Large-stroke heavy-load slipway structure

A technology of large stroke and sliding table, which is applied in the field of large stroke and heavy-duty sliding table structure, which can solve the complicated design of the dustproof mechanism of the rack and pinion, increase the labor intensity of production workers, increase the shear force of guide rails and sliders, etc. problems, to achieve the effect of reasonable structural design, compact structure, and reduced shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

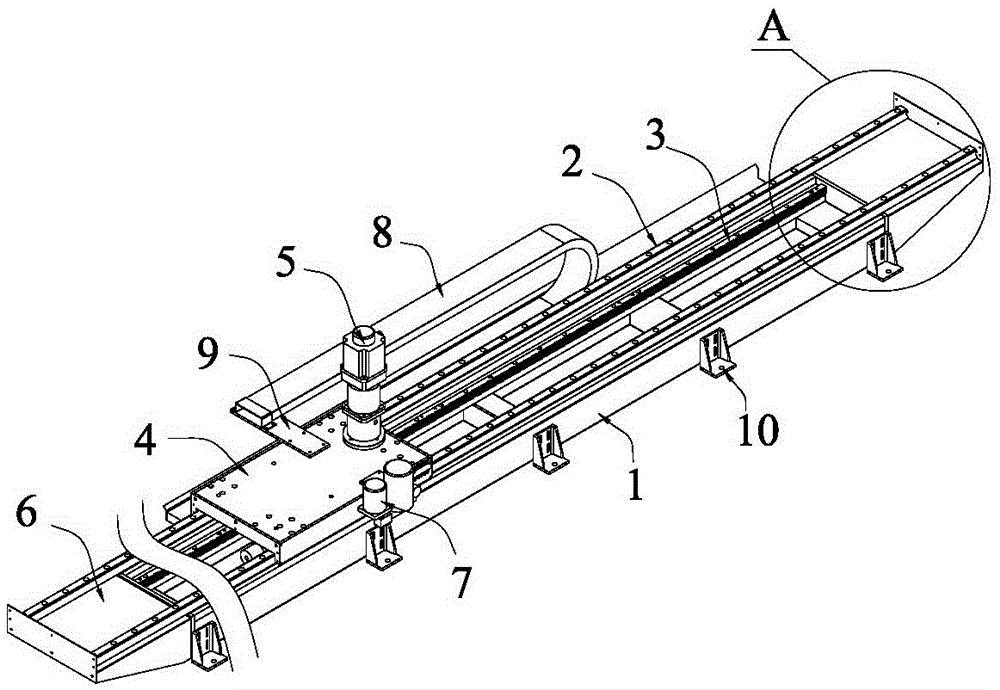

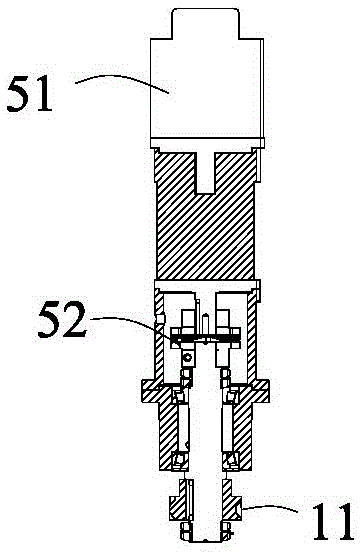

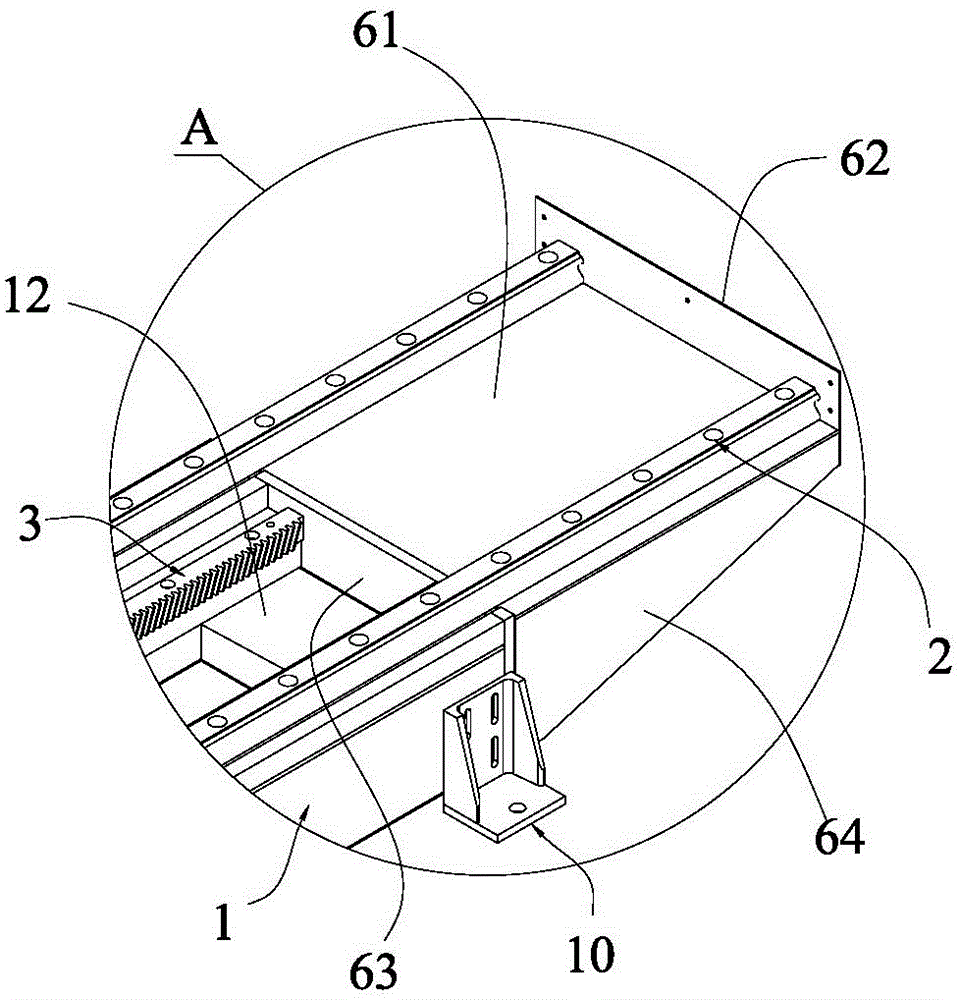

[0016] see figure 1 , figure 2 and image 3 , the present embodiment provides a large-stroke heavy-load sliding table structure, which includes a sliding table frame body 1, a linear sliding rail 2, a transmission rack 3, a load-bearing slide plate 4, a power output device 5, a dust-proof stopper 6 and a supply Oil device 7, two linear slide rails 2 are symmetrically arranged on both sides of the upper surface of the slide frame body 1, the load slide 4 is movably arranged on the linear slide rail 2 through the slide block, the slide frame body 1 There is an accommodating groove 12 extending along the running direction of the linear slide rail 2 at the middle position of the upper surface of the accommodating groove. , the position of the power output device 5 corresponding to the transmission rack 3 is arranged on the load sliding plate 4, and the output end of the power output device 5 is provided with a transmission gear 11 meshing with the transmission rack 3, the suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com