Patents

Literature

30results about How to "Improve the stability of force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanical machining platform device capable of adjusting angle

InactiveCN105479417AImprove the stability of forceImprove mechanical stabilityWork benchesBilateral symmetryMachining

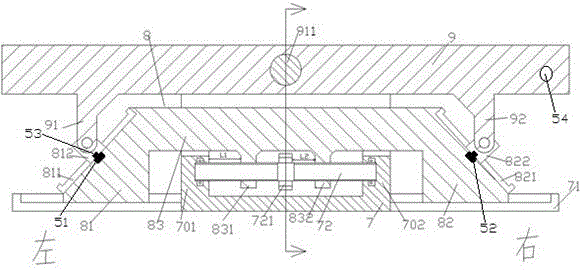

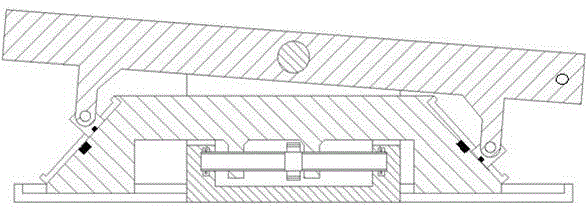

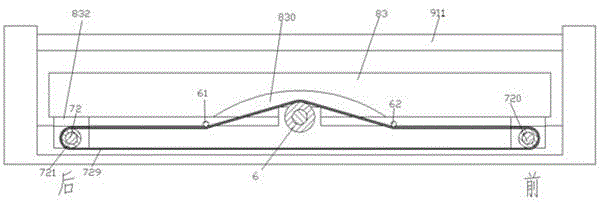

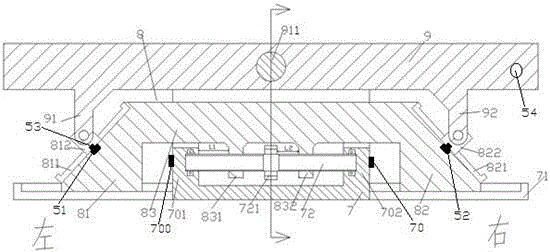

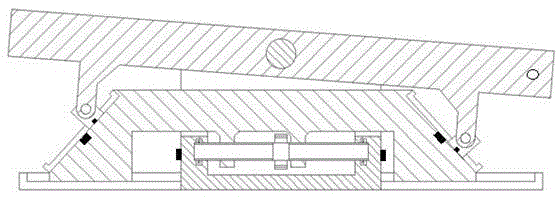

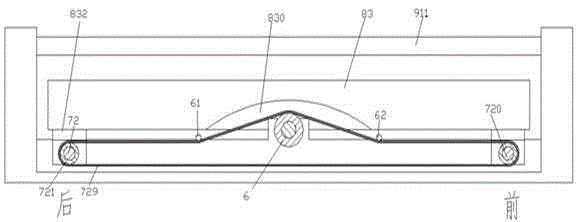

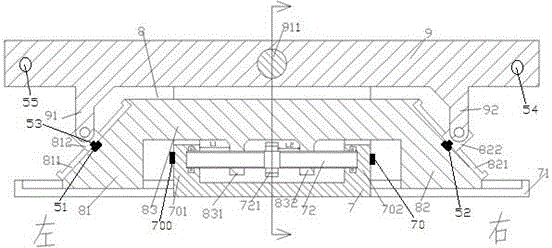

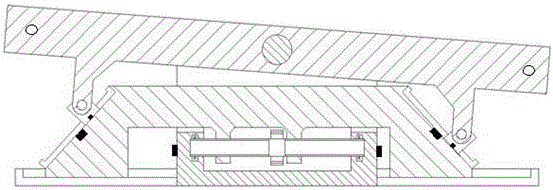

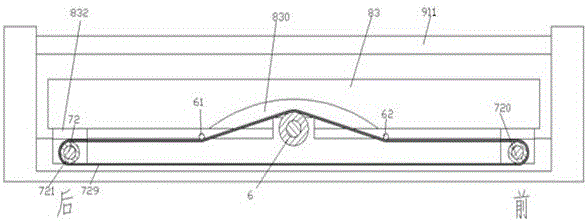

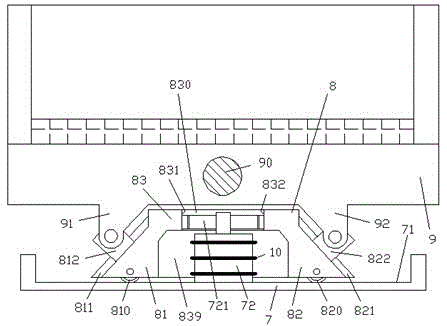

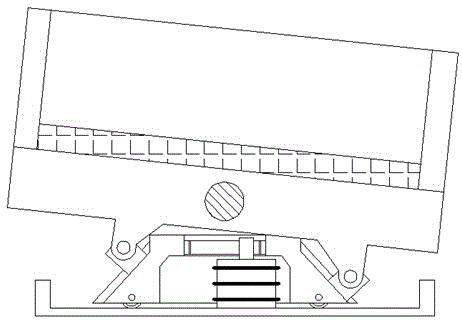

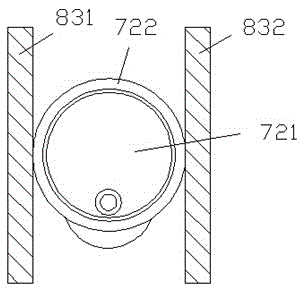

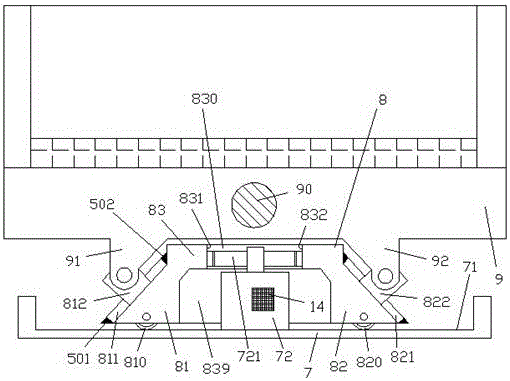

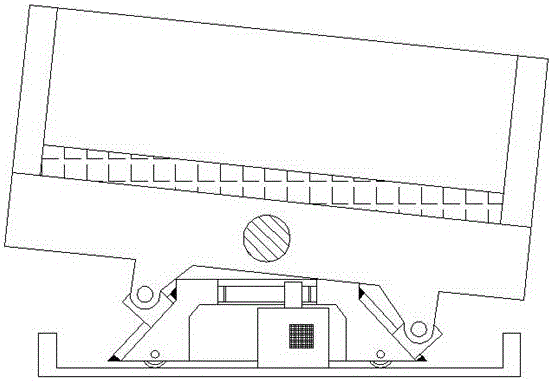

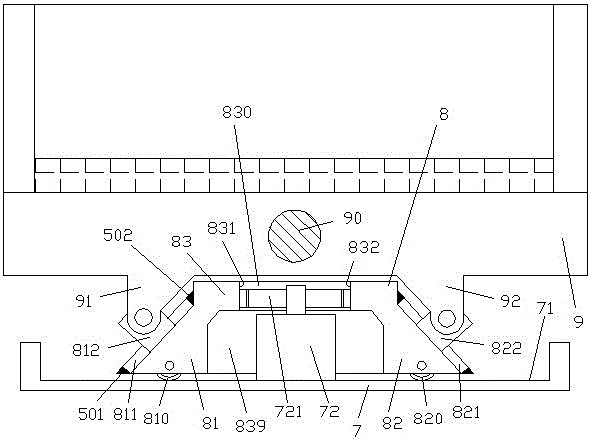

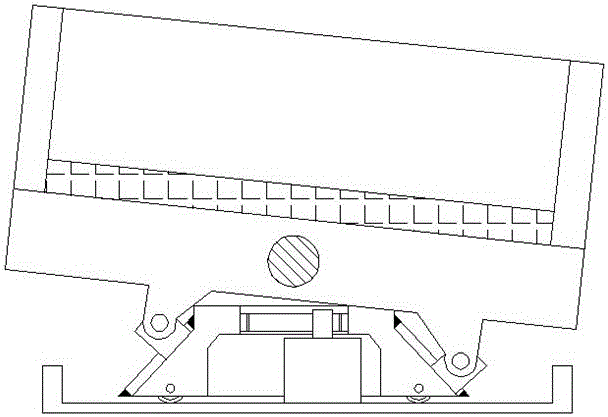

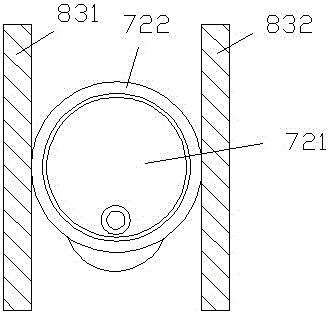

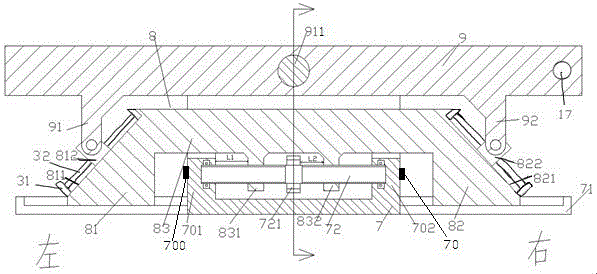

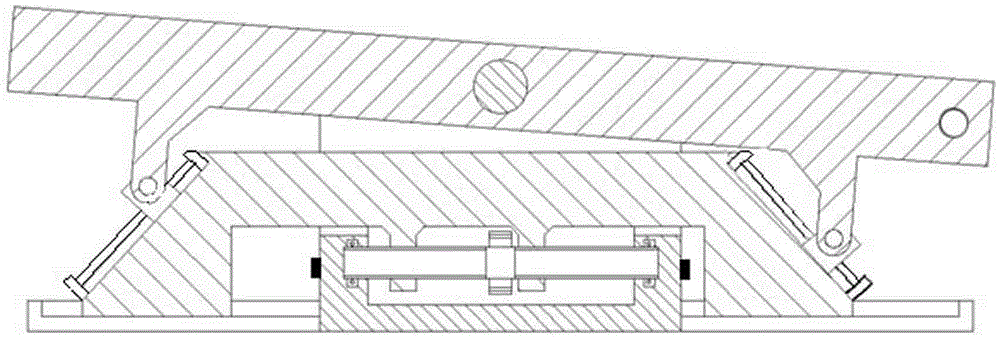

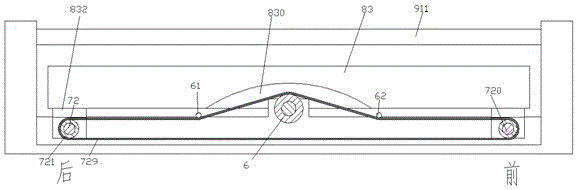

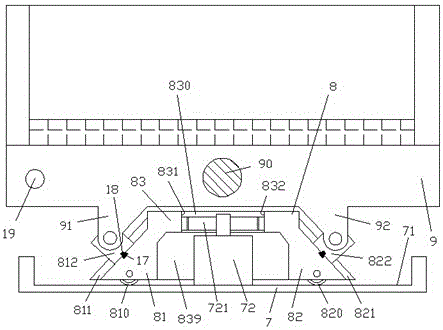

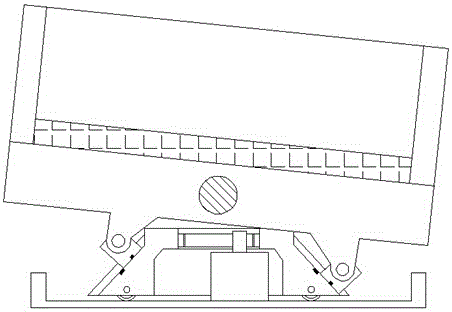

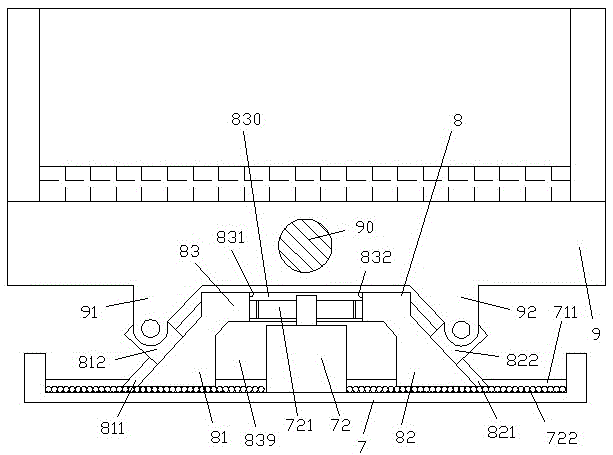

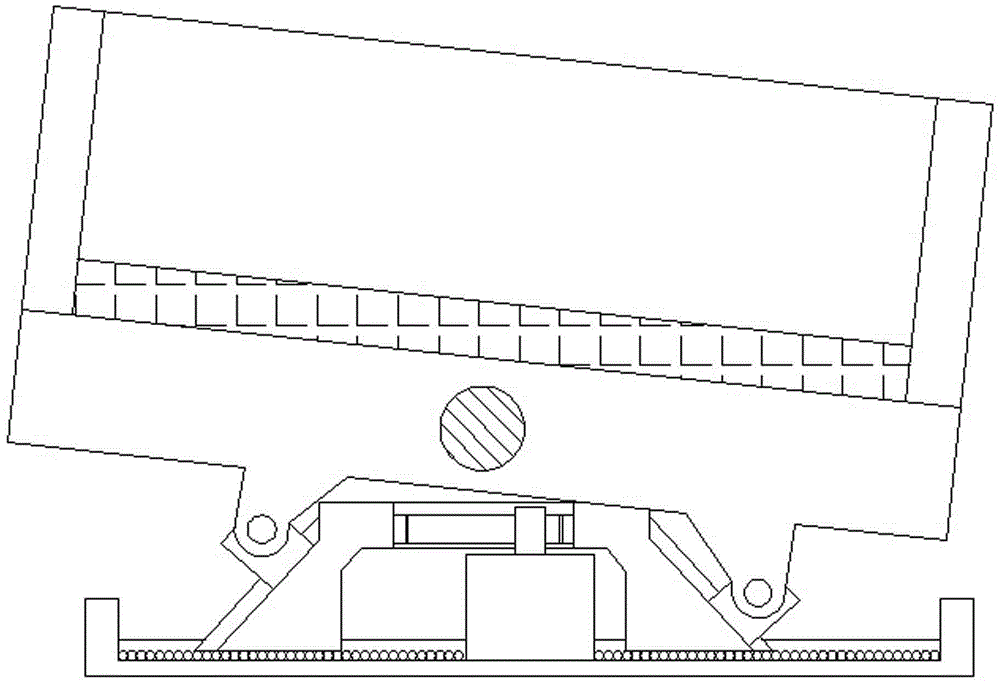

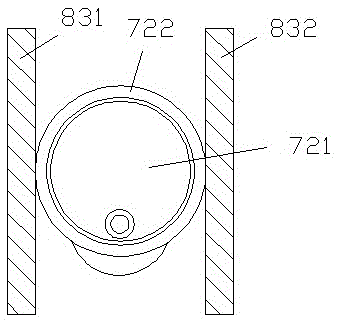

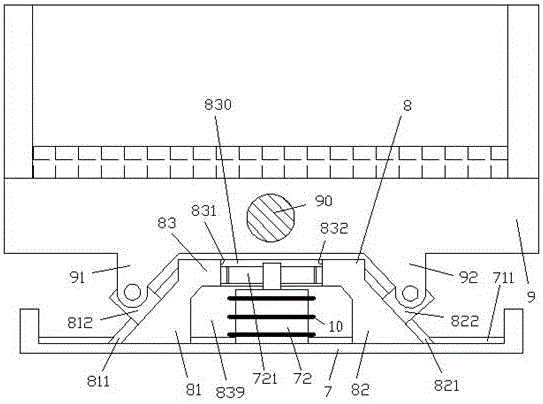

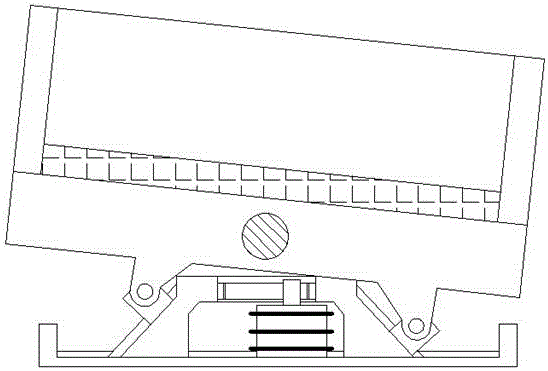

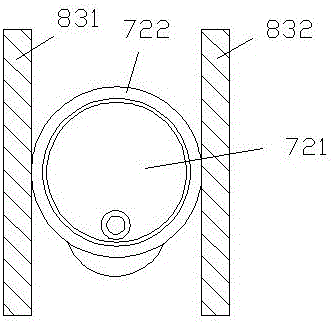

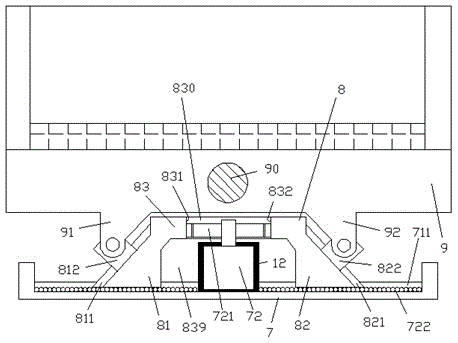

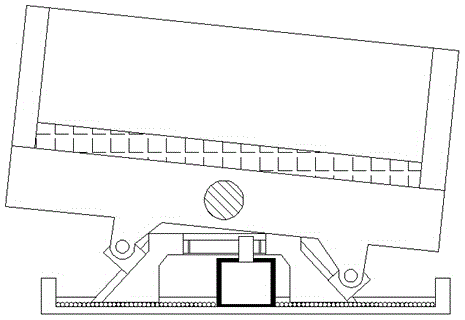

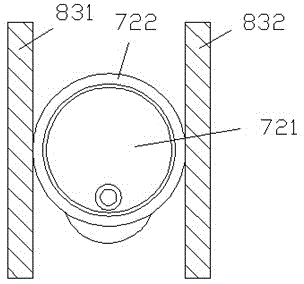

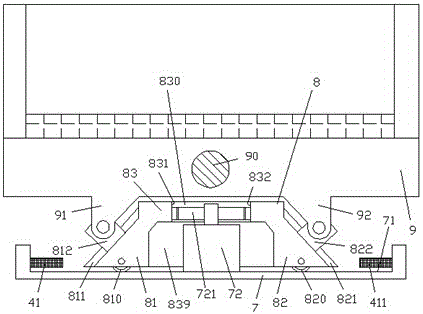

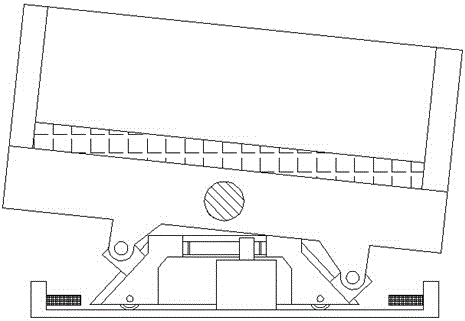

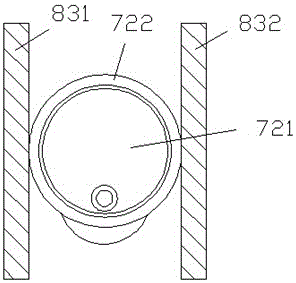

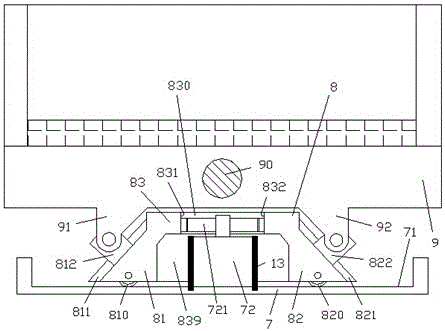

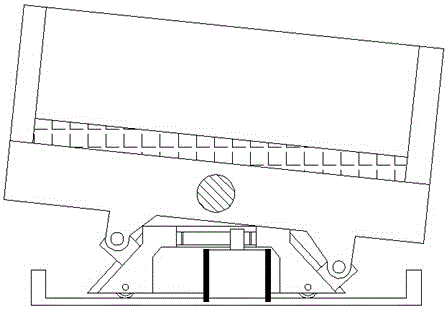

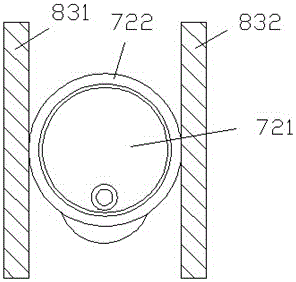

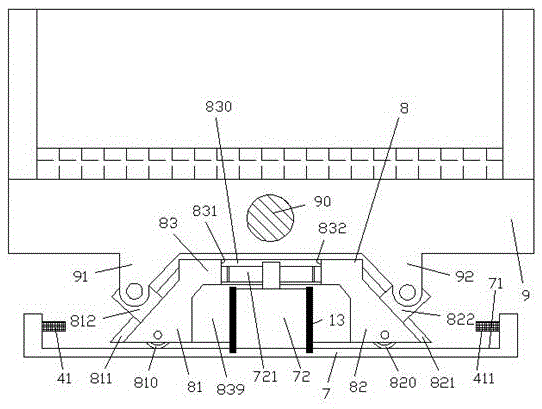

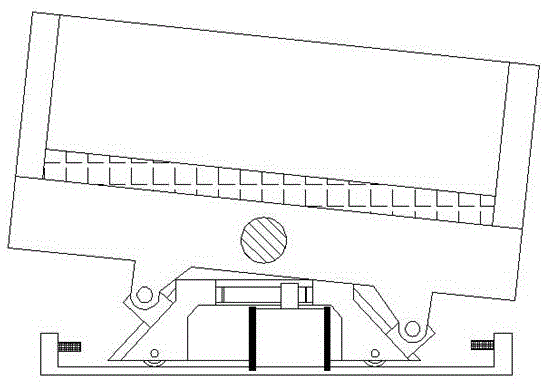

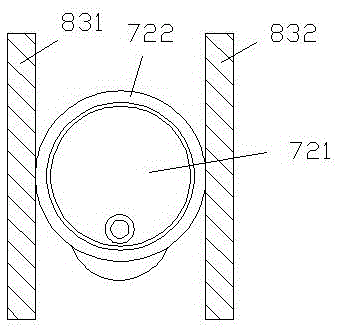

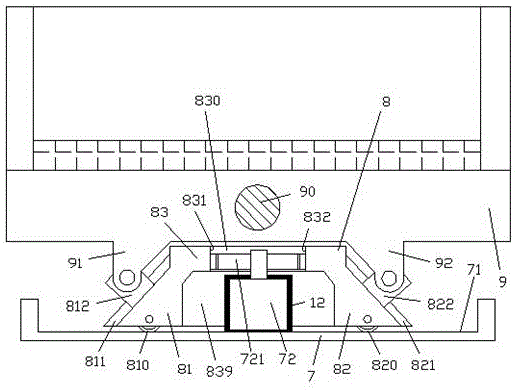

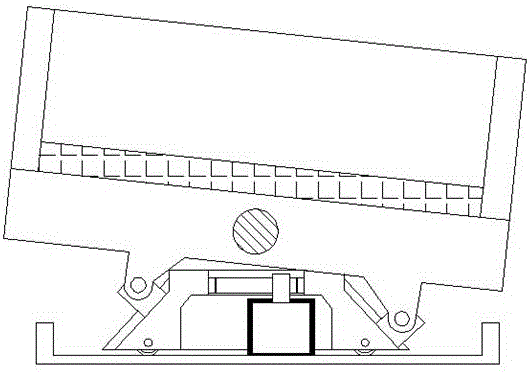

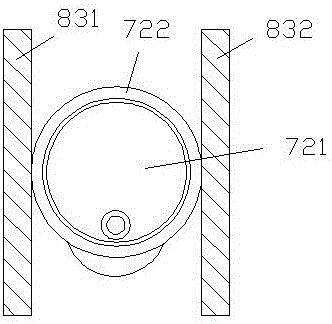

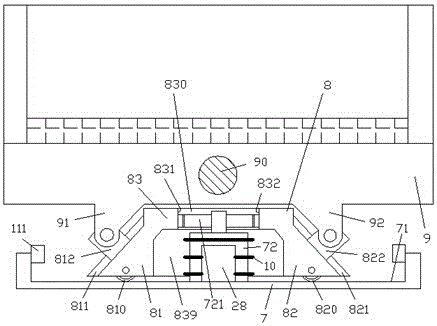

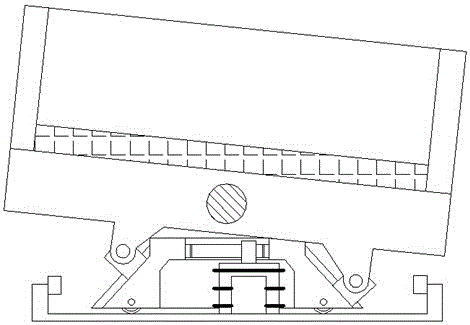

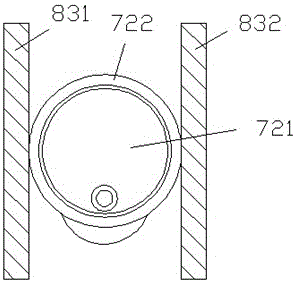

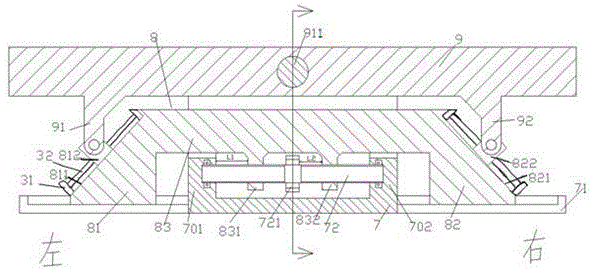

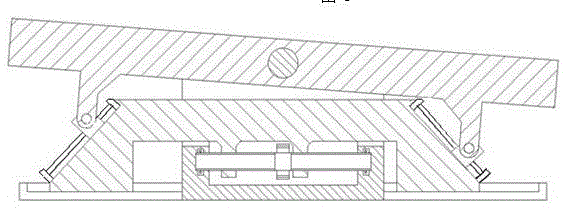

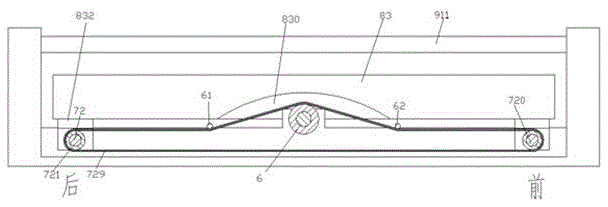

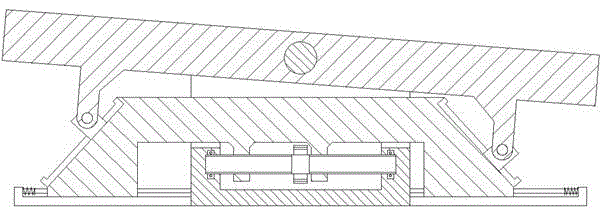

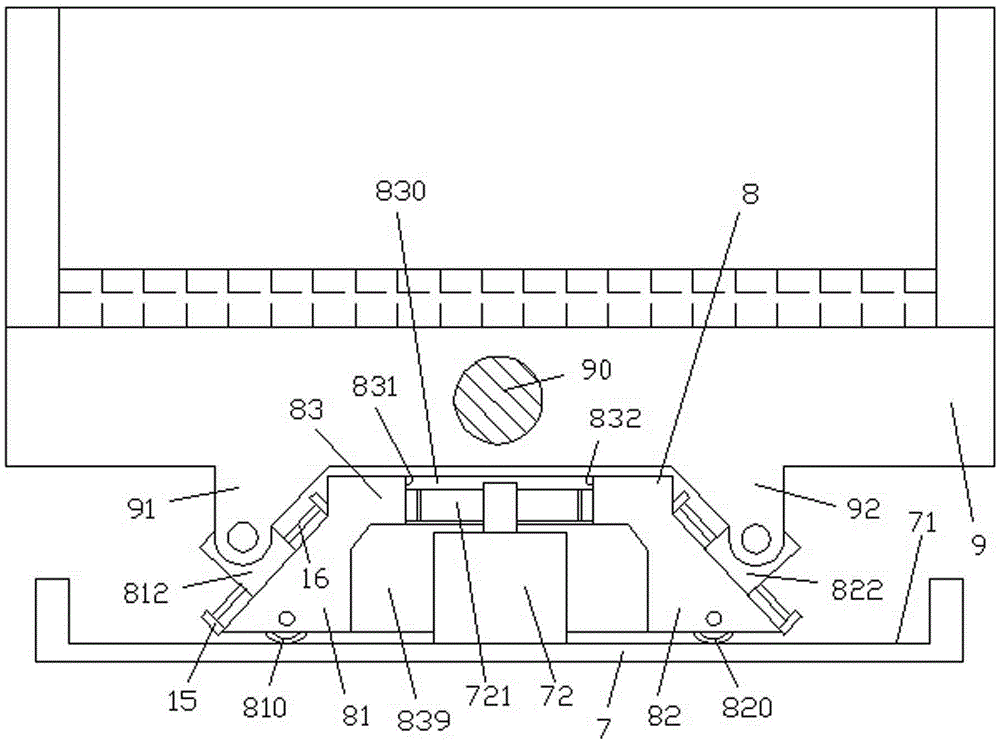

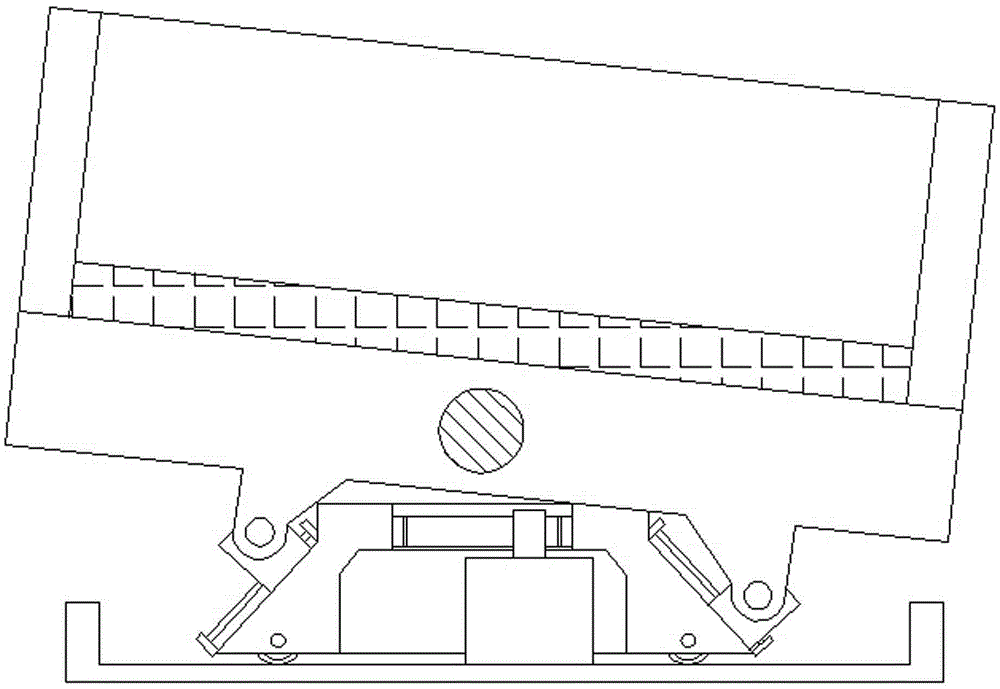

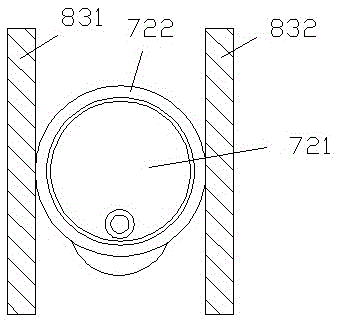

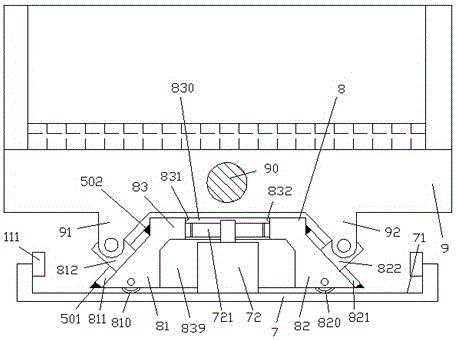

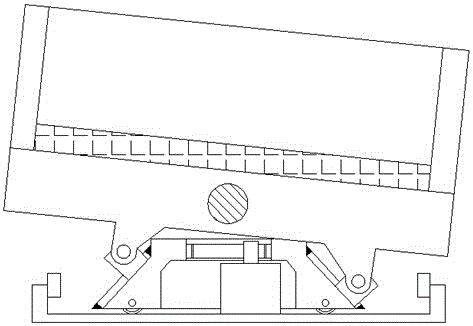

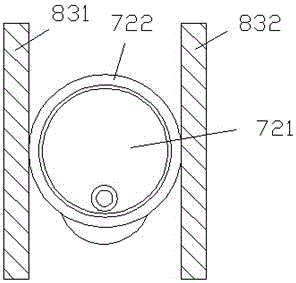

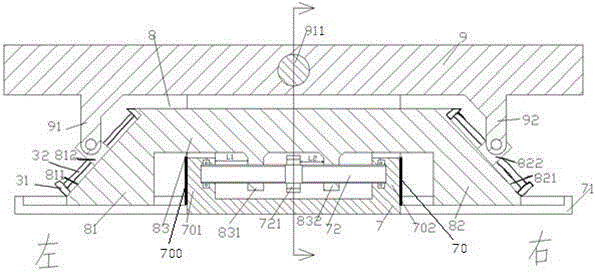

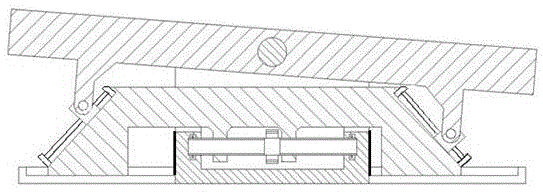

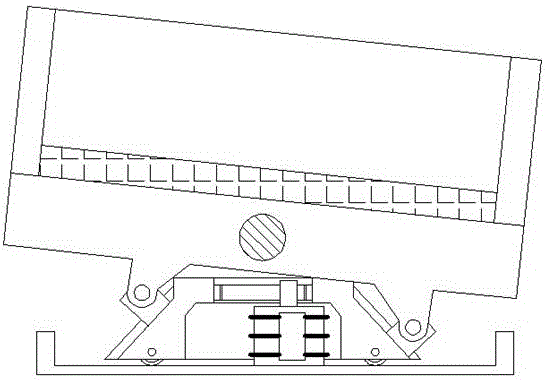

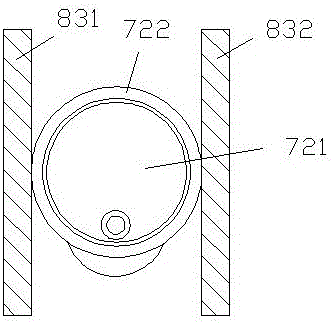

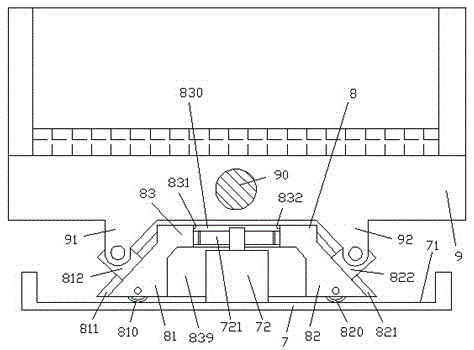

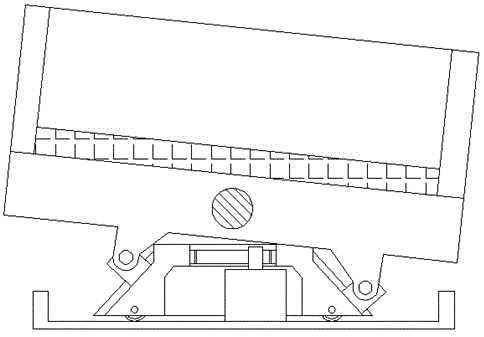

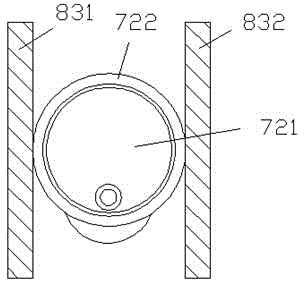

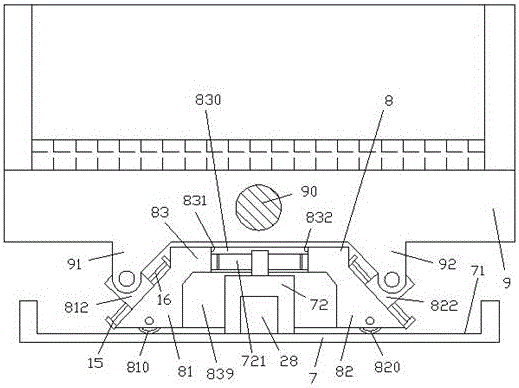

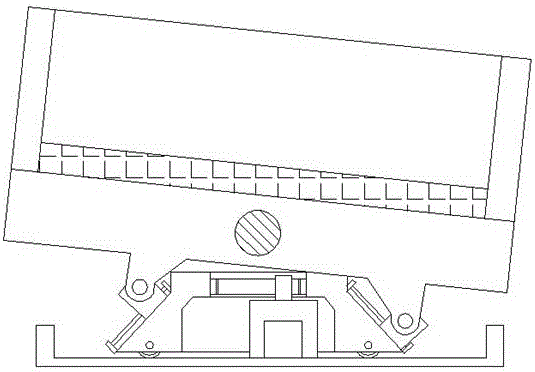

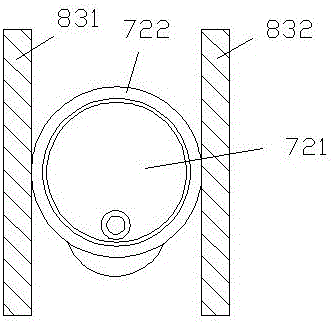

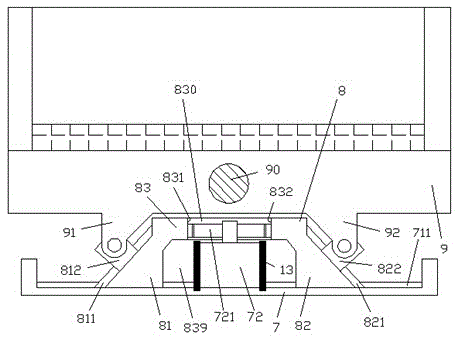

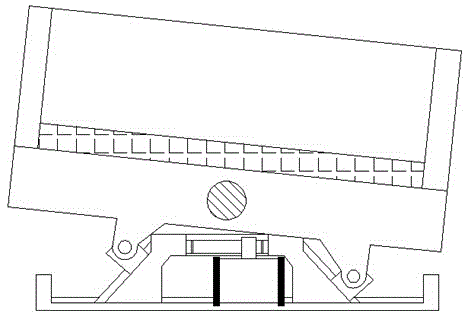

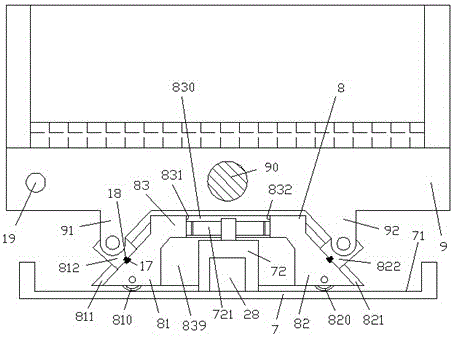

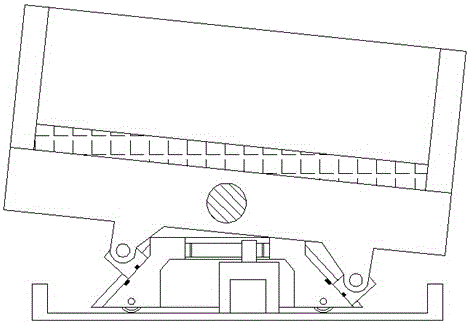

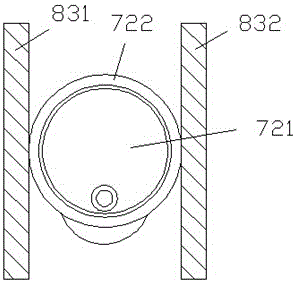

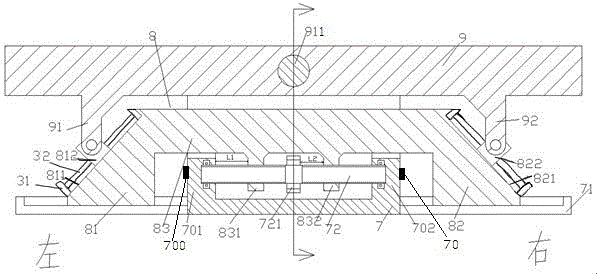

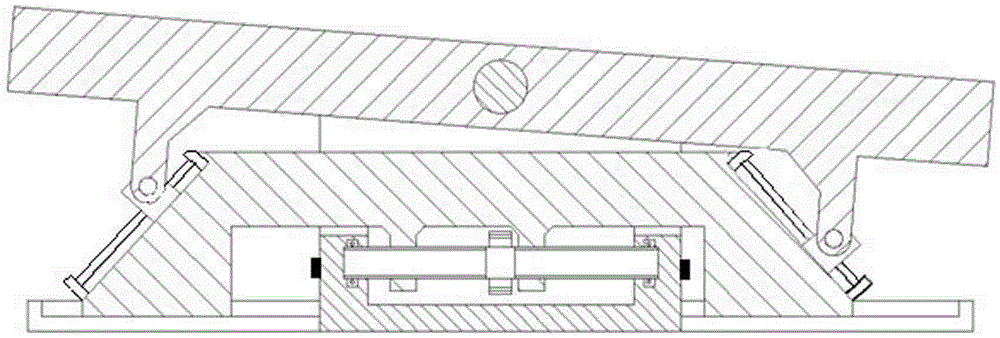

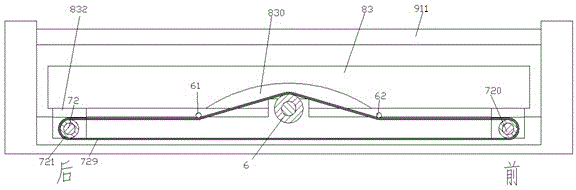

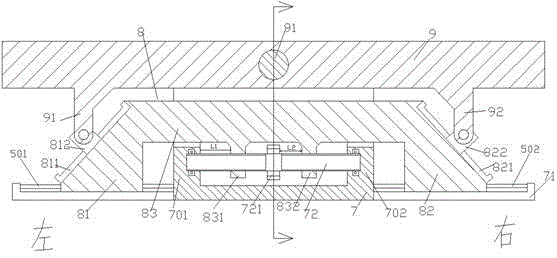

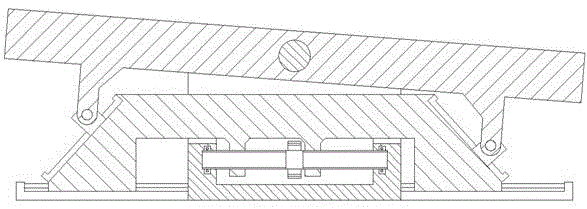

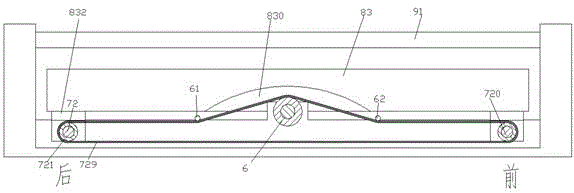

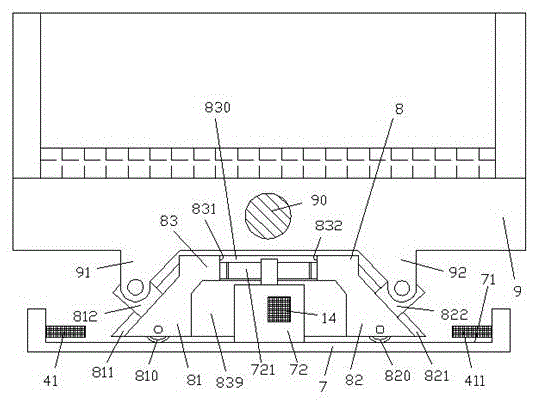

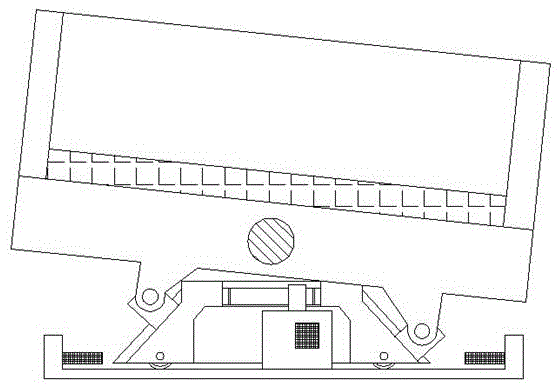

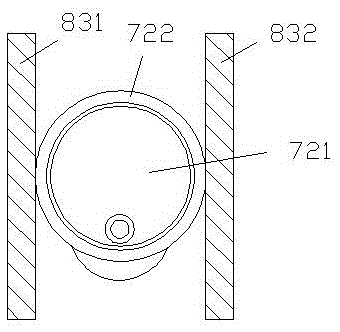

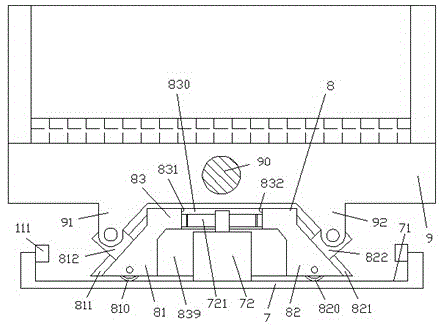

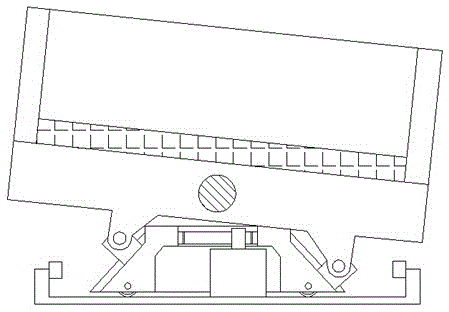

The invention provides a mechanical machining platform device capable of adjusting the angle. The mechanical machining platform device comprises a rack (7), a working platform part (9) and an angle adjusting support sliding block part (8); the working platform part (9) is hinged to the upper portion of the rack (7) through a hinge shaft (911); the angle adjusting support sliding block part (8) can slide left and right in a sliding groove part (71) which is fixedly arranged in the bottom of the rack (7) and comprises a middle main body portion (83) and two slope portions (81, 82) arranged in a bilateral symmetry mode; the slope portions (81, 82) are provided with slope sliding grooves (811, 821) which are symmetrical to each other respectively, the slope sliding grooves (811, 821) are used for allowing a left support sliding block (812) and a right support sliding block (822) to slide in respectively, and the left support sliding block (812) and the right support sliding block (822) are hinged to support legs (91, 92) which are symmetrically arranged at the left end and the right end of the lower side of the working platform part (9) respectively.

Owner:余丽君

Novel angle-adjustable intelligent working platform device

InactiveCN105598928AImprove the stability of forceImprove mechanical stabilityWork benchesEngineeringBilateral symmetry

The invention provides a novel angle-adjustable intelligent working platform device. The novel angle-adjustable intelligent working platform device comprises a rack (7), a working platform part (9) hinged to the upper portion of the rack (7) through a hinge shaft (911) and an angle adjustment support sliding block part (8) capable of sliding in a sliding groove part (71) fixedly arranged at the bottom of the rack (7) left and right, wherein the angle adjustment support sliding block part (8) comprises a middle main body portion (83) and two bevel portions (81, 82) arranged in a bilateral symmetry mode; the two bevel portions (81, 82) are provided with bevel sliding grooves (811, 821) which are symmetrical with each other respectively, the bevel sliding grooves (811, 821) are used for allowing a left support sliding block (812) and a right support sliding block (822) to slide in respectively, and the left support sliding block (812) and the right support sliding block (822) are hinged to support legs (91, 92) which are symmetrically arranged at the left end and the right end of the lower side of the working platform part (9) respectively.

Owner:莫焕东

Operating platform used for mechanical equipment and having adjustable angle

InactiveCN105729430AImprove the stability of forceImprove mechanical stabilityWork benchesMechanical equipmentEngineering

The invention relate to an operating platform used for mechanical equipment and having an adjustable angle. The operating platform comprises a rack (7), a working platform component (9) hinged with the upper part of the rack (7) by an articulated shaft (911), and an angle adjusting support sliding block component (8) capable of sliding left and right in a chute component (71) fixedly arranged at the bottom of the rack (7), wherein the angle adjusting support sliding block component (8) comprises a middle main body part (83) and two bevel parts (81, 82) arranged in bilateral symmetry, the two bevel parts (81, 82) are respectively provided with a bevel chute (811) and a bevel chute (821) which are symmetric to each other and are used for respectively accepting sliding of a left support sliding block (812) and a right support sliding block (822) therein, and the left support sliding block (812) and the right support sliding block (822) are respectively hinged with support leg parts (91, 92) symmetrically arranged at the left end and the right end of the lower side of the working platform component (9).

Owner:莫焕东

Safe material shaking device

InactiveCN105540164AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

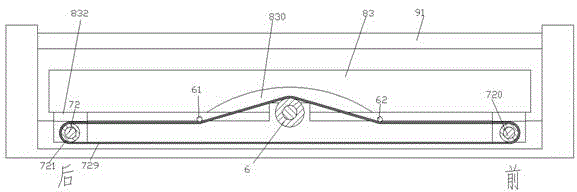

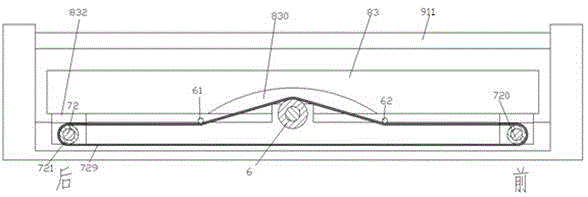

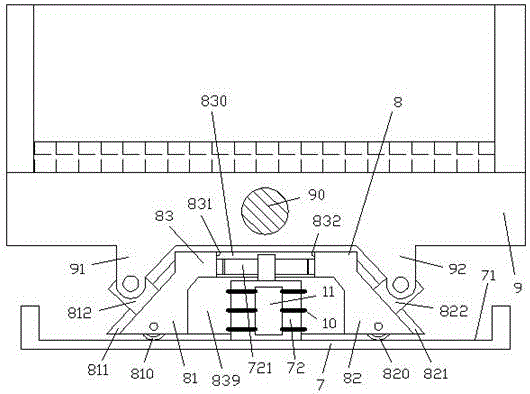

A safe material shaking device comprises a machine frame (7), a shaken material containing part (9) hinged to the upper portion of the machine frame (7) through an articulated shaft (90), and a shake driving slide block (8) capable of moving on a rolling wheel walking track fixedly arranged at the bottom position of the machine frame (7) in a left-right mode, wherein the shake driving slide block (8) comprises a middle body portion (83) and two oblique plane portions (81 and 82) arranged bilaterally and symmetrically. The two oblique plane portions (81 and 82) are respectively provided with mutually-symmetrical oblique plane chutes (811 and 821) respectively bearing a left supporting slide block (812) and a right supporting slide block (822) for sliding, and the left supporting slide block (812) and the right supporting slide block (822) are respectively hinged to supporting protrusion portions (91 and 92) symmetrically arranged at the left end and the right end of the lower side of the shaken material containing part (9).

Owner:何慧敏

Material vibrator capable of achieving limiting control

InactiveCN105728317AStable structureImprove the stability of forceSievingScreeningEngineeringBilateral symmetry

The invention relates to a material vibrator capable of achieving limiting control. The material vibrator comprises a rack (7), a vibration material containing component (9) hinged to the upper portion of the rack (7) through a hinge shaft (90) and a vibration driving sliding block (8) capable of moving left and right on a roller walking track (71) fixedly arranged at the bottom of the rack (7); the vibration driving sliding block (8) comprises a middle body part (83) and two slope faces (81 and 82) arranged in a bilateral symmetry manner; the two slope faces (81 and 82) are provided with symmetrical slope face sliding grooves (811 and 821) and are used for bearing a left supporting sliding block (812) and a right supporting sliding block (822) to slide; the left supporting sliding block (812) is hinged to a supporting protrusion (91) at the left end of the lower side of the vibration material containing component (9), the right supporting sliding block (822) is hinged to a supporting protrusion (92) at the right end of the lower side of the vibration material containing component (9), and the left supporting sliding block (812) and the right supporting sliding block (822) are symmetrically arranged.

Owner:董海斌

Material vibrating device capable of achieving sliding limiting

InactiveCN105750191AStable structureImprove the stability of forceSievingScreeningEngineeringMechanical engineering

A material vibrating device capable of achieving sliding limiting comprises a machine frame (7), a vibrating material containing part (9) hinged to the upper portion of the machine frame (7) through a hinge shaft (9), and a vibrating driving slider (8) which can be fixedly arranged on a roller traveling rail (71) at the bottom of the machine frame (7) and can move left and right.The vibrating driving slider (8) comprises a middle body part (83) and two inclined face parts (81 and 82) symmetrically arranged on the left side and the right side.The two inclined face parts (81 and 82) are provided with symmetric inclined face sliding grooves (811 and 821) respectively and used for bearing sliding of a left supporting slider (812) and a right supporting slider (822) respectively, and the left supporting slider (812) and the right supporting slider (822) are symmetrically hinged to supporting protruding parts (91 and 92) at the left end and the right end of the lower side of the vibrating material containing part (9) respectively.

Owner:XIAOGAN BUJI ELECTRONICS COMMERCE CO LTD

Working table used for carrying out machining and allowing angle to be adjusted

InactiveCN105643578AImprove the stability of forceImprove mechanical stabilityWork benchesBilateral symmetryMachining

The invention provides a working table used for carrying out machining and allowing the angle to be adjusted. The working table comprises a rack (7), a working platform part (9) hinged to the upper portion of the rack (7) through a hinge shaft (911), and an angle adjusting and supporting slide block part (8) capable of sliding left and right in a sliding groove part (71) fixedly arranged at the bottom of the rack (7). The angle adjusting and supporting slide block part (8) comprises a middle body part (83) and two slope parts (81 and 82) arranged in a bilateral symmetry manner. The two slope parts (81 and 82) are provided with slope sliding grooves (811 and 821) symmetrical to each other respectively, wherein a left supporting slide block (812) and a right supporting slide block (822) can slide in the slope sliding grooves (811 and 821) respectively.

Owner:YIWU CITY SHOUGEN CRAFTS

Material vibration device with horizontal position detection function

InactiveCN105692085AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

Owner:何慧敏

Ball-driven material vibration device

InactiveCN105478345AStable structureImprove the stability of forceSievingScreeningEngineeringBilateral symmetry

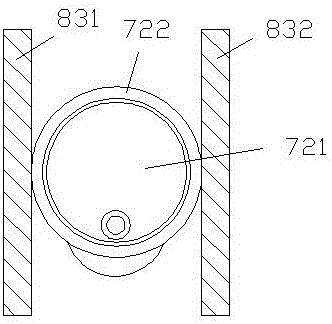

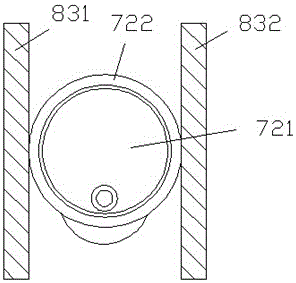

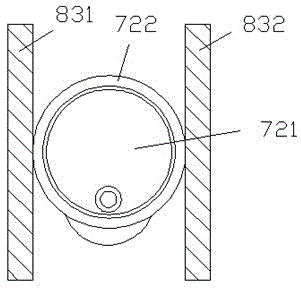

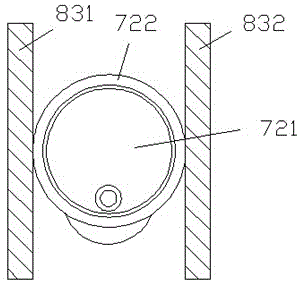

The invention discloses a ball-driven material vibration device. The device comprises a rack (7), a vibrating material containing component (9) hinged to the upper portion of the rack (7) through an articulated shaft (90) and a vibration driving slide block (8) capable of moving left and right at the bottom of the rack (7), wherein a guiding slide groove (711) in sliding fit with the vibration driving slide block (8) is formed in the bottom of the rack (7) and used for guiding the left and right movement of the vibration driving slide block (8); the vibration driving slide block (8) comprises a middle body part (83) and two bevel parts (81 and 82) arranged in bilateral symmetry; the two bevel parts (81 and 82) are provided with bevel slide grooves (811 and 821) respectively, the bevel slide grooves (811 and 821) are in mutual symmetry and are used for bearing a left supporting slide block (812) and a right supporting slide block (822) to slide, the left supporting slide block (812) and the right supporting slide block (822) are hinged to supporting convex parts (91 and 92) respectively, and the supporting convex parts (91 and 92) are symmetrically arranged at the left end and the right end of the lower side of the vibrating material containing component (9).

Owner:晋江市东坤电子实业有限公司

Guiding heat dissipation type material vibrator

InactiveCN105692083AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

A guiding heat dissipation type material vibrator comprises a machine frame (7), a vibrated material containing component (9) and a vibration driving sliding block (8), wherein the vibrated material containing component (9) is hinged to the upper portion of the machine frame (7) through a hinge shaft (90); and the vibration driving sliding block (8) can move leftwards and rightwards at the bottom of the machine frame (7). A guide sliding groove (711) which is slidably matched with the vibration driving sliding block (8) is formed in the bottom of the machine frame (7) and used for guiding the leftward movement and the rightward movement of the vibration driving sliding block (8). The vibration driving sliding block (8) comprises a middle main body part (83) and two oblique surface parts (81 and 82), wherein the two oblique surface parts (81 and 82) are symmetrically arranged on the left side and the right side correspondingly. The two oblique surface parts (81 and 82) are provided with mutually symmetrical oblique surface sliding grooves (811 and 821) correspondingly, and the oblique surface sliding grooves (811 and 821) are used for bearing a left supporting sliding block (812) and a right supporting sliding block (822) to slide correspondingly. The left supporting sliding block (812) and the right supporting sliding block (822) are symmetrically hinged to supporting protrusions (91 and 92) which are symmetrically arranged at the left end and the right end of the lower side of the vibrated material containing component (9) correspondingly.

Owner:董海斌

Vibrator capable of stabilizing materials

InactiveCN105600318AStable structureImprove the stability of forceJigging conveyorsMechanical engineeringEngineering

Owner:黎钊彬

Buffer type material vibration device

InactiveCN105692084AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

Owner:何慧敏

Anti-shock type material vibrating device

InactiveCN105728319AImprove the stability of forceImplementation driveSievingScreeningEngineeringMechanical engineering

Owner:何慧敏

Buffering and shocking resisting type material vibration device

InactiveCN105523351AStable structureImprove the stability of forceJigging conveyorsBilateral symmetryEngineering

A buffering and shocking resisting type material vibration device comprises a machine frame (7), a vibratory material containing part (9) and a vibratory drive sliding block (8), wherein the vibratory material containing part (9) is hinged to the upper part of the machine frame (7) through a hinged shaft (90), and the vibratory drive sliding block (8) can horizontally move on a rolling wheel walking track (71) fixedly arranged on the bottom of the machine frame (7); the vibratory drive sliding block (8) comprises a middle main body part (83) and two inclined surface parts (81 and 82) arranged in bilateral symmetry, the two inclined surface parts (81 and 82) are provided with symmetric inclined surface sliding grooves (811 and 821) respectively for bearing a left supporting sliding block (812) and a right supporting sliding block (822) to slide respectively, and the left supporting sliding block (812) and the right supporting sliding block (822) are hinged to supporting protrusion parts (91 and 92) symmetrically arranged at the left end and the right end of the lower side of the vibratory material containing part (9) respectively.

Owner:董海斌

Noise-reducing material vibrating device

InactiveCN105668150AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

A noise-reducing material vibrating device comprises a machine frame (7), a vibrated material containing component (9) and a vibration driving sliding block (8), wherein the vibrated material containing component (9) is hinged to the upper part of the machine frame (7) through a hinged shaft (90); the vibration driving sliding block (8) can move left and right on a roller travelling track (71) fixed at the bottom of the machine frame (7); the vibration driving sliding block (8) comprises a middle main body part (83), a left inclined surface part (81) and a right inclined surface part (82); the two inclined surface parts (81 and 82) are arranged symmetrically and are provided with inclined surface sliding grooves (811 and 821) respectively; the inclined surface sliding grooves (811 and 821) are mutually symmetric and are used for allowing a left support sliding block (812) and a right support sliding block (822) to slide in respectively; and the left support sliding block (812) and the right support sliding block (822) are respectively hinged to support bulges (91 and 92), which are symmetrically arranged at the left and right ends on the lower side of the vibrated material containing component (9).

Owner:郑静

Energy-saving material vibrator

InactiveCN105689262AStable structureImprove the stability of forceSievingScreeningLED lampMechanical engineering

An energy-saving material vibrator comprises a machine fame (7), a vibrated material containing component (9) and a vibration driving sliding block (8), wherein the vibrated material containing component (9) is hinged to the upper portion of the machine frame (7) through a hinge shaft (90); and the vibration driving sliding block (8) can move leftwards and rightwards on a roller traveling rail (71) fixedly arranged at the bottom of the machine frame (7). LED lamps (111) are arranged above the left end and the right end of the roller traveling rail (71). The LED lamps (111) are fixed to the machine frame (7) and used for illuminating so that the leftward movement and rightward movement of the vibration driving sliding block (8) can be observed conveniently, and faults can be eliminated in time when the leftward movement and rightward movement of the vibration driving sliding block (8) fail. The vibration driving sliding block (8) comprises a middle main body part (83) and two oblique surface parts (81 and 82), wherein the two oblique surface parts (81 and 82) are arranged on the left side and the right side symmetrically.

Owner:黎钊彬

Machining workbench device capable of adjusting angle

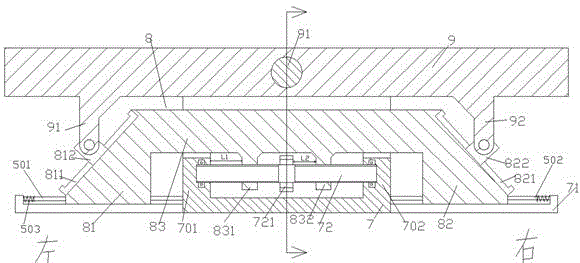

InactiveCN105537977AImprove the stability of forceImprove mechanical stabilityLarge fixed membersMachiningWorkbench

A machining workbench device capable of adjusting the angle comprises a rack (7), a work platform part (9) hinged to the upper portion of the rack (7) through a hinging shaft (911), and an angle adjusting and supporting slider part (8) which can slide left and right in a slide groove part (71) fixedly arranged at the bottom of the rack (7), wherein the angle adjusting and supporting slider part (8) comprises a middle body part (83) and two bevel parts (81 and 82) which are bilaterally symmetrical. The two bevel parts (81 and 82) are provided with symmetrical bevel slide grooves (811 and 821) used for a left supporting slider (812) and a right supporting slider (822) to slide therein. The upper ends and the lower ends of the bevel slide grooves (811 and 821) of the two bevel parts (81 and 82) are both provided with installing blocks (31) which are internally and fixedly provided with guiding rods (32) parallel with the bevel slide grooves (811 and 821). The guiding rods penetrate the left supporting slider (812) and the right supporting slider (822), and the left supporting slider (812) and the right supporting slider (822) are hinged to supporting leg parts (91 and 92) symmetrically arranged at the left end and the right end of the lower side of the work platform part (9) respectively.

Owner:郑静

Angle-adjustable working platform mechanism for machining operation

InactiveCN105598709AImprove the stability of forceImprove mechanical stabilityLarge fixed membersEngineeringBilateral symmetry

The invention provides an angle-adjustable working platform mechanism for machining operation. The working platform mechanism comprises a rack (7), a working platform part (9) hinged to the upper portion of the rack (7) through a hinge shaft (91) and an angle adjustment support sliding block part (8) capable of sliding in a sliding groove part (71) fixedly arranged at the bottom of the rack (7) left and right, wherein the angle adjustment support sliding block part (8) comprises a middle main body portion (83) and two bevel portions (81, 82) arranged in a bilateral symmetry mode; the two bevel portions (81, 82) are provided with bevel sliding grooves (811, 821) which are symmetrical with each other respectively, the bevel sliding grooves (811, 821) are used for allowing a left support sliding block (812) and a right support sliding block (822) to slide in respectively, and the left support sliding block (812) and the right support sliding block (822) are hinged to support legs (91, 92) which are symmetrically arranged at the left end and the right end of the lower side of the working platform part (9) respectively.

Owner:莫焕东

Stable-sliding material vibrating device

InactiveCN105668152AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

A stable-sliding material vibrating device comprises a machine frame (7), a vibrated material containing component (9) and a vibration driving sliding block (8), wherein the vibrated material containing component (9) is hinged to the upper part of the machine frame (7) through a hinged shaft (90); the vibration driving sliding block (8) can move left and right on a roller travelling track (71) fixed at the bottom of the machine frame (7); the vibration driving sliding block (8) comprises a middle main body part (83), a left inclined surface part (81) and a right inclined surface part (82); and the two inclined surface parts (81 and 82) are arranged symmetrically and are used for allowing a left support sliding block (812) and a right support sliding block (822) to slide on respectively.

Owner:YIWU CITY SHOUGEN CRAFTS

Material vibrator

InactiveCN105668148AStable structureImprove the stability of forceJigging conveyorsLED lampMechanical engineering

A material vibrator comprises a machine frame (7), a vibrated material containing component (9) and a vibration driving sliding block (8), wherein the vibrated material containing component (9) is hinged to the upper part of the machine frame (7) through a hinged shaft (90); the vibration driving sliding block (8) can move left and right on a roller travelling track (71) fixed at the bottom of the machine frame (7); LED lamps (111) are arranged at the upper parts of the left end and the right end of the roller travelling track (71); the LED lamps (111) are fixed on the machine frame (7) and used for illumination, so that the left and right movement of the vibration driving sliding block (8) can be observed conveniently, and failures can be removed in time when the vibration driving sliding block (8) goes wrong during left and right movement; the vibration driving sliding block (8) comprises a middle main body part (83), a left inclined surface part (81) and a right inclined surface part (82); and the inclined surface parts (81 and 82) are arranged symmetrically.

Owner:黎钊彬

Workbench device with angle capable of being adjusted stably

InactiveCN105619361AImprove the stability of forceImprove mechanical stabilityWork benchesLarge fixed membersEngineeringBilateral symmetry

A workbench device with the angle capable of being adjusted stably comprises a rack, a work platform component hinged to the upper portion of the rack through a hinged shaft and an angle adjusting supporting sliding block component capable of sliding in a chute component left and right, wherein the chute component is fixedly arranged at the bottom of the rack. The angle adjusting supporting sliding block component comprises a middle body part and two bevel parts arranged in a bilateral symmetry manner. The two bevel parts are provided with symmetric bevel chutes. The bevel chutes are used for allowing a left supporting sliding block and a right supporting sliding block to slide therein. The upper ends and the lower ends of the bevel chutes of the two bevel parts are provided with mounting blocks. Guide rods parallel to the bevel chutes are fixedly mounted in the mounting blocks and penetrate the left supporting sliding block and the right supporting sliding block. The left supporting sliding block and the right supporting sliding block are hinged to supporting leg parts symmetrically arranged at the left end and the right end of the lower side of the work platform component.

Owner:余丽君

Material vibrating device running safely

InactiveCN105728318AStable structureImprove the stability of forceSievingScreeningMechanical engineeringEngineering

A material vibrating device with safe operation, comprising a frame (7), a vibrating material containing part (9) hinged to the upper part of the frame (7) through a hinge shaft (90), and a The vibration-driven slider (8) that moves left and right on the roller track (71) at the bottom of the frame (7), wherein the vibration-driven slider (8) includes a middle main body (83) and a left-right symmetrical The two slopes (81, 82) of the two slopes (81, 82) are respectively provided with mutually symmetrical slope chute (811, 821) to carry the left support slider (812) and the right The supporting slider (822) slides, and the left supporting slider (812) and the right supporting slider (822) are symmetrically arranged at the left and right ends of the lower side of the vibrating material holding part (9) respectively. The supporting protrusions (91, 92) are hinged.

Owner:郑静

Material vibrating device

InactiveCN105668151AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

A material vibrating device comprises a machine frame (7), a vibrated material containing component (9) and a vibration driving sliding block (8), wherein the vibrated material containing component (9) is hinged to the upper part of the machine frame (7) through a hinged shaft (90); the vibration driving sliding block (8) can move left and right on a roller travelling track (71) fixed at the bottom of the machine frame (7); the vibration driving sliding block (8) comprises a middle main body part (83), a left inclined surface part (81) and a right inclined surface part (82); the two inclined surface parts (81 and 82) are arranged symmetrically and are provided with inclined surface sliding grooves (811 and 821) respectively; the inclined surface sliding grooves (811 and 821) are mutually symmetric and are used for allowing a left support sliding block (812) and a right support sliding block (822) to slide in respectively; and the left support sliding block (812) and the right support sliding block (822) are respectively hinged to support bulges (91 and 92), which are symmetrically arranged at the left and right ends on the lower side of the vibrated material containing component (9).

Owner:何慧敏

Material vibration equipment capable of achieving energy saving

InactiveCN105728307AStable structureImprove the stability of forceMechanical vibrations separationBilateral symmetryEnergy analysis

The invention relates to material vibration equipment capable of achieving energy saving. The material vibration equipment comprises a rack (7), a vibration material containing component (9) hinged to the upper portion of the rack (7) through a hinge shaft (90) and a vibration driving sliding block (8) capable of moving left and right on a roller walking track (71) fixedly arranged at the bottom of the rack (7); the vibration driving sliding block (8) comprises a middle body part (83) and two slope faces (81 and 82) arranged in a bilateral symmetry manner; and the two slope faces (81 and 82) are used for bearing a left supporting sliding block (812) and a right supporting sliding block (822) to slide.

Owner:董海斌

Material vibrating equipment

InactiveCN105668147AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

Material vibrating equipment comprises a machine frame (7), a vibrated material containing component (9) and a vibration driving sliding block (8), wherein the vibrated material containing component (9) is hinged to the upper part of the machine frame (7) through a hinged shaft (90); the vibration driving sliding block (8) can move left and right at the bottom of the machine frame (7); guiding sliding grooves (711) in sliding fit with the vibration driving sliding block (8) are formed in the bottom of the machine frame (7) and used for guiding the left and right movement of the vibration driving sliding block (8); the vibration driving sliding block (8) comprises a middle main body part (83), a left inclined surface part (81) and a right inclined surface part (82); the inclined surface parts (81 and 82) are arranged symmetrically and are provided with inclined surface sliding grooves (811 and 821) respectively; the inclined surface sliding grooves (811 and 821) are mutually symmetric and are used for allowing a left support sliding block (812) and a right support sliding block (822) to slide in respectively; and the left support sliding block (812) and the right support sliding block (822) are respectively hinged to support bulges (91 and 92), which are symmetrically arranged at the left and right ends on the lower side of the vibrated material containing component (9).

Owner:黎钊彬

Energy-saving material vibrating device

InactiveCN105728308AImprove the stability of forceImplementation driveMechanical vibrations separationEngineeringBilateral symmetry

Owner:黎钊彬

Angle-adjustable machining operation platform

InactiveCN105619093AImprove the stability of forceImprove mechanical stabilityLarge fixed membersMachiningEngineering

The invention discloses an angle-adjustable machining operation platform. The angle-adjustable machining operation platform comprises a frame (7), a working platform part (9) hinged to the upper part of the frame (7) through a hinge shaft (911), and an angle adjusting support slide block part (8) capable of sliding left and right in a chute part (71) fixedly arranged at the bottom of the frame (7), wherein the angle adjusting support slide block part (8) includes a middle body part (83) and two inclined surface parts (81, 82) symmetrically arranged left and right; the two inclined surface parts (81, 82) are respectively provided with symmetric inclined surface chutes (811, 821) for enabling a left support slide block (812) and a right support slide block (822) to slide in correspondingly; mounting blocks (31) are respectively arranged at the upper ends and the lower ends of the inclined surface chutes (811, 821) of the two inclined surface parts (81, 82); and guide rods (32) parallel to the inclined surface chutes (811, 821) are fixedly mounted in the mounting blocks (31).

Owner:PUJIANG JIANFENG ENVIRONMENTAL SCI & TECH

Angle-adjustable and anti-offset working platform

InactiveCN105598929AImprove the stability of forceImprove mechanical stabilityWork benchesBilateral symmetry

The invention provides an angle-adjustable and anti-offset working platform. The angle-adjustable and anti-offset working platform comprises a rack (7), a working platform part (9) hinged to the upper portion of the rack (7) through a hinge shaft (911) and an angle adjustment support sliding block part (8) capable of sliding in a sliding groove part (71) fixedly arranged at the bottom of the rack (7) left and right, wherein the angle adjustment support sliding block part (8) comprises a middle main body portion (83) and two bevel portions (81, 82) arranged in a bilateral symmetry mode; the two bevel portions (81, 82) are provided with bevel sliding grooves (811, 821) which are symmetrical with each other respectively, the bevel sliding grooves (811, 821) are used for allowing a left support sliding block (812) and a right support sliding block (822) to slide in respectively, and the left support sliding block (812) and the right support sliding block (822) are hinged to support legs (91, 92) which are symmetrically arranged at the left end and the right end of the lower side of the working platform part (9) respectively.

Owner:莫焕东

Material vibration equipment convenient to control

InactiveCN105540166AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

Owner:董海斌

Material vibration device convenient to maintain

InactiveCN105523352AStable structureImprove the stability of forceJigging conveyorsEngineeringLED lamp

The invention discloses a material vibration device convenient to maintain. The material vibration device comprises a rack (7), a vibration material containing assembly (9) hinged to the upper portion of the rack (7) through an articulated shaft (90), and a vibration driving sliding block (8) capable of moving left and right on a rolling wheel travelling track (71) which is fixedly arranged at the bottom of the rack (7), wherein LED lamps (111) are arranged on the upper portions of the left end and the right end of the rolling wheel travelling track (71). The LED lamps (111) are fixed to the rack (7) and used for illumination so that the left-right movement of the vibration driving sliding block (8) can be observed conveniently, and thus troubles can be removed timely when the vibration driving sliding block (8) breaks down during left-right movement. The vibration driving sliding block (8) comprises a middle main body part (83) and two inclined face parts (81 and 82) symmetrically arranged left and right.

Owner:何慧敏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com