Carrying robot, container taking method and container placing method

A technology for handling robots and cargo boxes, applied in the field of warehousing and logistics, which can solve problems such as waste of resources, increase of robot load, waste of resources and energy consumption, etc., and achieve the effect of improving efficiency, improving utilization rate, and reducing activity space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

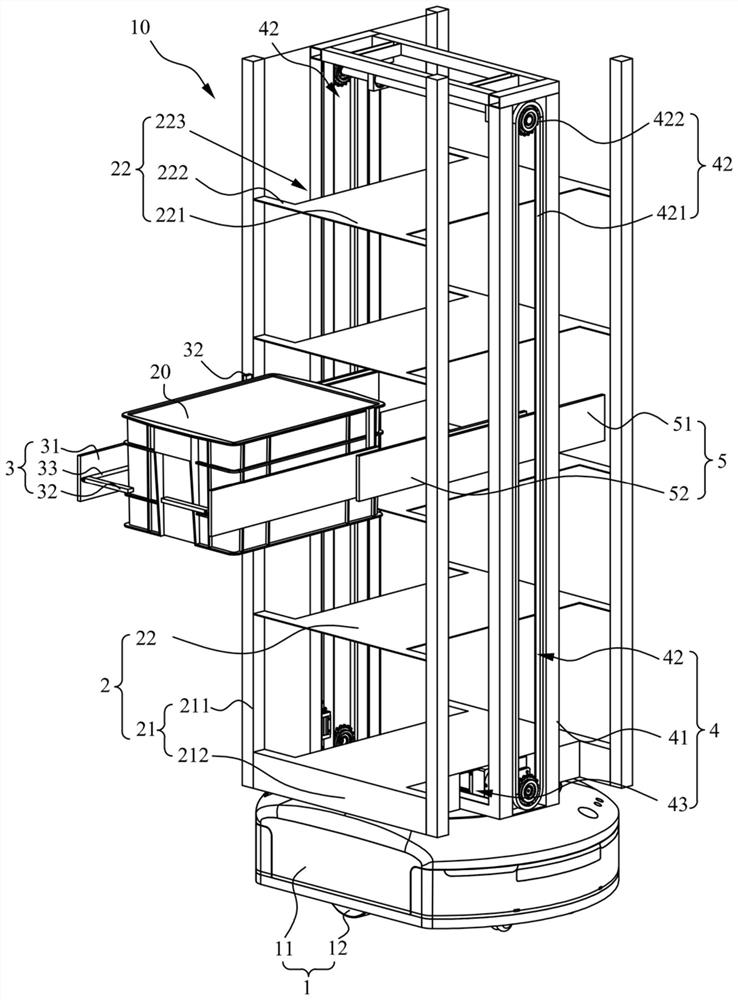

[0063] figure 1 The structural schematic diagram of the handling robot 10 provided for the embodiment of the present invention, such as figure 1 As shown, this embodiment provides a handling robot 10, which is used to carry and pick and place the target container 20. It is mainly used in the warehousing and logistics industry to pick and place the target container 20 with the order goods or express delivery. Put and ship for order-based pick-up or put-up operations. It can also be applied to other places where the target container 20 or goods need to be transported. The application of the transport robot 10 in this embodiment is only exemplary, and this embodiment does not specifically limit it.

[0064] In this embodiment, the application of the handling robot 10 in the warehousing and logistics industry is mainly to pick up, load and move the target container 20 in the warehouse container based on the order: when the order management center receives the pick-up order, the o...

Embodiment 2

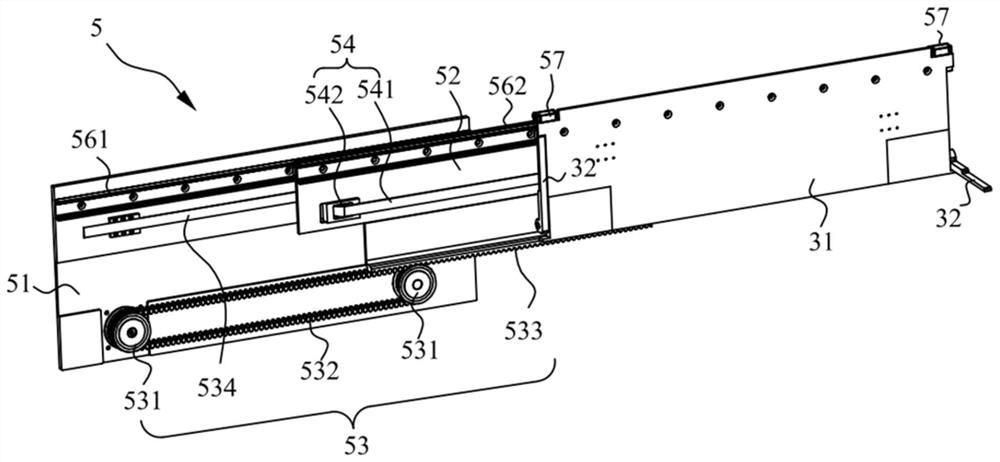

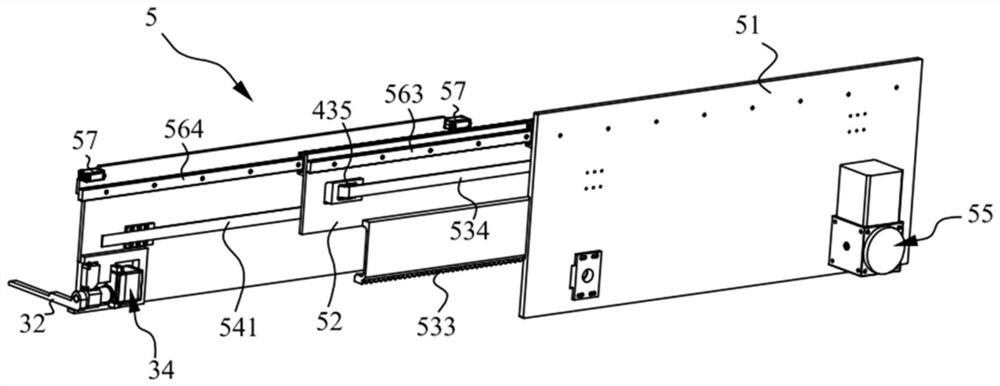

[0136] Figure 6 The structural schematic diagram of the handling robot 10 provided for the embodiment of the present invention, such as Figure 6 As shown, this embodiment provides a handling robot 10 for carrying the target container 20 . Compared with Embodiment 1, the basic structure of the handling robot 10 provided in this embodiment is the same as that of the handling robot 10 provided in Embodiment 1, and both include a mobile chassis 1, a lift adjustment assembly 4, a temporary storage rack 2, a telescopic adjustment assembly 5, a take-off The structure of box assembly 3, control assembly and detection assembly, and mobile chassis 1, lifting adjustment assembly 4, telescopic adjustment assembly 5, box removal assembly 3, control assembly and detection assembly is the same as that of Embodiment 1, only the setting of temporary storage rack 2 There are differences in this embodiment, and the same content or structure as the first embodiment will not be repeated in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com