) by the plummer blocks (4) through bolts, nuts and spring washers positively and reversely; one end of a driving chain (7) and one end of a driving chain (9) are hooked to the double row sprockets (6) of the output shafts of the reducers, while the other ends are hooked to the double row sprocket (5) arranged on the driving roller (3); and double row sprockets (5) are respectively connected through a traction chain (2). The invention has the advantage that: the double-roller bed conveyor device is stable to convey, simple and compact in structure, convenient to use, and convenient to install and maintain.

Owner:GUIYANG AL-MG DESIGN & RES INST

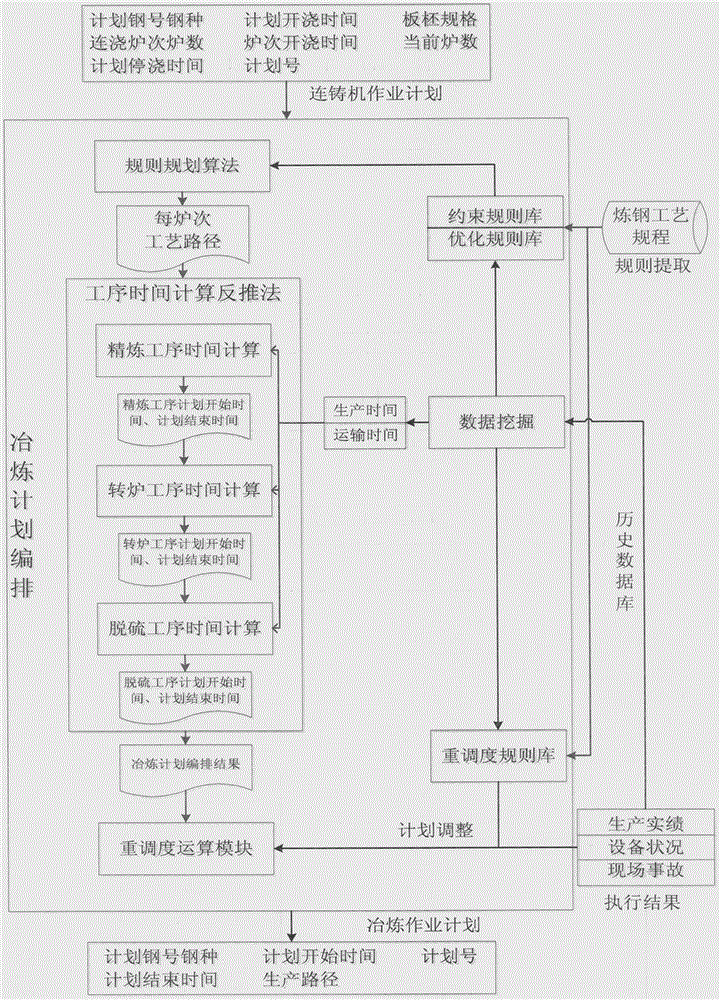

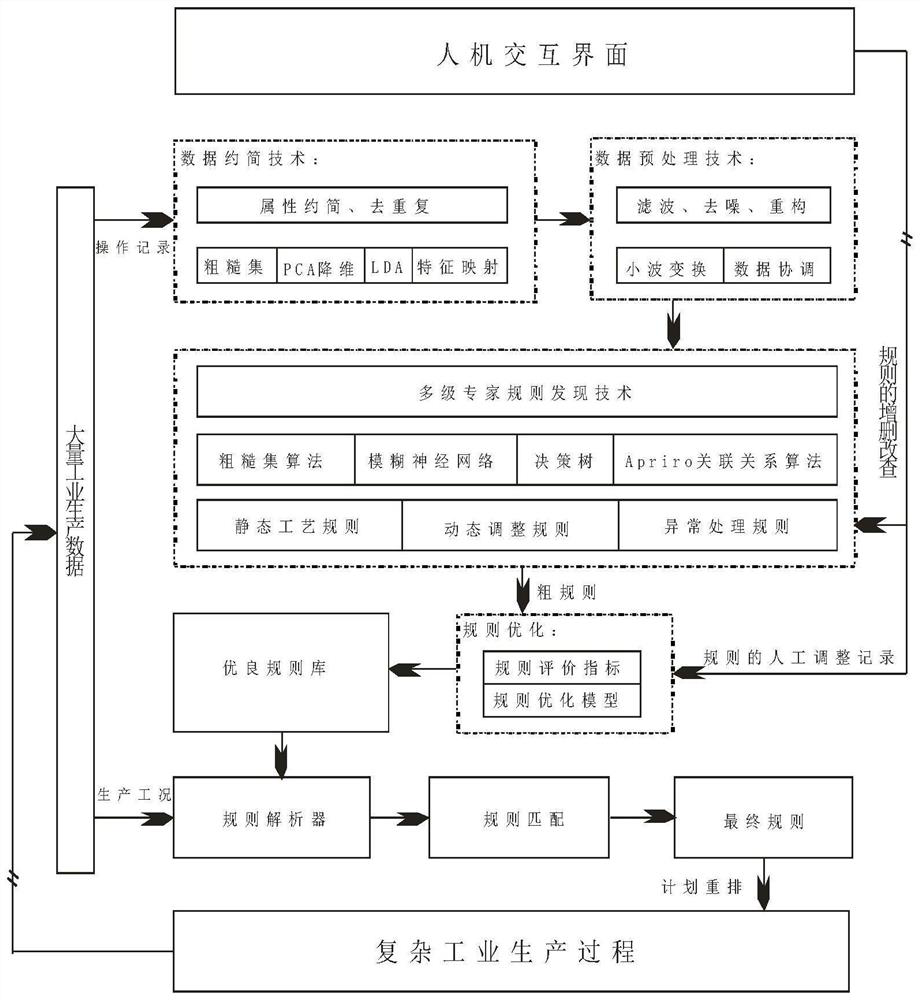

Steelmaking production plan intelligent scheduling method based on big data rule self-learning

The invention discloses a steelmaking production plan intelligent scheduling method based on big data rule self-learning, and the method mainly comprises the following steps: 1), forming a schedulingdecision table according to historical scheduling records, alignment time, scenes and scheduling operation; 2) rule mining: generating a rule base from historical records by adopting rule mining algorithms such as a rough set and deep learning; 3) plan arrangement: based on a continuous casting machine plan of actual data, based on a bottom layer equipment scheduling plan of container tracking technology, a production operation plan based on a time parallel back calculation method; 4) disturbance rearrangement: realizing intelligent rearrangement based on a rule description mode of'disturbance+ scene description + adjustment strategy 'and an expert rule base; and 5) plan display: displaying the operation plan through a Gantt chart, and providing dynamic interface adjustment. By means of the method, efficient and orderly operation of the steelmaking-continuous casting production process is ensured, the production and operation cost is reduced, energy is saved, consumption is reduced, the production efficiency is improved, and maximization of enterprise benefits is achieved.

Owner:HUNAN NORMAL UNIVERSITY

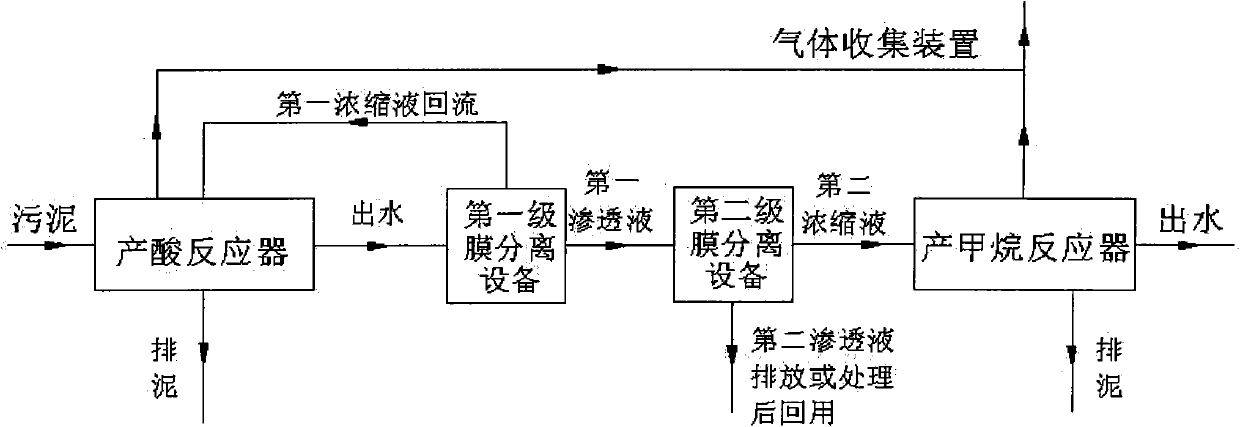

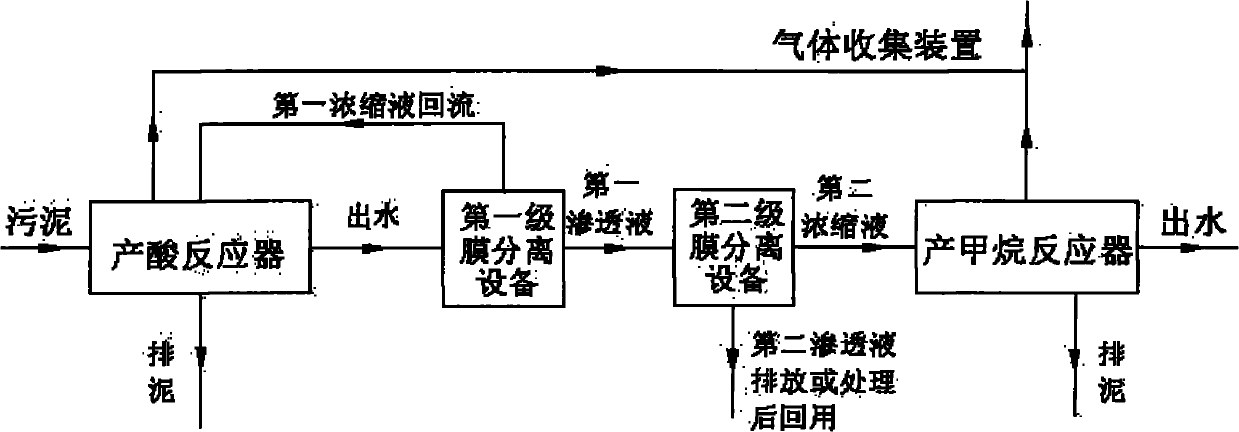

Municipal sludge energy treatment system

ActiveCN101905945AAchieve separationHigh activityWaste based fuelBiological sludge treatmentSeparation technologyKinetic control

The invention belongs to the field of sludge treatment and relates to a municipal sludge energy treatment system. The system comprises an acidogenic reactor and a methanogenic reactor; and first-level membrane separation equipment and second-level membrane separation equipment are arranged between the acidogenic reactor and a methanogenic reactor. The sludge passes through the acidogenic reactor and is hydrolyzed to generate acid in the methanogenic reactor, and then passes through the first-level membrane separation equipment to be separated into first concentrated solution and first penetrating fluid. The first concentrated solution reflows to the acidogenic reactor, and the first penetrating fluid enters the second-level membrane separation equipment to be separated into second concentrated solution and second penetrating fluid; and the second concentrated solution enters the methanogenic reactor to be fermented to generate methane. By organically combining the two-phase anaerobic digestion technology with the membrane separation technology, the municipal sludge energy treatment system realizes the combination of a physical dialysis method and a kinetic control method and really realizes the separation of fermentative bacteria bacteria and methanogenic bacteria. Therefore, the bacteria in two phases can exert the maximum activity, and the operating stability and energy efficiency of the whole system are improved.

Owner:广州微启生物科技有限公司

Knowledge representation-based steel production scheduling model matching method

InactiveCN106647674AThe whole process of steelmaking is orderlyGuaranteed uptimeEnergy industryTotal factory controlOperational costsOrder form

The invention provides a knowledge representation-based steel production scheduling model matching method which specifically comprises the following steps: 1) a production plan is input, and the production plan comprises a production order and a hot delivery and hot charging production plan given by a hot rolling workshop; 2) a slab quantity is calculated; the order is decomposed based on steel types, slab specifications and delivery dates; 3) a casting order is arranged, and all castings are ordered according to difference between continuous caster usage conditions and order delivery dates; 4) characteristic signals are collected, and characteristic signals of a key position of a bottom layer device can be obtained via a corresponding sensor; 5) a crown block optimization algorithm is performed; 6) a transport task state is switched; 7) a plan is rearranged; 8) the adjusted plan is displayed to a scheduling worker in a form of a Gantt chart. Via the matching method, production safety of steel making processes can be ensured, production and operation costs can be lowered, energy can be saved, enterprise management can be enhanced, production efficiency can be improved, and enterprise profit maximization can be facilitated.

Owner:WUHAN UNIV OF SCI & TECH

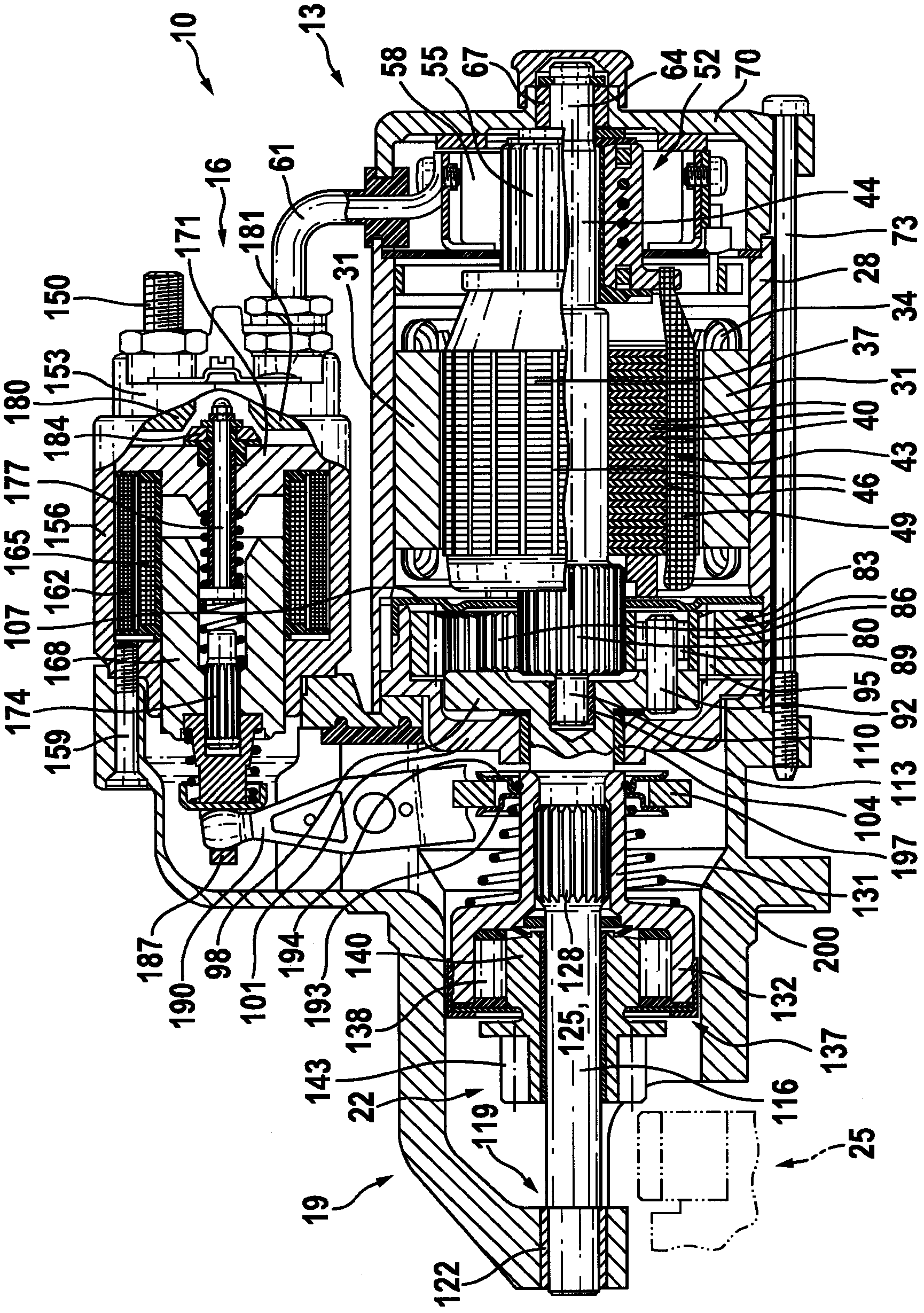

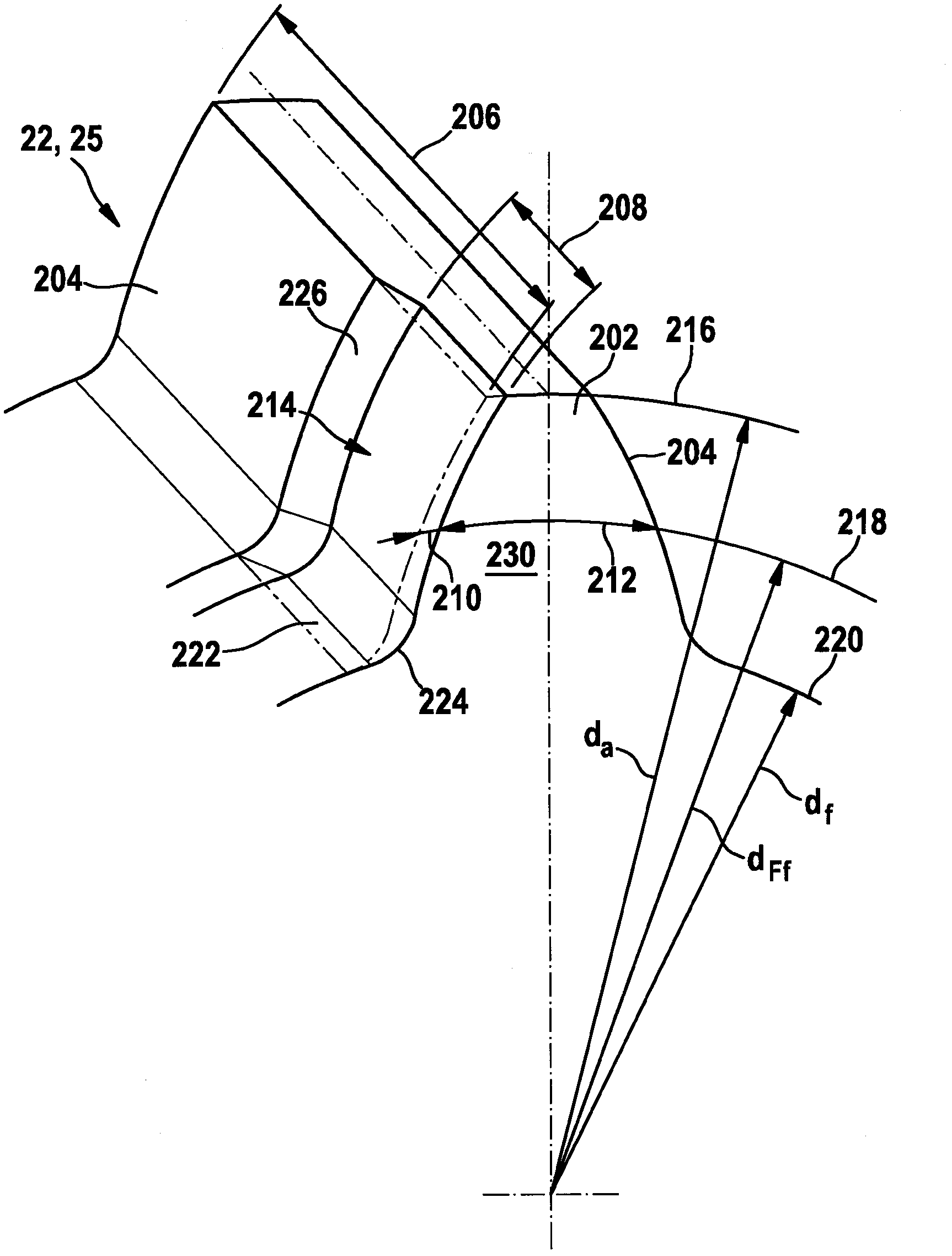

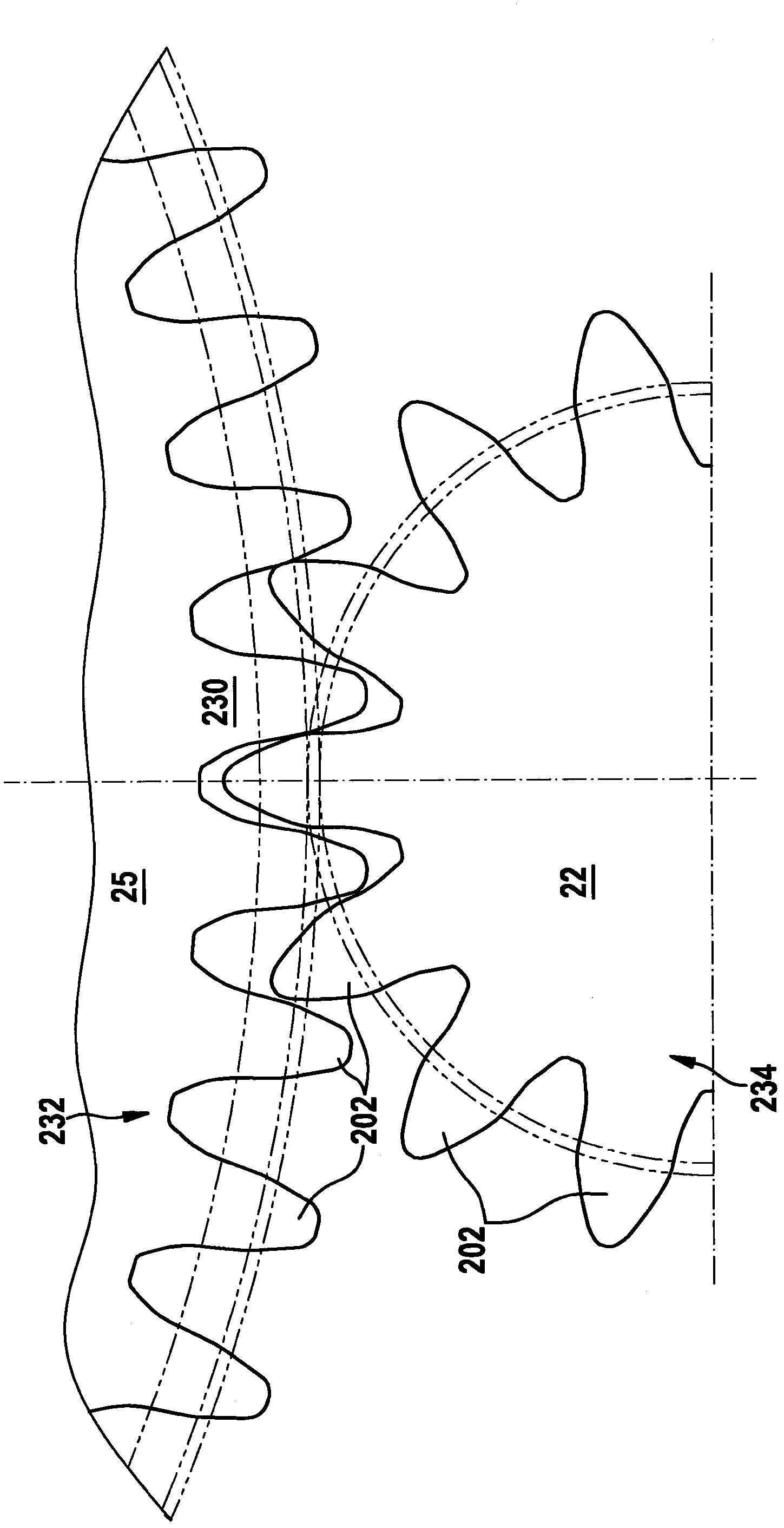

Noise-optimized toothing system

ActiveCN102918257AImprove noiseImproved vibration characteristicsPower operated startersGear vibration/noise dampingElectric machineInternal combustion engine

The invention relates to an electric machine, in particular a starter device (10) for an internal combustion engine. The electric machine comprises a noise-optimized toothing system (232, 234) of two gearwheels (22, 25) which can be brought into engagement with one another. The noise-optimized toothing system (232, 234) is configured as an extra-deep toothing system on at least one of the gearwheels (22, 25). The extra-deep toothing system has an asymmetrical toothing profile (214).

Owner:SEG AUTOMOTIVE GERMANY GMBH

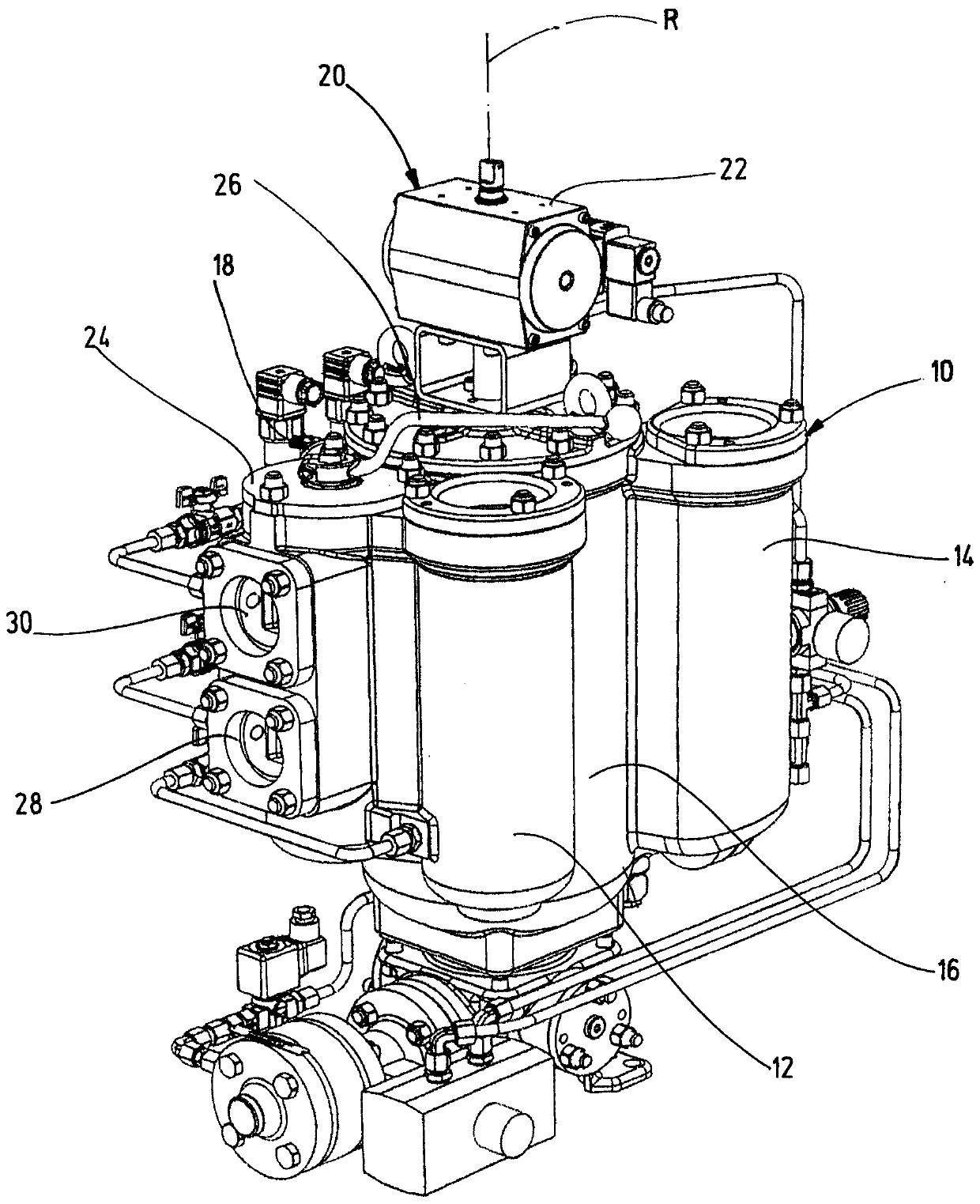

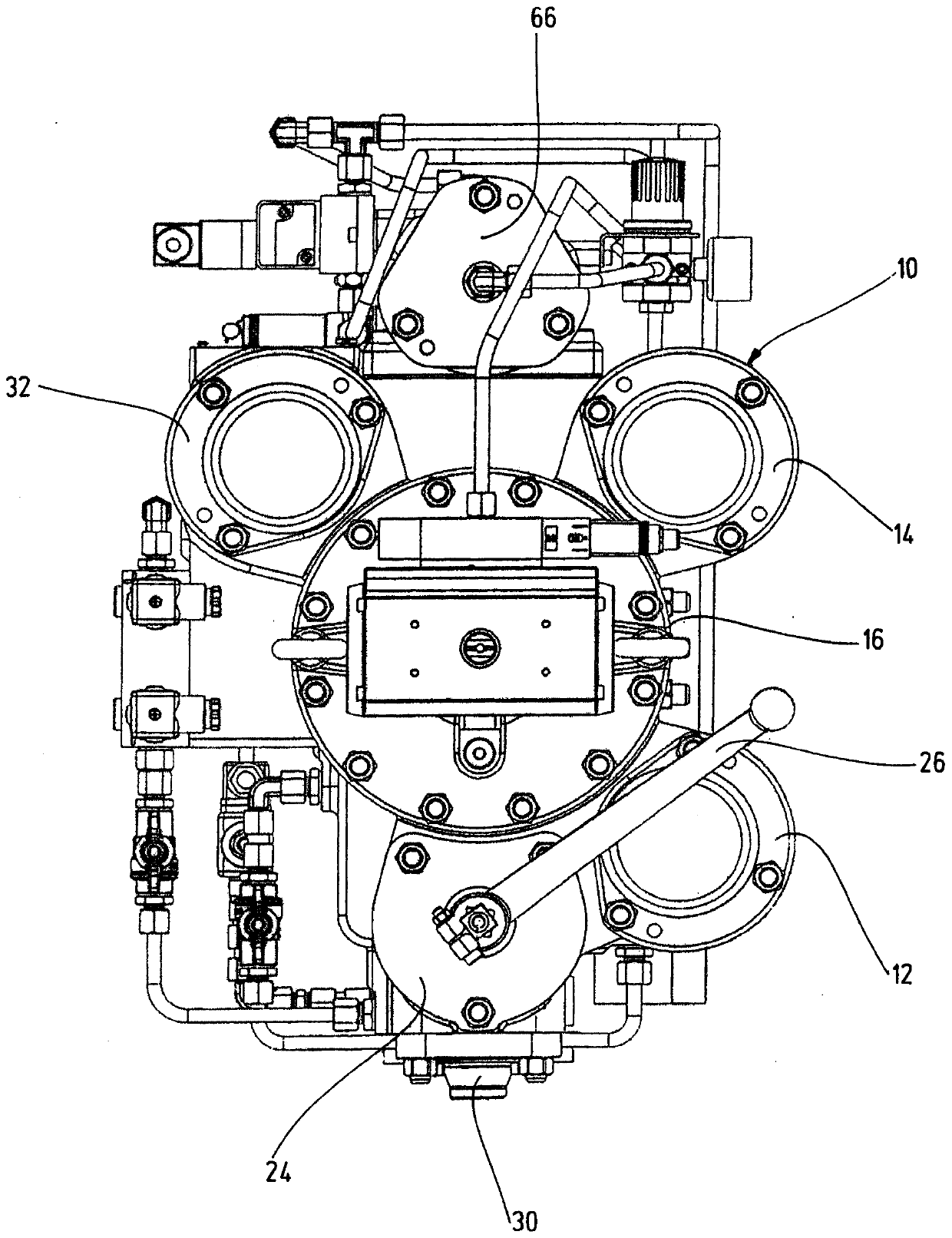

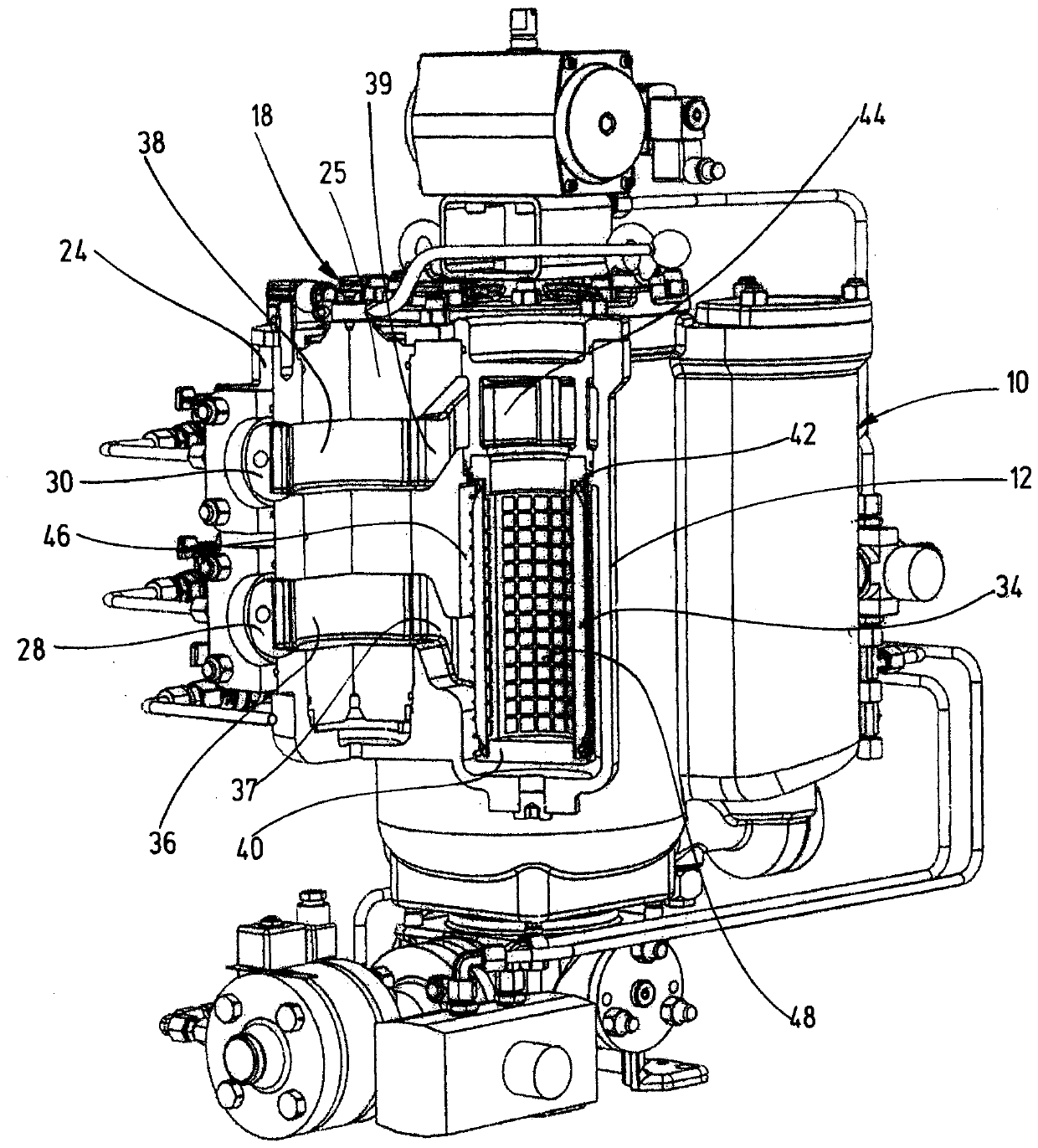

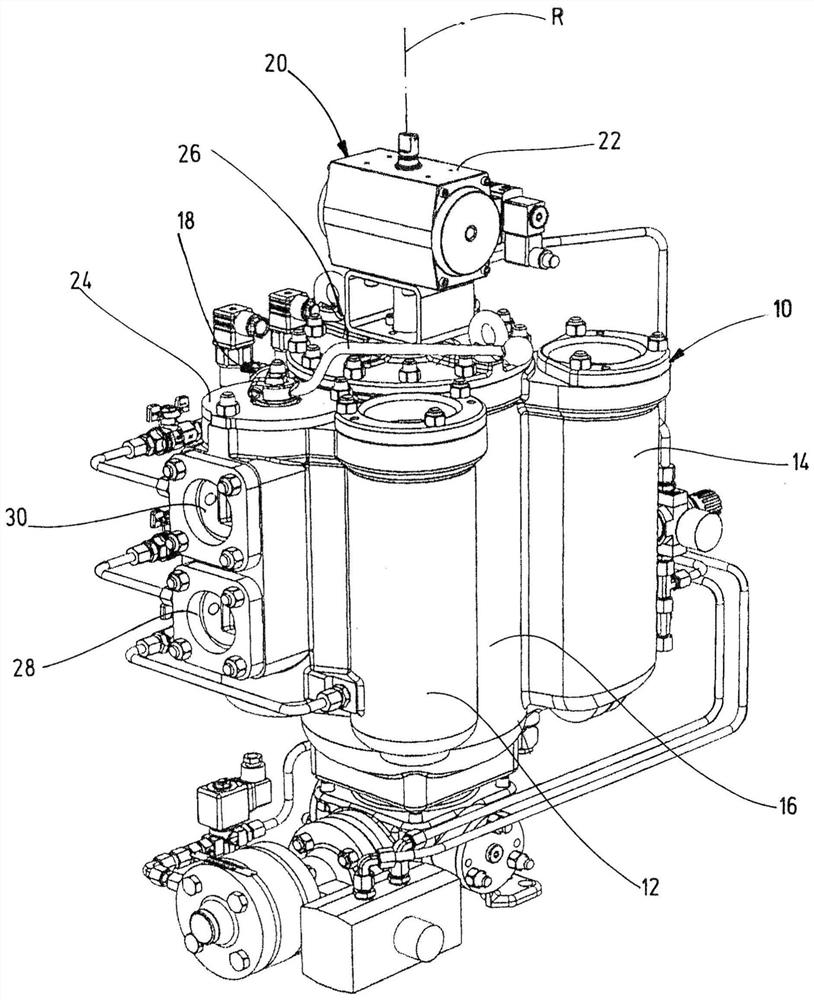

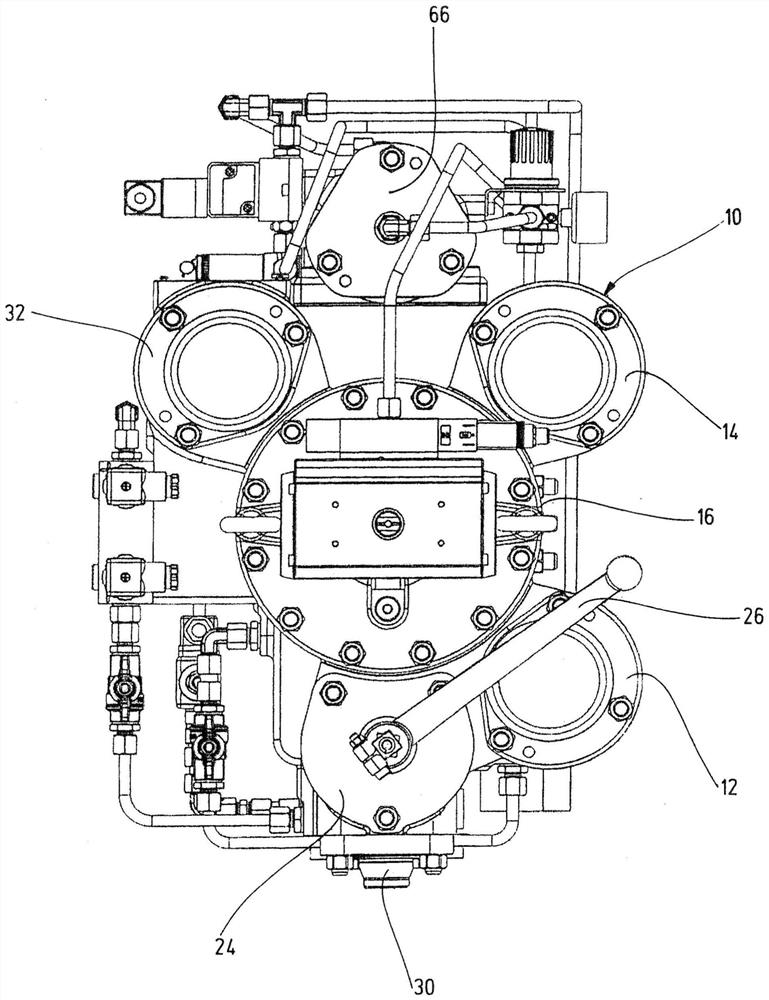

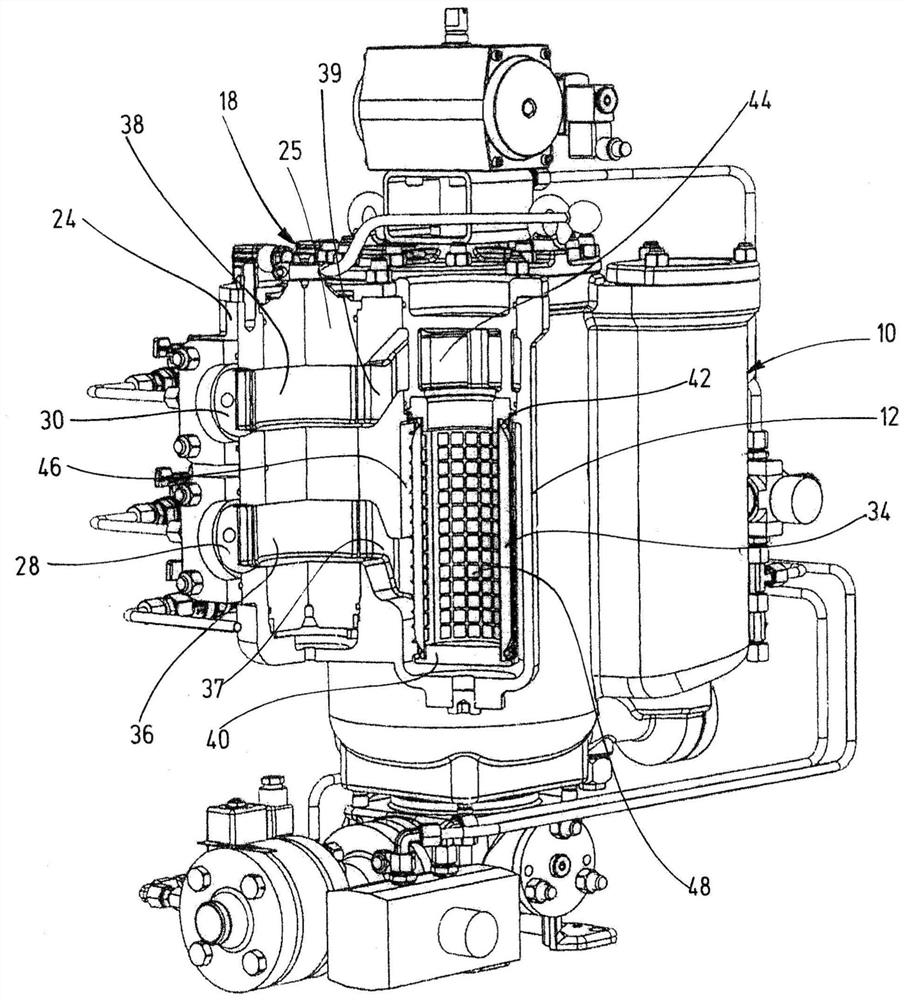

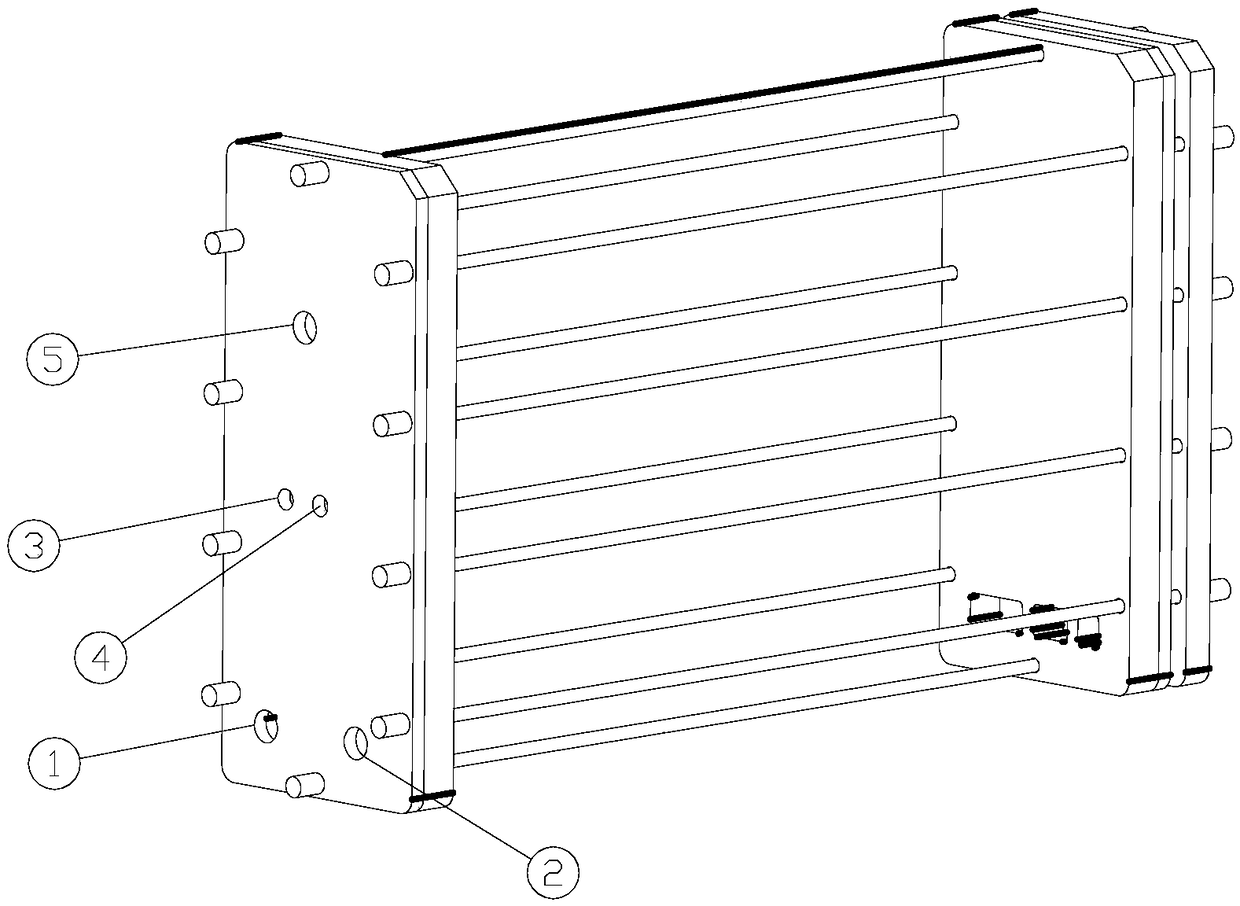

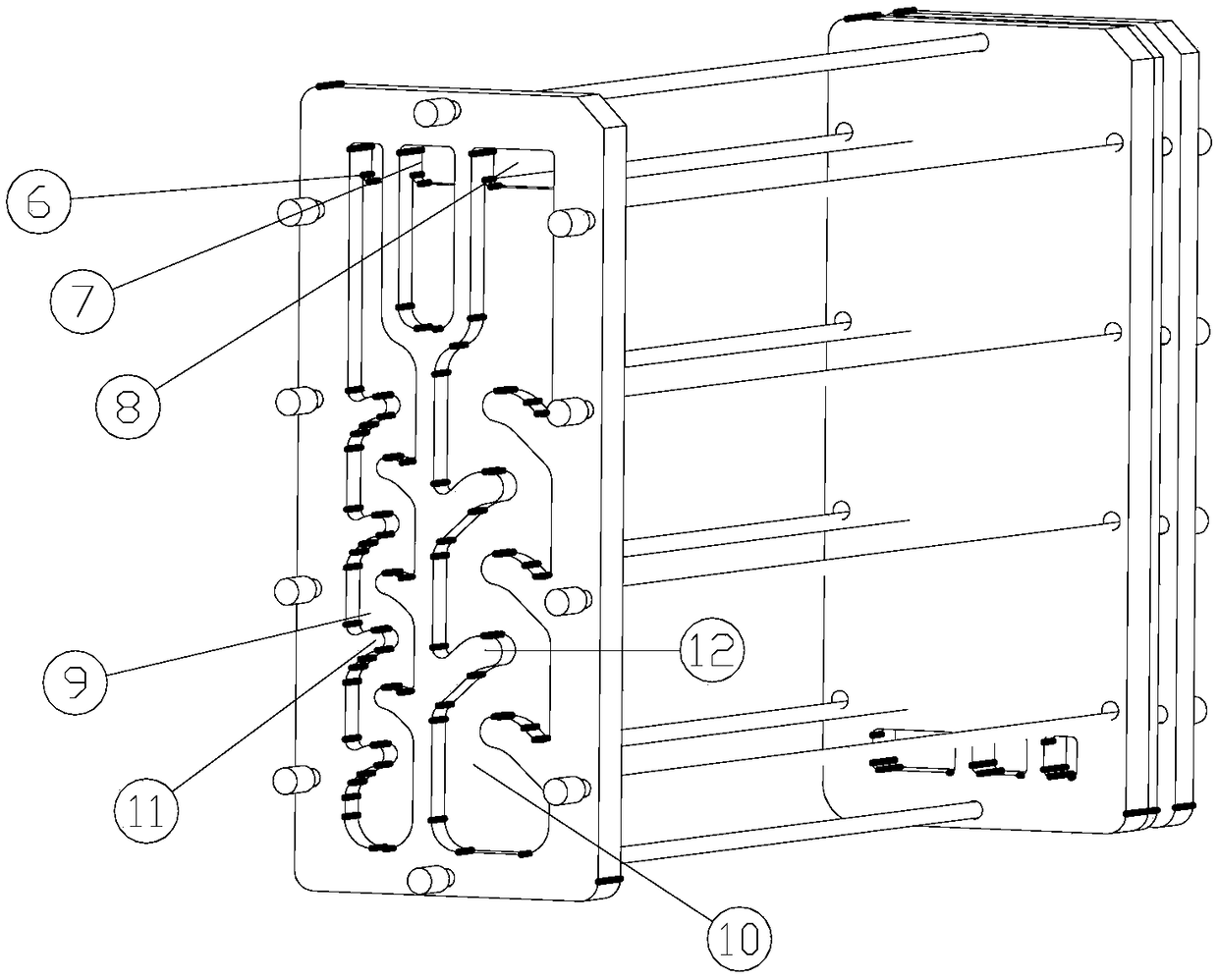

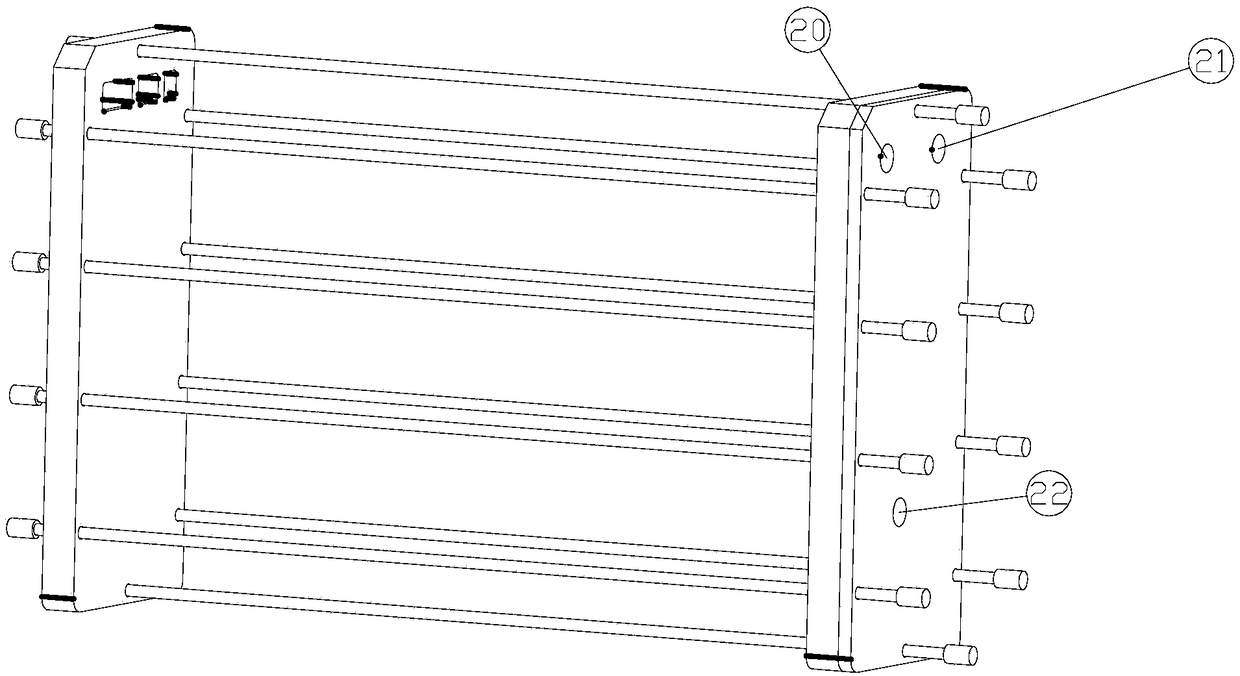

Filter apparatus

ActiveCN111263657ASimple operabilitySimple structure costsMembrane filtersStationary filtering element filtersEnvironmental engineeringMechanical engineering

The invention relates to a filter apparatus for cleaning particulate contaminants out of a fluid flow, having a plurality of filter elements (34, 60), which, received in filter chambers (12, 14, 32) as a component of a common filter housing (10), group about a backwash device (20), which, in order to receive a backwash volume, has a piston accumulator (56), in the accumulator housing (64) of whicha piston (57) is guided in a longitudinally movable manner, said piston, actuated by a pressure medium, forwarding the backwash volume stored in the accumulator housing (64) to at least one filter element (60), which is to be backwashed for cleaning thereof, via a backwash device (20), which also undertakes removal of the backwash volume from the filter apparatus, characterized in that a specificfilter element, as a bypass filter element (34), which is selected from the plurality of filter elements (34, 60), solely undertakes the particle cleaning after actuating a changeover device (18), and the other filter elements (60) are excluded from said cleaning.

Owner:HYDAC PROCESS TECH

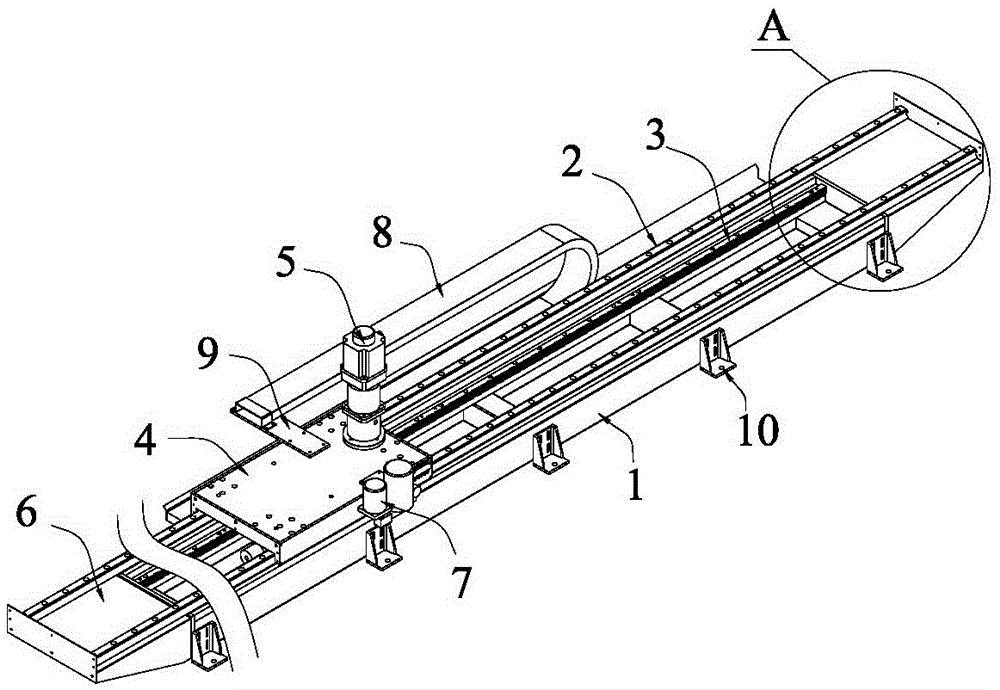

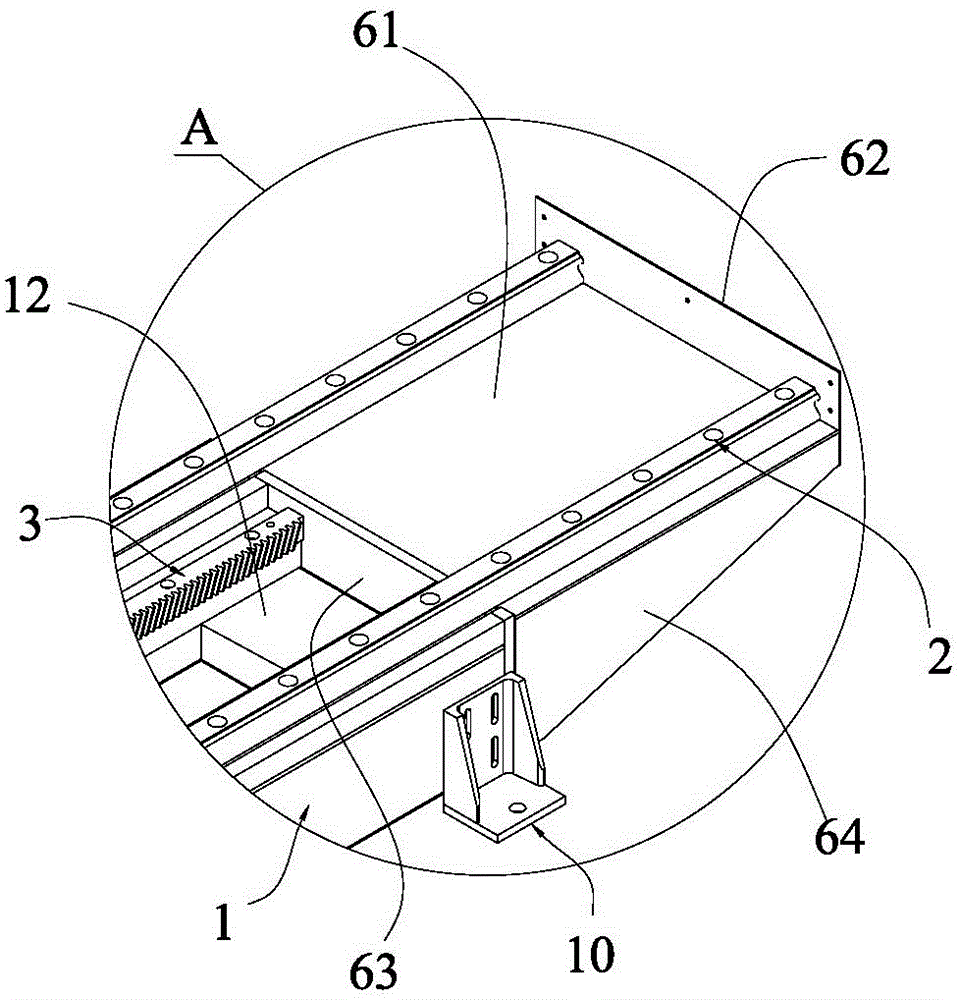

Large-stroke heavy-load slipway structure

ActiveCN105135159AReduce shear forceReasonable structural designGear lubrication/coolingStands/trestlesSlide plateEngineering

The invention discloses a large-stroke heavy-load slipway structure which comprises a slipway frame body, linear sliding rails, a transmission rack, a load sliding plate, a power output device, a dustproof blocking piece and an oil supply device. The two linear sliding rails are symmetrically arranged on the two sides of the upper surface of the slipway frame body. The transmission rack is arranged on one side wall of a containing groove. The portion, corresponding to the transmission rack in position, of the power output device is arranged on the load sliding plate. The output end of the power output device is provided with a transmission gear engaged with the transmission rack. The large-stroke heavy-load slipway structure is clever and reasonable in structural design, the transmission rack is located between the two liner sliding rails, the shearing force between a guide rail and a sliding block is lowered effectively, operation stability is good, and site occupation is avoided; the structure is more compact, the occupied area is reduced, and a dustproof structure is simplified greatly; and the oil supply device can supply oil to all movable parts regularly so that a device can operate more flexibly and stably, working efficiency is improved, and wide application and popularization are facilitated.

Owner:DONGGUAN LEBAOT ROBOT

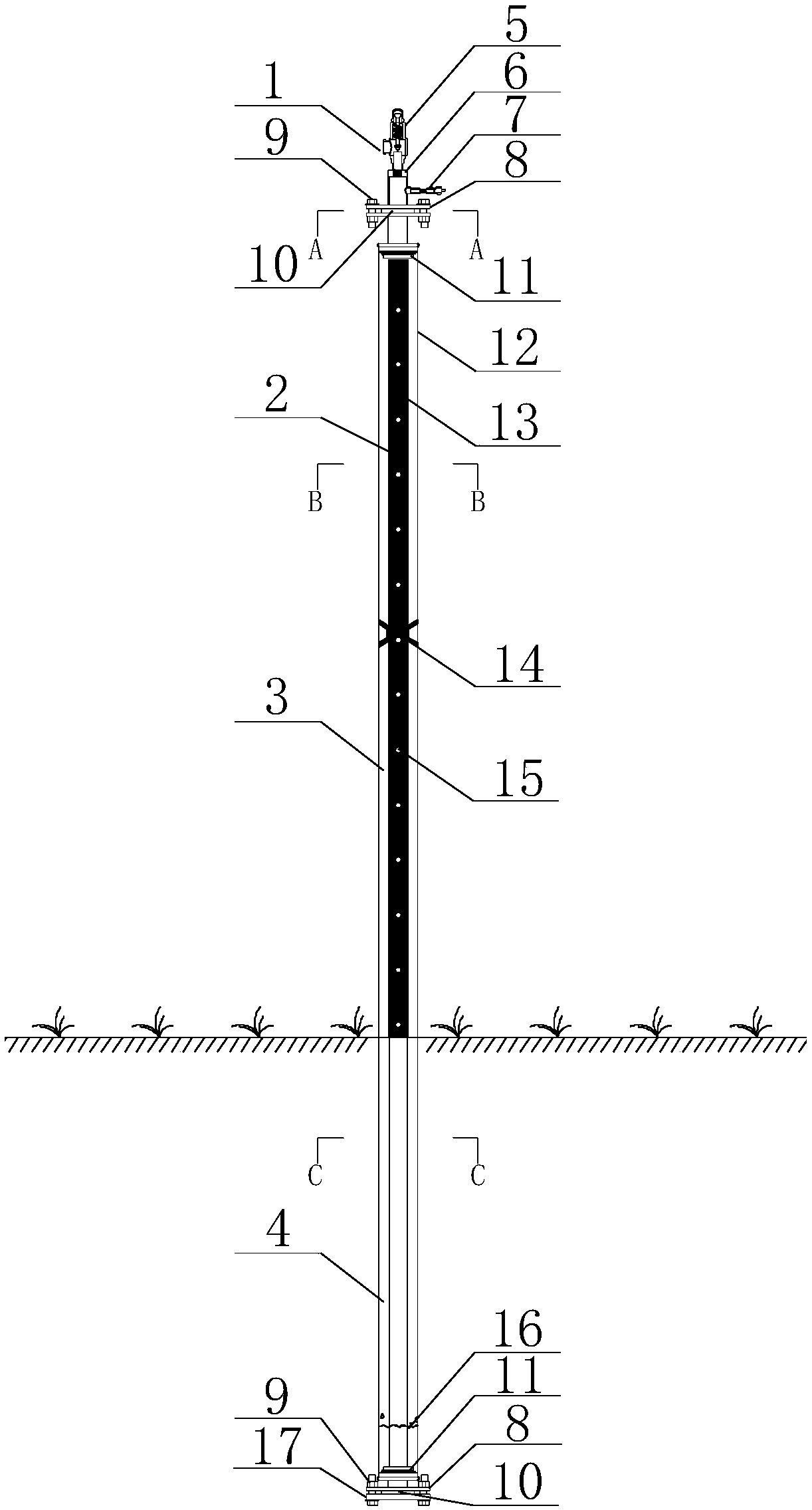

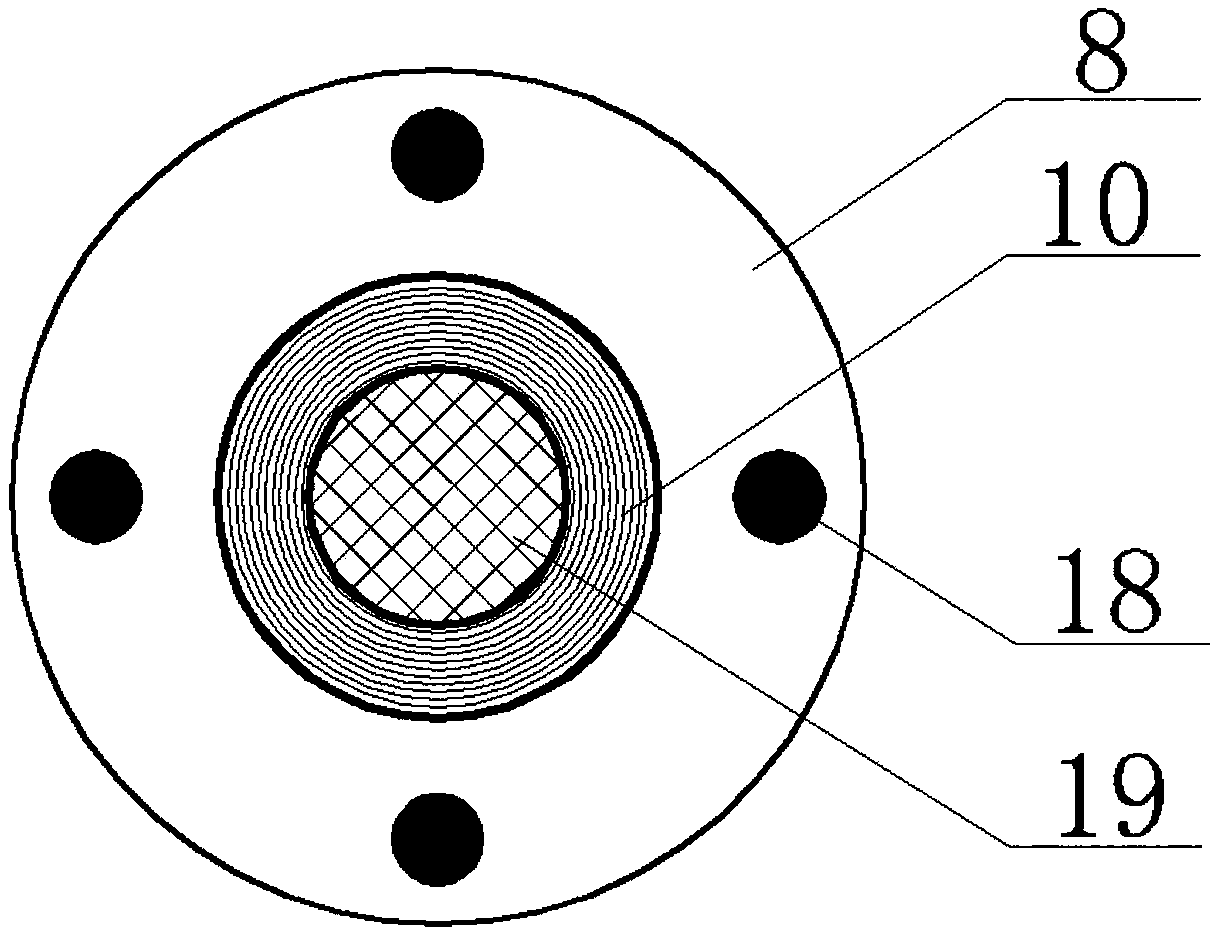

Solar adsorption type refrigeration device and method for subgrade engineering in permafrost regions

ActiveCN107782014AInhibit segregation and frost heaveSeparation and frost heavingSolar heating energyClimate change adaptationAdsorption refrigerationPermafrost degradation

An embodiment of the invention provides a solar adsorption type refrigeration device and method for subgrade engineering in permafrost regions. The device mainly comprises a stainless steel pipe, a glass pipe, a mechanical sealing structure and connecting components, wherein the stainless steel pipe is nested in the glass pipe to form a vacuum casing pipe structure, the mechanical sealing structure is arranged at the top of the vacuum casing pipe structure, the part, embedded in frozen soil foundation, of the vacuum casing pipe structure is an evaporative refrigeration section, the part abovethe ground comprises a heat collecting / adsorbing section and a condensation section, and the heat collecting / adsorbing section and the evaporative refrigeration section are filled with an adsorbent and a refrigerant respectively; the heat collecting / adsorbing section automatically converts solar energy into heat energy to drive adsorption refrigeration cycle, and the refrigerant desorption processand the adsorption process is circularly performed by use of the night and day difference of solar intensity. Solar energy can be utilized for automatic adsorption refrigeration, frozen soil is efficiently protected in real time, and permafrost degradation and subgrade engineering heat damage are prevented effectively.

Owner:BEIJING JIAOTONG UNIV

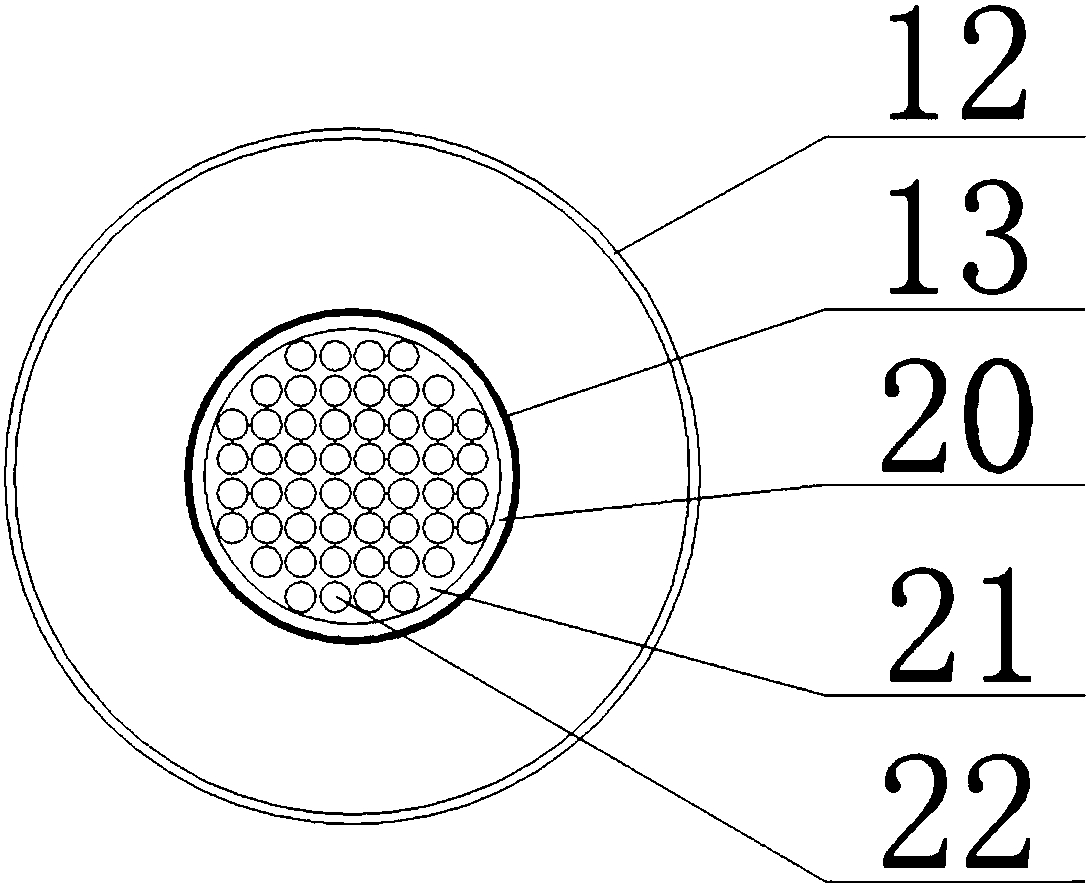

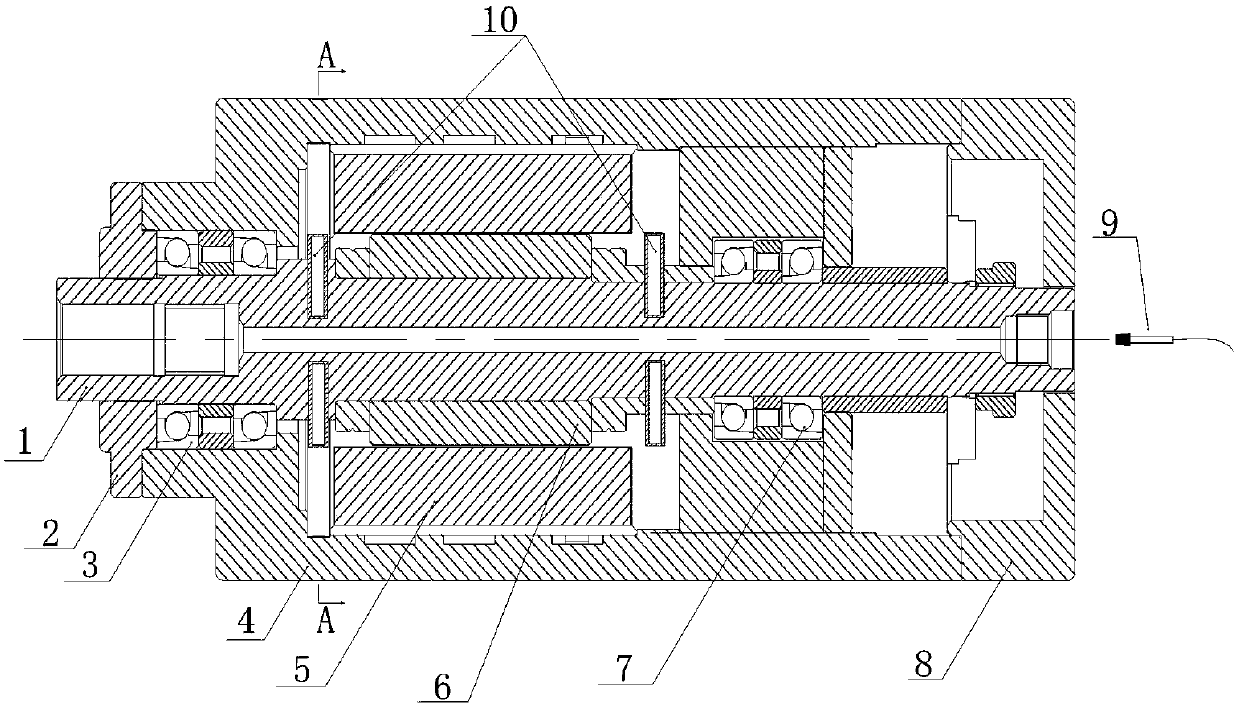

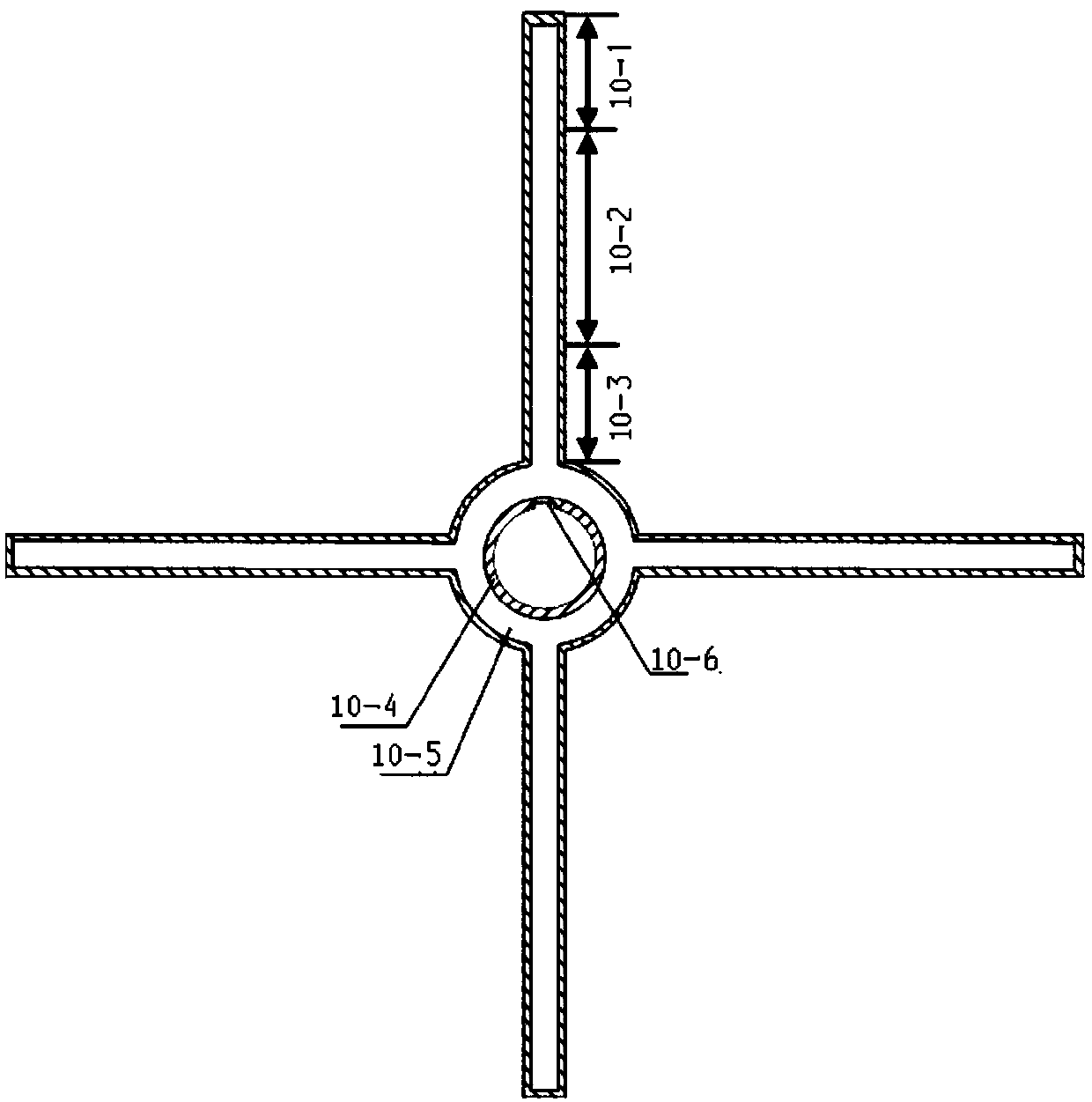

Radially-rotating heat pipe structure for cooling high-speed electric spindle inner cavity

InactiveCN107717625AImprove heat transfer effectEasy to implementMaintainance and safety accessoriesElectricityStator

The invention provides a radially-rotating heat pipe structure for cooling a high-speed electric spindle inner cavity. Radially-rotating heat pipe assemblies are mounted on the positions, at the frontends and the rear ends of a motor stator and a motor rotor in an electric spindle, of a rotary shaft and used for guiding out an air gap between the motor stator and the motor rotor and heat generated by the outer circles of a front bearing set and a rear bearing set. Each radially-rotating heat pipe assembly comprises three or more uniformly-distributed radially-rotating heat pipe, all the radially-rotating heat pipes mutually communicate with one another through a communicating cavity in the center, and a mounting ring in the middle of the communicating cavity is fixed to the rotary shaft.Each radially-rotating heat pipe is composed of three parts, an evaporating section at the top, a heat insulation section in the middle and a condensing section at the bottom, and the pipeline lengthof each radially-rotating heat pipe needs to enable the corresponding evaporating section of the mounted radially-rotating heat pipe to be exactly located at the gap between the motor stator and the motor rotor. The radially-rotating heat pipe structure for cooling the high-speed electric spindle inner cavity is capable of reducing heat deformation of a spindle and improving machining accuracy andmeanwhile further has the advantages that the reliability is high, change of an original structure of the electric spindle is small, and the cost is low.

Owner:XI AN JIAOTONG UNIV

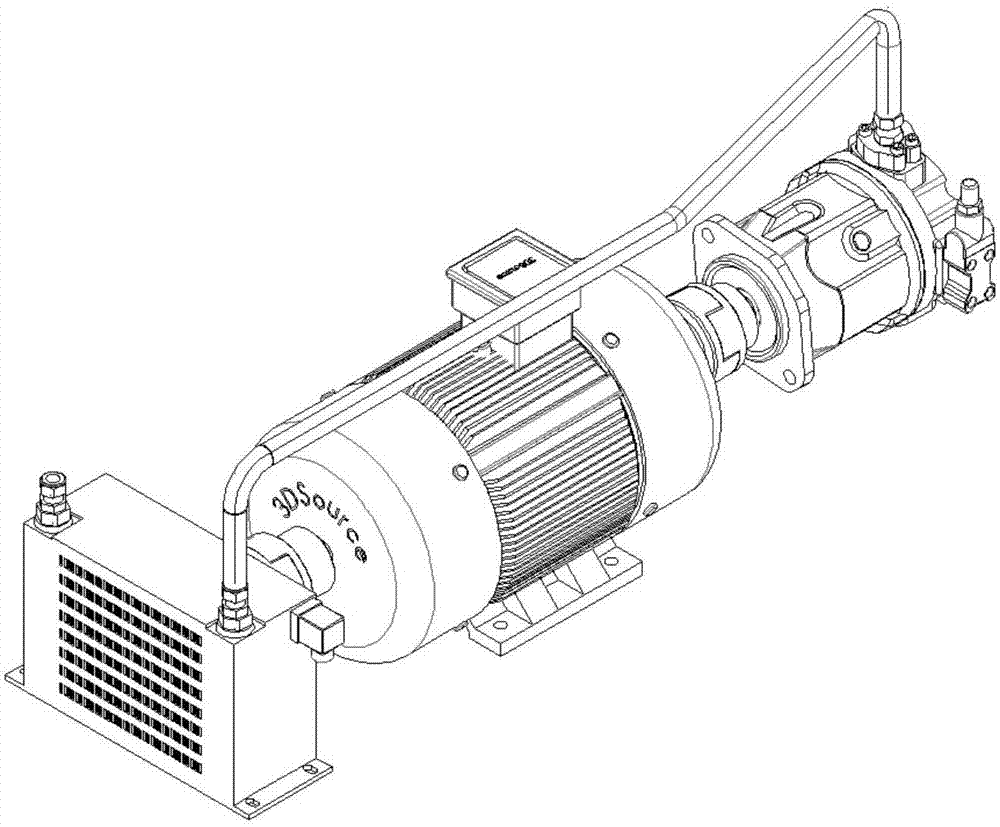

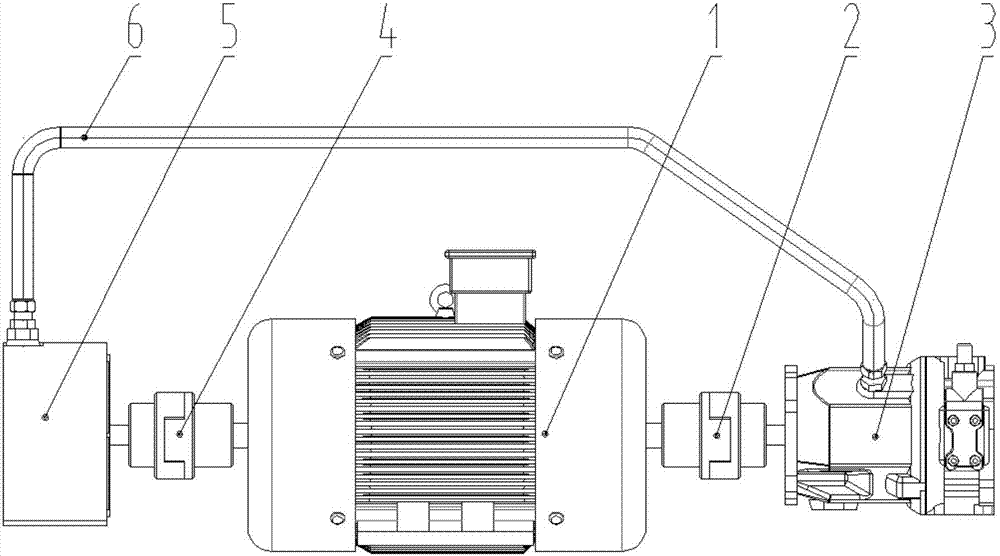

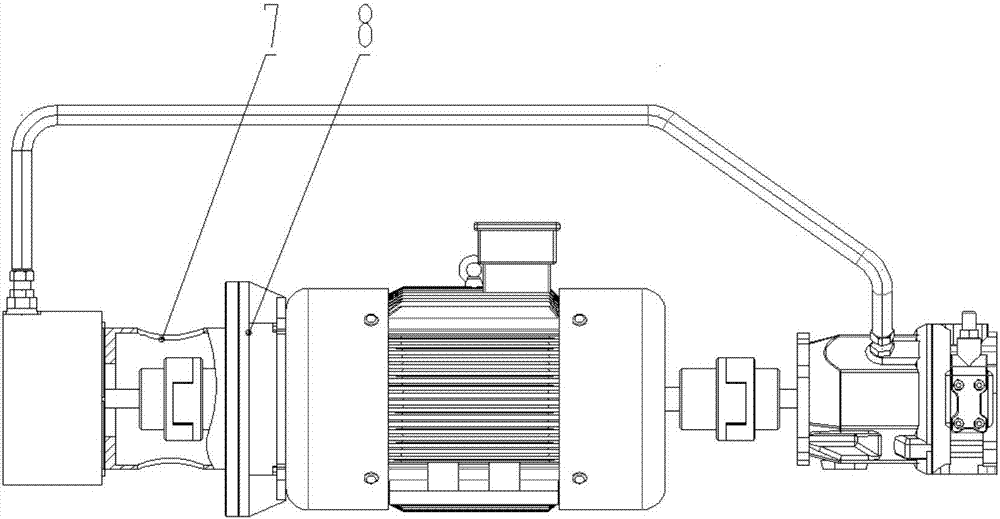

Hydraulic cooling device

The invention relates to a hydraulic cooling device. The hydraulic cooling device comprises a double-head motor; one end of the double-head motor is connected with a hydraulic pump through a first coupler, and the other end of the double-head motor is connected with an air cooling machine through a second coupler; the air cooling machine is connected with one end of an oil conveying pipeline; andthe other end of the oil conveying pipeline is connected with a hydraulic pump. The hydraulic cooling device has the beneficial effects that by using the double-head motor, the air cooling machine isdriven to run while the hydraulic pump is driven, it is not needed to additionally arrange a motor for the air cooling machine, and the hydraulic system cost is reduced; and a new structure is adoptedfor a fan device of the air cooling machine, running is stable, the cooling air volume is sufficient, the structure is compact, and the occupied space is small.

Owner:陕西德立机电科技有限公司

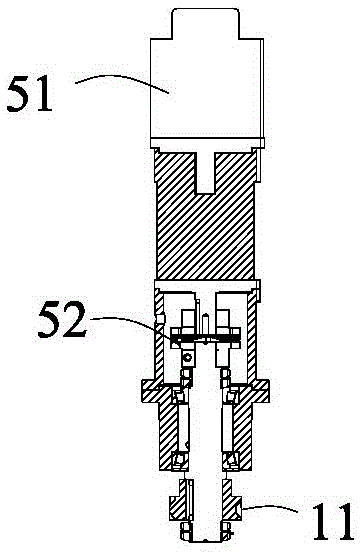

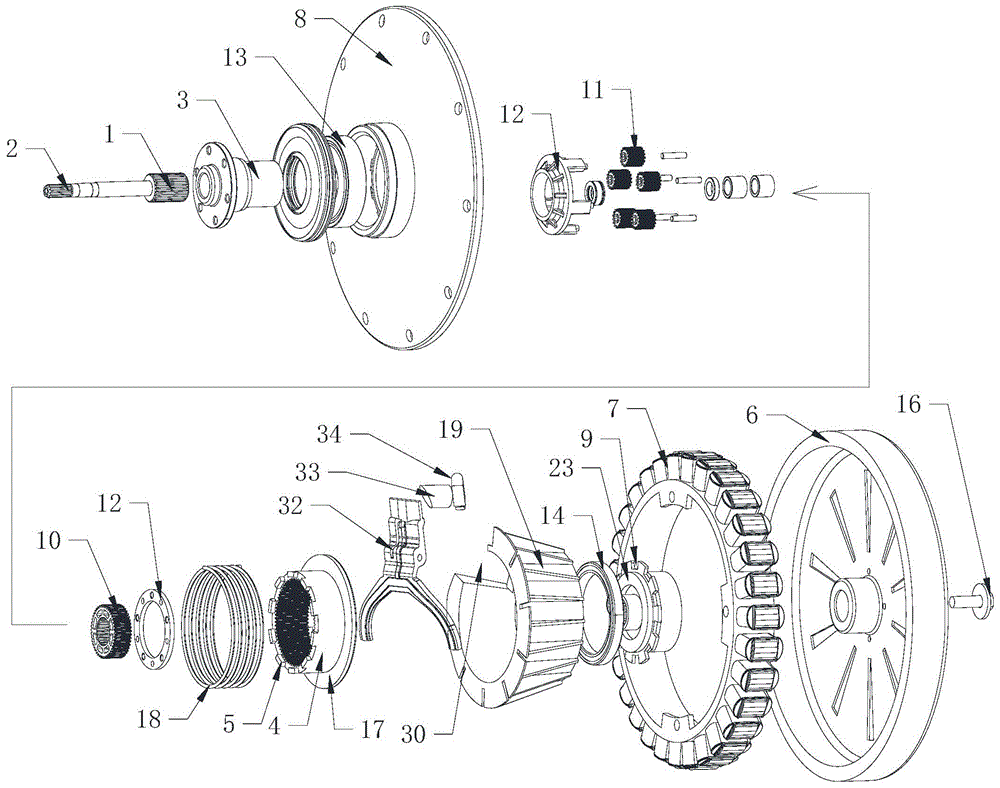

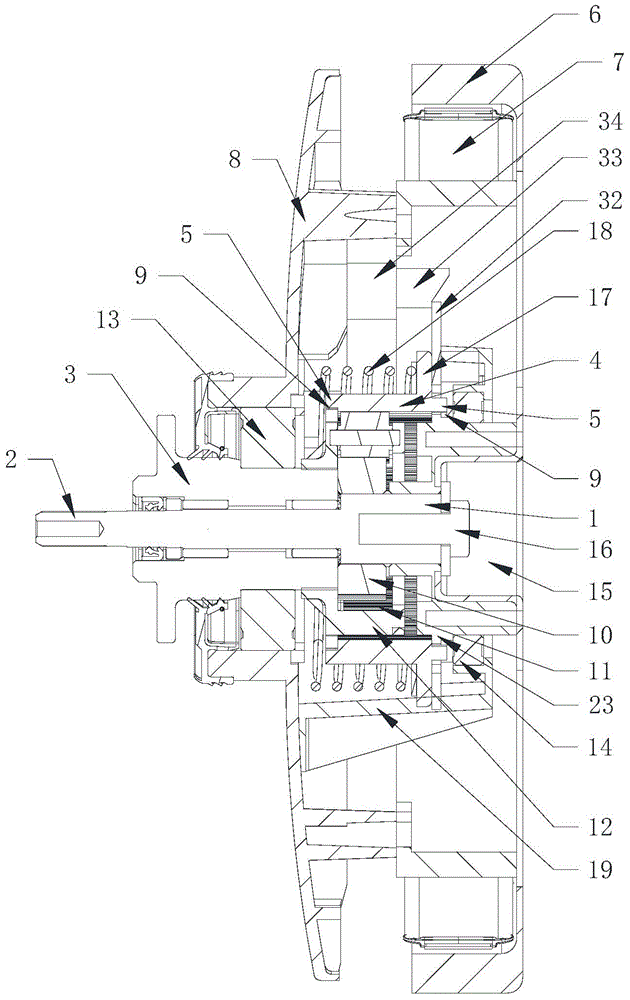

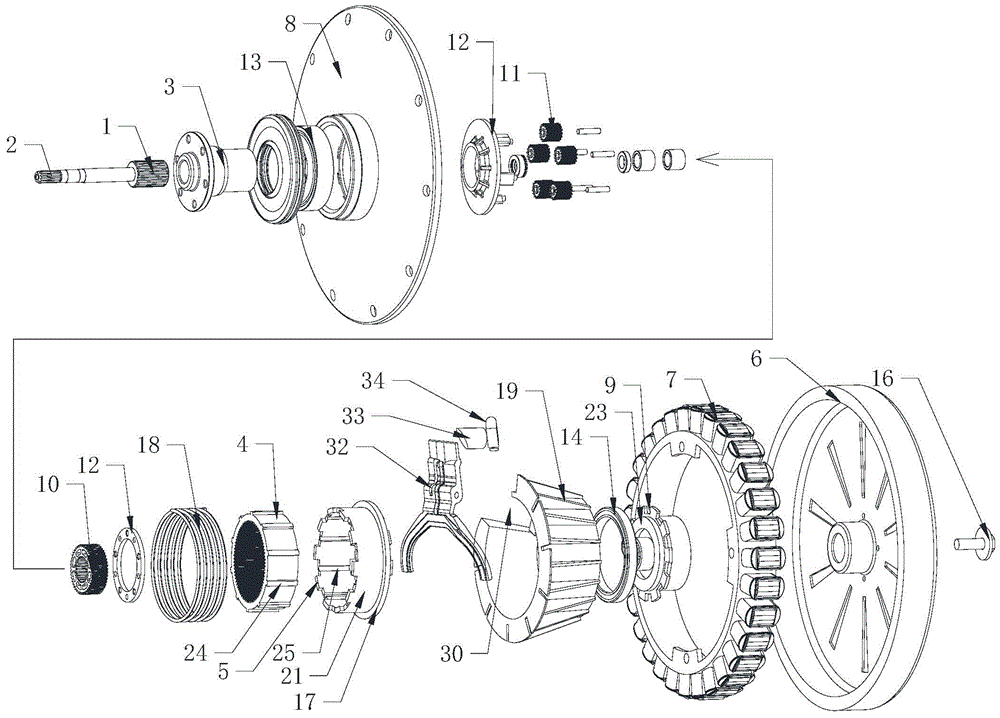

Washing machine deceleration clutch and washing machine

ActiveCN105332239ALower the altitudeReduce volumeClutchesOther washing machinesElectric machineEngineering

The invention relates to a washing machine deceleration clutch and a washing machine. The deceleration clutch comprises an input shaft, a deceleration device, a clutch device, an output shaft and an output shaft sleeve, wherein the clutch device is at least partially arranged on the periphery of the deceleration device; the deceleration clutch axially occupies little space; the clutch device comprises a clutch shaft sleeve capable of axially moving and a driving device driving the clutch shaft sleeve to axially move; the clutch shaft sleeve is an annular gear of the deceleration device; the driving device drives the annular gear to axially move to control different output states of the output shaft and the output shaft sleeve; the driving device comprises at least one shifting fork rod; the shifting fork rod is provided with a fixing part; and one end of the shifting fork rod is provided with a shifting fork controlling the annular gear to axially move and the other end is provided with a driving end in transmission connection with a driving motor. The driving device is simply structured, has reliable control, small stroke, and compact structure and occupies small space; stable and reliable operation and low fault rate can be achieved; and with the compact structure, a modularized structure can be achieved and high component integration degree can be realized.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

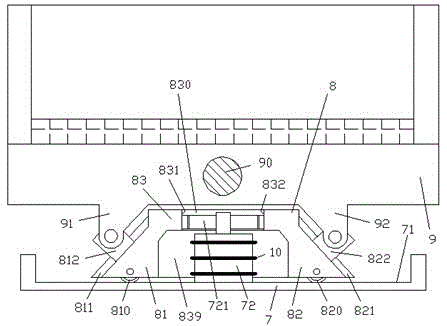

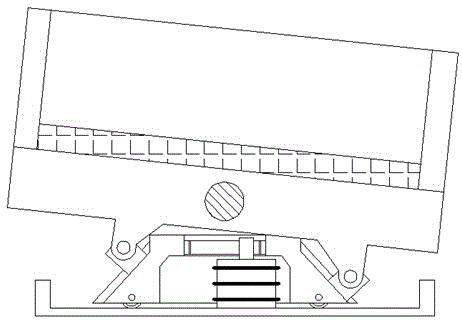

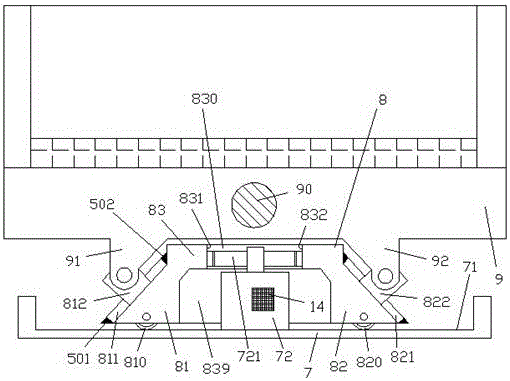

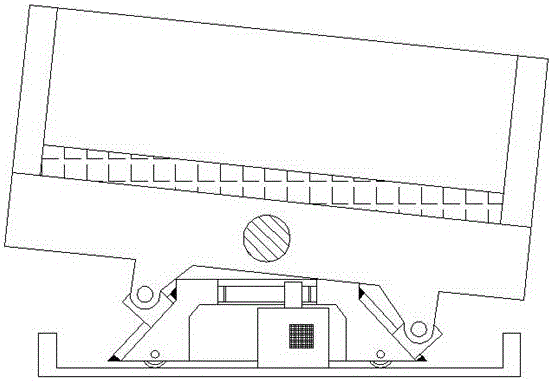

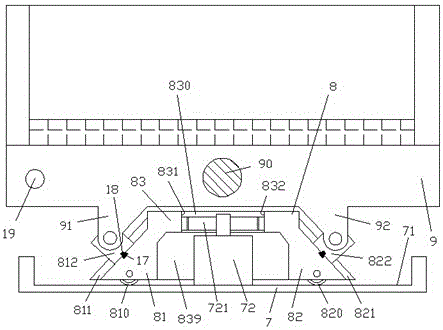

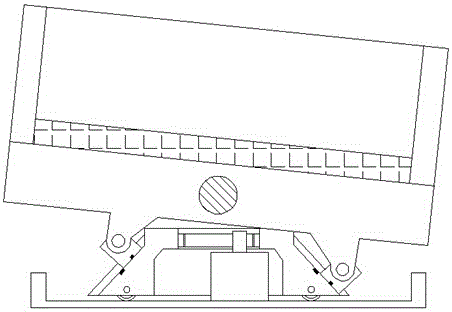

Safe material shaking device

InactiveCN105540164AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

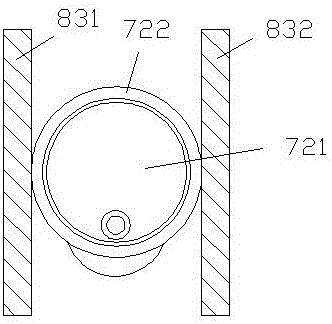

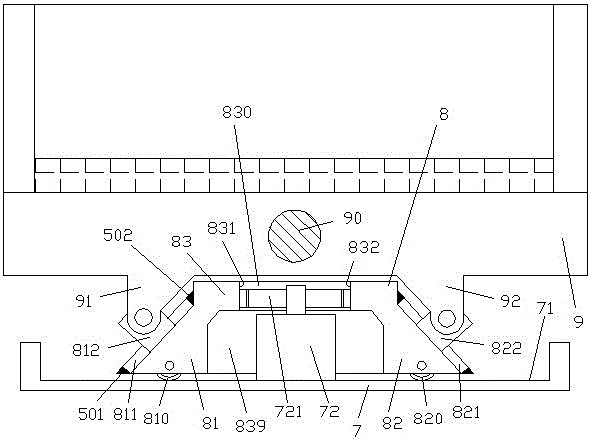

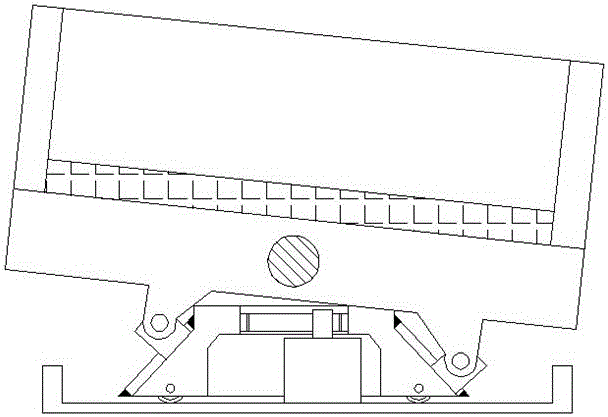

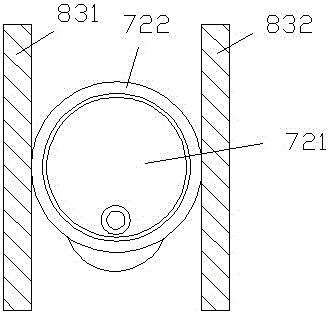

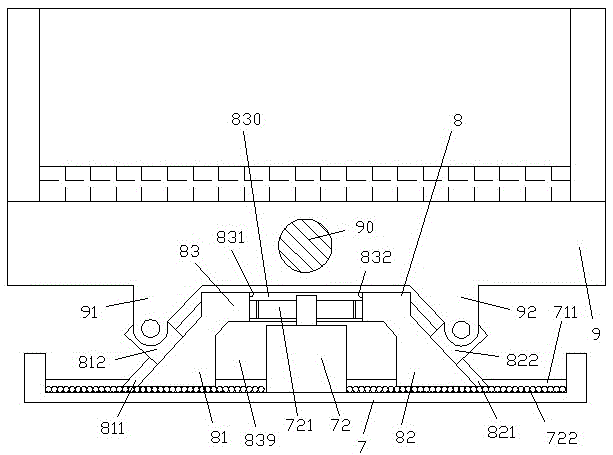

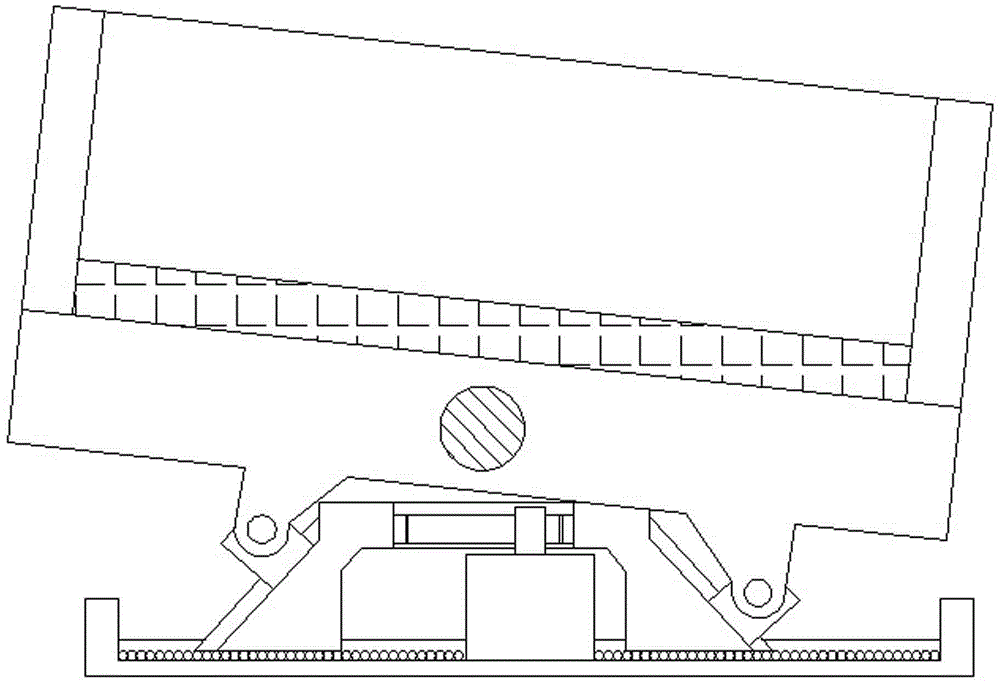

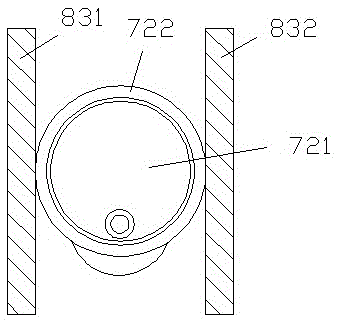

A safe material shaking device comprises a machine frame (7), a shaken material containing part (9) hinged to the upper portion of the machine frame (7) through an articulated shaft (90), and a shake driving slide block (8) capable of moving on a rolling wheel walking track fixedly arranged at the bottom position of the machine frame (7) in a left-right mode, wherein the shake driving slide block (8) comprises a middle body portion (83) and two oblique plane portions (81 and 82) arranged bilaterally and symmetrically. The two oblique plane portions (81 and 82) are respectively provided with mutually-symmetrical oblique plane chutes (811 and 821) respectively bearing a left supporting slide block (812) and a right supporting slide block (822) for sliding, and the left supporting slide block (812) and the right supporting slide block (822) are respectively hinged to supporting protrusion portions (91 and 92) symmetrically arranged at the left end and the right end of the lower side of the shaken material containing part (9).

Owner:何慧敏

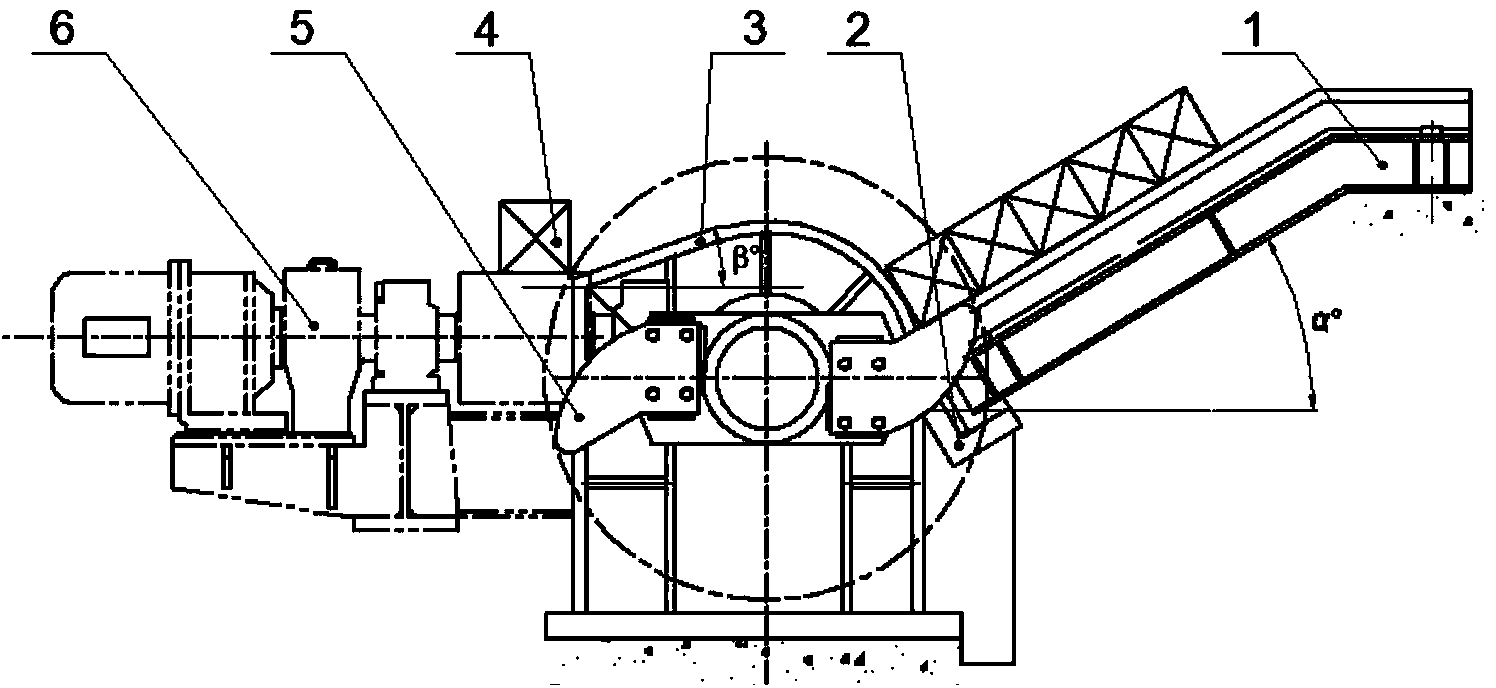

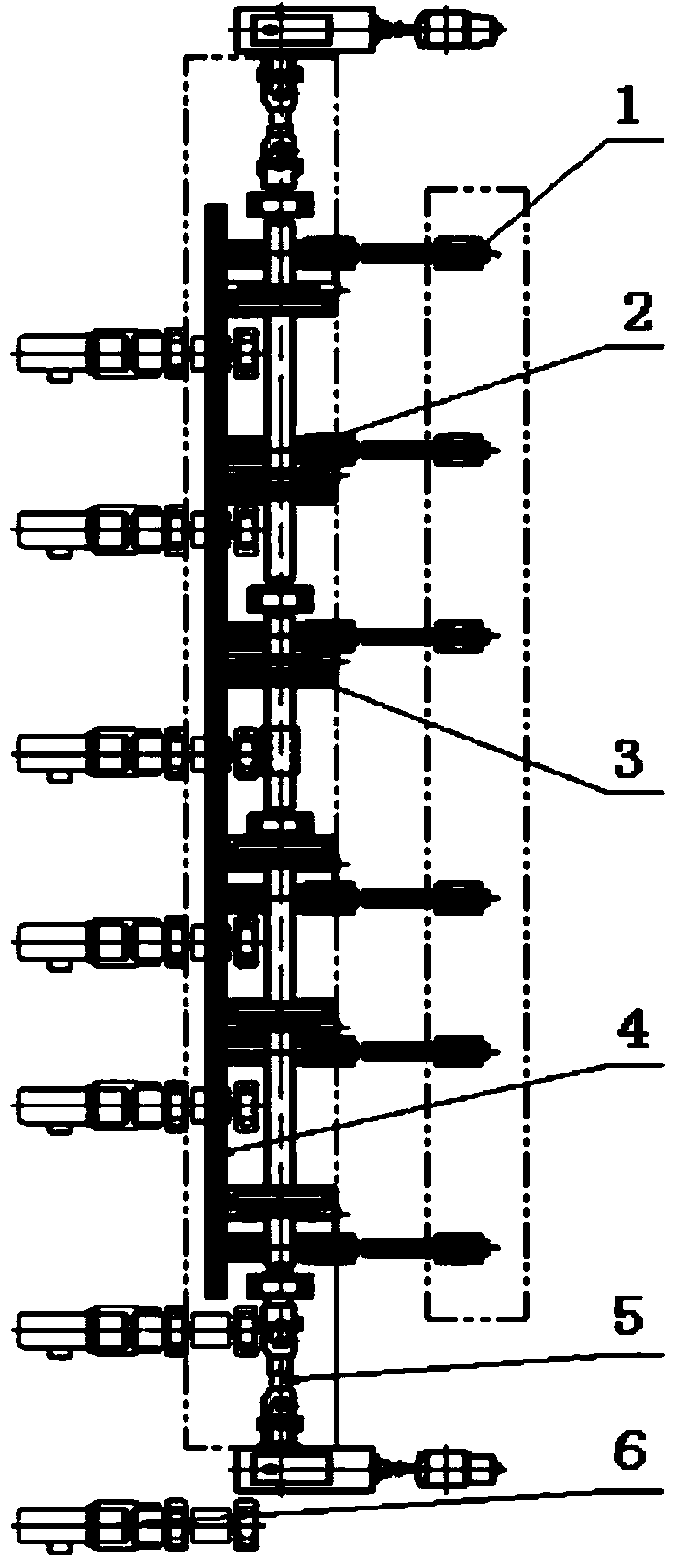

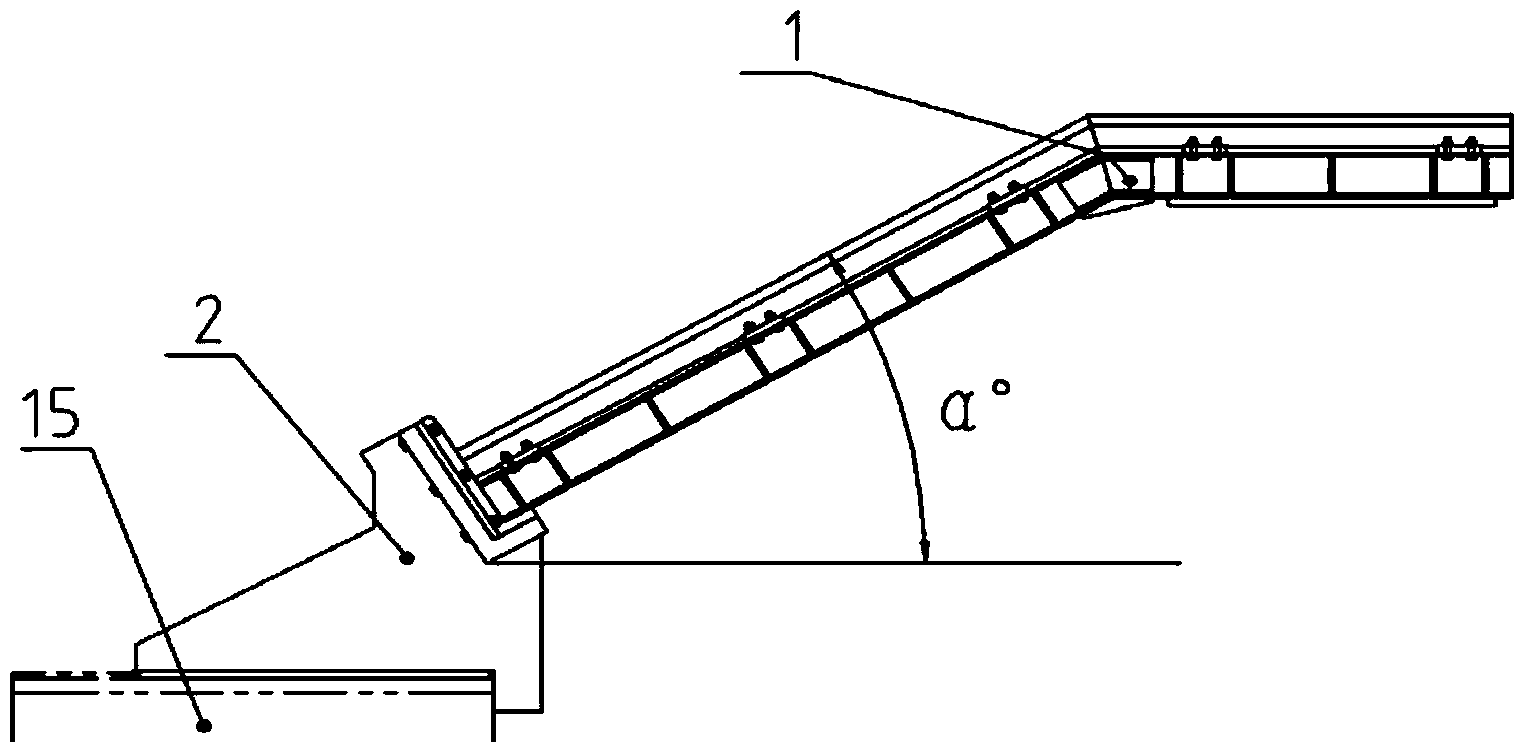

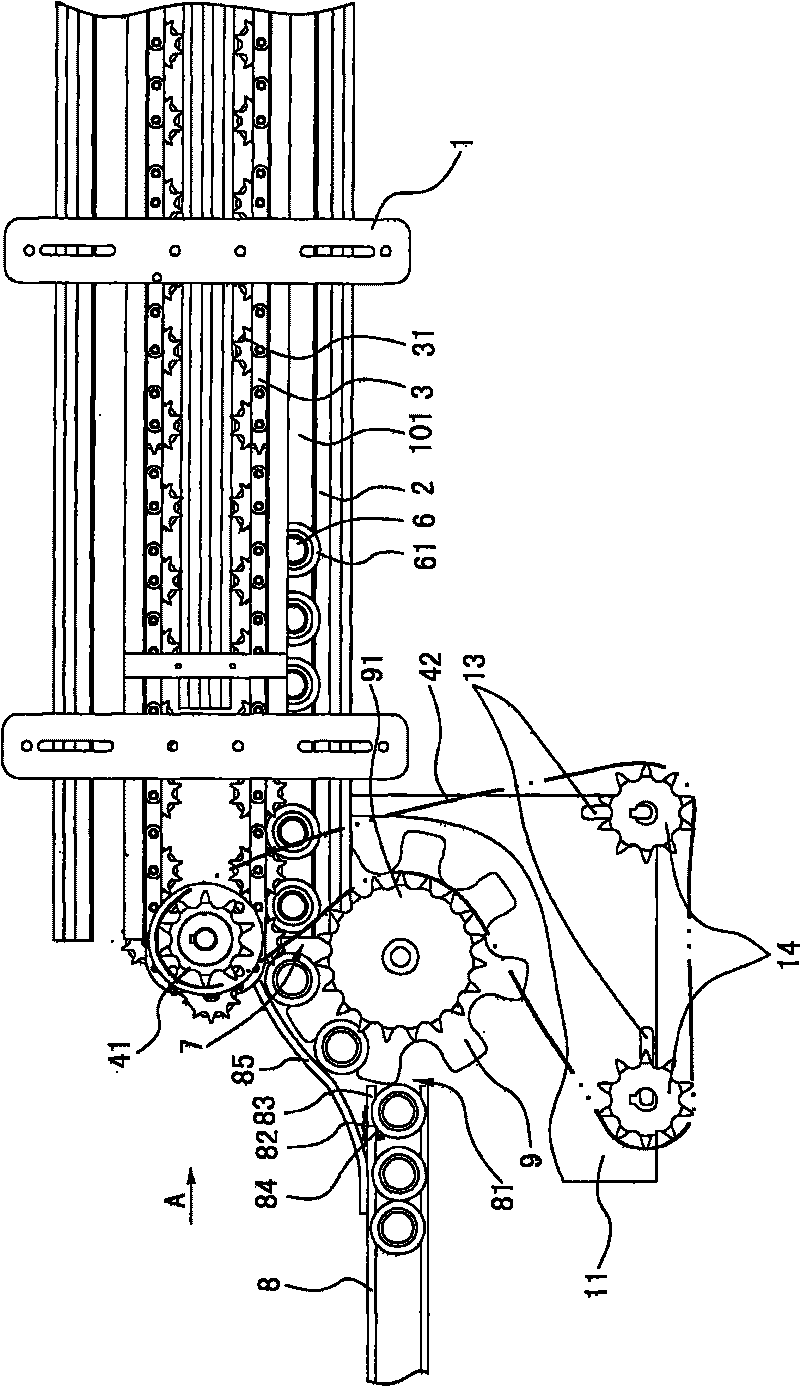

Rotary shaft type steel bar splitting machine

ActiveCN104368780AExtended service lifeSimple structureMetal rolling arrangementsLong axisRoller chain

The invention provides a rotary shaft type steel bar splitting machine. The rotary shaft type steel bar splitting machine comprises sliding rail steel connecting racks, a steel connecting rack seat, a steel bar splitting machine body and guide rail frames, and is characterized in that the sliding rail steel connecting racks, steel poking claws and the guide rail frames are sequentially arranged in the length direction of steel blanks in a staggered mode, the number of the sliding rail steel connecting racks, the number of the steel poking claws and the number of the guide rail frames are each at least two, and inclination angles of sliding rails of the sliding rail steel connecting racks enable steel blanks to automatically slide into steel through self gravity and be accurately positioned at the initial steel splitting position; the steel bar splitting machine body sequentially splits the steel blanks at the initial steel splitting position one by one, and the steel blanks move along guide rails of the guide rail frames and slide into conveying equipment connected with the guide rails; the steel bar splitting machine body adopts a double-side driving mode and is designed symmetrically; a key part long shaft of the steel bar splitting machine body is of a hollow shaft structure; the two steel poking claws are evenly distributed along the circumference; a water cooling sliding bearing seat is adopted, and a single-row roller chain coupler is adopted. The rotary shaft type steel bar splitting machine has the advantages of being simple in structure, convenient to maintain, light in weight, stable in operation, uniform in stress, long in service life, low in cost, capable of feeding steel automatically, accurate in positioning, saving in energy, environmentally friendly, and favorable for energy saving and consumption reduction of enterprises.

Owner:北京中冶设备研究设计总院有限公司

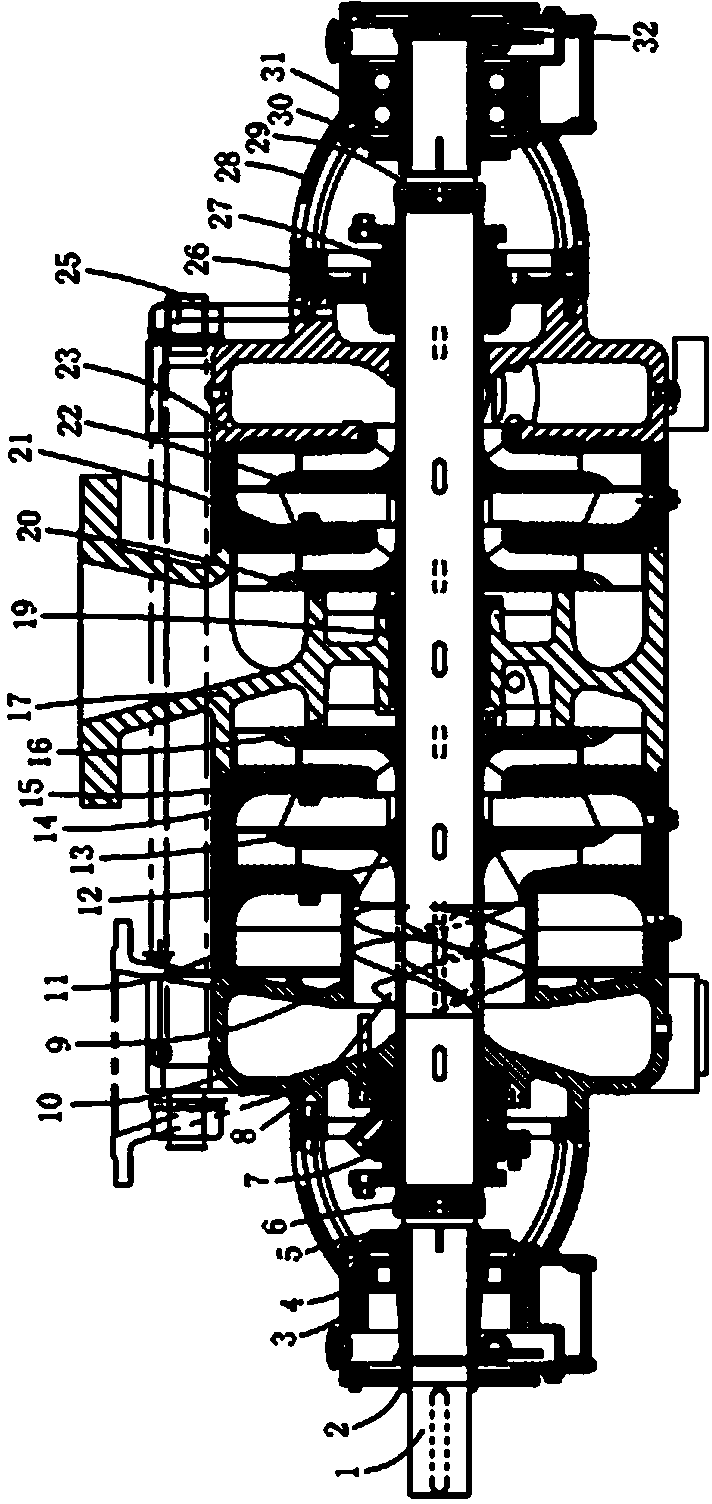

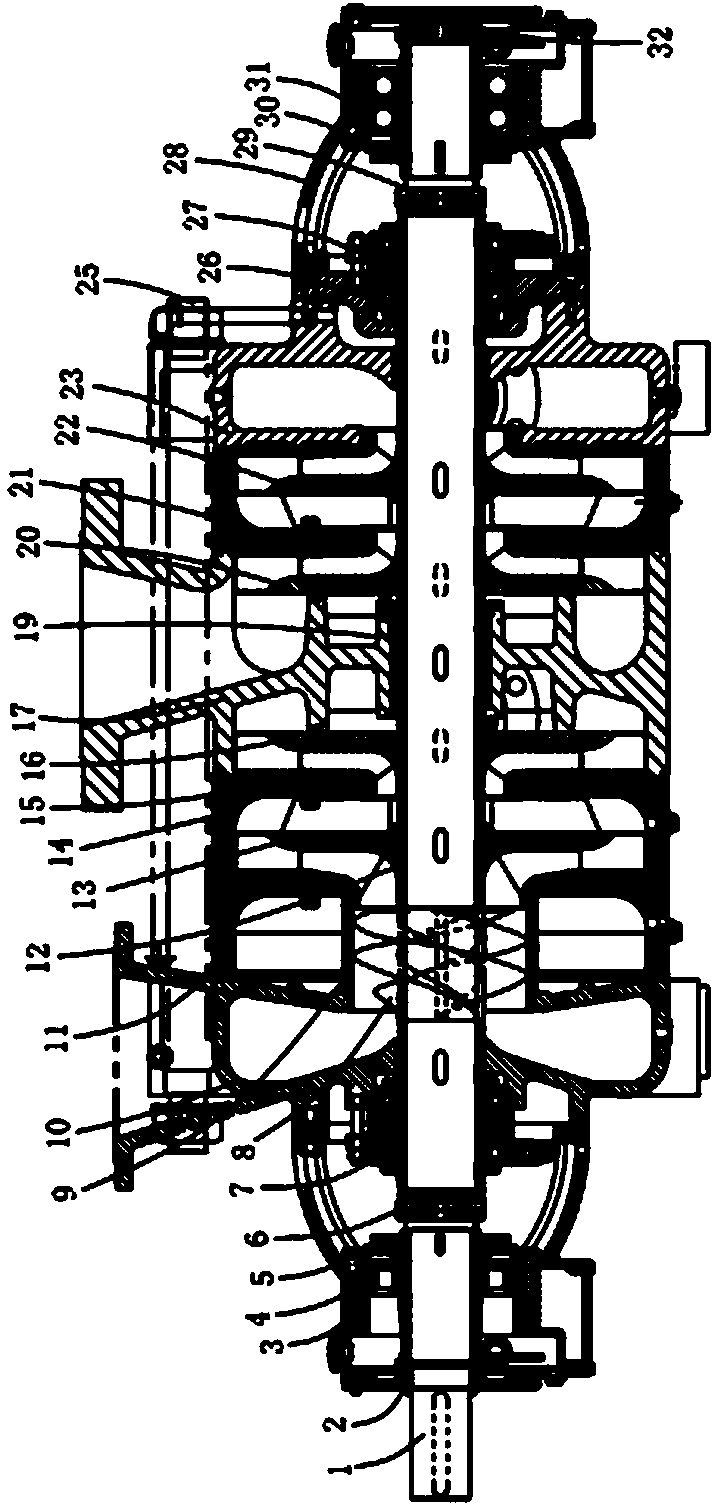

Horizontal type self-balancing multistage centrifugal pump with high cavitation resistance

InactiveCN103352875AAvoid damageSolve running problemsPump componentsRadial flow pumpsDrive shaftEngineering

A horizontal type self-balancing multistage centrifugal pump with high cavitation resistance comprises a stator component and a rotor component, wherein the stator component comprises a water inlet section, an inducer middle section, a flow guide sealing ring, a middle section, a front guide vane, a front final-stage guide vane, a water outlet section, a rear final-stage guide vane, a rear guide vane and a secondary induction section which are fixed through a tightening bolt assembly; the rotor component comprises a shaft, a shaft sleeve with two ends locked and fixed on the shaft through round nuts, an inducer, a first-stage impeller, a front impeller, an intermediate shaft sleeve, a rear impeller and a bearing and dirt blocking plate fixed through a bearing locking nut and a round nut; the first-stage impeller and the front impeller and the rear impeller are arranged symmetrically back to back; the inducer matched with the first-stage impeller is equipped in front of the first-stage impeller; the inducer and the first-stage impeller are fixed on a pump shaft and is connected with the shaft through keys for transmission; an axial direction fixes the inducer, the first-stage impeller, the front impeller and the rear impeller are fixed by the round nuts close to two ends in the axial direction; the flow guide sealing ring is arranged on the outer side of the inducer; and the two ends of the flow guide sealing ring are fixed at the inducer middle section and the water inlet section respectively.

Owner:SHANGHAI FIRST PUMP WORKS

Arc core-pulling device for die

The invention discloses an arc core-pulling device for a die, which mainly comprises a movable die insert panel, a teeth row oil cylinder, a teeth row, a fixed gear, a movable gear, a U-shaped gear and a bending core, wherein the movable die insert panel is installed on a movable die, a rod end of a piston rod of the teeth row oil cylinder is connected with the teeth row, the fixed gear is rotatably installed on the movable die insert panel, and the U-shaped gear is installed in the movable die and located below the movable die insert panel; and the movable gear is rotatably connected with one end of the bending core, the outer teeth of the movable gear are respectively engaged with the outer teeth of the fixed gear and the arc inner teeth of the U-shaped gear, and the bending core is slidably connected to the interior of a bending groove of the movable die insert panel. Because the U-shaped gear is provided with the arc inner teeth, the movable gear engaged with the U-shaped gear moves along an arc inner teeth surface to drive the bending core to be stably pulled out from a die cavity. The fixed gear, the movable gear and the U-shaped gear are engaged with each other to realize power transmission as well as stable and reliable running.

Owner:厦门市方圆通模具有限公司

Plastic bottle pipe heater feed delivering device

The invention relates to a plastic bottle pipe heater feed delivering device which comprises a heater, wherein an inlet of the heater is connected with a bottle pipe feed mechanism; the heater comprises a frame, and a delivering passage is arranged in the frame; one side of the delivering passage is provided with a drive chain which is installed on the frame, and the other side of the delivering passage is provided with a placing bar which is installed on the frame; the drive chain does annular motion by a drive wheel and a driven wheel which are driven by power; a positioning friction wheel is installed in the drive chain, extends among all plastic bottle pipes to be in contact with the heads of the plastic bottle pipes and drives the bottle pipes to run; a baffle plate of the bottle pipes is placed on the placing bar; and the feed mechanism comprises a pipe delivering slideway which is connected with an inlet of a bottle pipe heater and a plastic bottle pipe delivering device. The bottle pipe delivering device is characterized by comprising a delivering disk which is installed between the pipe delivering slideway and the inlet of the bottle pipe heater; the edge of the delivering disk is provided with delivering teeth, and the delivering teeth are in contact with the plastic bottle pipes; the delivering disk is driven to rotate by a drive mechanism, and an outlet of the pipe delivering slideway is provided with a pipe clamping prevention device and a pipe release preventing device.

Owner:林明茳

Material vibrator capable of achieving limiting control

InactiveCN105728317AStable structureImprove the stability of forceSievingScreeningEngineeringBilateral symmetry

The invention relates to a material vibrator capable of achieving limiting control. The material vibrator comprises a rack (7), a vibration material containing component (9) hinged to the upper portion of the rack (7) through a hinge shaft (90) and a vibration driving sliding block (8) capable of moving left and right on a roller walking track (71) fixedly arranged at the bottom of the rack (7); the vibration driving sliding block (8) comprises a middle body part (83) and two slope faces (81 and 82) arranged in a bilateral symmetry manner; the two slope faces (81 and 82) are provided with symmetrical slope face sliding grooves (811 and 821) and are used for bearing a left supporting sliding block (812) and a right supporting sliding block (822) to slide; the left supporting sliding block (812) is hinged to a supporting protrusion (91) at the left end of the lower side of the vibration material containing component (9), the right supporting sliding block (822) is hinged to a supporting protrusion (92) at the right end of the lower side of the vibration material containing component (9), and the left supporting sliding block (812) and the right supporting sliding block (822) are symmetrically arranged.

Owner:董海斌

Material vibrating device capable of achieving sliding limiting

InactiveCN105750191AStable structureImprove the stability of forceSievingScreeningEngineeringMechanical engineering

A material vibrating device capable of achieving sliding limiting comprises a machine frame (7), a vibrating material containing part (9) hinged to the upper portion of the machine frame (7) through a hinge shaft (9), and a vibrating driving slider (8) which can be fixedly arranged on a roller traveling rail (71) at the bottom of the machine frame (7) and can move left and right.The vibrating driving slider (8) comprises a middle body part (83) and two inclined face parts (81 and 82) symmetrically arranged on the left side and the right side.The two inclined face parts (81 and 82) are provided with symmetric inclined face sliding grooves (811 and 821) respectively and used for bearing sliding of a left supporting slider (812) and a right supporting slider (822) respectively, and the left supporting slider (812) and the right supporting slider (822) are symmetrically hinged to supporting protruding parts (91 and 92) at the left end and the right end of the lower side of the vibrating material containing part (9) respectively.

Owner:XIAOGAN BUJI ELECTRONICS COMMERCE CO LTD

filter equipment

ActiveCN111263657BSimple operabilitySimple structure costsMembrane filtersStationary filtering element filtersEnvironmental engineeringMechanical engineering

Filter device for cleaning a fluid flow of particulate contamination, having a plurality of filter elements (34, 60) received in a filter chamber as part of a common filter housing (10) (12, 14, 32) and surrounds the backwash device (20), which has a piston accumulator (56) in order to receive the backwash volume, in its accumulator housing (64) the piston (57) Guided longitudinally, the piston is controlled by a pressure medium to transfer the backflush quantity stored in the accumulator housing (64) via the backflush device (20) to at least one unit to be backwashed for its cleaning. The filter element (60), the backwashing device also leads the backwash amount from the filter equipment, it is characterized in that a certain filter element selected from the plurality of filter elements (34, 60) is used as a bypass filter element ( 34) After operating the switching device (18), only particle cleaning takes place, while the other filter elements (60) are excluded from this cleaning.

Owner:HYDAC PROCESS TECH

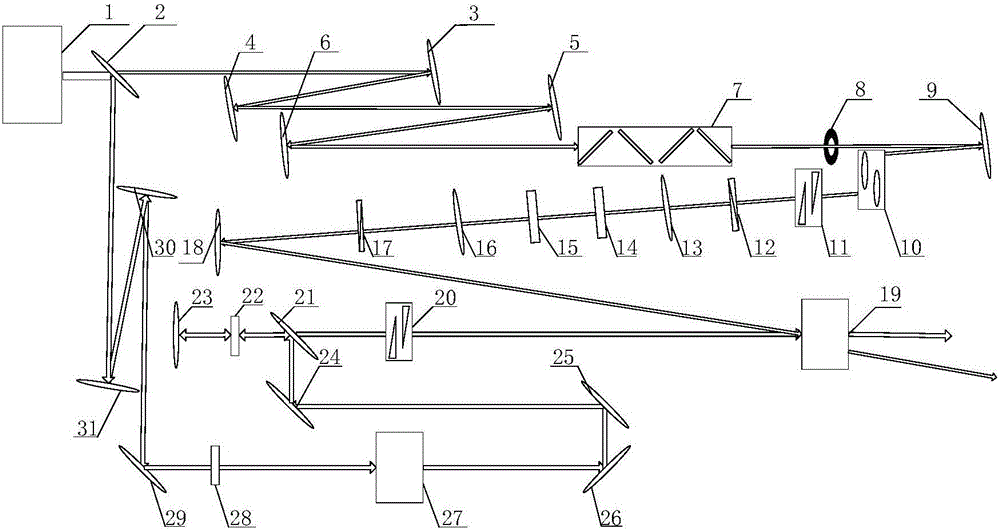

High-energy few-cycle ultra-high-signal to noise ratio femtosecond seed pulse generation device

The invention relates to a high-energy few-cycle ultra-high-signal to noise ratio femtosecond seed pulse generation device. Laser outputted by an 800nm-wave band 1kHz laser is split into two beams; one of the two laser beams passes through a beam contracting system and a frequency multiplication crystal, so that a 400nm frequency-multiplied light can be generated, and the frequency-multiplied light passes through a light delay system, and then, adopted as pumping light, is injected into a nonlinear crystal; the other laser beam passes through a beam contracting system, a focusing system, an all-solid-state spectral broadening system, a dispersion compensation system and a cross polarization wave generating system sequentially, and then, adopted as signal lights, are injected into the nonlinear crystal, and the signal lights and the pumping light are altogether subjected to optical parametric amplification. The all-solid-state spectral broadening system is adopted, so that the spectrum of incident light can be effectively broadened, and therefore, the system can operate compactly and stably assuredly, and at same time, the device is convenient to adjust, is simple and efficient, can achieve integration and miniaturization, and can provide a high-quality seed source for ultrashort laser system.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

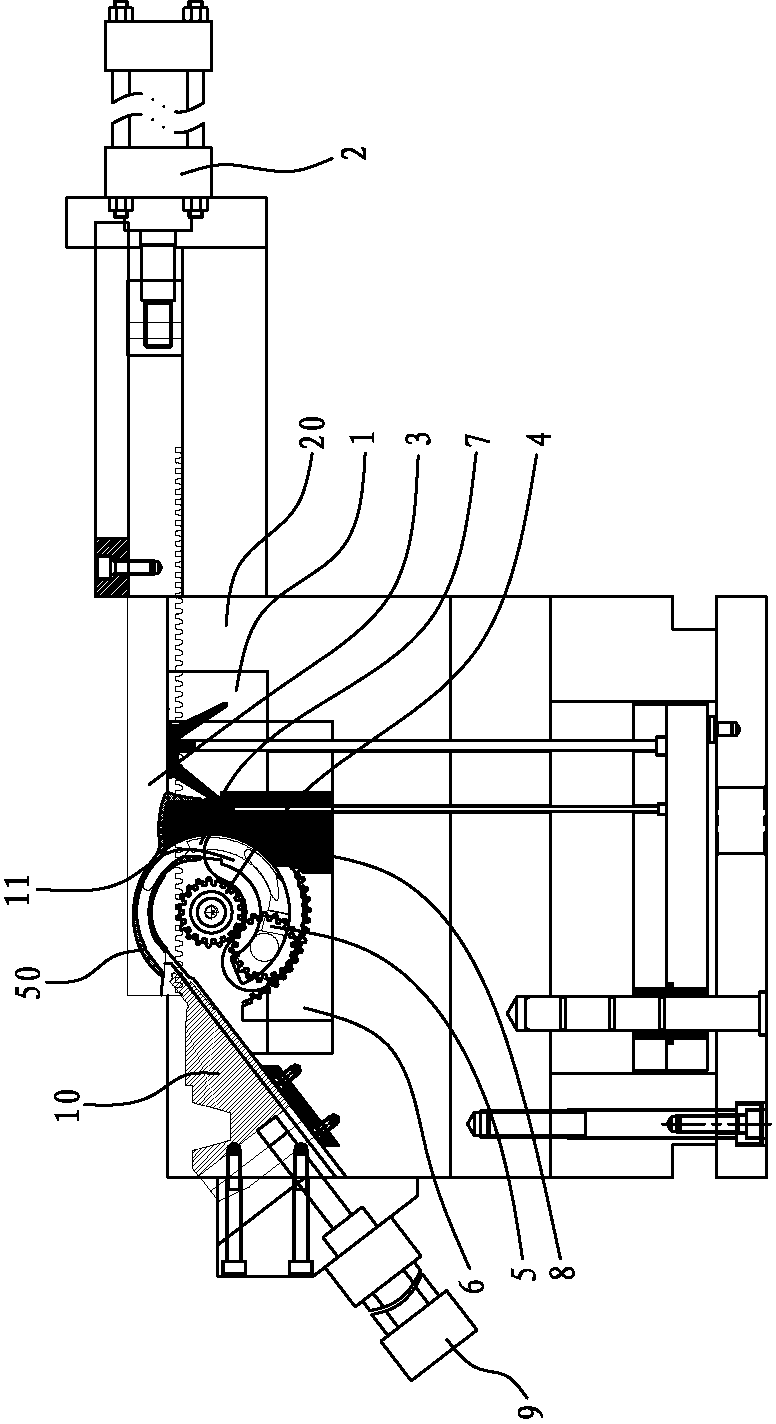

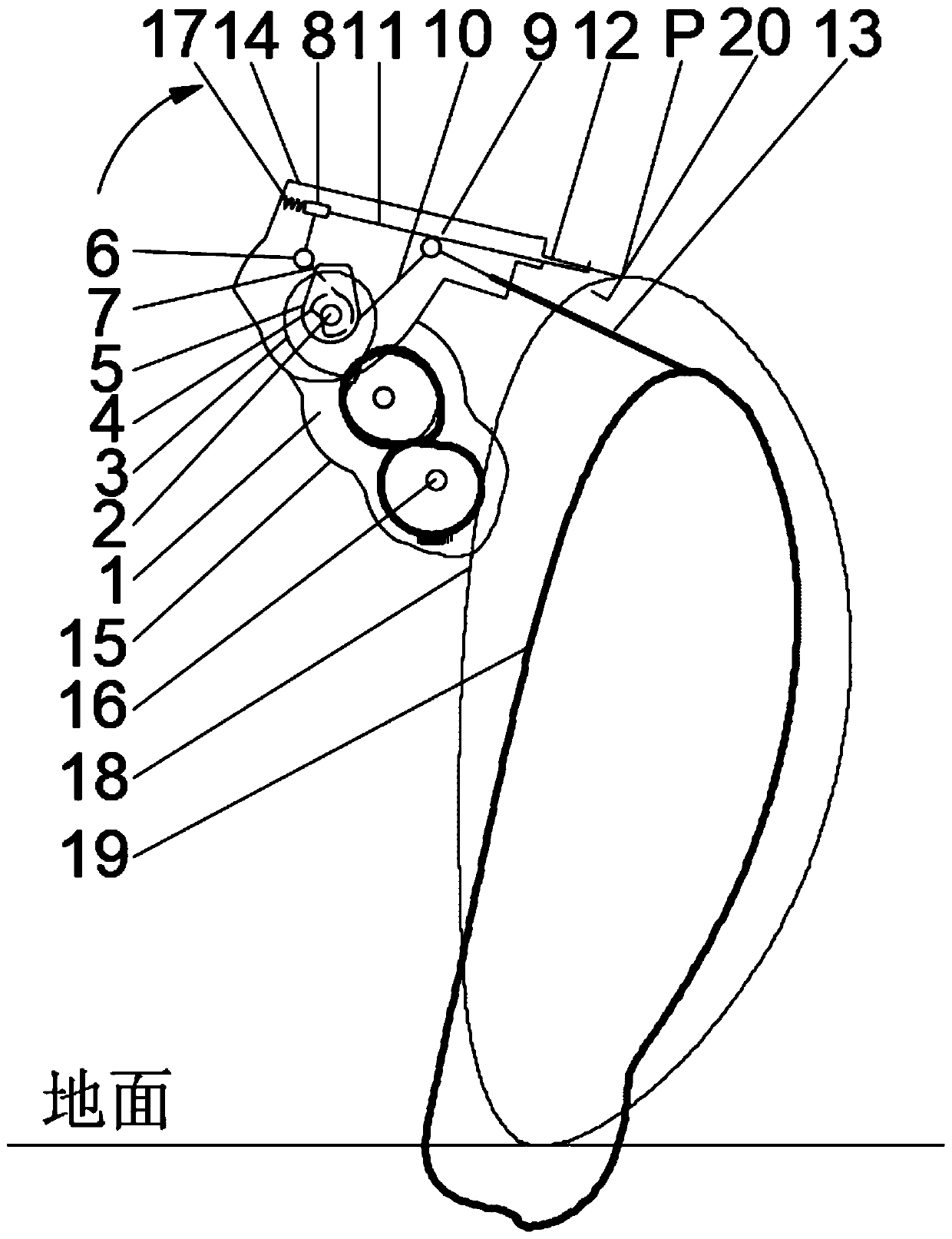

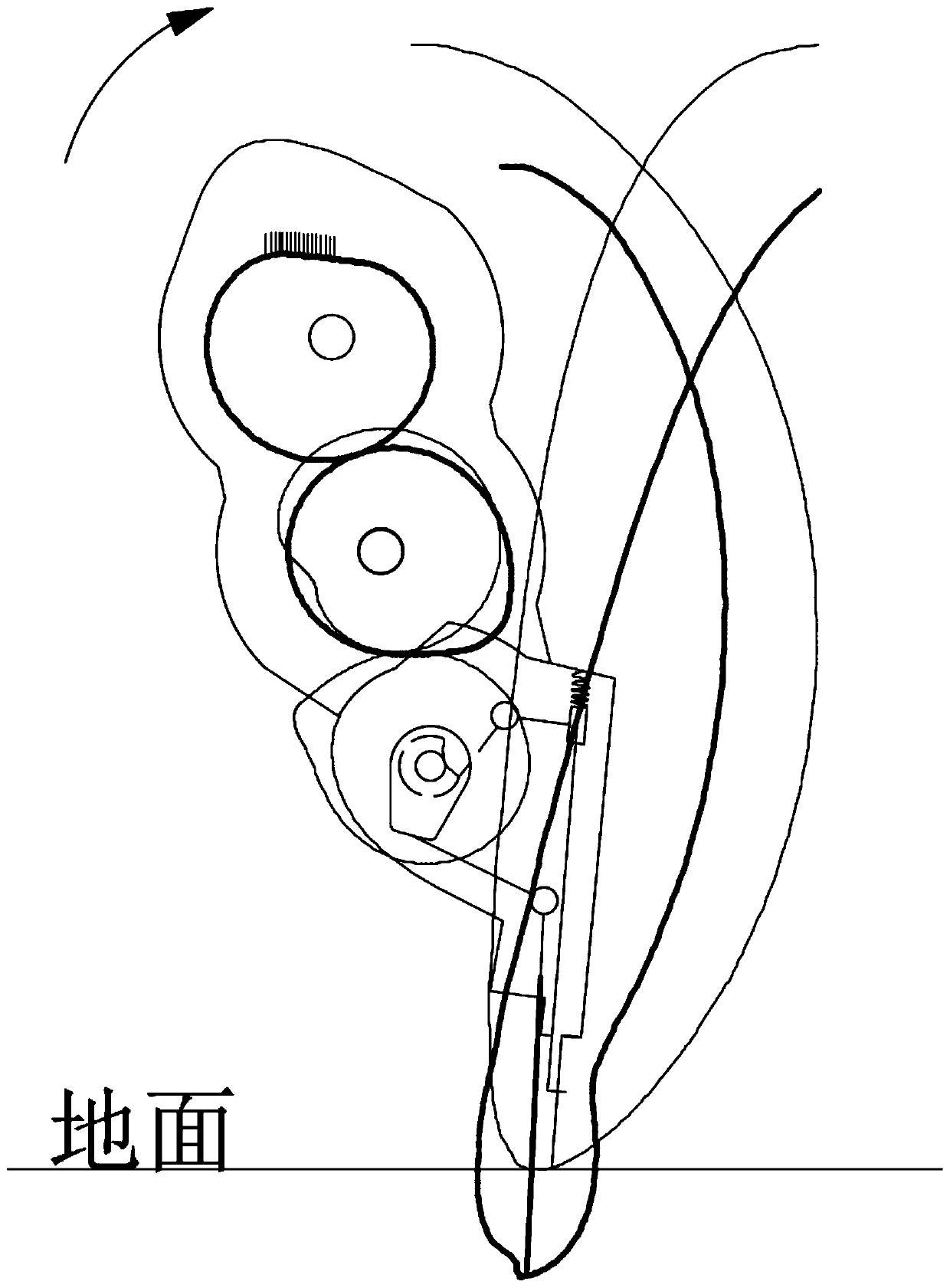

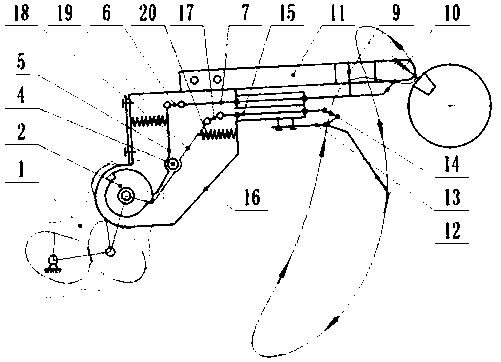

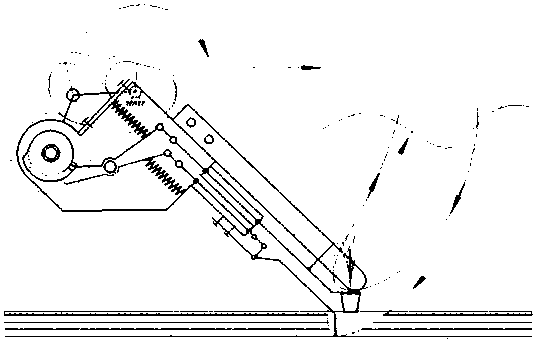

Transplanting mechanism for hole formation and seedling taking of rapeseed carpet seedlings and transplanting method thereof

PendingCN109699255AGood compatibility with transplantingGuaranteed normal inputTransplantingFurrow making/coveringRapeseedBiology

The invention discloses a transplanting mechanism for hole formation and seedling taking of rapeseed carpet seedlings and a transplanting method thereof. An existing rapeseed carpet seedling transplanting machine cannot achieve seedling taking and seedling planting through one set of mechanism. A planting arm includes a seedling throwing cam, a hole formation cam, a shifting fork, a hole formationrod, a seedling pushing rod, a seedling needle, a hole formation knife and a planting arm shell; when the planting arm runs to the positions of rapeseed carpet seedlings, and the seedling needle catches the seedlings from the rapeseed carpet seedlings; when the planting arm runs to a seedling throwing position, the hole formation cam runs to a push stage, and the hole formation knife swings to beparallel to the seedling needle under driving of the hole formation rod; at the moment, the hole formation knife is used for hole formation on the ground; after hole formation, the push stage of thehole formation cam is over, the hole formation knife returns to an initial position, at the moment, the seedling throwing cam runs to a push stage, the shifting fork drives the seedling pushing rod tomove forwards to push the seedlings clamped by the seedling needle out, the seedlings fall in the holes formed by the hole formation knife, and then transplanting is completed. According to the transplanting mechanism, seedling taking, conveying, hole formation and transplanting can be completed through one set of mechanism.

Owner:ZHEJIANG SCI-TECH UNIV

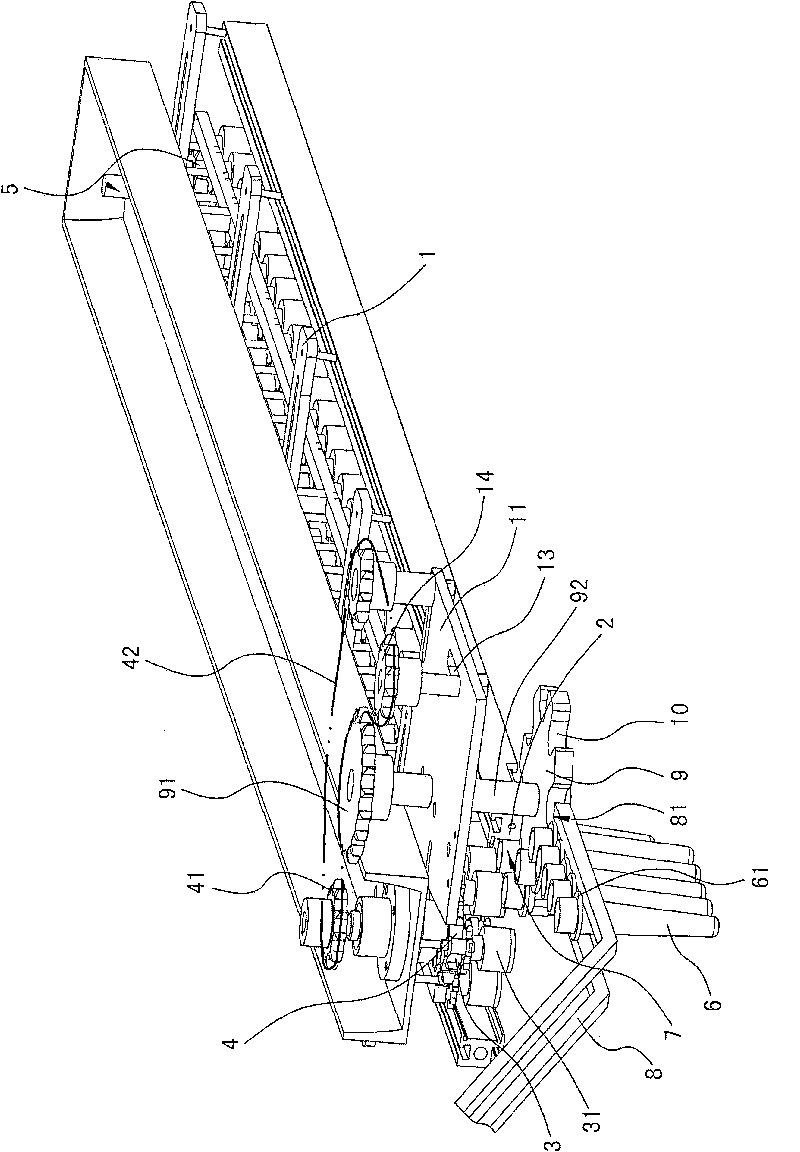

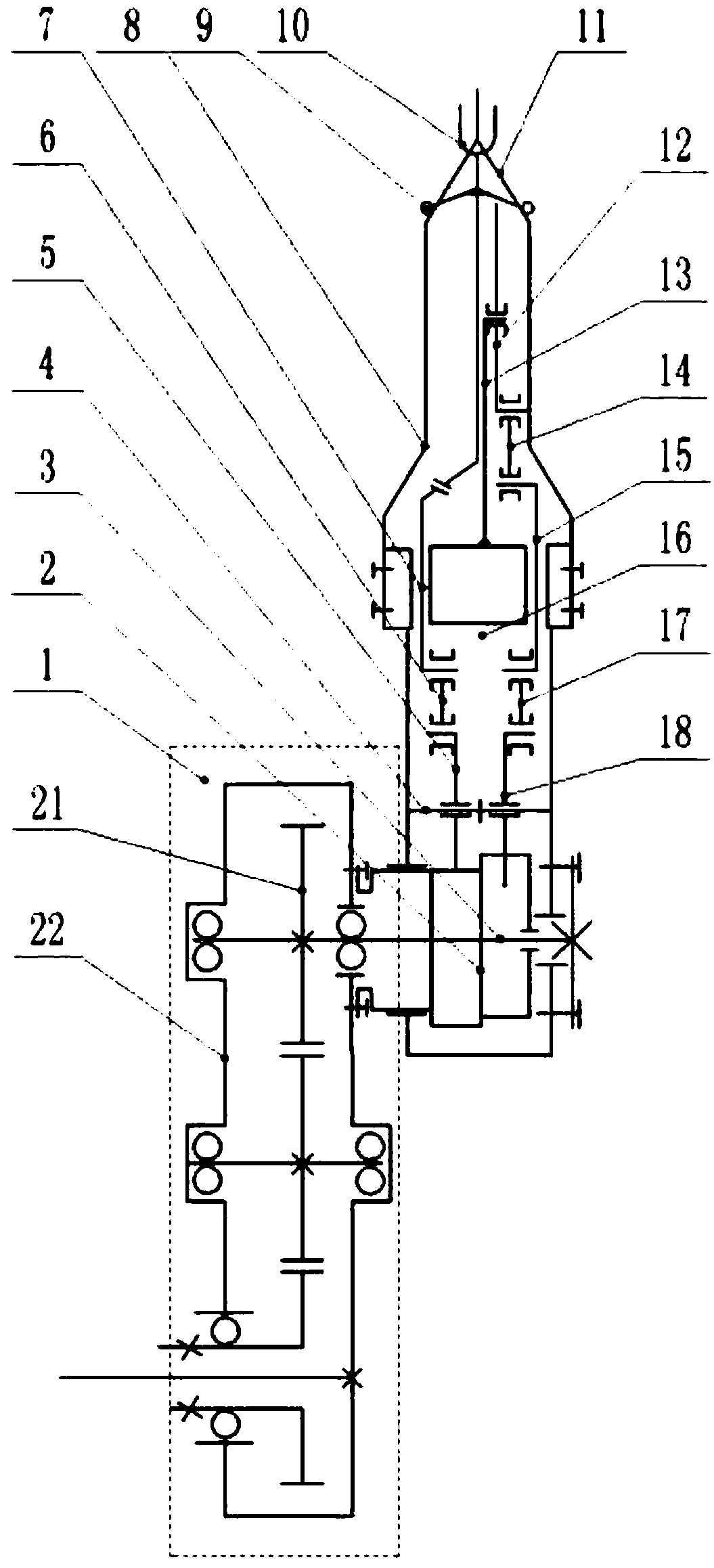

Transplanting mechanism for forming holes in rice pot seedling film

The invention discloses a transplanting mechanism for forming holes in rice pot seedling film, and belongs to the agricultural machinery. A planetary shaft is fixedly installed on a planetary wheel ofa non-circular gear planetary gear train mechanism, a conjugate cam is rotatably mounted on the planetary shaft, and the planetary shaft is fixedly connected with a transplanting arm housing; a leftspring clip and right spring clip are fixedly installed on two sides of the transplanting arm housing separately, and the transplanting arm housing is separately provided with a transplanting mechanism body and a film hole-forming mechanism in a matched mode, wherein the transplanting mechanism body comprises a shifting fork shaft, a transplanting shifting fork, a transplanting shifting fork chainlink, a seedling pushing rod, the left spring clip, the right spring clip, a U-shaped clamp, a seedling pushing claw and a compression spring, and a film hole-forming mechanism comprises the shiftingfork shaft, a hole-forming shifting fork, a hole-forming shifting fork chain link, a hole-forming rod, a hole-forming chain link, a hole-forming device and an extension spring. The structure of the mechanism is novel, reasonable, simple and compact, cooperation between hole forming in the film and pot seedling transplanting is good, and the mechanism has stable operation, an outstanding operationeffect and a high work efficiency.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Material vibration device with horizontal position detection function

InactiveCN105692085AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

Owner:何慧敏

Electric pile end plate with gas pressure buffering and dehumidifying functions

PendingCN109378504AChange humidityGuaranteed uptimeReactant parameters controlEngineeringWater level

The invention discloses an electric pile end plate with gas pressure buffering and dehumidifying functions. A first end plate is of a hollow structure, and an inner cavity of the first end plate is partitioned into a fuel gas side gas-inlet buffering area and an oxidant gas side gas-inlet buffering area by a partition plate; and a fuel gas side humidifying water supplementing opening and an oxidant gas side humidifying water supplementing opening are further formed in the side walls of the fuel gas side gas-inlet buffering area and the oxidant gas side gas-inlet buffering area correspondinglyand used for filling the fuel gas side gas-inlet buffering area and the oxidant gas side gas-inlet buffering area with humidifying water correspondingly, the heights of the water levels of the humidifying water on the two sides are larger than the height of a fuel gas end plate inlet and the height of an oxidant gas end plate inlet correspondingly. The electric pile end plate has the gas pressurebuffering and dehumidifying functions, the humidity of gas entering an electric pile is adjusted and changed through design of the buffer areas and the humidifying water temperature, the performanceof the electric pile is exerted advantageously, the service life of the electric pile is prolonged advantageously, and thus the electric pile operates more stably and is longer in service life.

Owner:江苏氢电新能源有限公司

Ball-driven material vibration device

InactiveCN105478345AStable structureImprove the stability of forceSievingScreeningEngineeringBilateral symmetry

The invention discloses a ball-driven material vibration device. The device comprises a rack (7), a vibrating material containing component (9) hinged to the upper portion of the rack (7) through an articulated shaft (90) and a vibration driving slide block (8) capable of moving left and right at the bottom of the rack (7), wherein a guiding slide groove (711) in sliding fit with the vibration driving slide block (8) is formed in the bottom of the rack (7) and used for guiding the left and right movement of the vibration driving slide block (8); the vibration driving slide block (8) comprises a middle body part (83) and two bevel parts (81 and 82) arranged in bilateral symmetry; the two bevel parts (81 and 82) are provided with bevel slide grooves (811 and 821) respectively, the bevel slide grooves (811 and 821) are in mutual symmetry and are used for bearing a left supporting slide block (812) and a right supporting slide block (822) to slide, the left supporting slide block (812) and the right supporting slide block (822) are hinged to supporting convex parts (91 and 92) respectively, and the supporting convex parts (91 and 92) are symmetrically arranged at the left end and the right end of the lower side of the vibrating material containing component (9).

Owner:晋江市东坤电子实业有限公司

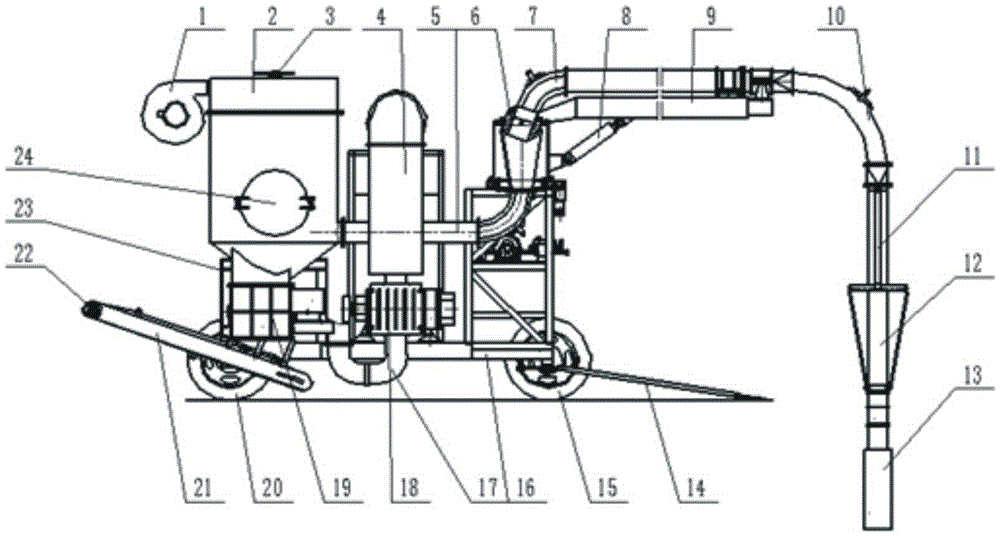

Wheeled multifunctional integrated cement casting pump truck

InactiveCN105332512AImprove stirring efficiencyImprove delivery capacityBuilding material handlingWork performanceFixed frame

The invention discloses a wheeled multifunctional integrated cement casting pump truck, which comprises a mixing and stirring tank, a secondary mixing tank, a concrete ultimate delivery nozzle and a recovery tank, wherein front wheels are arranged at two ends of the front side of the bottom of a main frame; shaft ends of rear wheels at two sides are fixedly connected with a conveyer device fixing plate and a mixing and stirring tank fixing frame; the mixing and stirring tank is arranged at the upper part; the other end of a secondary delivery pipe is connected with the end part of a tertiary delivery pipe; a booster spray pipe is connected to a port of the tertiary delivery pipe; a transition nozzle is assembled at the other end of the booster spray pipe; the concrete ultimate delivery nozzle is fixedly arranged at the other end of the transition nozzle; and a spray pipe support rib plate is arranged at the outer peripheral side of a booster spray nozzle. The wheeled multifunctional integrated cement casting pump truck has the beneficial effects that the wheeled multifunctional integrated cement casting pump truck is matched with multi-stage delivery pipes and a stirring device; and the booster spray pipe is added, so that the working performance is high and is prominently reflected; and the concrete stirring efficiency and conveying property are improved by the overall design.

Owner:CHENGDU ERJUE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com