Dynamic scheduling method of steelmaking operation plan

A technology of operation planning and planning, applied in the direction of calculation, data processing application, resources, etc., can solve the problems that the operation plan cannot be adjusted automatically, the results of on-site operation are not ideal, and it is difficult to consider all constraints, so as to save production costs and reduce energy consumption. The effect of low power consumption and compact operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

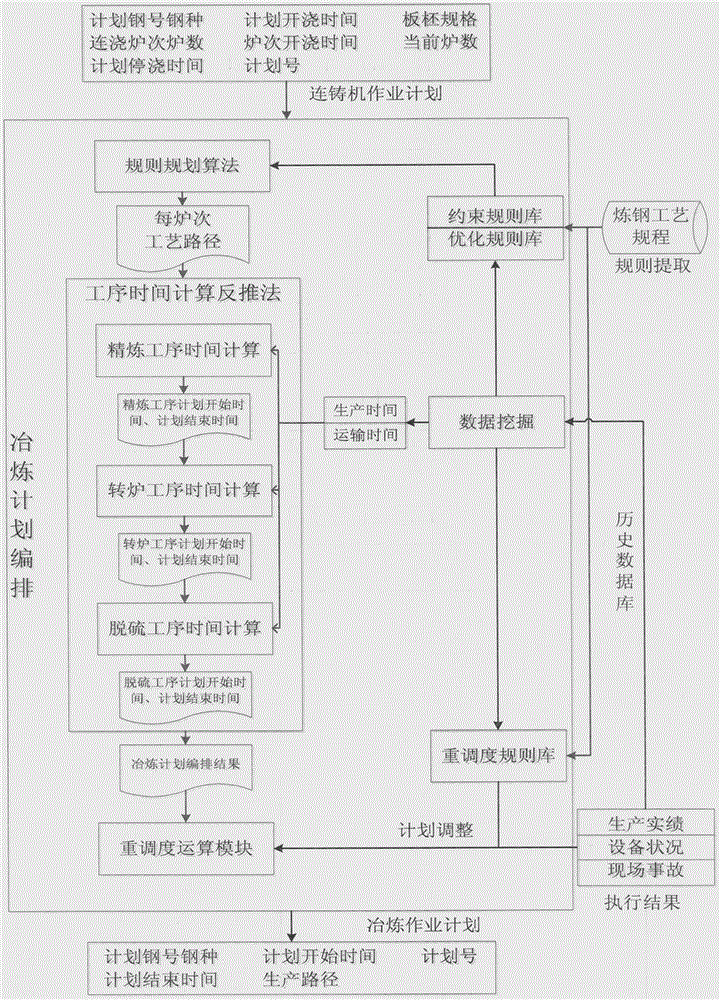

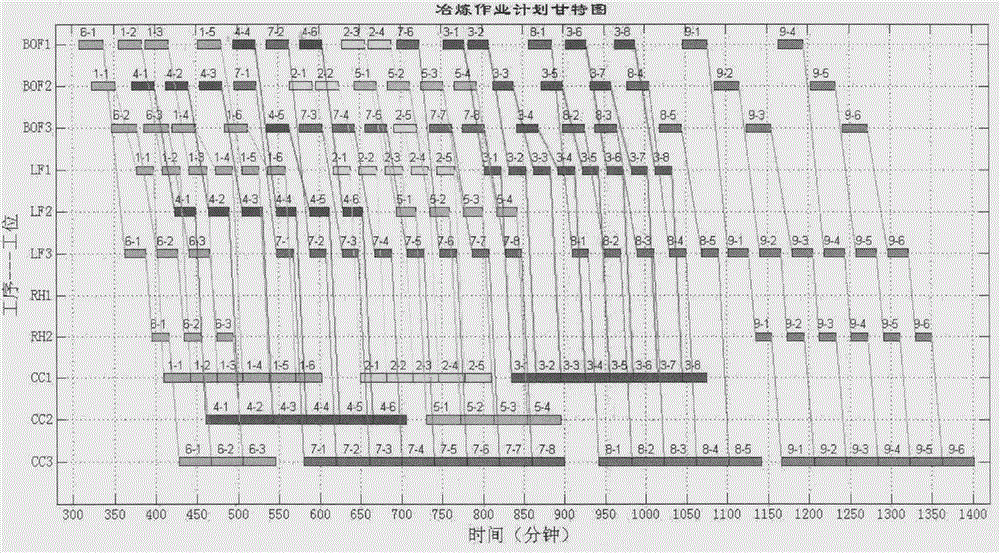

[0030] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

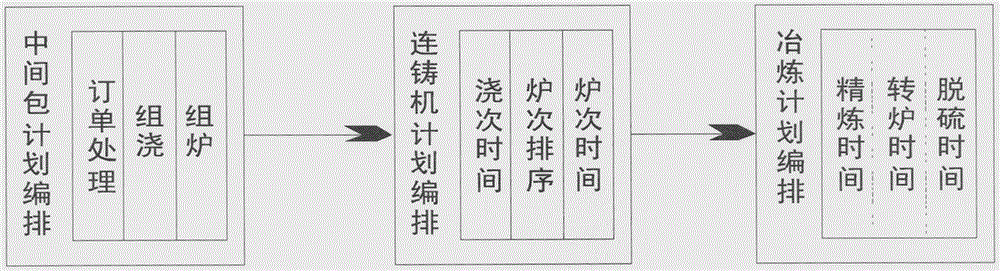

[0031] Such as figure 1 , figure 2 As shown, a dynamic scheduling method for steelmaking operation planning, the method mainly includes the following steps:

[0032] Step 1. Tundish plan layout. According to the production order from the steel mill and / or the slab rolling plan that needs to be hot loaded and sent from the hot rolling mill, the steel mill tundish plan is compiled. The specific steps are as follows:

[0033] 101) Order preprocessing: According to the steel grade, specification, and output information of the customer order, it is matched with the current inventory to calculate the number of slabs to be smelted; secondly, the customer order is divided into multiple small orders according to product information. The order corresponds to a steel grade and slab specification.

[0034] 102) Order grouping, grouping multiple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com