Gas power type natural gas compressor lubricating oil composition

A lubricating oil composition and gas power technology, which is applied in the field of lubrication, can solve problems such as unsatisfactory lubrication effects, and achieve the effects of improving mechanical conversion efficiency, prolonging service life, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: 111.4 parts of base oil, 255.7 parts of base oil, 9.4 parts of ashless gas engine oil compounding agent, 0.005 part of antifoaming agent, and 0.5 part of pour point depressant;

[0016] In step A, add base oil 1, base oil 2, gas engine oil compounding agent, antifoaming agent, pour point depressant and other raw materials into the blending kettle in proportion, and stir and blend at 50°C for 40 minutes.

[0017] Step B is based on the above step A, adding 22.2 parts of balance accelerator and 0.2 part of nano-carbon, and stirring and blending at 40-50° C. for 35 minutes. Then negative pressure dehydration, filtration purification, packaging.

Embodiment 2

[0018] Embodiment 2: 19.8 parts of base oil; 251.5 parts of base oil; 10 parts of low-ash gas engine oil compounding agent; 0.005 part of antifoaming agent; 0.5 part of pour point depressant;

[0019] In step A, base oil 1, base oil 2, gas engine oil compounding agent, antifoaming agent, pour point depressant and other raw materials are added to the blending kettle in proportion, and stirred and blended at 50-60°C for 60 minutes.

[0020] Step B is based on the above step A, adding balance accelerator 22.2 and nano-carbon 0.2 in proportion, and stirring and blending at 40-50° C. for 35 minutes. Then negative pressure dehydration, filtration purification, packaging.

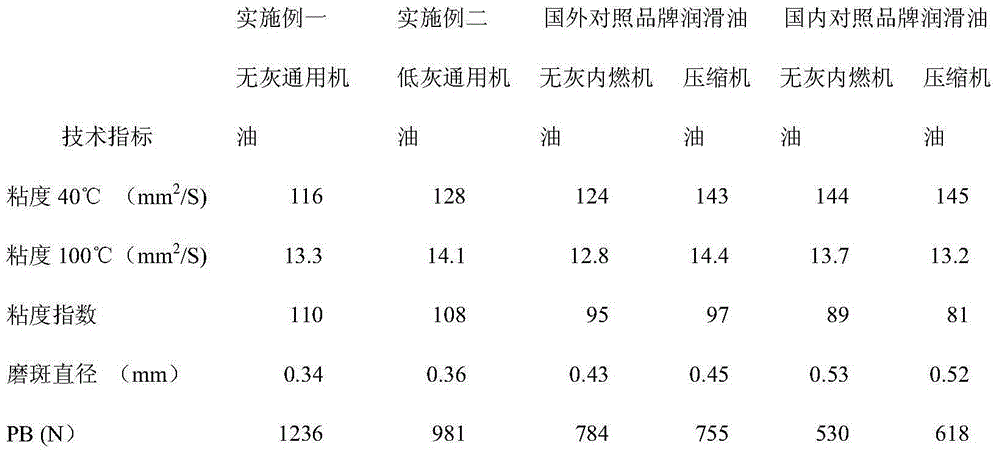

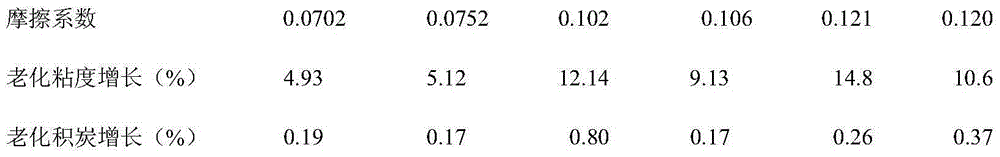

[0021] Table 1 is the comparison of embodiment 1, embodiment 2 and reference oil technical indicators.

[0022] Table 1

[0023] Embodiment contrasts with reference oil technical index

[0024]

[0025]

[0026] The gas-powered natural gas compressor lubricating oil composition involved in the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com