Automatic focus lens module

A focusing lens and automatic technology, applied in the field of automatic focusing lens modules, can solve the problems of complexity, multiple components and structures, and limit the thinning of the automatic focusing lens module, and achieve the reduction of lens movement space, simple structure, and easy assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

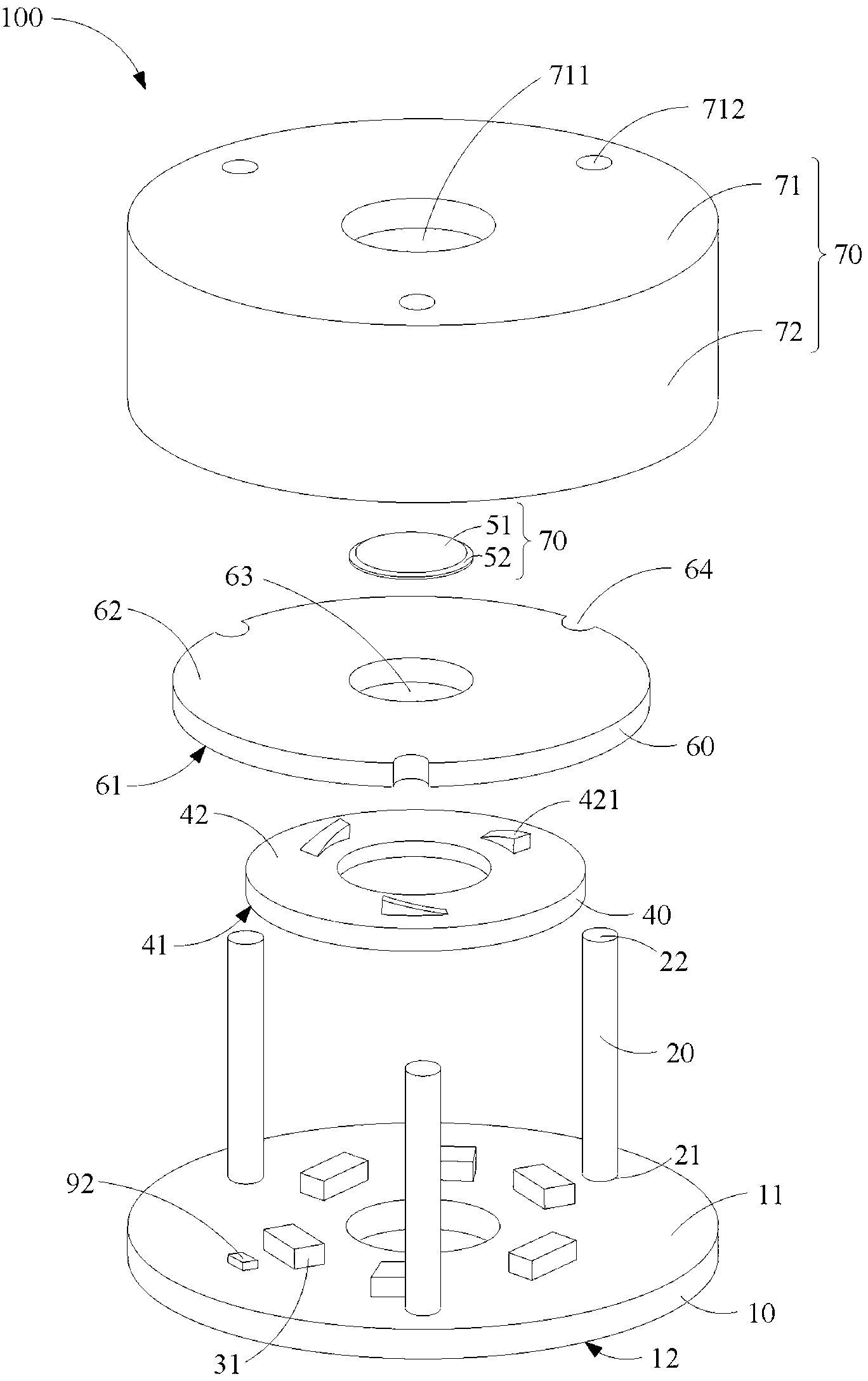

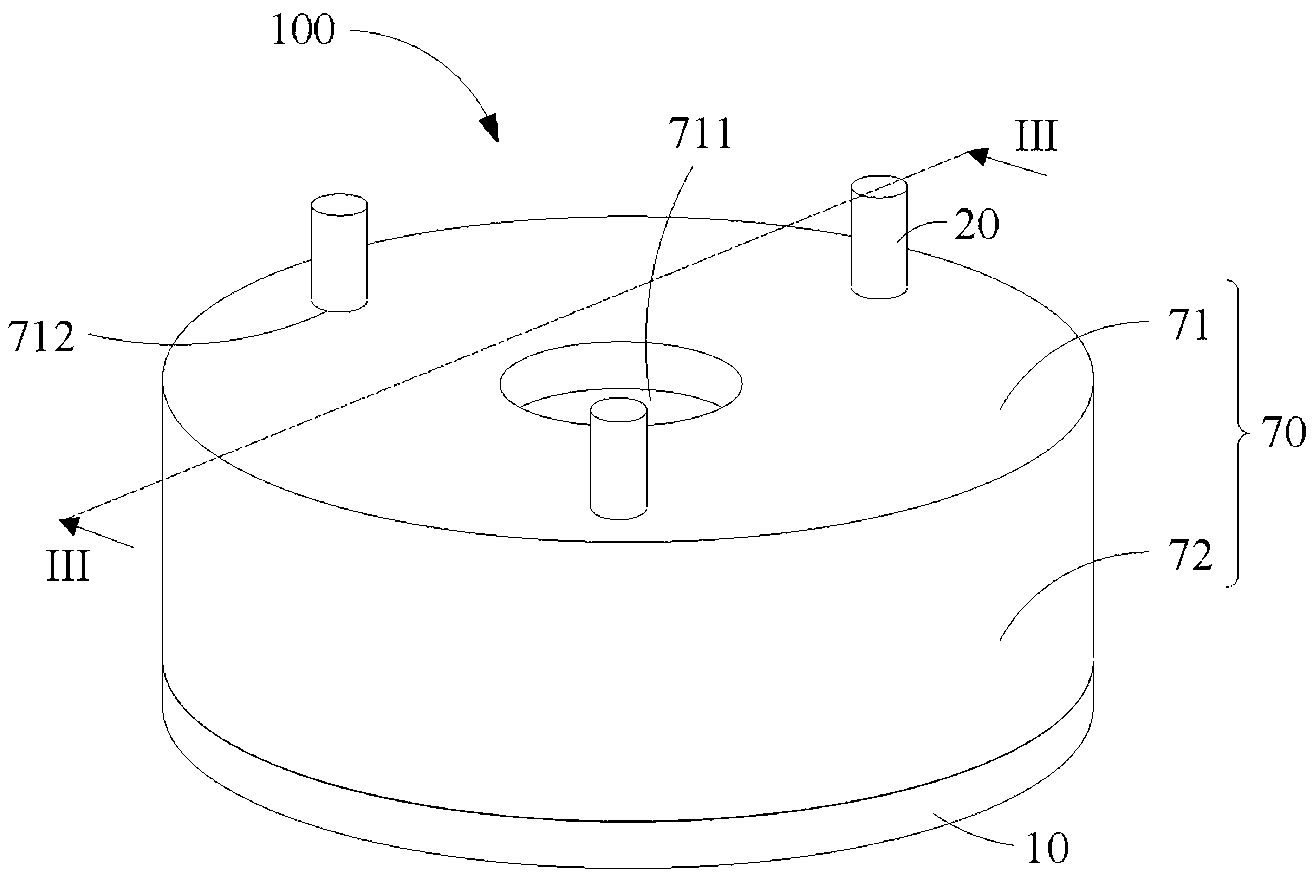

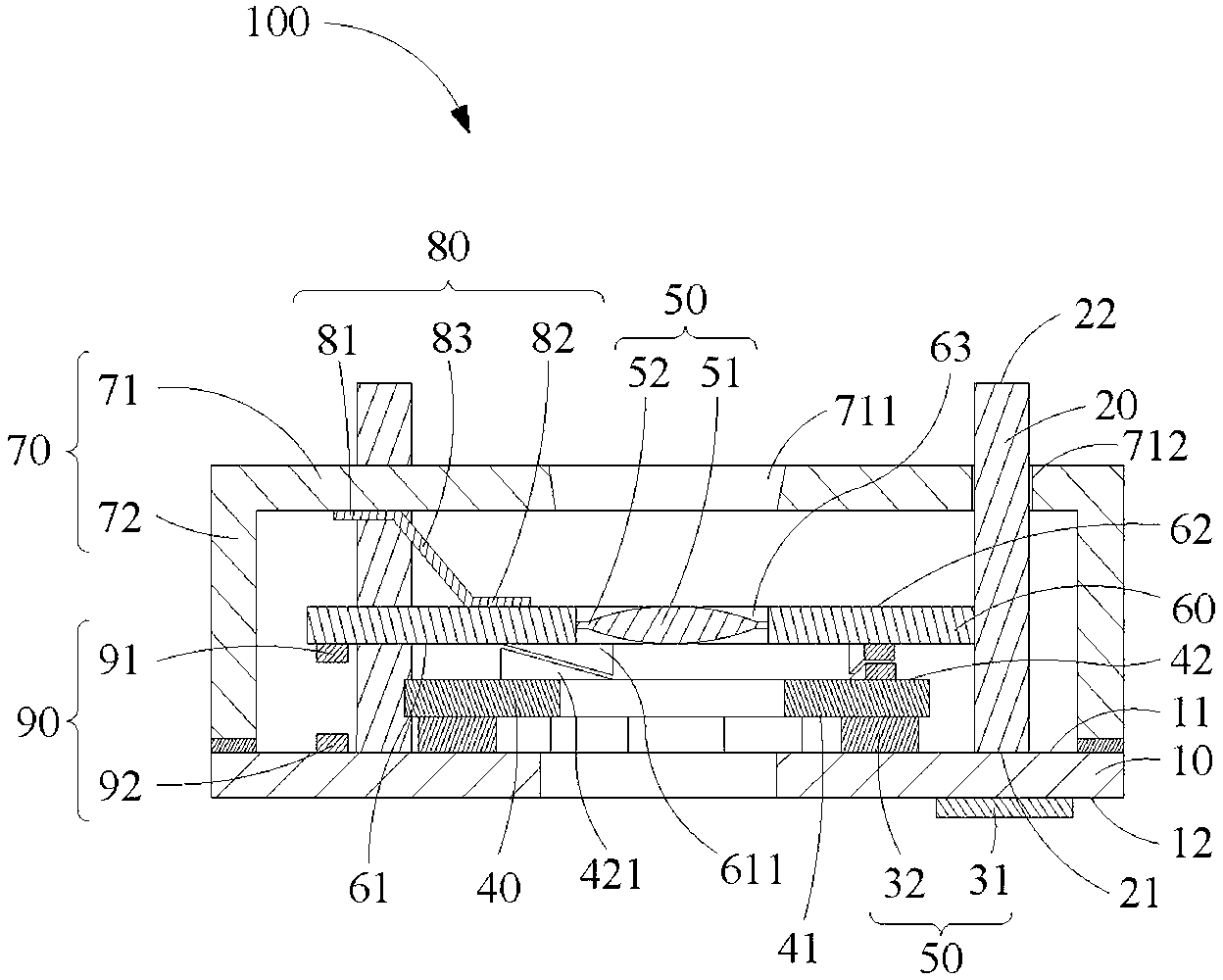

[0014] see Figure 1 to Figure 3 , is shown as a structural diagram of the autofocus lens module 100 of the present invention, the autofocus lens module 100 includes a substrate 10, a plurality of guides 20, a piezoelectric driver 30, an active plate 40, a Lens 50 , a lens holder 60 and an outer cover 70 .

[0015] The substrate 10 is ring-shaped and includes a first surface 11 and a second surface 12 opposite to the first surface 11 . The substrate 10 is made of hard materials, such as ceramics or resin materials. A printed circuit (not shown) for electrically connecting electronic components is disposed on the substrate 10 .

[0016] Each guiding member 20 is cylindrical and includes a first end 21 and a second end 22 separated from the first end 21 . The first end 21 is fixed on the first surface 11 of the substrate 10 , and the second end 22 is away from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com