Patents

Literature

45results about How to "Improve mechanical conversion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

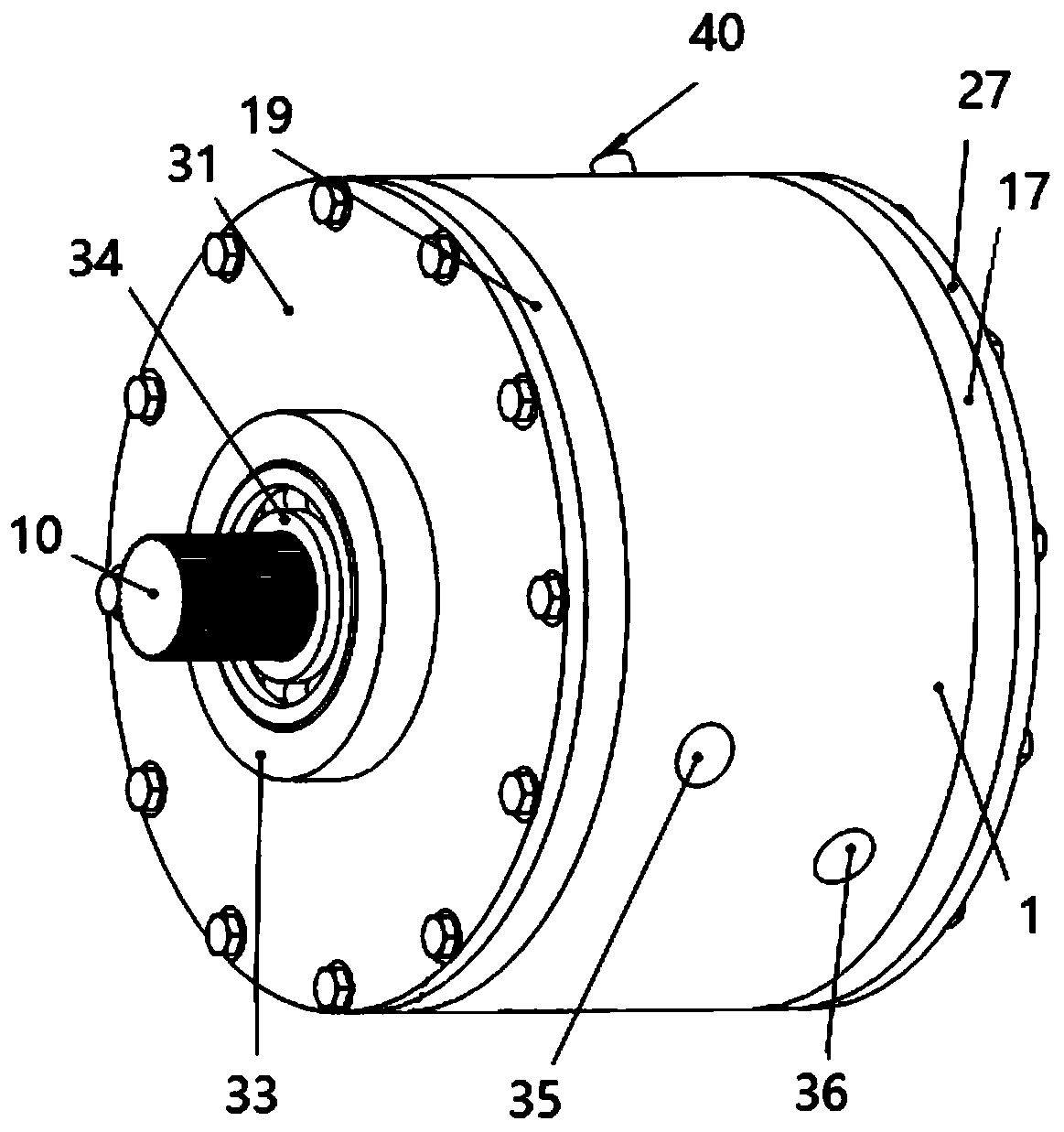

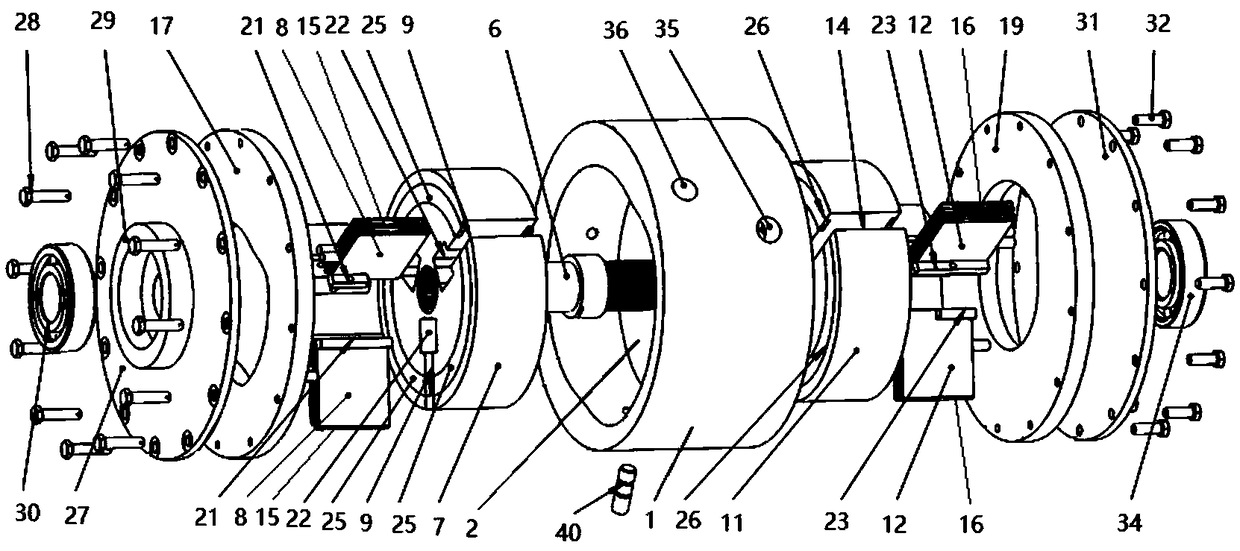

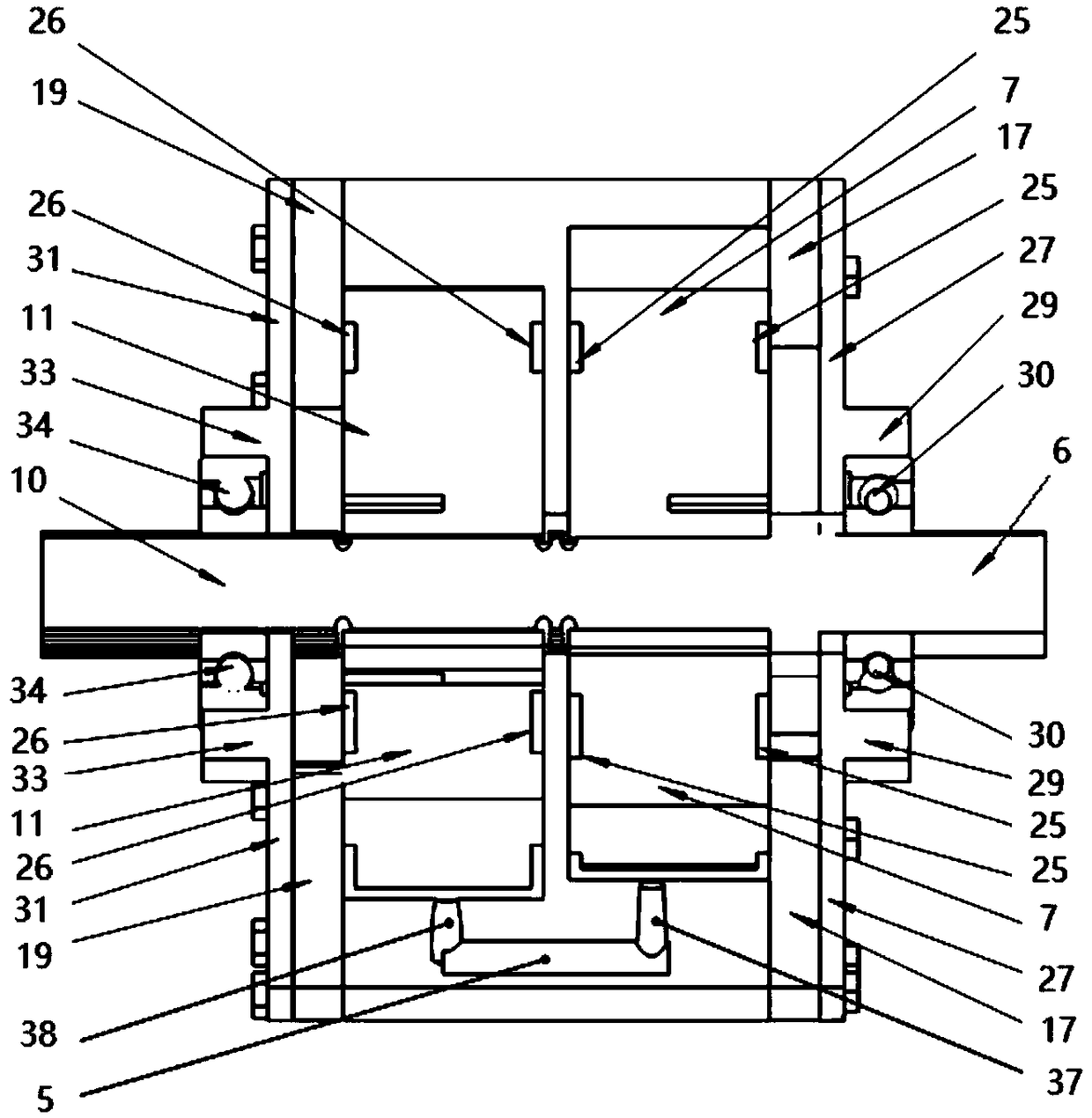

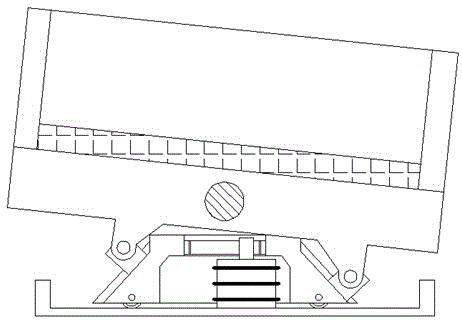

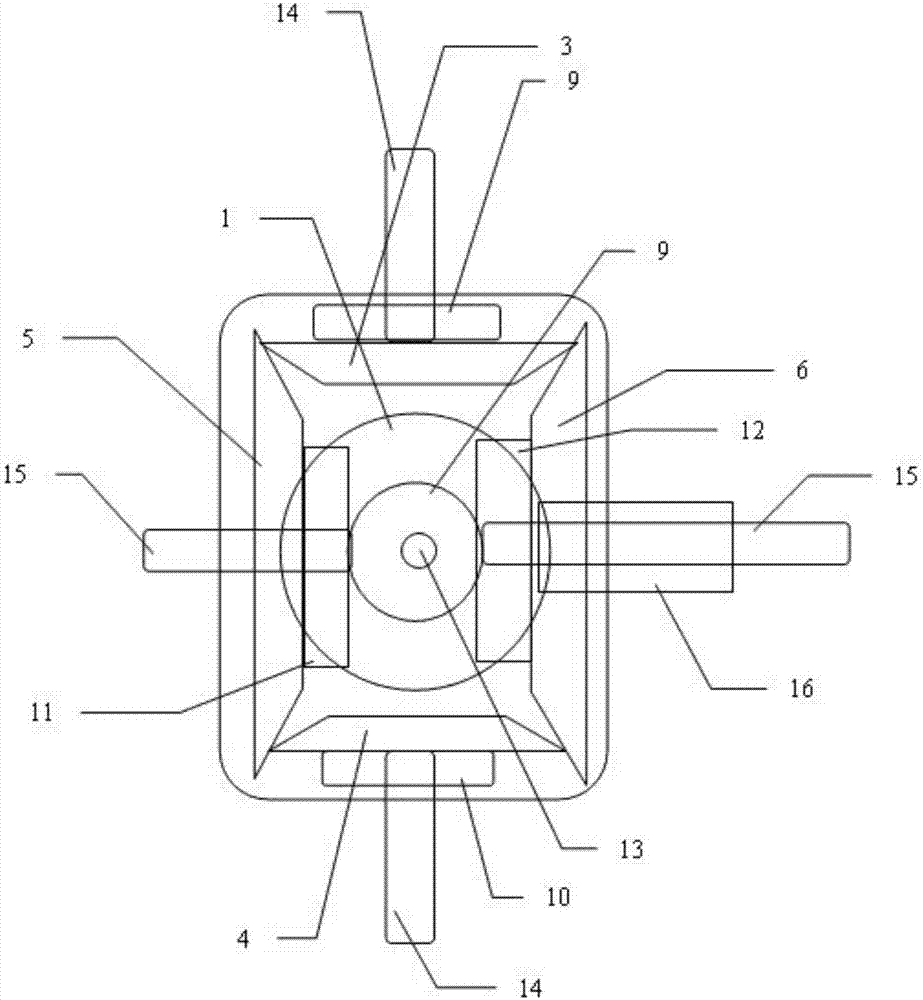

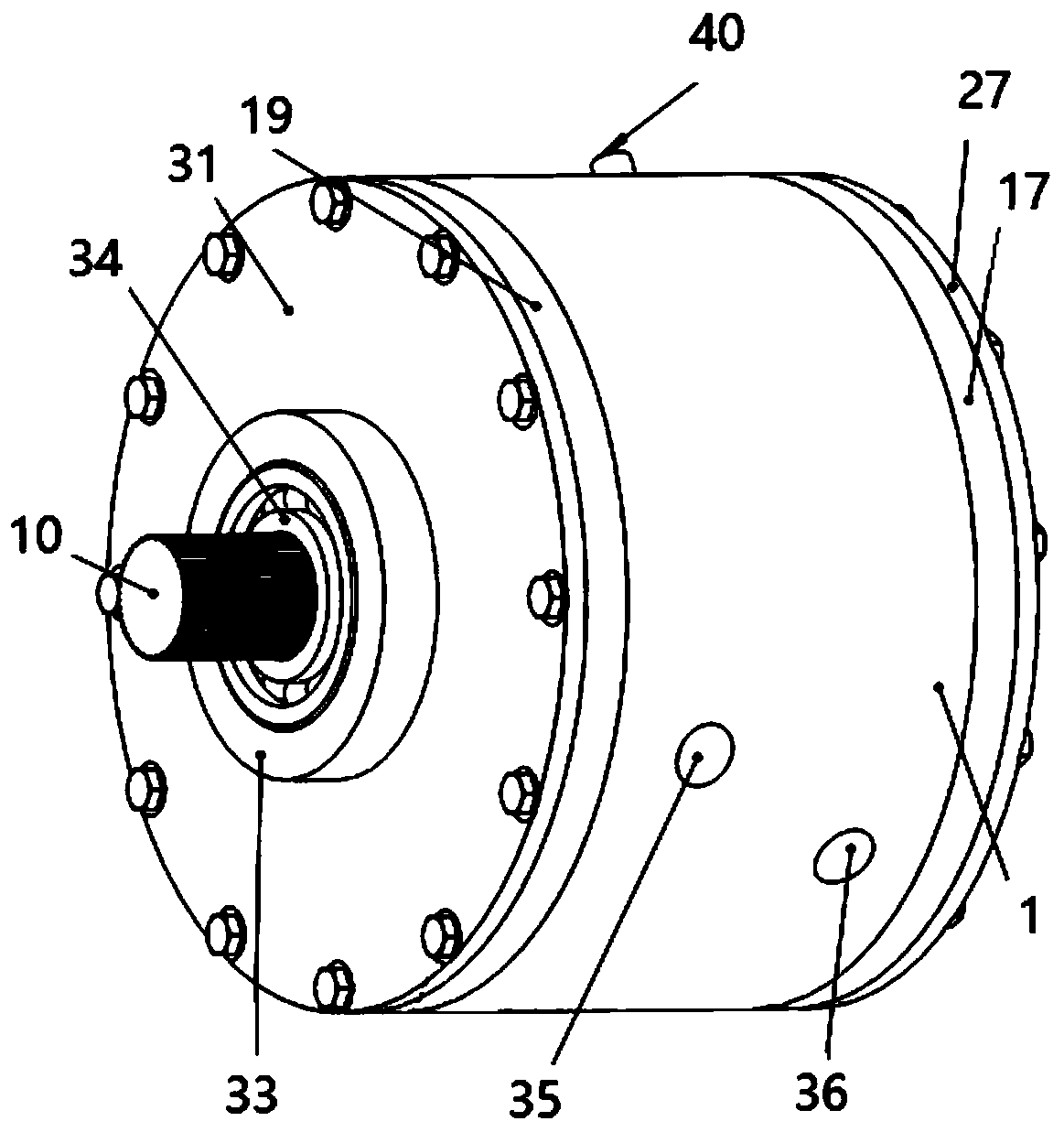

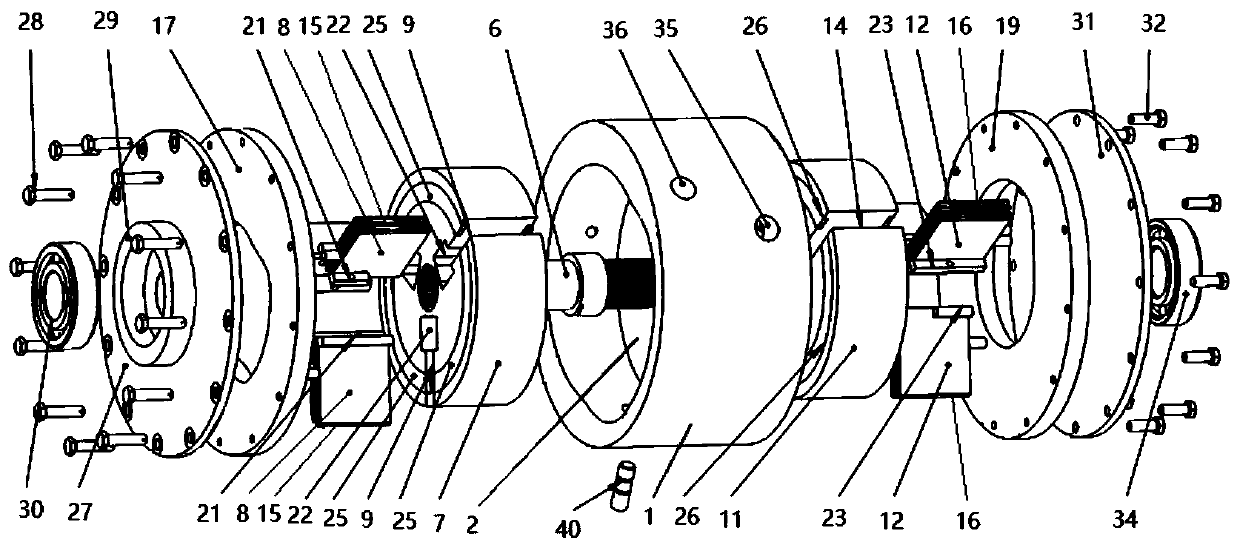

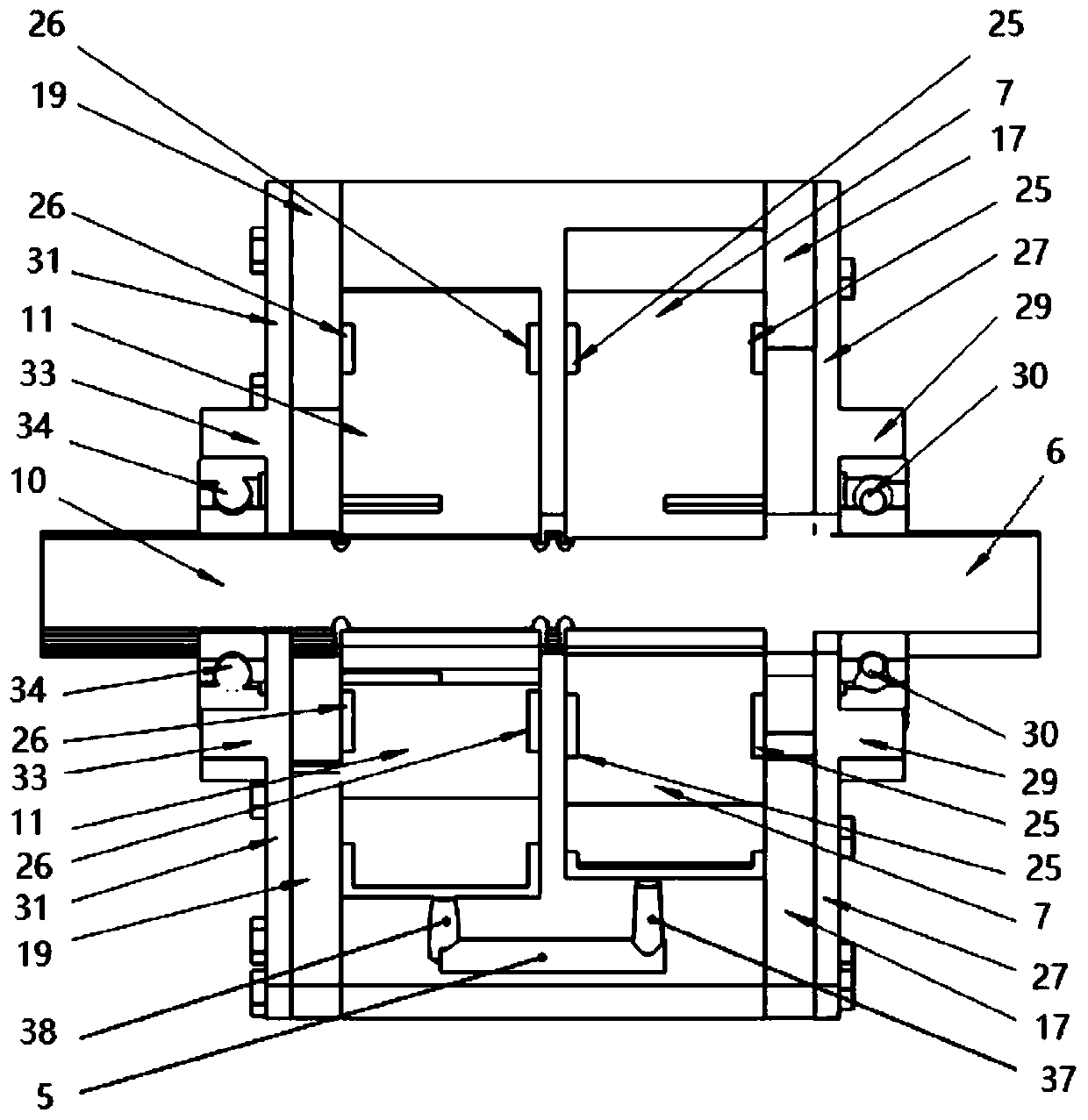

Rotor-to-stator flow guiding rotor internal combustion engine

InactiveCN109339940AImprove mechanical conversion efficiencyReduce power lossInternal combustion piston enginesCombustionExternal combustion engine

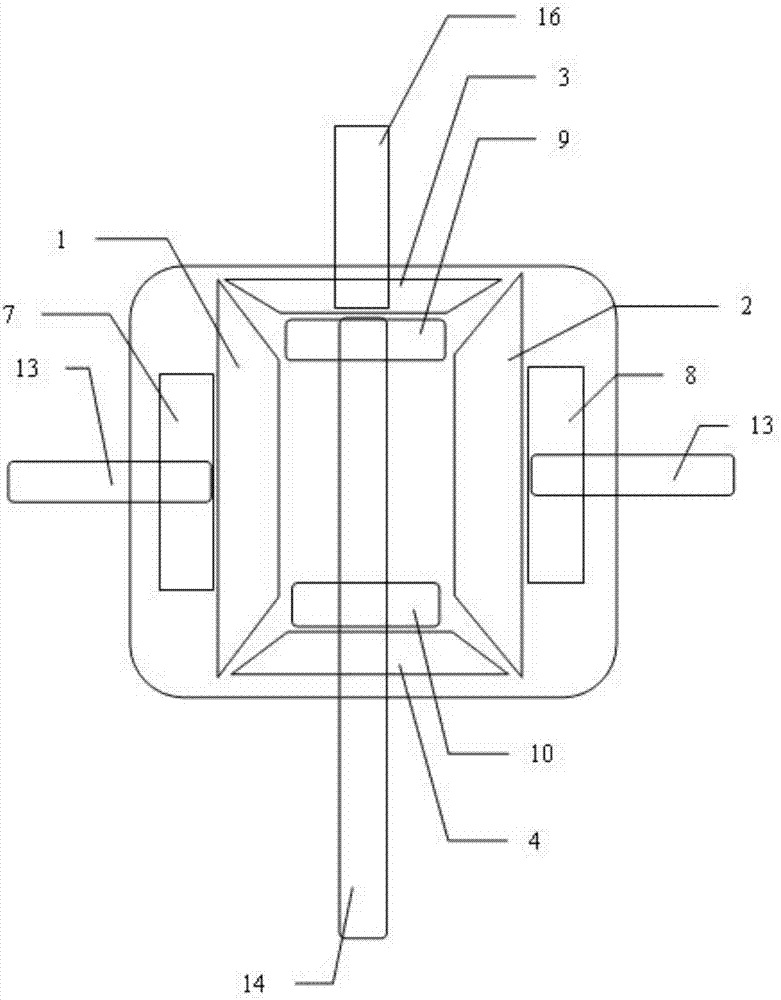

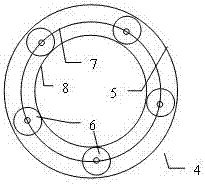

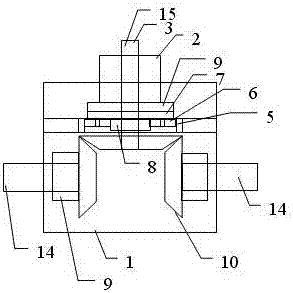

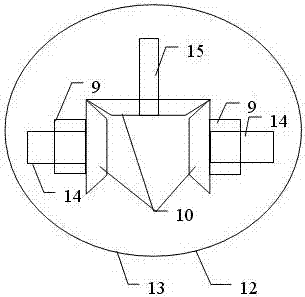

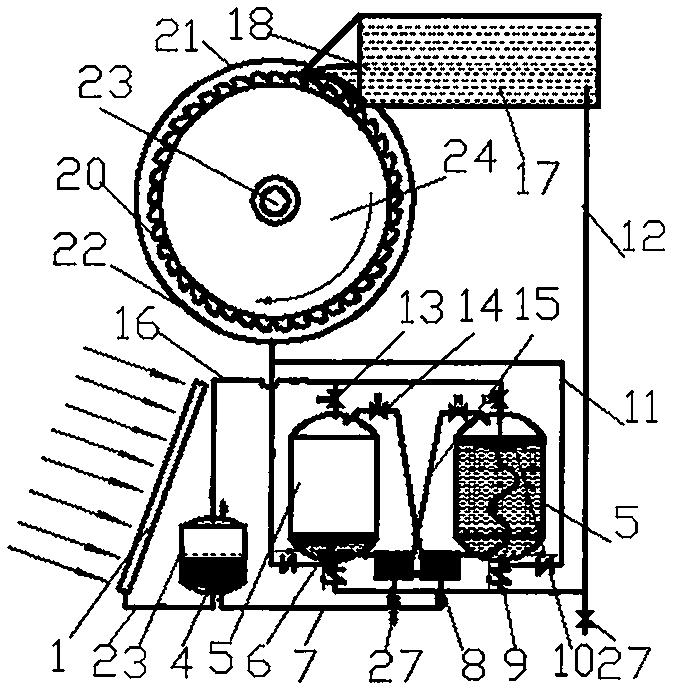

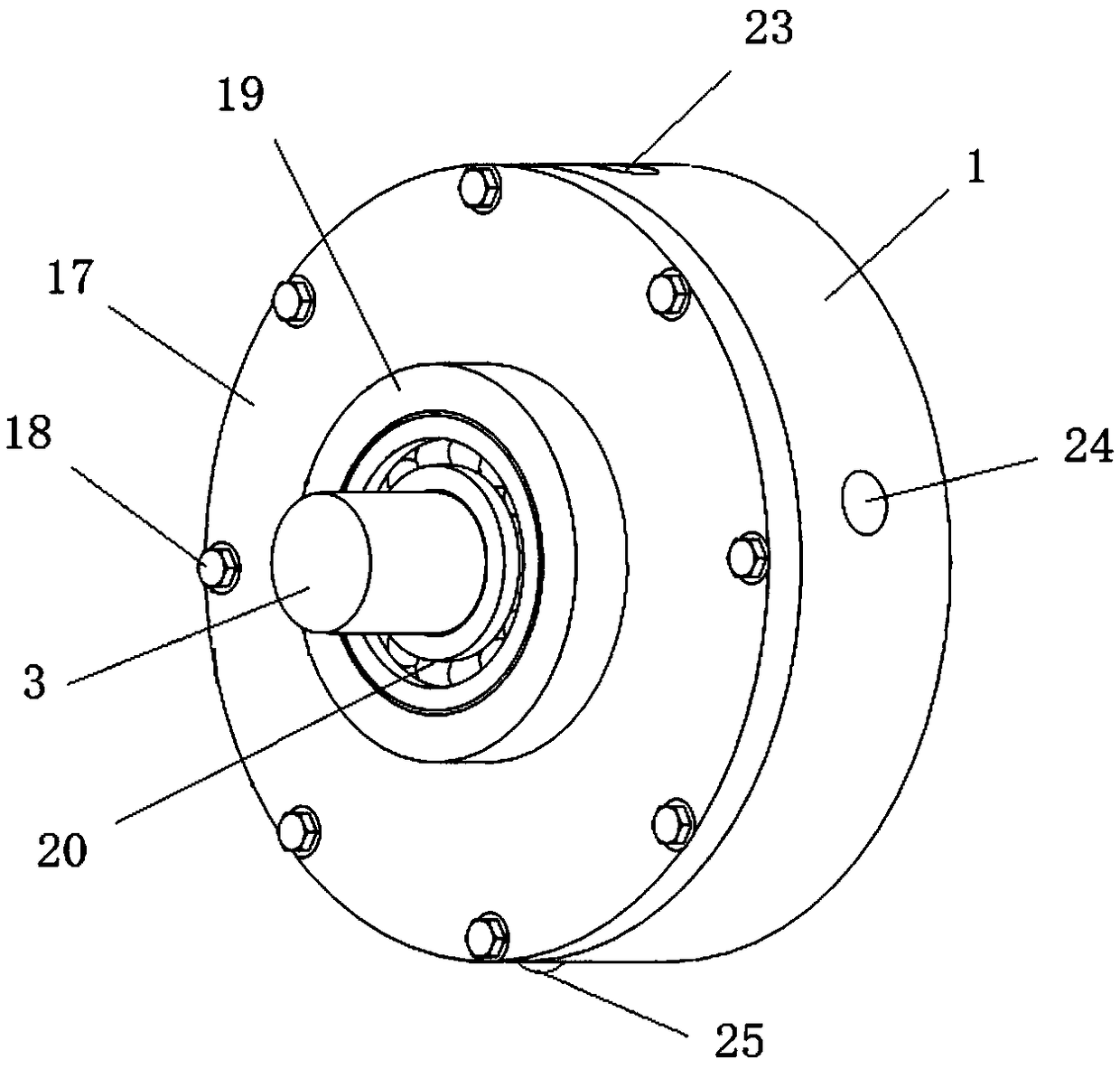

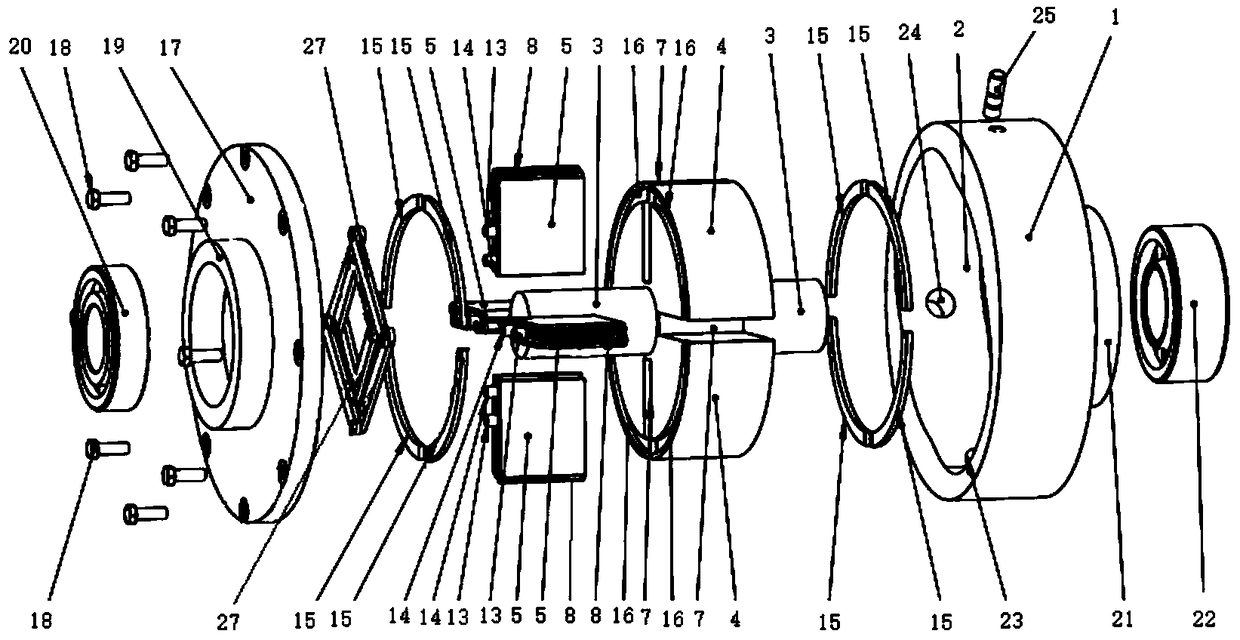

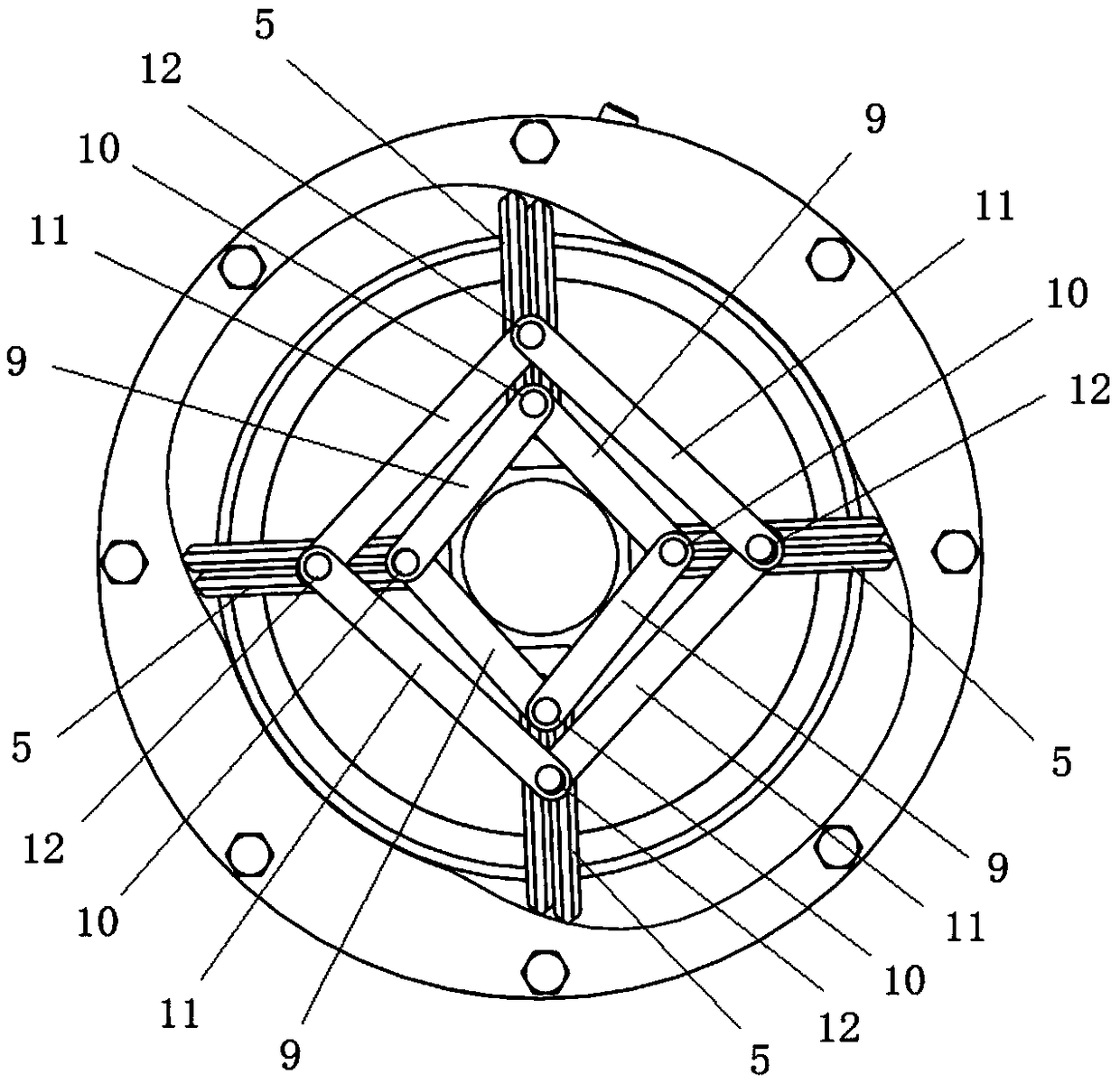

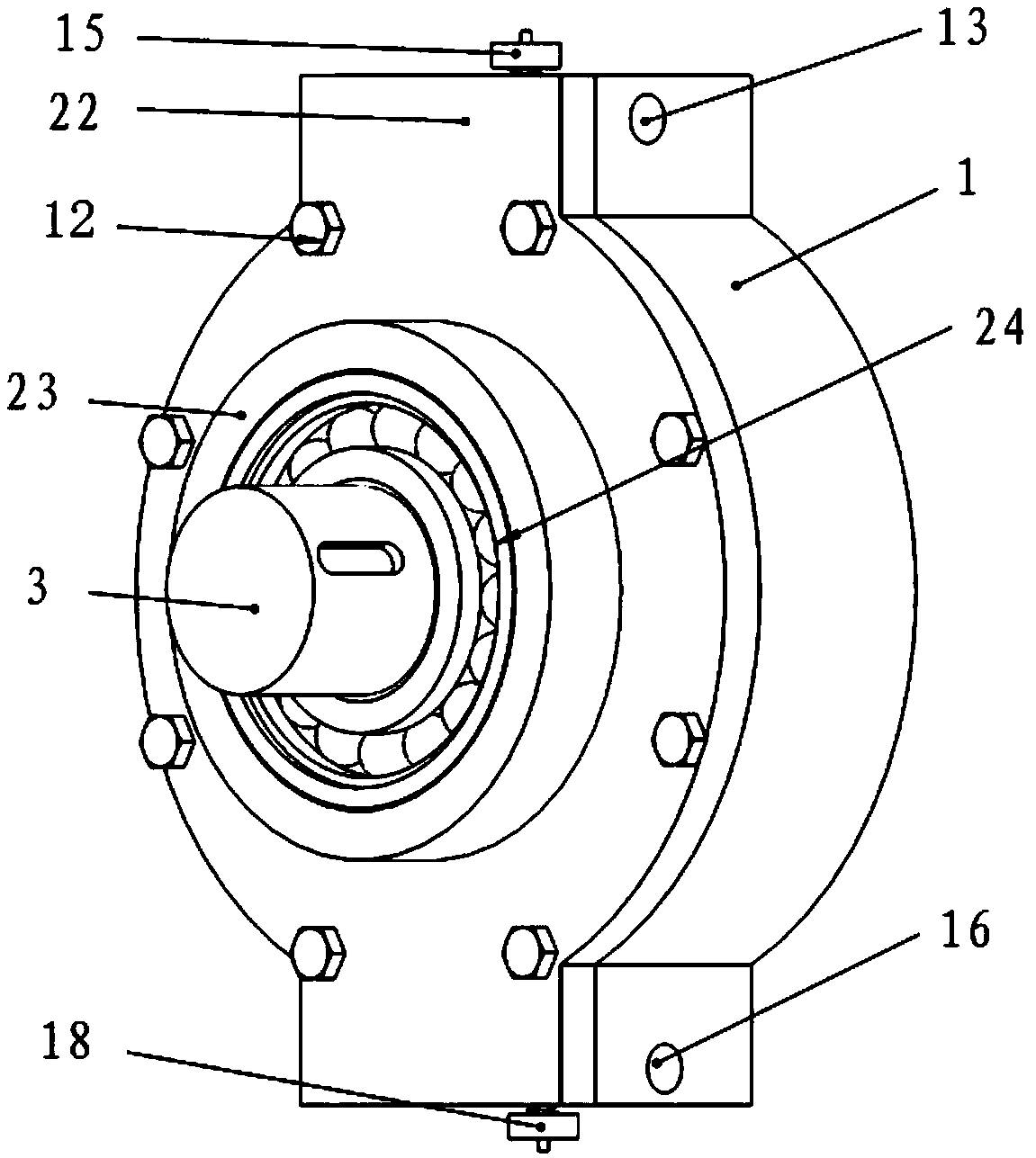

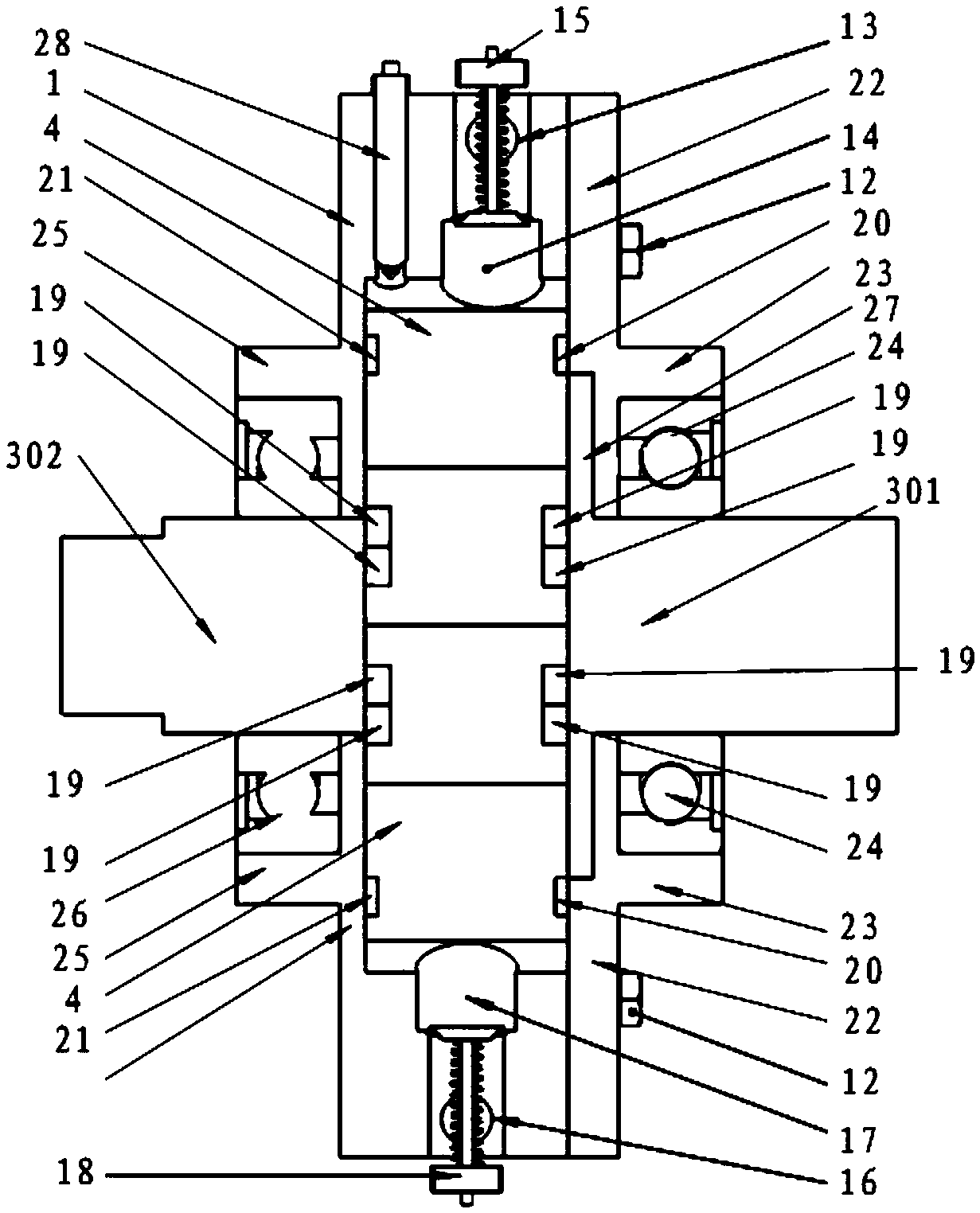

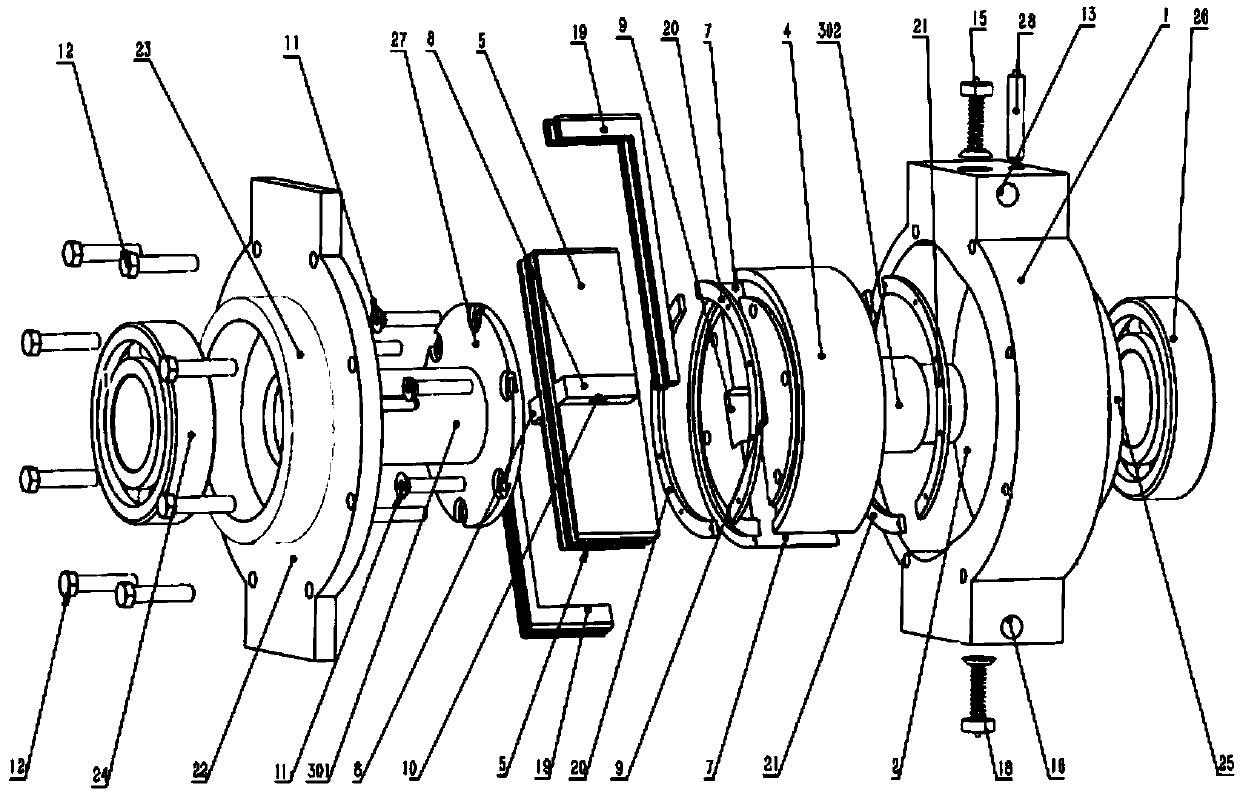

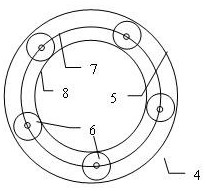

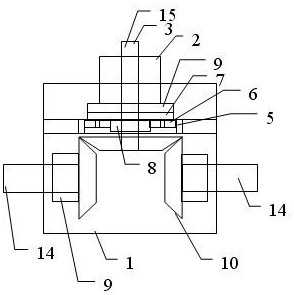

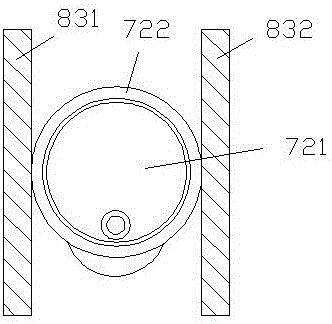

The invention relates to the technical field of internal combustion engines, in particular to a rotor-to-stator flow guiding rotor internal combustion engine. The rotor-to-stator flow guiding rotor internal combustion engine comprises a stator assembly, a gas engine rotor assembly and a compressor rotor assembly, wherein the stator assembly includes at least a stator body, a gas engine stator cavity and a compressor stator cavity; gas engine follower gastight sliding plates divide the gas engine stator cavity into three independent and mutually gastight gas engine chambers; and compressor follower gastight sliding plates divide the compressor stator cavity into three independent and mutually gastight compressor chambers. The rotor-to-stator flow guiding rotor internal combustion engine canconvert a tangential torque of the working of the gas expanding into a one-way driving torque of the circular motion, thereby effectively reducing the power loss and improving the mechanical conversion efficiency of the rotor internal combustion engine.

Owner:王亚东

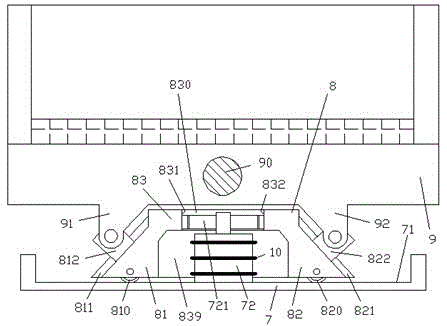

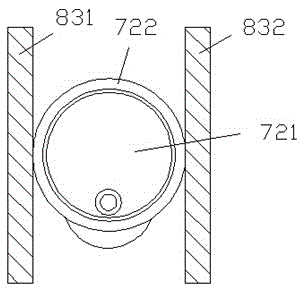

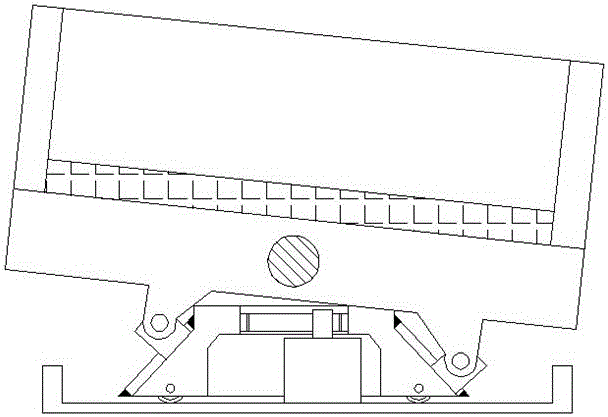

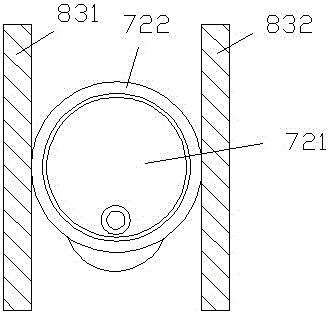

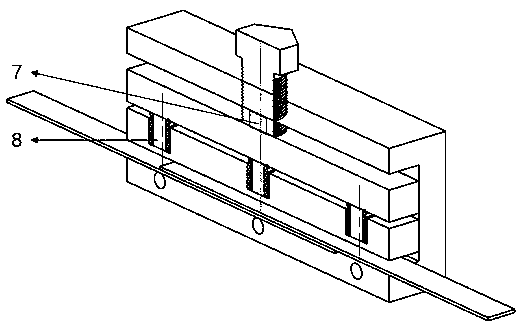

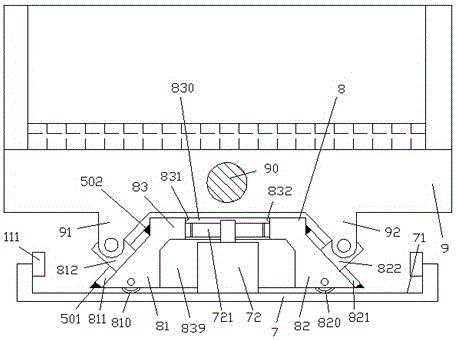

Safe material shaking device

InactiveCN105540164AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

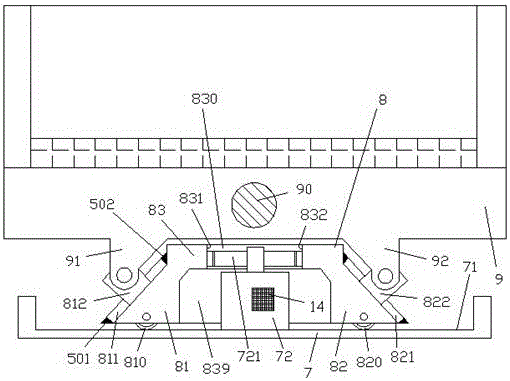

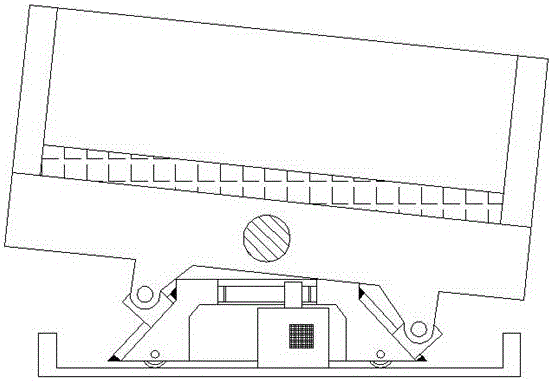

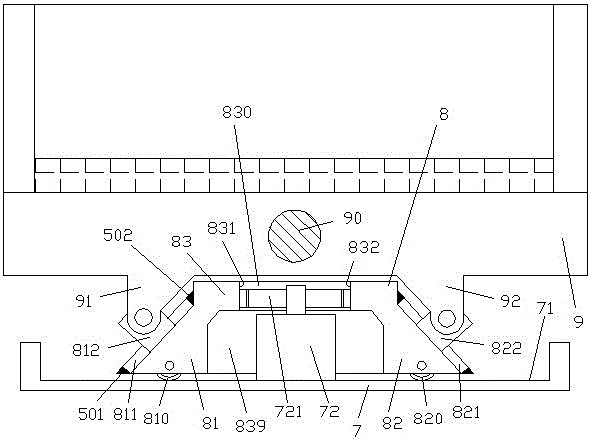

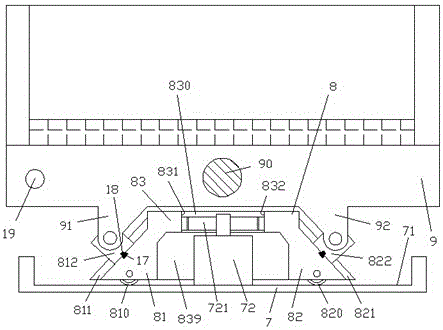

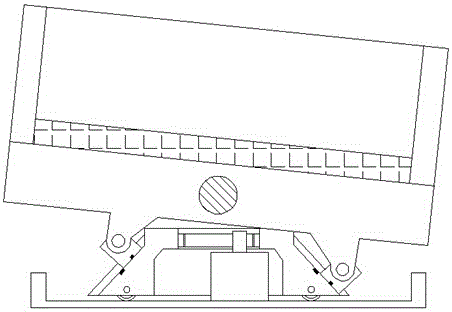

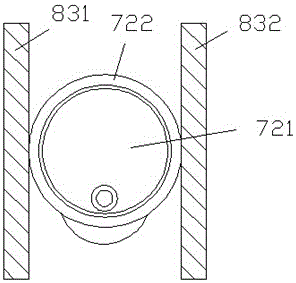

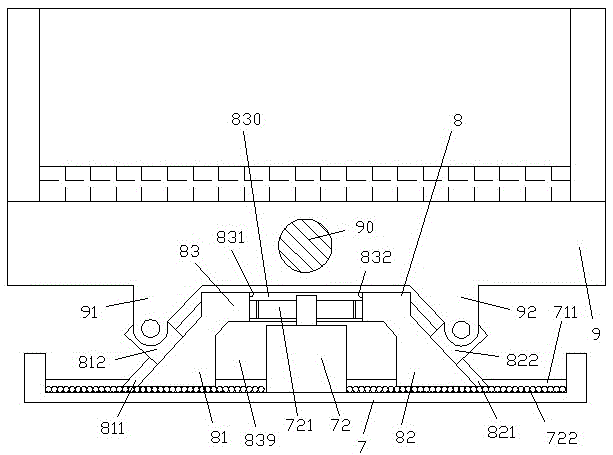

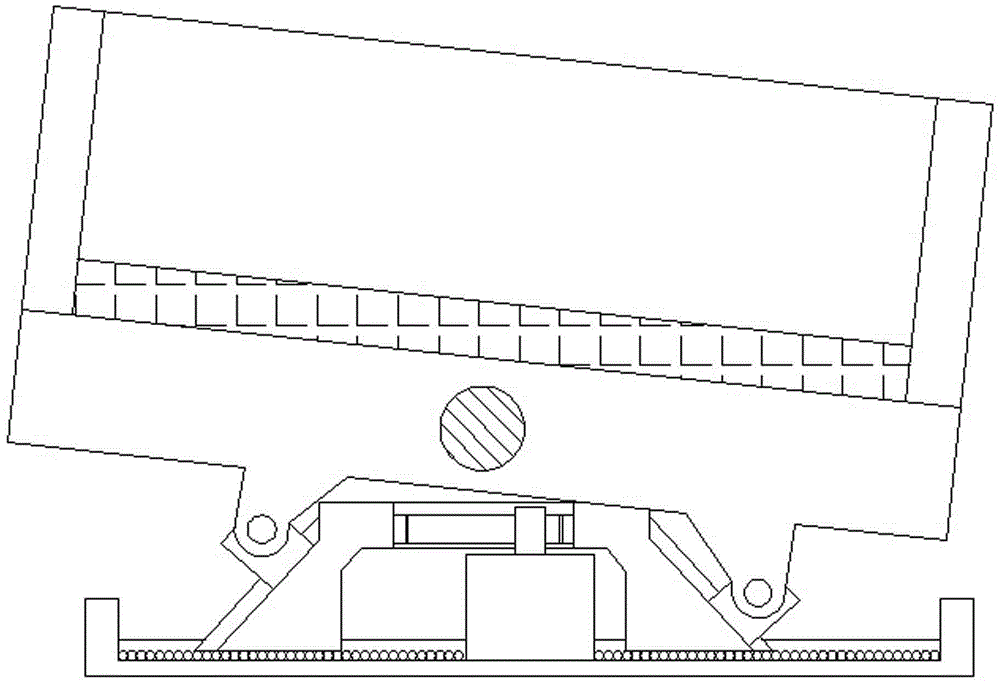

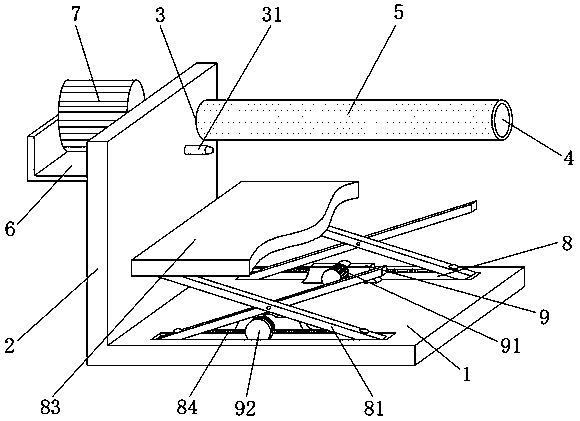

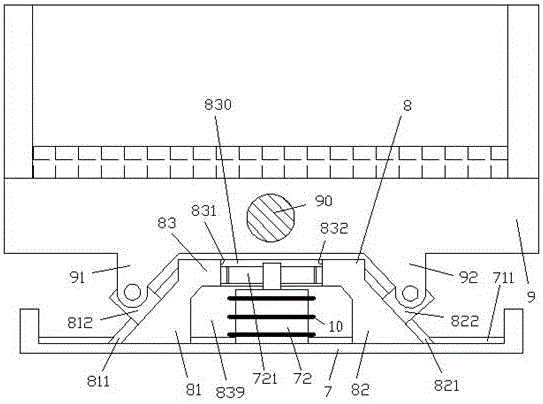

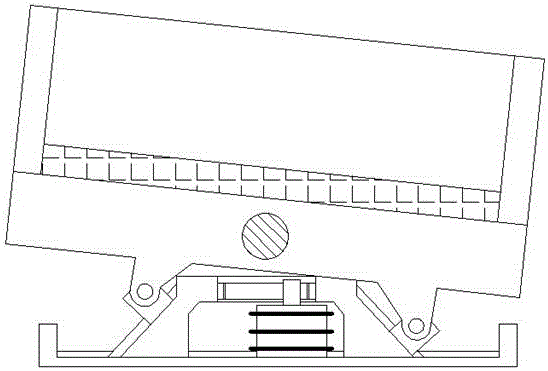

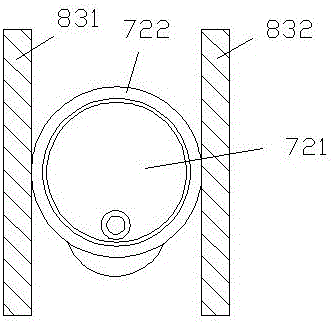

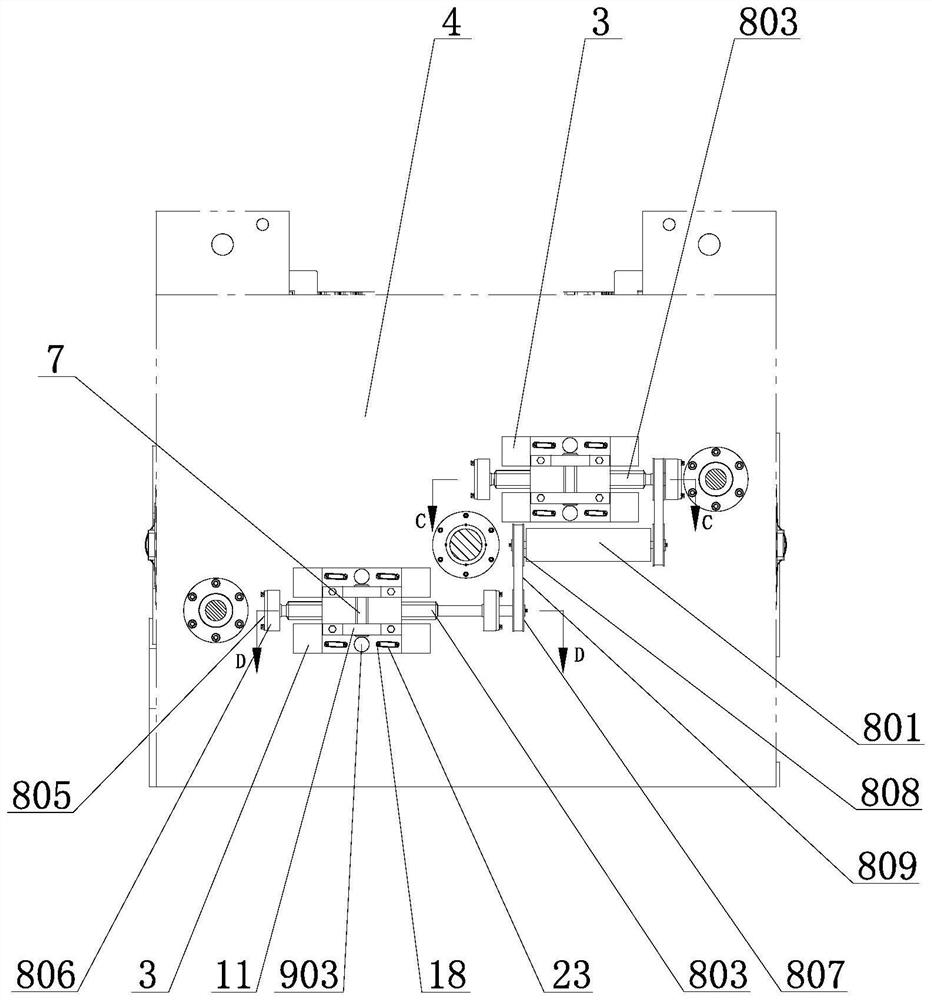

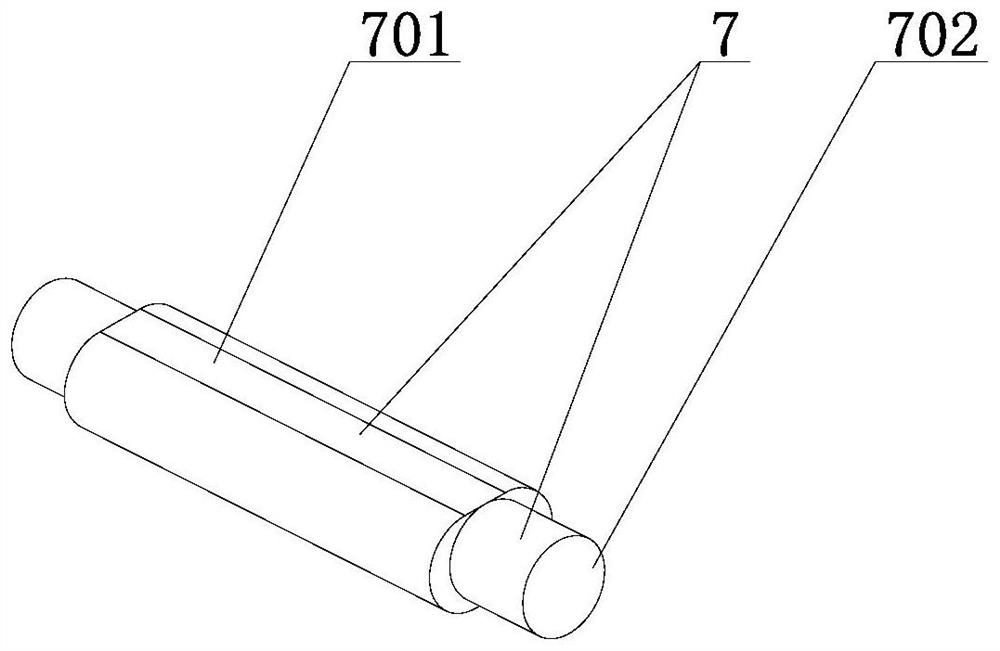

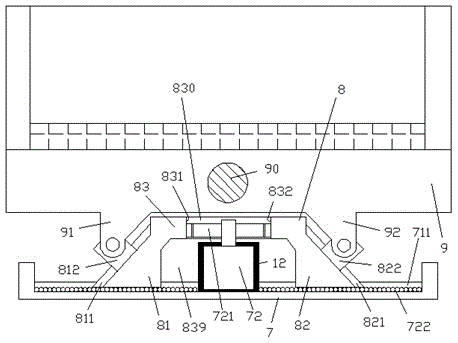

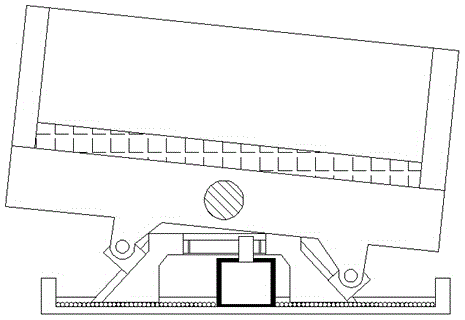

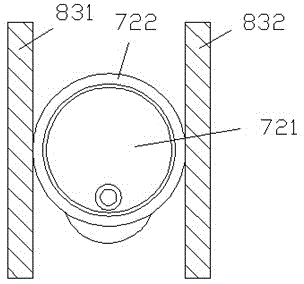

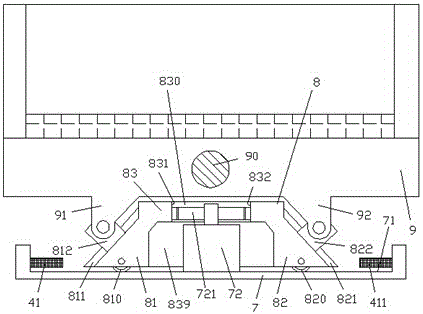

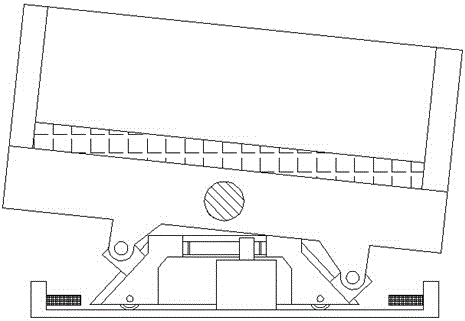

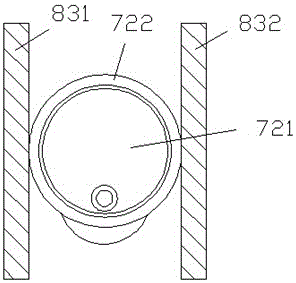

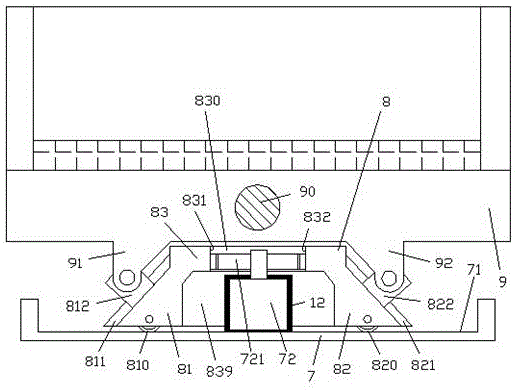

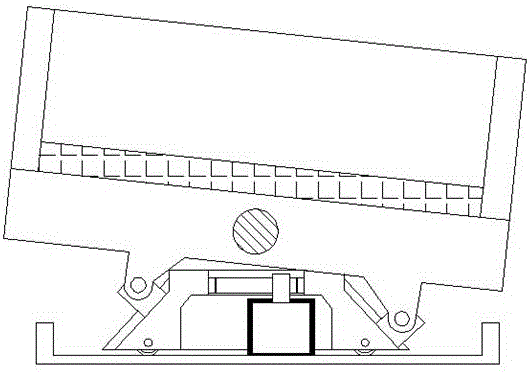

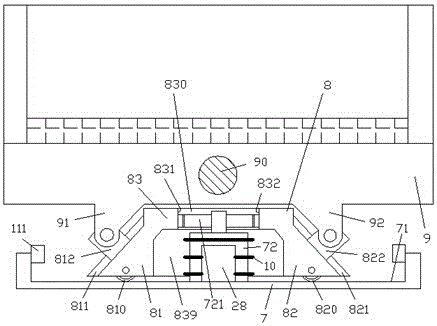

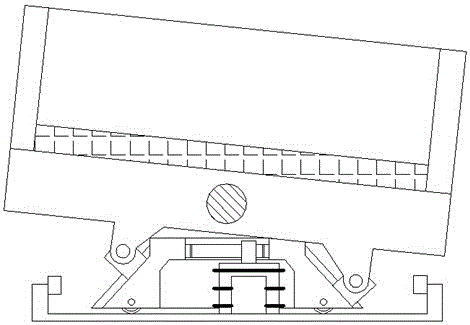

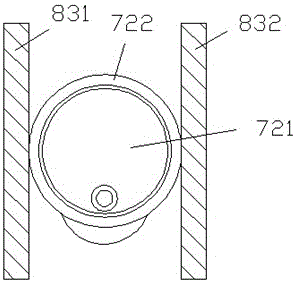

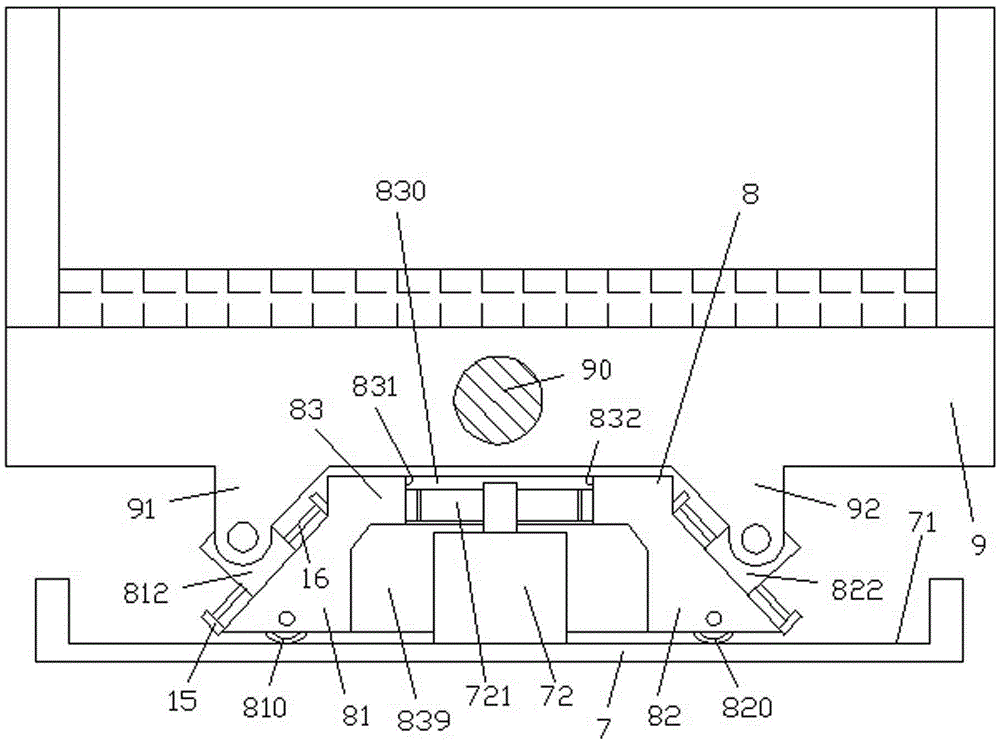

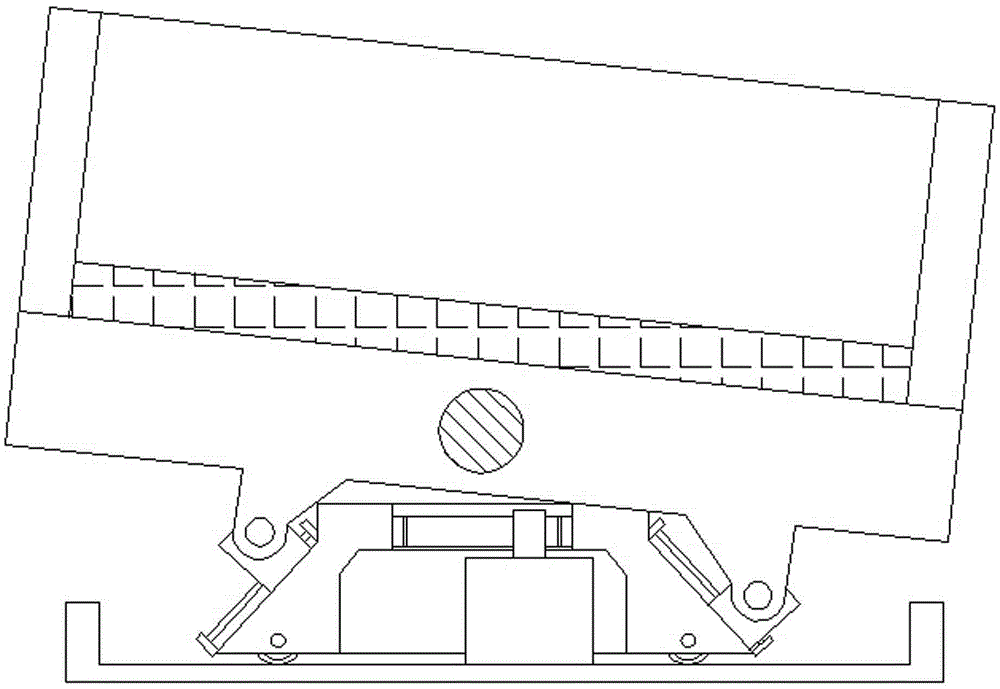

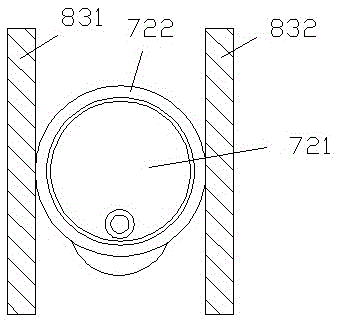

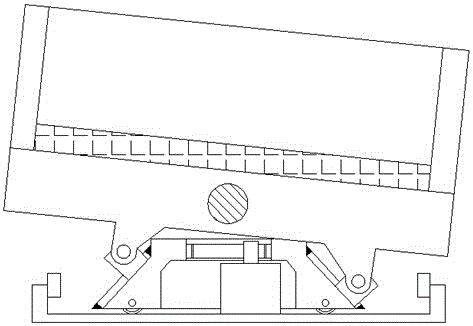

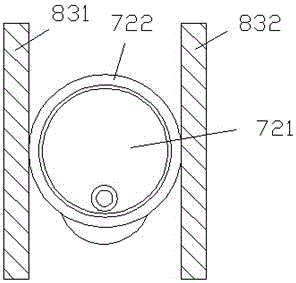

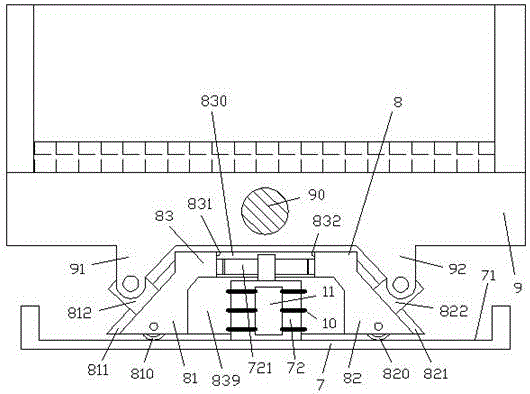

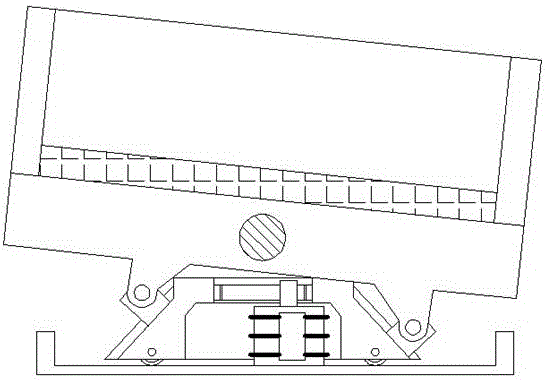

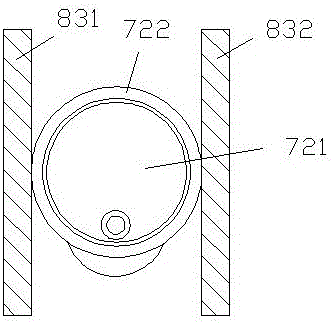

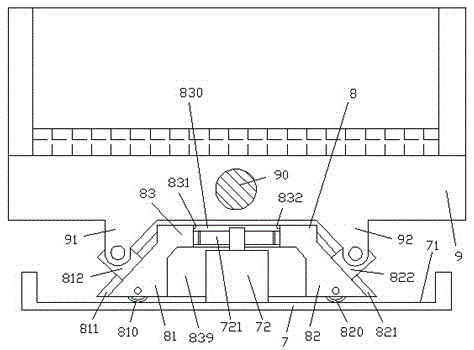

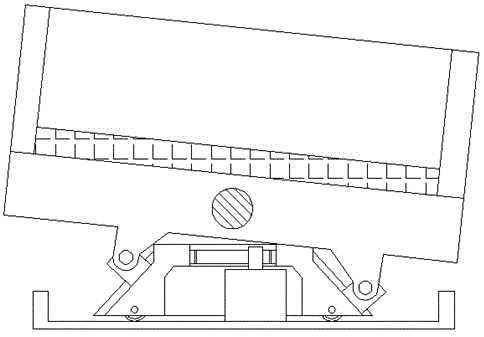

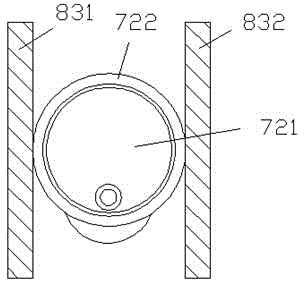

A safe material shaking device comprises a machine frame (7), a shaken material containing part (9) hinged to the upper portion of the machine frame (7) through an articulated shaft (90), and a shake driving slide block (8) capable of moving on a rolling wheel walking track fixedly arranged at the bottom position of the machine frame (7) in a left-right mode, wherein the shake driving slide block (8) comprises a middle body portion (83) and two oblique plane portions (81 and 82) arranged bilaterally and symmetrically. The two oblique plane portions (81 and 82) are respectively provided with mutually-symmetrical oblique plane chutes (811 and 821) respectively bearing a left supporting slide block (812) and a right supporting slide block (822) for sliding, and the left supporting slide block (812) and the right supporting slide block (822) are respectively hinged to supporting protrusion portions (91 and 92) symmetrically arranged at the left end and the right end of the lower side of the shaken material containing part (9).

Owner:何慧敏

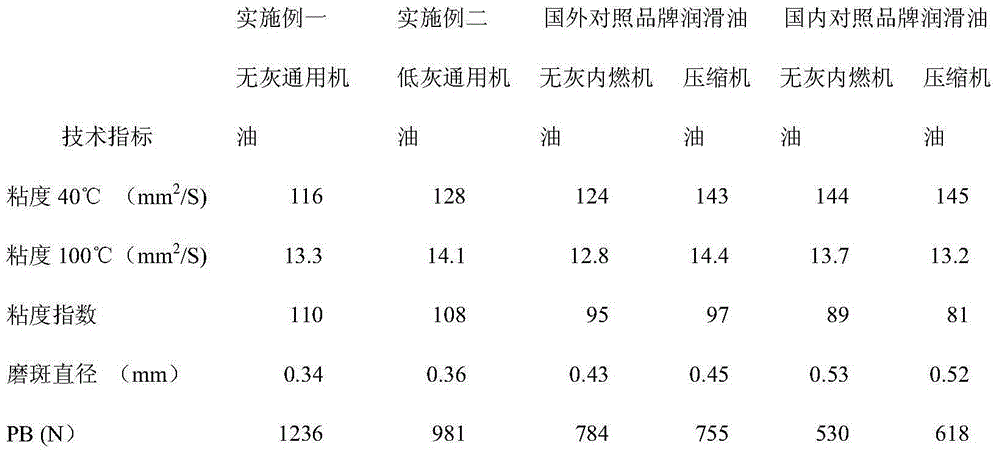

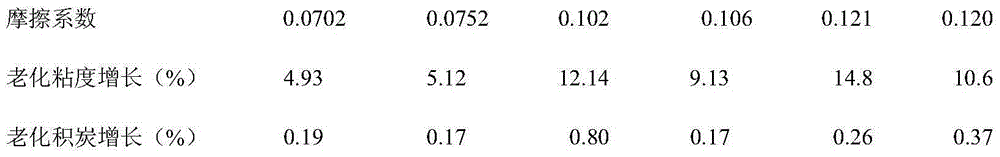

Gas power type natural gas compressor lubricating oil composition

ActiveCN105176648AExtend oil change intervalsExtended service lifeLubricant compositionFoaming agentProcess engineering

The invention discloses a gas power type natural gas compressor lubricating oil composition. The composition is mainly prepared from, by mass, 10-30 parts of first base oil, 40-63 parts of second base oil, 6-12 parts of gas oil compound additives, 0.2-0.5 part of pour point reducer, 0.001-0.005 part of anti-foaming agent, 17-27 parts of balance promoter and 0.1-0.6 part of nanometer friction modifier. The composite has the advantages that one type of lubricating oil can be universally used for lubricating a gas power machine and a compressor, the service life of a gas power type natural gas compressor device is prolonged, mechanical conversion efficiency is improved, power consumption is lowered, the lubricating oil change period is prolonged, and the corresponding final waste discharge is reduced.

Owner:SICHUAN SANDING LUBRICATION SCI & TECH

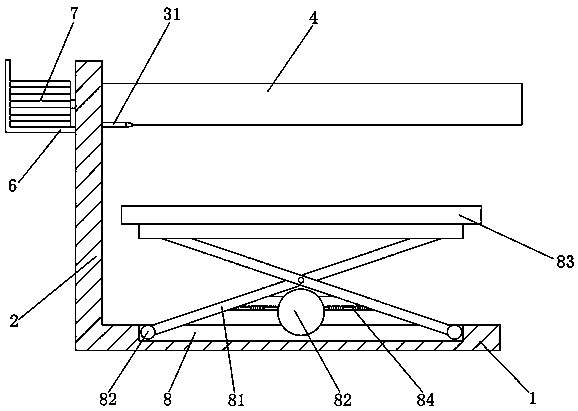

Material vibrator capable of achieving limiting control

InactiveCN105728317AStable structureImprove the stability of forceSievingScreeningEngineeringBilateral symmetry

The invention relates to a material vibrator capable of achieving limiting control. The material vibrator comprises a rack (7), a vibration material containing component (9) hinged to the upper portion of the rack (7) through a hinge shaft (90) and a vibration driving sliding block (8) capable of moving left and right on a roller walking track (71) fixedly arranged at the bottom of the rack (7); the vibration driving sliding block (8) comprises a middle body part (83) and two slope faces (81 and 82) arranged in a bilateral symmetry manner; the two slope faces (81 and 82) are provided with symmetrical slope face sliding grooves (811 and 821) and are used for bearing a left supporting sliding block (812) and a right supporting sliding block (822) to slide; the left supporting sliding block (812) is hinged to a supporting protrusion (91) at the left end of the lower side of the vibration material containing component (9), the right supporting sliding block (822) is hinged to a supporting protrusion (92) at the right end of the lower side of the vibration material containing component (9), and the left supporting sliding block (812) and the right supporting sliding block (822) are symmetrically arranged.

Owner:董海斌

Material vibrating device capable of achieving sliding limiting

InactiveCN105750191AStable structureImprove the stability of forceSievingScreeningEngineeringMechanical engineering

A material vibrating device capable of achieving sliding limiting comprises a machine frame (7), a vibrating material containing part (9) hinged to the upper portion of the machine frame (7) through a hinge shaft (9), and a vibrating driving slider (8) which can be fixedly arranged on a roller traveling rail (71) at the bottom of the machine frame (7) and can move left and right.The vibrating driving slider (8) comprises a middle body part (83) and two inclined face parts (81 and 82) symmetrically arranged on the left side and the right side.The two inclined face parts (81 and 82) are provided with symmetric inclined face sliding grooves (811 and 821) respectively and used for bearing sliding of a left supporting slider (812) and a right supporting slider (822) respectively, and the left supporting slider (812) and the right supporting slider (822) are symmetrically hinged to supporting protruding parts (91 and 92) at the left end and the right end of the lower side of the vibrating material containing part (9) respectively.

Owner:XIAOGAN BUJI ELECTRONICS COMMERCE CO LTD

Unidirectional conversion device and power system provided with same

ActiveCN107250536AExtended service lifeLow costMachines/enginesEngine componentsEngineeringPower load

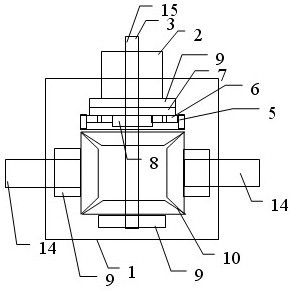

Disclosed is a unidirectional conversion device (22). The unidirectional conversion device (22) comprises a power output part and power selected from at least one of a first swinging input shaft (13) for receiving front and rear swinging power, a second swinging input shaft (14) for receiving left and right swinging power and a third swinging input shaft (15) for receiving horizontal swinging power. Further disclosed is a power system including the unidirectional conversion device; the power system comprises one or more unidirectional conversion devices (22); the plurality of unidirectional conversion devices (22) are combined as a whole by means of sharing the swinging input shafts; the unidirectional conversion devices are connected to one or more swinging devices and / or are arranged on the swinging devices; and the power output part is connected to a power load. The unidirectional conversion device and the power system provided with the device can absorb swinging power from different directions simultaneously and have advantages such as high conversion efficiency, high stability, and wide range of applicability.

Owner:吴钦发

Material vibration device with horizontal position detection function

InactiveCN105692085AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

Owner:何慧敏

Ball-driven material vibration device

InactiveCN105478345AStable structureImprove the stability of forceSievingScreeningEngineeringBilateral symmetry

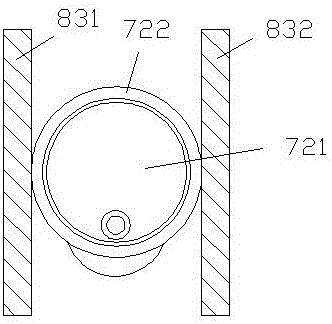

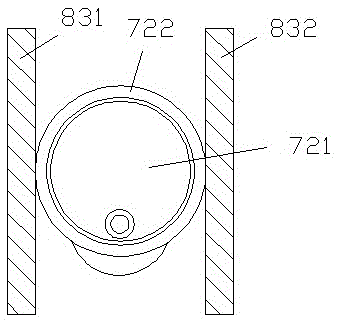

The invention discloses a ball-driven material vibration device. The device comprises a rack (7), a vibrating material containing component (9) hinged to the upper portion of the rack (7) through an articulated shaft (90) and a vibration driving slide block (8) capable of moving left and right at the bottom of the rack (7), wherein a guiding slide groove (711) in sliding fit with the vibration driving slide block (8) is formed in the bottom of the rack (7) and used for guiding the left and right movement of the vibration driving slide block (8); the vibration driving slide block (8) comprises a middle body part (83) and two bevel parts (81 and 82) arranged in bilateral symmetry; the two bevel parts (81 and 82) are provided with bevel slide grooves (811 and 821) respectively, the bevel slide grooves (811 and 821) are in mutual symmetry and are used for bearing a left supporting slide block (812) and a right supporting slide block (822) to slide, the left supporting slide block (812) and the right supporting slide block (822) are hinged to supporting convex parts (91 and 92) respectively, and the supporting convex parts (91 and 92) are symmetrically arranged at the left end and the right end of the lower side of the vibrating material containing component (9).

Owner:晋江市东坤电子实业有限公司

High temperature superconductive tape welding pressure control and performance testing device

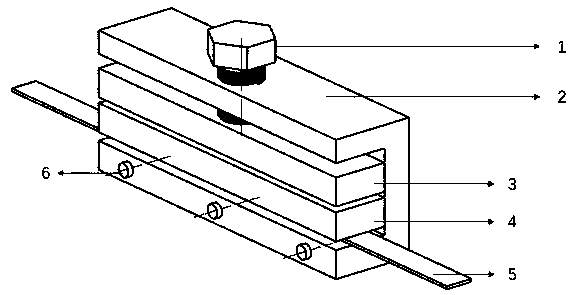

ActiveCN108762328AEasy to controlImprove mechanical conversion efficiencyMachine part testingElectrical testingHysteresisEngineering

The invention provides a high temperature superconductive tape welding pressure control and performance testing device. The high temperature superconductive tape welding pressure control and performance testing device comprises a welding pressure main bracket, wherein a through groove is formed in the front side of the welding pressure main bracket, and a position adjusting block is arranged in the through groove; a sample pressure applying block is arranged below the position adjusting block; a super hysteresis telescopic driver is arranged on the sample pressure applying block; a heater is arranged in the lower side frame of the through groove; a force sensor is arranged in an adjusting bolt; solder paste materials are smeared on the surfaces of high temperature superconductive samples,and the surfaces, coated with the soldering tin materials, of the two samples are in butt joint and then are arranged in a clamp; the adjusting bolt is adjusted to enable the position adjusting blockto drive the sample pressure applying block to move downward, and the excitation current in a drive coil is set, and a PID takes the welding pressure as a target value to control the current intensityof the excitation power source to control the expansion and contraction quantity of a super magnetic induced shrinkage or elongation bar so as to enable the magnitude of the welding pressure to be constant; and the heater is used to heat and weld the high temperature superconductive samples. The high temperature superconductive tape welding pressure control and performance testing device has theadvantages of simple structure, economical and practical performance, high integrated level and simple operation.

Owner:XIAN JUNENG SUPERCONDUCTING MAGNET TECH

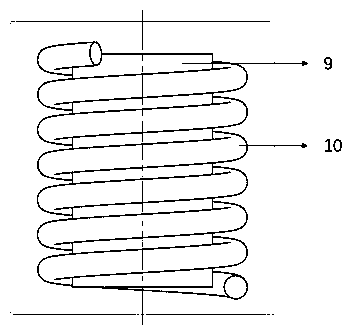

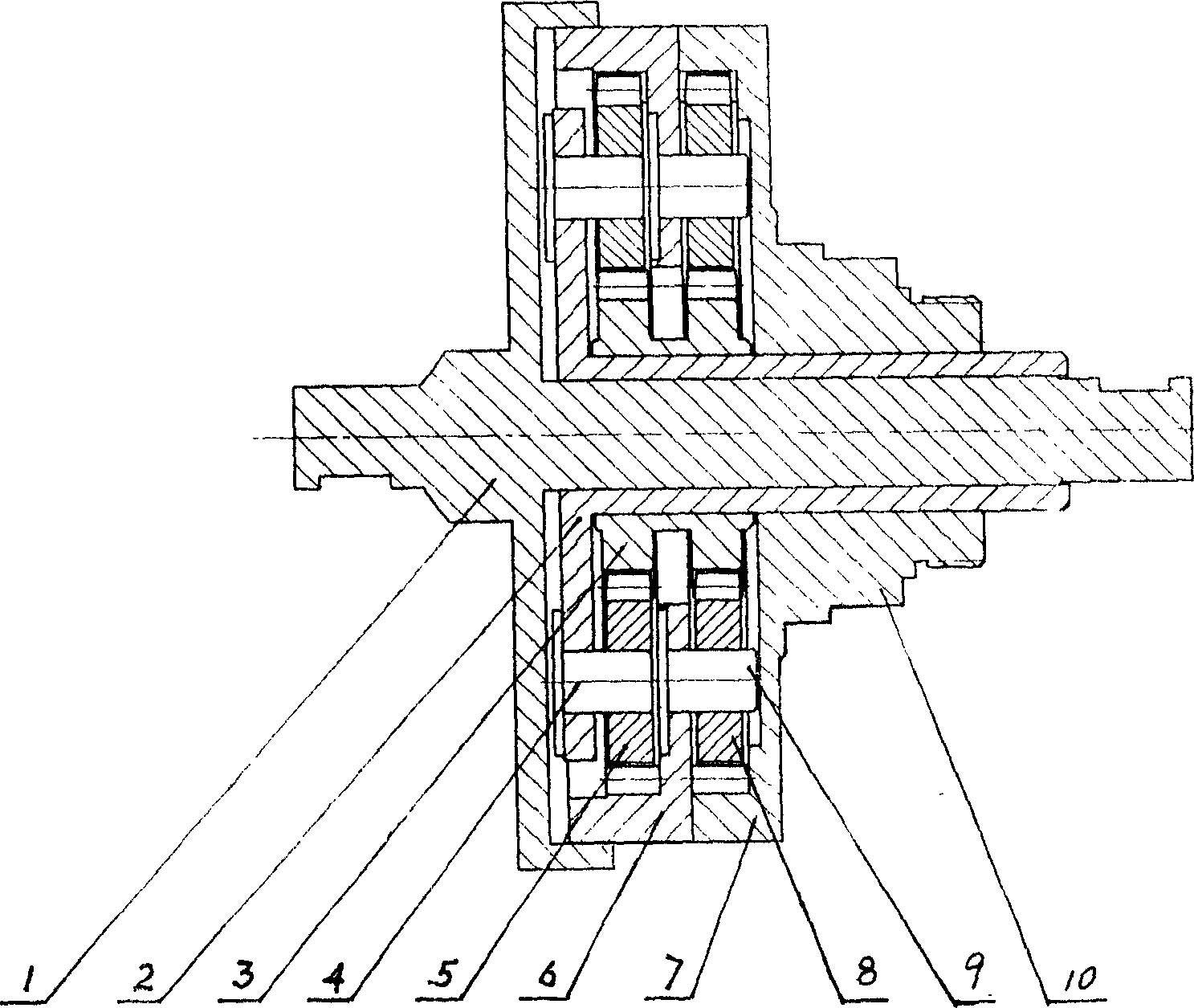

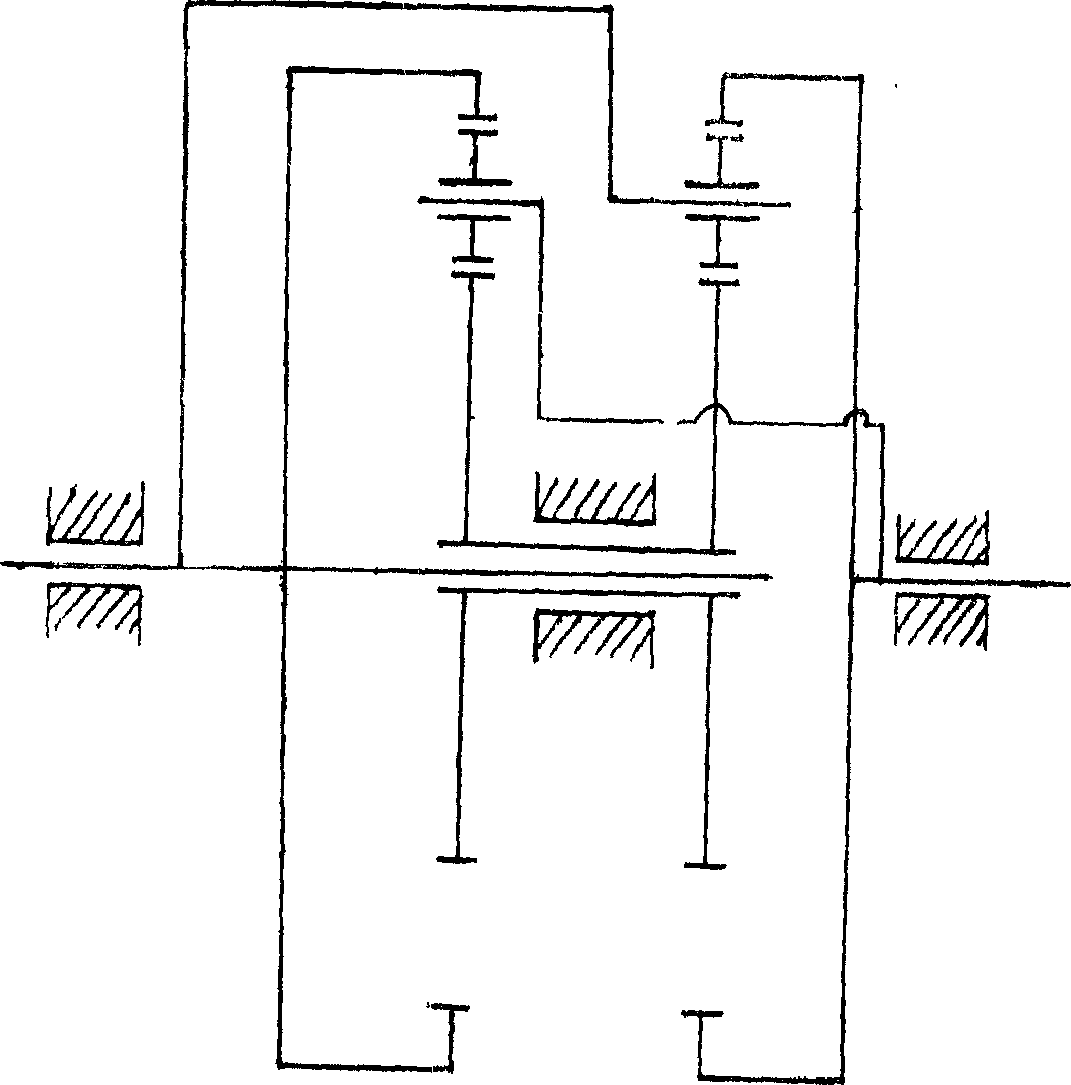

Energy-saving speeding and boosting mechanism and method

InactiveCN1847696AHigh speedImprove mechanical conversion efficiencyToothed gearingsMANDRILElectrical and Electronics engineering

The present invention relates to one kind of power transferring speeding and boosting mechanism and method. The power transferring speeding and boosting mechanism includes planet carrier around the input shaft, sun gear around the planet carrier, planet gear connected to the planet carrier via mandril and meshed to the sun gear, annular gear around the sun gear meshed to the planet gear and with outer wall connected to the input shaft, output annular gear connected to the planet carrier and meshed to the planet gear, and output shaft integrated with the output annular gear. The present invention has the advantages of doubled output speed, and high mechanical conversion efficiency.

Owner:王红军

Unidirectional power conversion device provided with rocking rotary shell and unidirectional power conversion method

ActiveCN107023623AAvoid damageIncrease load bearing capacityGearingSea energy generationHigh absorptionEngineering

The invention provides a unidirectional power conversion device provided with a rocking rotary shell and a unidirectional power conversion method. The unidirectional power conversion device comprises a rocking rotary shell supporting shaft, a power output shaft, a first one-way isolator and a second one-way isolator. The device comprises one or more unidirectional power conversion units in mutual combination. Universal rocking power can be absorbed and converted into unidirectional available rotary power. By adoption of the unidirectional power conversion device provided with the rocking rotary shell, the rocking power in all random orientations can be absorbed, and the advantages of high absorption conversion efficiency, low manufacturing and maintenance cost, high stability, wide application range and the like are achieved.

Owner:吴钦发

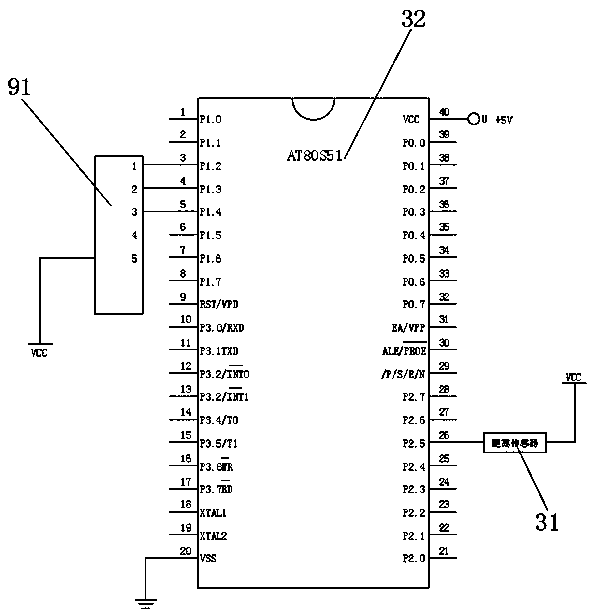

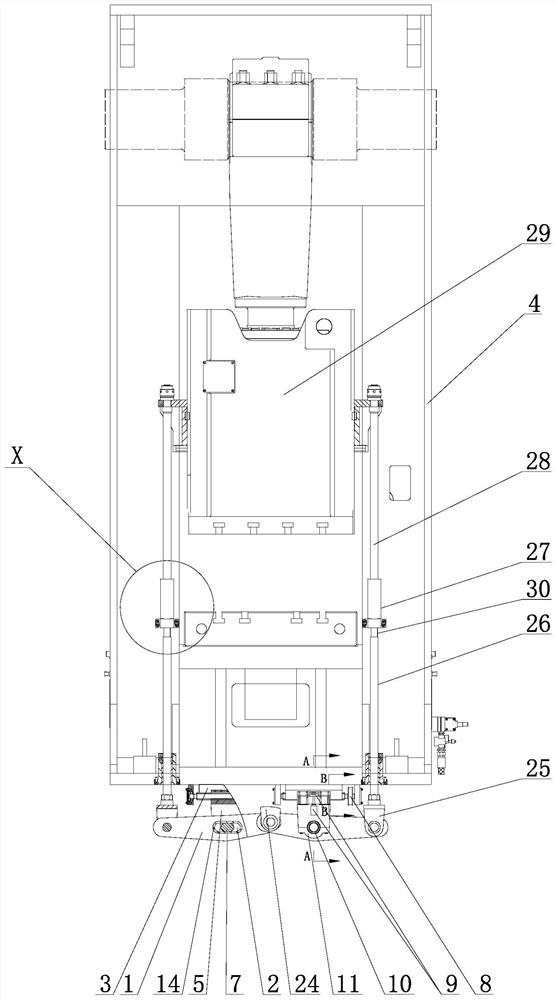

Glass blanking working table body adjusting device for tempered glass production

InactiveCN110803525AImprove handling efficiencySave human effortConveyorsControl devices for conveyorsEngineeringStructural engineering

The invention discloses a glass blanking working table body adjusting device for tempered glass production. The glass blanking working table body adjusting device for tempered glass production comprises a bearing platform. A bearing plate is integrally arranged on one side of the bearing platform. A rotating hole is formed in the lateral side of the bearing plate. The interior of the rotating holeis provided with a roller wheel. A power output shaft of a motor is fixed to the center of one end of the roller wheel. The top surface of the bearing table is provided with a slideway. A fixing lugis arranged at the position, close to the slideway, of the top surface of the bearing table. A telescopic frame is arranged on the top surface of the bearing table. The end portion of a bottom foot ofthe telescopic frame extends into the slideway. A fixing plate is fixed to the top end of the telescopic frame. Servo motors are fixed to one side, away from the slideway, of the fixing lug. The twoservo motors are connected in parallel through wires. One side, close to the bearing table, of the bearing plate is fixedly provided with a distance sensor at a position flush with the bottom side ofan anti-sliding sleeve. The output end of the distance sensor is connected with a single chip microcomputer through a wire. Through cooperative use of the devices, the glass carrying efficiency is improved, manpower is liberated, and stacked glass can be transferred.

Owner:利辛县天鑫玻璃制品有限公司

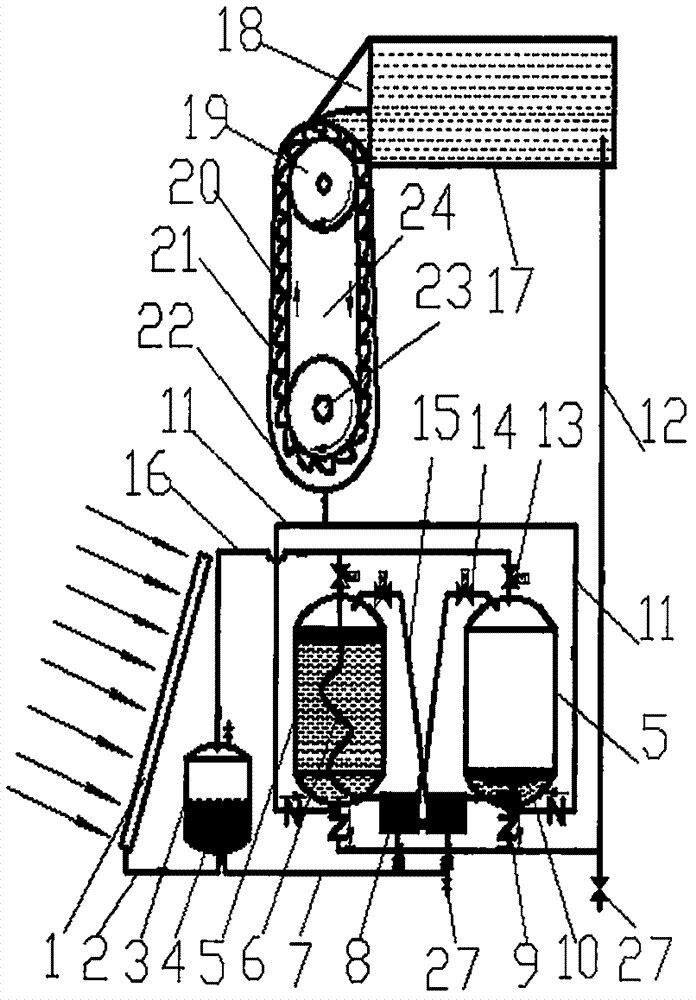

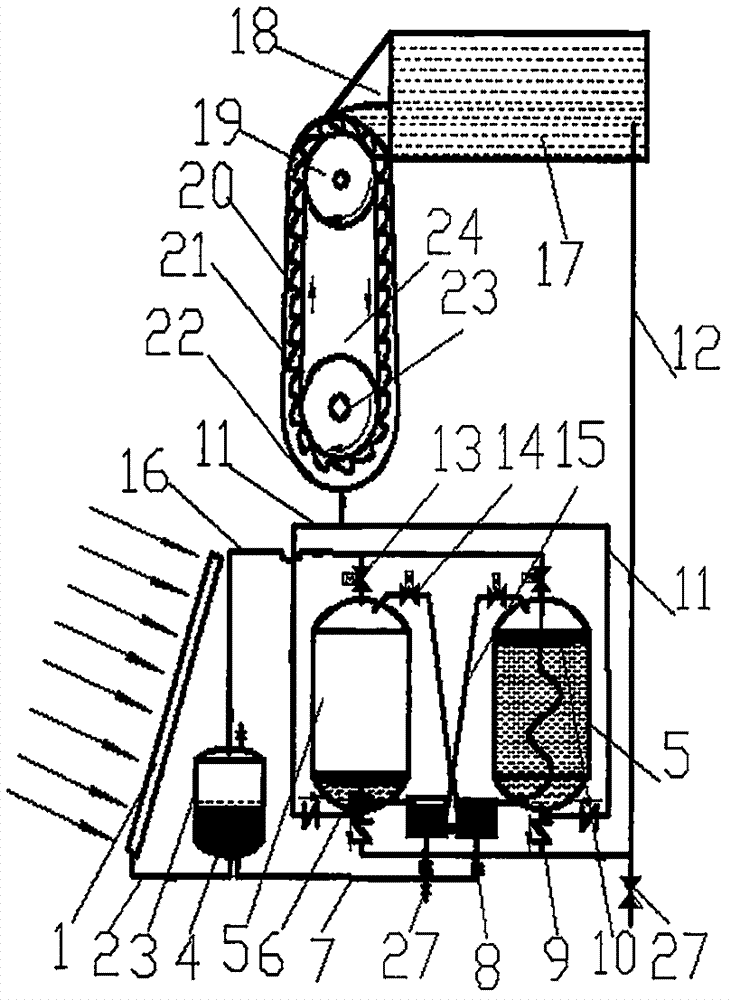

Thermal energy water lifting energy storage power generation equipment

InactiveCN107191309ANo maintenanceReduce evaporative lossPressure pumpsHydro energy generationThermal energySteam pressure

The invention discloses thermal energy water lifting energy storage power generation equipment, and aims to provide water lifting energy storage power generation equipment which is high in thermal energy utilization efficiency. The thermal energy water lifting energy storage power generation equipment comprises heat pipes of waste heat of a solar thermal energy heat collector, geothermal energy, a chemical plant, a cement plant, an iron and steel plant, a thermal power plant and a nuclear power station, a steam boiler, a power generator, and grid-connected terminal equipment. The thermal energy water lifting energy storage power generation equipment is characterized in that the heat pipes communicate with a heat exchanger inside the boiler, a hot steam pressure pipe of the boiler communicates with a first water extrusion tank containing water, and a water lifting pipe of the first water extrusion tank communicates with a water storage container located in the higher position; a gravity rotating waterwheel composed of a plurality of water receiving and containing hoppers is arranged below a water outlet of the water storage container; a backwater receiving and collecting disc is arranged below the waterwheel and communicates with a second empty water extrusion tank; backwater entering the second water extrusion tank generates pressure to press hot steam into a reflux condensation meter cold water tank; the steam is condensed and leaves heat to another meter cold water tank so that water can be supplied to the boiler; an output shaft of the gravity rotating waterwheel is connected with the power generator; and the power generator is connected with an electricity load and the grid-connected terminal equipment.

Owner:马洪峰

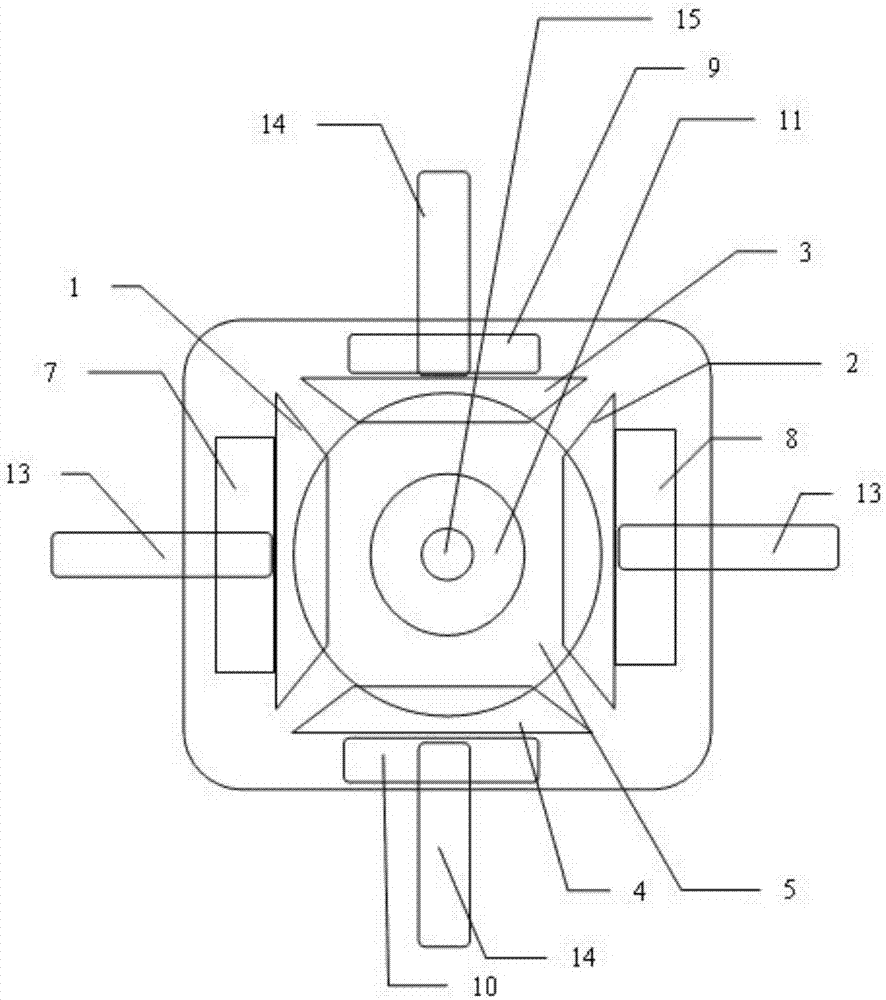

Flow guiding type rotor internal combustion engine between rotor and stator

InactiveCN109236461AReduce power lossImprove mechanical conversion efficiencyInternal combustion piston enginesStatorEngineering

The invention relates to the technical field of internal combustion engines, in particular to a flow guiding type rotor internal combustion engine between a rotor and a stator. The flow guiding type rotor internal combustion engine between the rotor and the stator comprises a rotor assembly and a stator assembly. The stator assembly comprises a stator body, the stator body is provided with a stator cavity, the inner wall of the stator cavity is formed by connecting four sections of arc hook faces in a smooth transition mode. The rotor assembly comprises a rotor shaft, a rotor body and four sets of servo airtight sliding plates, each set of servo airtight sliding plates are in closed sliding contact with the inner wall of the stator cavity, and the stator cavity is divided into four independent airtight cavities. According to the flow guiding type rotor internal combustion engine between the rotor and the stator, tangent line torque generated during gas expansion acting can be convertedinto one-way driving torque for circular motion, so that the power loss is effectively lowered, and the mechanical conversion efficiency of the rotor internal combustion engine is improved.

Owner:王亚东

Guiding heat dissipation type material vibrator

InactiveCN105692083AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

A guiding heat dissipation type material vibrator comprises a machine frame (7), a vibrated material containing component (9) and a vibration driving sliding block (8), wherein the vibrated material containing component (9) is hinged to the upper portion of the machine frame (7) through a hinge shaft (90); and the vibration driving sliding block (8) can move leftwards and rightwards at the bottom of the machine frame (7). A guide sliding groove (711) which is slidably matched with the vibration driving sliding block (8) is formed in the bottom of the machine frame (7) and used for guiding the leftward movement and the rightward movement of the vibration driving sliding block (8). The vibration driving sliding block (8) comprises a middle main body part (83) and two oblique surface parts (81 and 82), wherein the two oblique surface parts (81 and 82) are symmetrically arranged on the left side and the right side correspondingly. The two oblique surface parts (81 and 82) are provided with mutually symmetrical oblique surface sliding grooves (811 and 821) correspondingly, and the oblique surface sliding grooves (811 and 821) are used for bearing a left supporting sliding block (812) and a right supporting sliding block (822) to slide correspondingly. The left supporting sliding block (812) and the right supporting sliding block (822) are symmetrically hinged to supporting protrusions (91 and 92) which are symmetrically arranged at the left end and the right end of the lower side of the vibrated material containing component (9) correspondingly.

Owner:董海斌

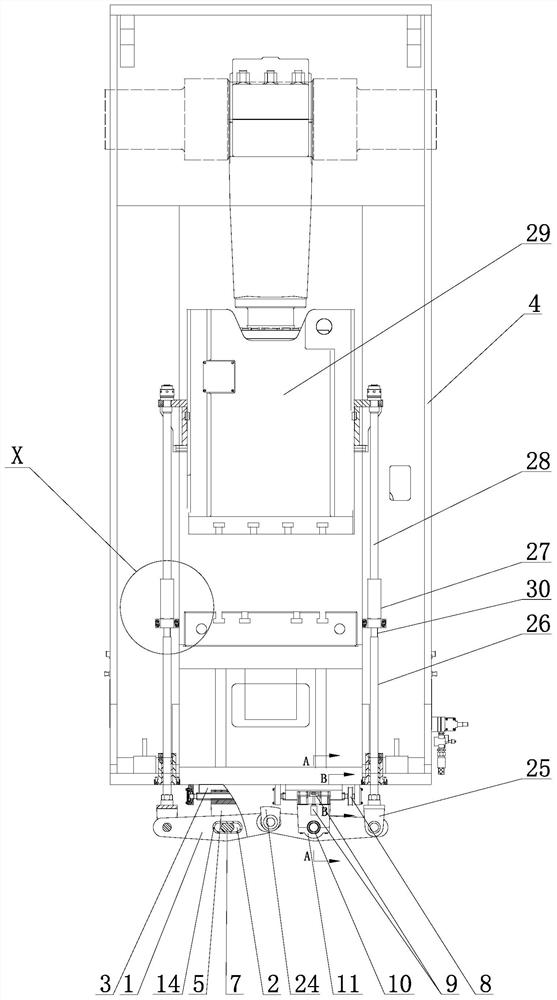

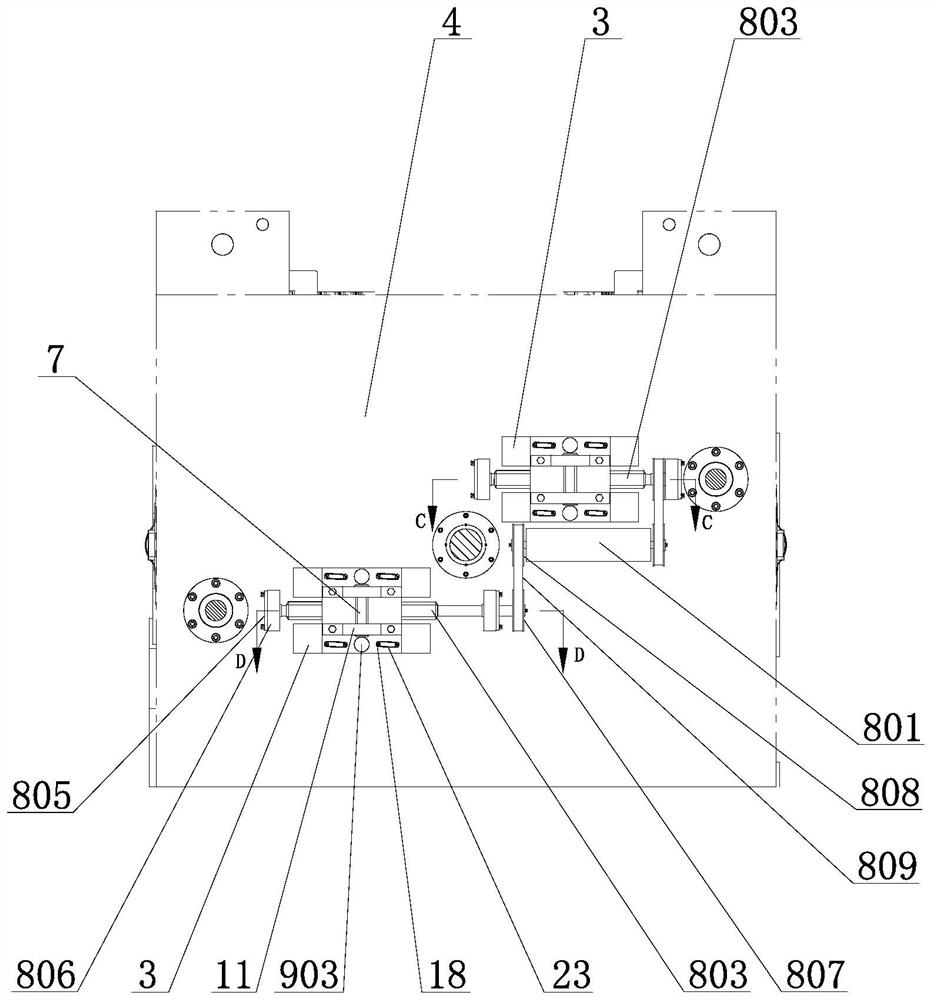

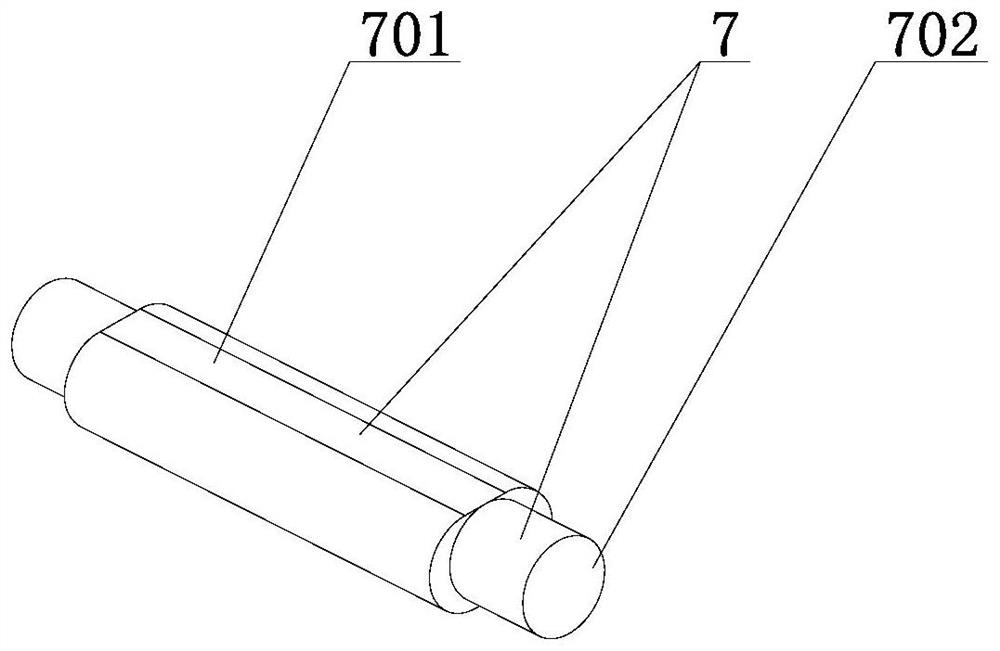

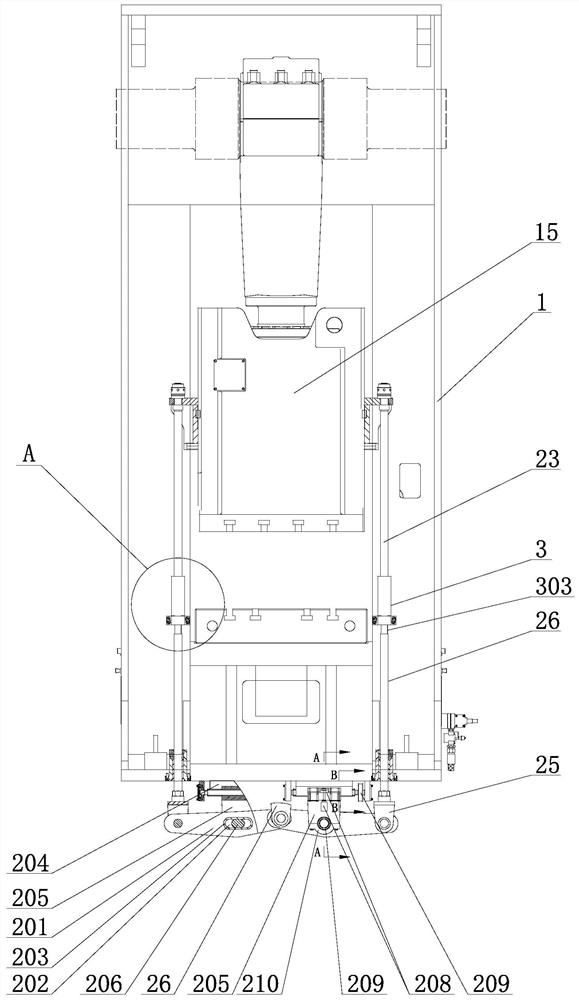

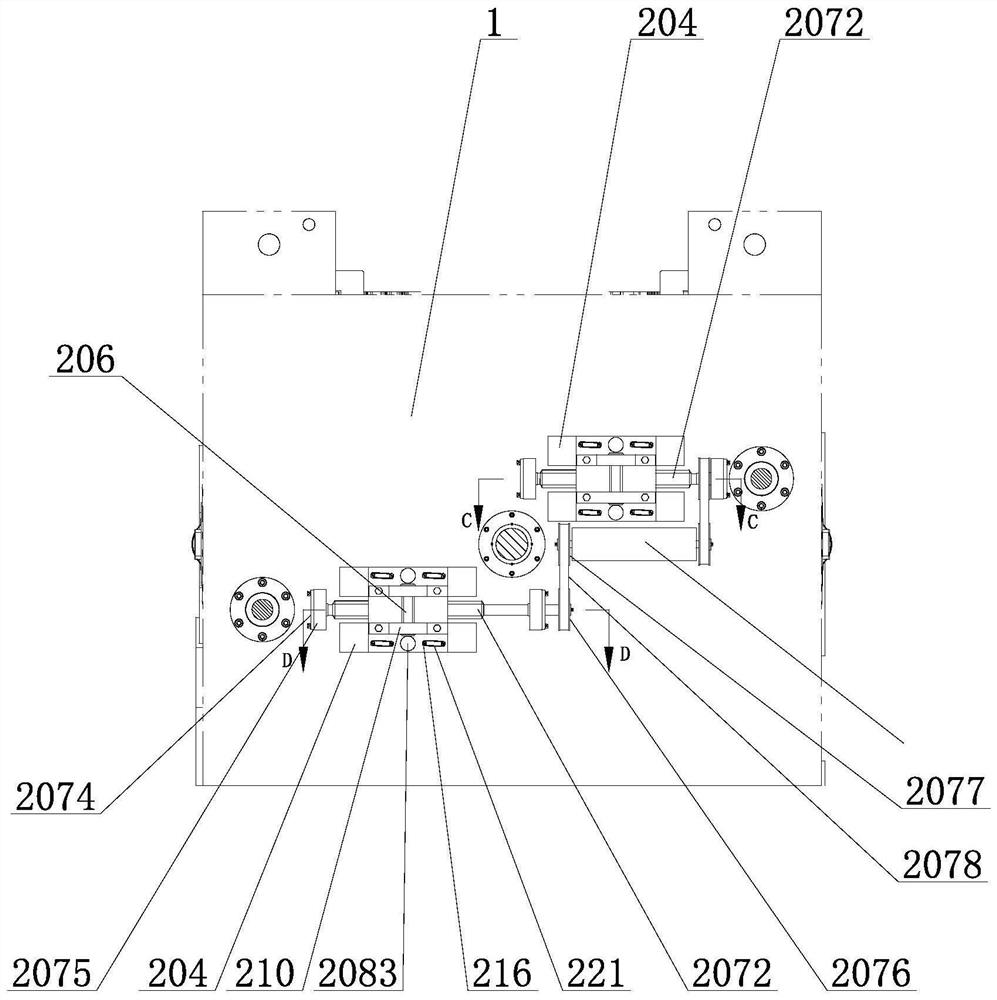

Hot die forging lever type heavy-load forging extrusion force automatic accurate regulation and control device and method

ActiveCN113290189AImprove movement guidance accuracyHigh extrusion forceForging press drivesAutomatic controlEngineering

The invention relates to the high-end equipment manufacturing industry, in particular to a hot die forging lever type heavy-load forging extrusion force automatic accurate regulation and control device and method. The hot die forging lever type heavy-load forging extrusion force automatic accurate regulation and control device comprises a lever, a guide rail, a heavy load resisting sliding strut beam, a lever fulcrum base, a power unit and a locking unit, wherein a fulcrum sliding groove is formed in the middle of the lever; a self-lubricating copper guide rail sleeve is arranged in the fulcrum sliding groove; two ends of the heavy load resisting sliding strut beam are rotatably connected with the lever fulcrum base; the middle part of the heavy load resisting sliding strut beam is in surface contact sliding connection with the self-lubricating copper guide rail sleeve; the upper end of the lever fulcrum base is connected with the guide rail; the power unit drives the lever fulcrum base to move along the guide rail and the fulcrum sliding groove; and the lever fulcrum base is locked on the guide rail by the locking unit. On the basis that the lever type mechanical lower forging extrusion force is good in synchronism, symmetrical and balanced and large in ejection force, the efficiency, the ejection force (improved by more than five times compared with the traditional technology) and the stability are effectively improved, the automatic control requirements of precise multi-station hot die forging and automatic line net near forming machining thereof are met, and the effect of automatically and accurately adjusting and controlling the heavy-load forging extrusion force is achieved.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY

Vibrator capable of stabilizing materials

InactiveCN105600318AStable structureImprove the stability of forceJigging conveyorsMechanical engineeringEngineering

Owner:黎钊彬

Buffer type material vibration device

InactiveCN105692084AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

Owner:何慧敏

Flow guide type rotor internal combustion engine between rotor and stator

InactiveCN109611195AImprove mechanical conversion efficiencyReduce power lossInternal combustion piston enginesCombustionEngineering

The invention relates to the technical field of internal combustion engines, in particular to a flow guide type rotor internal combustion engine between a rotor and a stator. The flow guide type rotorinternal combustion engine between the rotor and the stator comprises a rotor assembly and a stator assembly. The stator assembly comprises a stator body. The stator body is provided with a stator cavity. The inner wall of the stator cavity is formed by connecting two semicircular arc-shaped curved surfaces with different radiuses in a smooth transition mode. The rotor assembly comprises a rotorshaft, a rotor body and a follow-up airtight sliding plate. A gas flow guide channel is arranged between the stator cavity and the rotor body. The outer end surface of the follow-up airtight sliding plate is in sealed sliding contact with the inner wall of the stator cavity, and the stator cavity is divided into two independent chambers which are mutually airtight. By means of the flow guide typerotor internal combustion engine between the rotor and the stator, the tangential moment during gas expansion and working can be converted into a one-way driving torque for circular motion, so that the power loss is effectively reduced, and the mechanical conversion efficiency of the rotor internal combustion engine is improved.

Owner:王亚东

A one-way power conversion device with a swinging and rotating housing and a method for realizing the one-way power conversion

ActiveCN107023623BLarge load carrying capacityLow costGearingSea energy generationStructural engineeringPower output

The invention provides a one-way power conversion device with a swinging and rotating housing and a method for realizing the one-way power conversion. The one-way power conversion device includes a swinging and rotating housing support shaft, a power output shaft, and a first one-way device And the second one-way device, the device includes one or more one-way power conversion devices combined with each other, and forms a universal swing power that can absorb and convert this swing power into one-way usable rotary power. The invention provides a one-way power conversion device with a swinging and rotating housing, which can absorb swinging power in any direction, and has the advantages of high absorption and conversion efficiency, low manufacturing and maintenance costs, strong stability, and wide application range.

Owner:吴钦发

Noise-reducing material vibrating device

InactiveCN105668150AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

A noise-reducing material vibrating device comprises a machine frame (7), a vibrated material containing component (9) and a vibration driving sliding block (8), wherein the vibrated material containing component (9) is hinged to the upper part of the machine frame (7) through a hinged shaft (90); the vibration driving sliding block (8) can move left and right on a roller travelling track (71) fixed at the bottom of the machine frame (7); the vibration driving sliding block (8) comprises a middle main body part (83), a left inclined surface part (81) and a right inclined surface part (82); the two inclined surface parts (81 and 82) are arranged symmetrically and are provided with inclined surface sliding grooves (811 and 821) respectively; the inclined surface sliding grooves (811 and 821) are mutually symmetric and are used for allowing a left support sliding block (812) and a right support sliding block (822) to slide in respectively; and the left support sliding block (812) and the right support sliding block (822) are respectively hinged to support bulges (91 and 92), which are symmetrically arranged at the left and right ends on the lower side of the vibrated material containing component (9).

Owner:郑静

Hot die forging lever type heavy-duty forging extrusion force automatic and precise control device and method

ActiveCN113290189BImprove movement guidance accuracyHigh extrusion forceForging press drivesAutomatic controlEngineering

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY

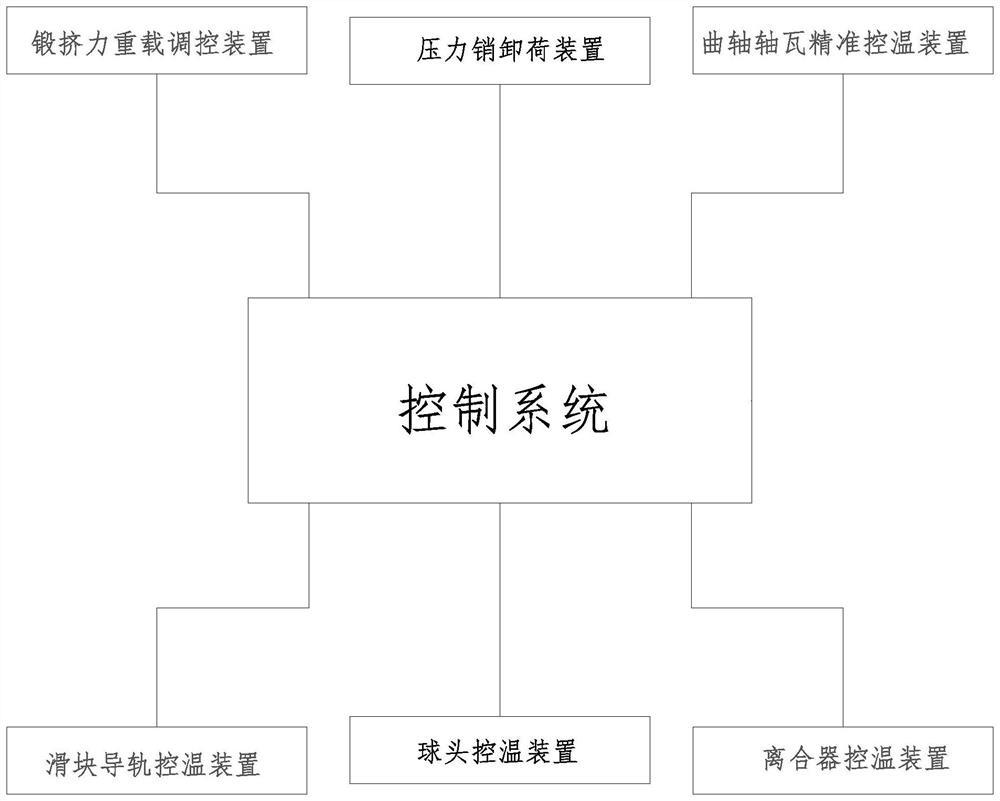

Precise and efficient hot die forging press

ActiveCN113245490BImprove movement guidance accuracyImprove mechanical conversion efficiencyUpsetting pressesSwagging pressesTemperature controlAutomatic control

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY

Energy-saving material vibrator

InactiveCN105689262AStable structureImprove the stability of forceSievingScreeningLED lampMechanical engineering

An energy-saving material vibrator comprises a machine fame (7), a vibrated material containing component (9) and a vibration driving sliding block (8), wherein the vibrated material containing component (9) is hinged to the upper portion of the machine frame (7) through a hinge shaft (90); and the vibration driving sliding block (8) can move leftwards and rightwards on a roller traveling rail (71) fixedly arranged at the bottom of the machine frame (7). LED lamps (111) are arranged above the left end and the right end of the roller traveling rail (71). The LED lamps (111) are fixed to the machine frame (7) and used for illuminating so that the leftward movement and rightward movement of the vibration driving sliding block (8) can be observed conveniently, and faults can be eliminated in time when the leftward movement and rightward movement of the vibration driving sliding block (8) fail. The vibration driving sliding block (8) comprises a middle main body part (83) and two oblique surface parts (81 and 82), wherein the two oblique surface parts (81 and 82) are arranged on the left side and the right side symmetrically.

Owner:黎钊彬

Stable-sliding material vibrating device

InactiveCN105668152AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

A stable-sliding material vibrating device comprises a machine frame (7), a vibrated material containing component (9) and a vibration driving sliding block (8), wherein the vibrated material containing component (9) is hinged to the upper part of the machine frame (7) through a hinged shaft (90); the vibration driving sliding block (8) can move left and right on a roller travelling track (71) fixed at the bottom of the machine frame (7); the vibration driving sliding block (8) comprises a middle main body part (83), a left inclined surface part (81) and a right inclined surface part (82); and the two inclined surface parts (81 and 82) are arranged symmetrically and are used for allowing a left support sliding block (812) and a right support sliding block (822) to slide on respectively.

Owner:YIWU CITY SHOUGEN CRAFTS

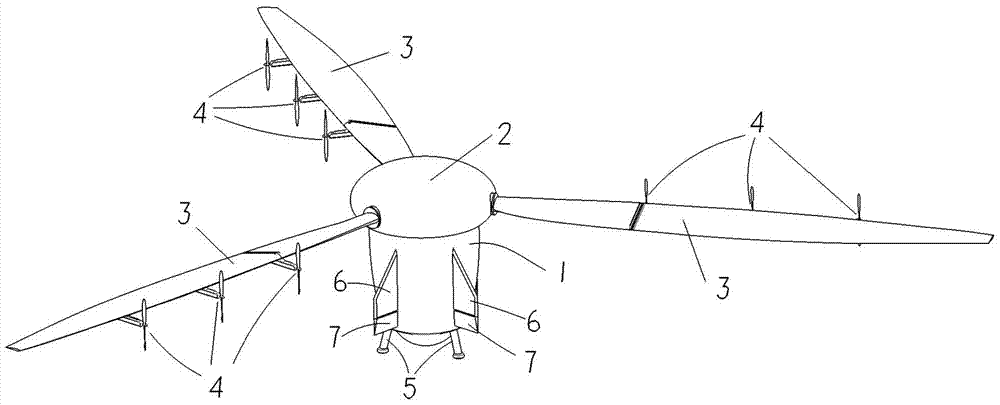

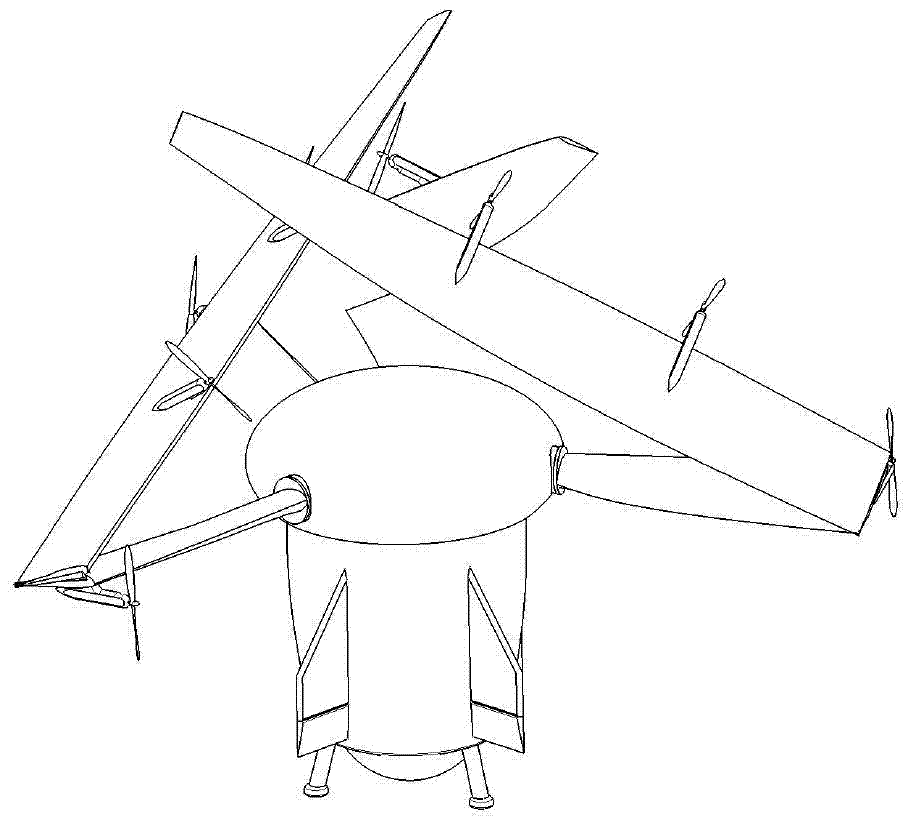

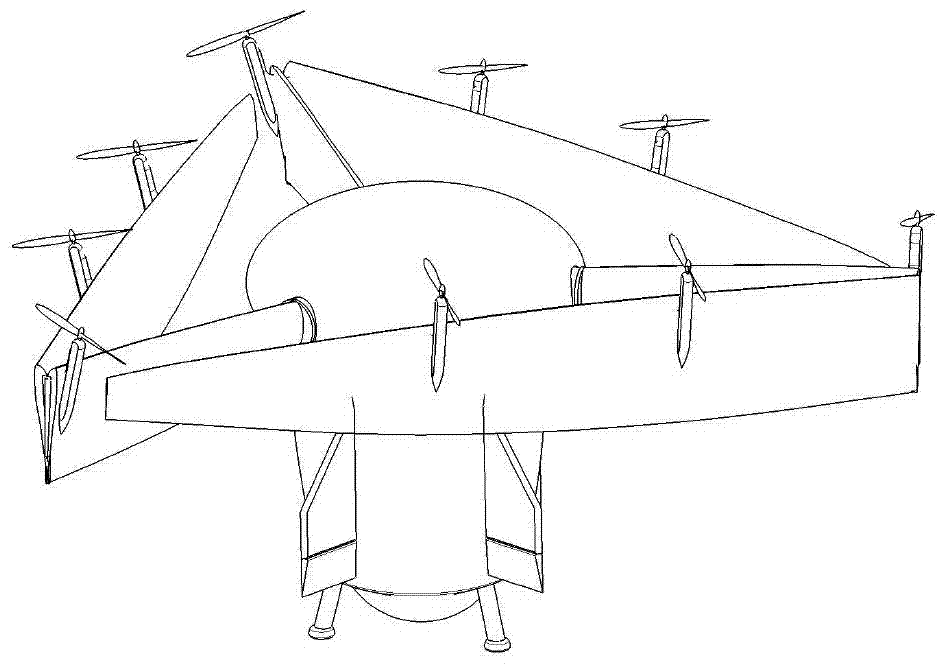

A kind of aircraft and control method thereof

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

A kind of rotor internal combustion engine with diversion between rotor and stator

InactiveCN109339940BImprove mechanical conversion efficiencyReduce power lossInternal combustion piston enginesInternal combustion engineGas engine

Owner:王亚东

Material vibrator

InactiveCN105668148AStable structureImprove the stability of forceJigging conveyorsLED lampMechanical engineering

A material vibrator comprises a machine frame (7), a vibrated material containing component (9) and a vibration driving sliding block (8), wherein the vibrated material containing component (9) is hinged to the upper part of the machine frame (7) through a hinged shaft (90); the vibration driving sliding block (8) can move left and right on a roller travelling track (71) fixed at the bottom of the machine frame (7); LED lamps (111) are arranged at the upper parts of the left end and the right end of the roller travelling track (71); the LED lamps (111) are fixed on the machine frame (7) and used for illumination, so that the left and right movement of the vibration driving sliding block (8) can be observed conveniently, and failures can be removed in time when the vibration driving sliding block (8) goes wrong during left and right movement; the vibration driving sliding block (8) comprises a middle main body part (83), a left inclined surface part (81) and a right inclined surface part (82); and the inclined surface parts (81 and 82) are arranged symmetrically.

Owner:黎钊彬

Material vibrating device running safely

InactiveCN105728318AStable structureImprove the stability of forceSievingScreeningMechanical engineeringEngineering

A material vibrating device with safe operation, comprising a frame (7), a vibrating material containing part (9) hinged to the upper part of the frame (7) through a hinge shaft (90), and a The vibration-driven slider (8) that moves left and right on the roller track (71) at the bottom of the frame (7), wherein the vibration-driven slider (8) includes a middle main body (83) and a left-right symmetrical The two slopes (81, 82) of the two slopes (81, 82) are respectively provided with mutually symmetrical slope chute (811, 821) to carry the left support slider (812) and the right The supporting slider (822) slides, and the left supporting slider (812) and the right supporting slider (822) are symmetrically arranged at the left and right ends of the lower side of the vibrating material holding part (9) respectively. The supporting protrusions (91, 92) are hinged.

Owner:郑静

Material vibrating device

InactiveCN105668151AStable structureImprove the stability of forceJigging conveyorsEngineeringMechanical engineering

A material vibrating device comprises a machine frame (7), a vibrated material containing component (9) and a vibration driving sliding block (8), wherein the vibrated material containing component (9) is hinged to the upper part of the machine frame (7) through a hinged shaft (90); the vibration driving sliding block (8) can move left and right on a roller travelling track (71) fixed at the bottom of the machine frame (7); the vibration driving sliding block (8) comprises a middle main body part (83), a left inclined surface part (81) and a right inclined surface part (82); the two inclined surface parts (81 and 82) are arranged symmetrically and are provided with inclined surface sliding grooves (811 and 821) respectively; the inclined surface sliding grooves (811 and 821) are mutually symmetric and are used for allowing a left support sliding block (812) and a right support sliding block (822) to slide in respectively; and the left support sliding block (812) and the right support sliding block (822) are respectively hinged to support bulges (91 and 92), which are symmetrically arranged at the left and right ends on the lower side of the vibrated material containing component (9).

Owner:何慧敏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com