Energy-saving speeding and boosting mechanism and method

A speed-increasing mechanism and force-increasing technology, which is applied in the direction of mechanical equipment, gear transmission, belt/chain/gear, etc., can solve problems such as power loss, and achieve the effect of speed increase and high mechanical conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

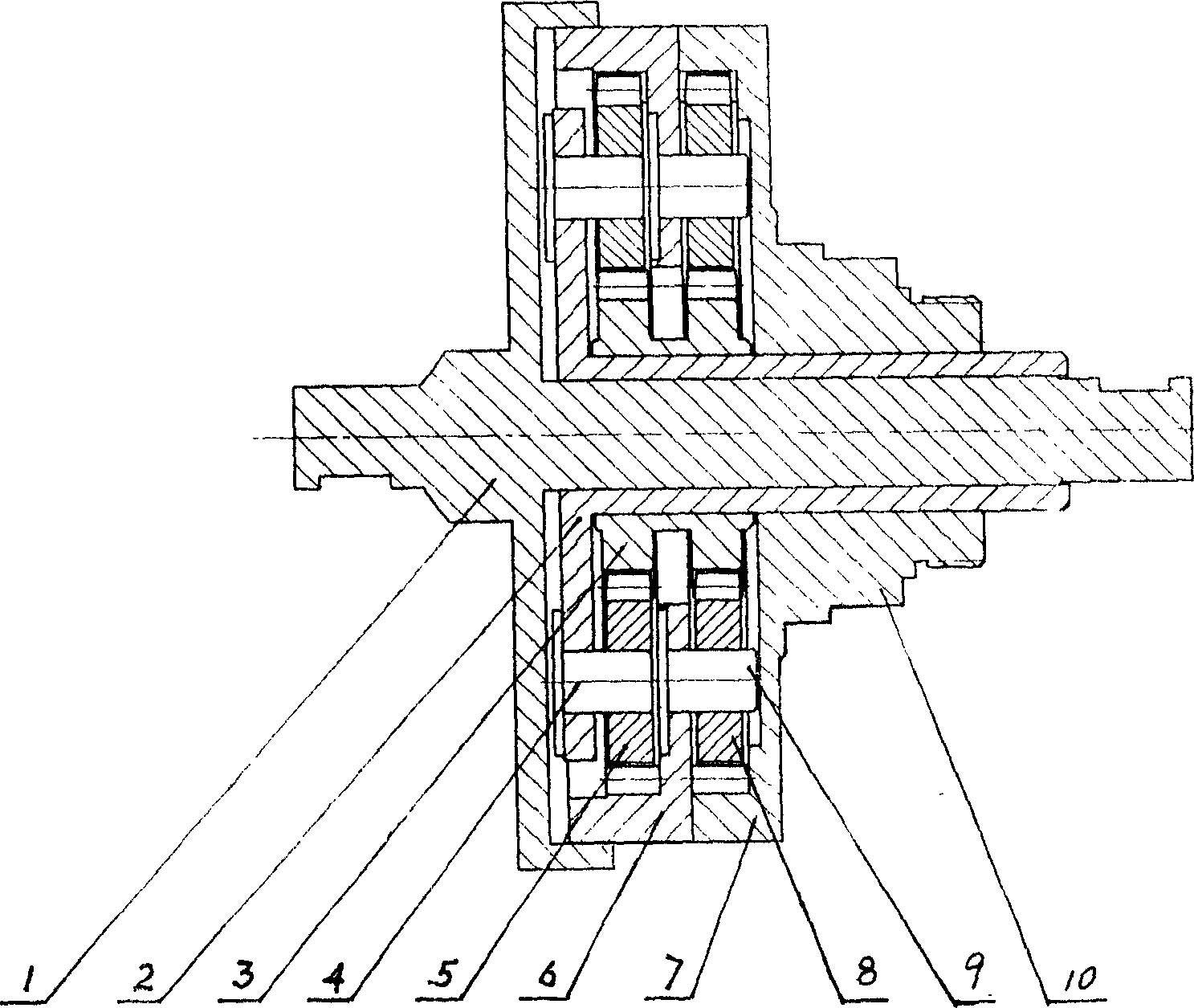

[0014] Embodiment 1: with reference to attached figure 1 . In the energy-saving power-increasing speed-up mechanism, the input shaft 1 is in the structure of a central shaft cover, and the shaft and the cover are connected as one or in an integral structure. The planetary carrier 2 has a T-shaped sleeve flange structure (that is, a flange sleeve structure---a circular cover with a middle hole is connected to the end of the sleeve). The planetary carrier 2 is sleeved on the shaft-in shaft 1, and the sun gear 3 is a double-wheel conjoined structure and is processed and manufactured by using the prior art. The sun gear 3 is set on the planetary carrier 2, the planetary gear 5 is connected with the planetary carrier through the mandrel 4 and the planetary gear 5 meshes with the sun gear 3, and the inner gear 6 is set on the sun gear, and the internal teeth of the inner gear mesh with the planetary gear 5 1. The outer wall of the inner gear is connected with the inner wall of the...

Embodiment 2

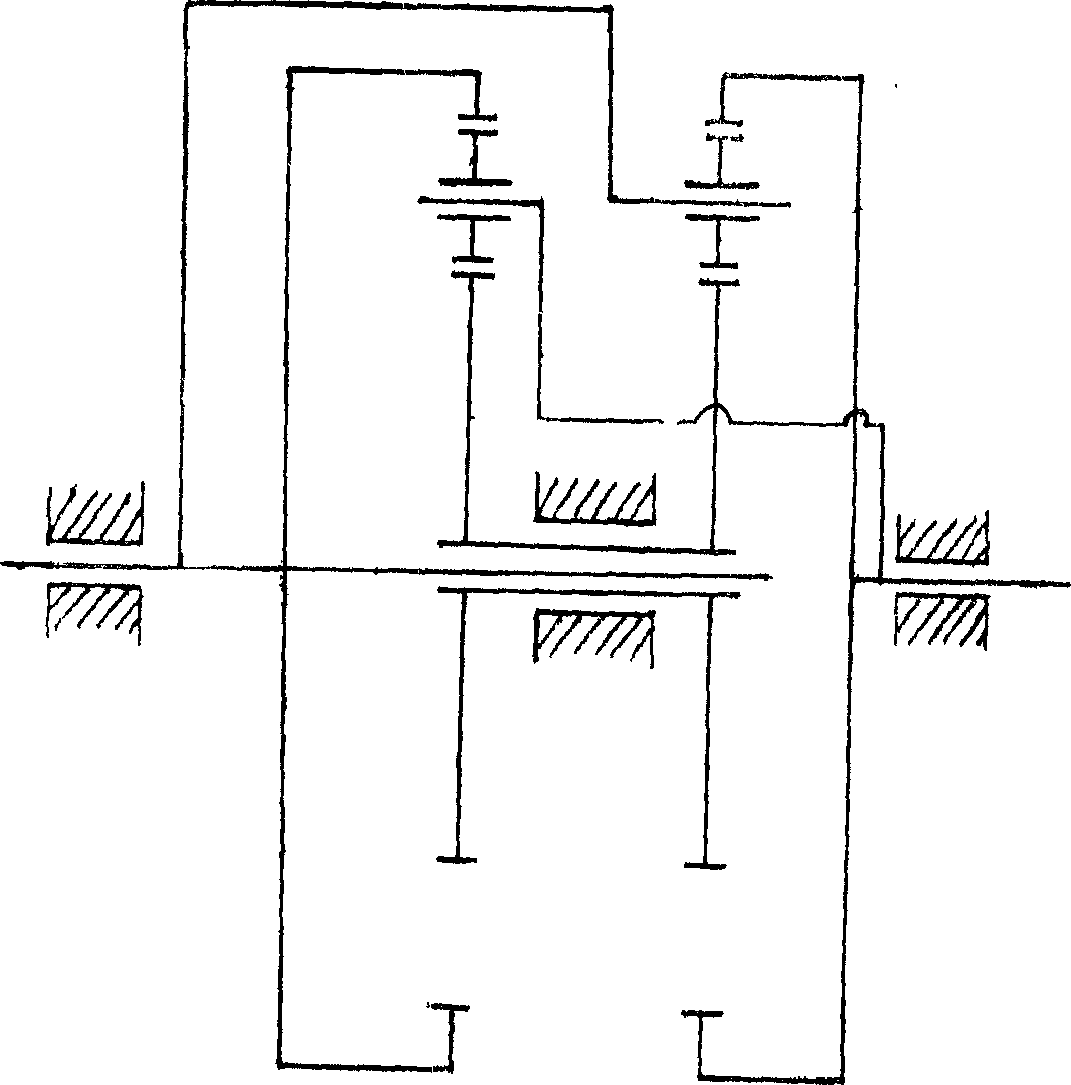

[0016] Embodiment 2: energy-saving and power-increasing speed-up method, the power on the input shaft is transmitted in two ways, one way is directly transmitted to the output shaft through the star gear set on the rotating arm and the output shaft, and the other way is passed through the star gear on the input shaft The star gear set on the group and the output shaft is transmitted to the output shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com