Glass blanking working table body adjusting device for tempered glass production

A technology of adjusting device and tempered glass, which is applied in hoisting device, conveyor control device, transportation and packaging, etc., can solve the problems of backward glass transfer method, unable to transfer glass in stacks, etc., to improve the mechanical conversion efficiency and structure. Simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

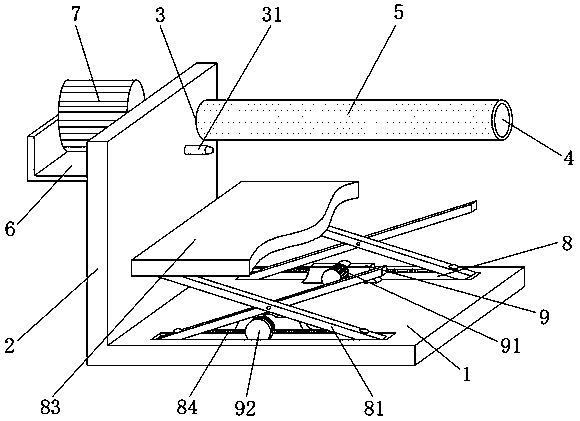

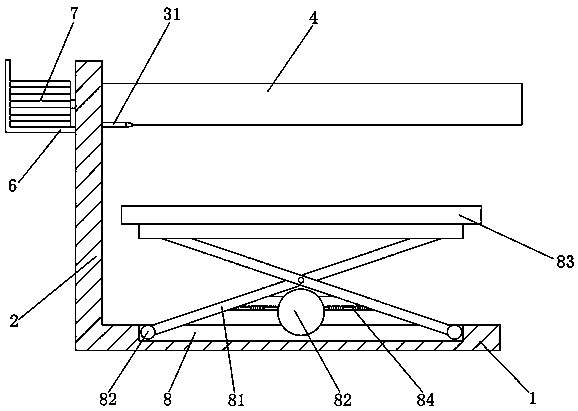

[0024] see Figure 1-3 , this embodiment provides a glass blanking workbench body adjustment device for tempered glass production, including a load-bearing platform 1, one side of the load-bearing platform 1 is integrally provided with a load-bearing plate 2, and the side of the load-bearing plate 2 is provided with a rotary hole 3 The inner wall of the rotating hole 3 is equipped with a freely rotatable roller 4 through the bearing, and the outer wall of the roller 4 is sleeved with a rubber anti-slip sleeve 5, and the side of the load-bearing plate 2 away from the bearing platform 1 is integrally arranged near the rotating hole 3. Fixed mount 6 is arranged, and the inside of fixed mount 6 is fixed with electric motor 7, and the power take-off shaft of electric motor 7 and roller 4 stretch into the center of one end of rotating hole 3 inside and fix, and electric motor 7 is connected with mains by lead.

[0025] The top surface of the load-bearing platform 1 is symmetrically ...

Embodiment 2

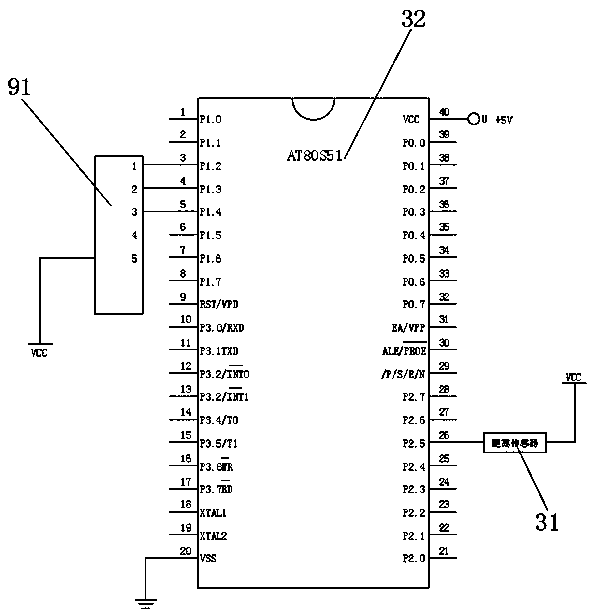

[0035] see Figure 1-2 On the basis of Embodiment 1, a further improvement has been made: the top surface of the load-bearing platform 1 is provided with a telescopic frame 81, and the end of the foot of the telescopic frame 81 extends into the inside of the slideway 8, and the bottom end of the telescopic frame 81 is installed There are freely slidable rollers 82, and the bottom side of the rollers 82 is attached to the inner wall of the bottom side of the slideway 8. The sliding friction between the telescopic frame 81 and the slideway 8 can be converted into rolling friction through the rollers 82, which can reduce the expansion and contraction. The resistance experienced by the feet of the frame 81 during relative movement can improve the mechanical conversion efficiency of the servo motor 91 , making the change of the length of the telescopic frame 81 free of frustration and more stable.

[0036] The outer wall of the roller 4 is sleeved with an anti-slip sleeve 5 made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com