Material vibration equipment capable of achieving energy saving

A technology for vibrating equipment and materials, applied in the direction of fluid using vibration, etc., can solve the problems of difficult to meet the bearing requirements of heavy loads, increase production line setup and operating costs, occupy a large area or space, and improve mechanical conversion efficiency. , Simplify the vibration generation structure, the effect of smooth vibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

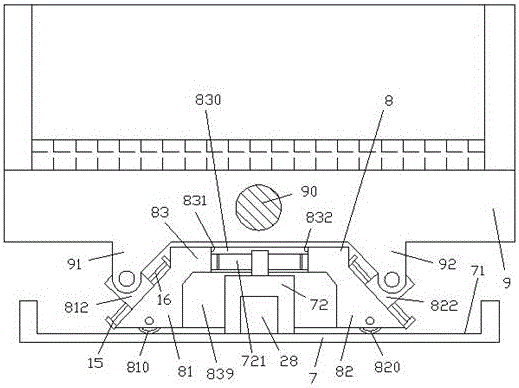

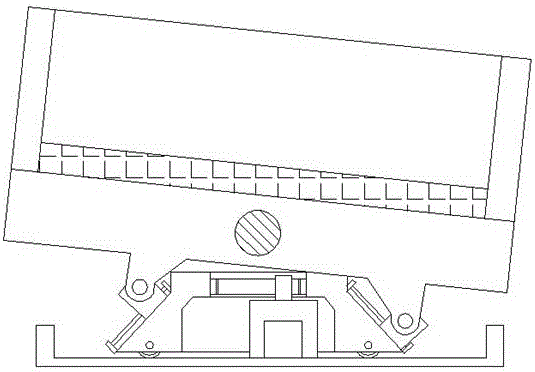

[0010] Combine below Figure 1-4 The present invention will be described in detail.

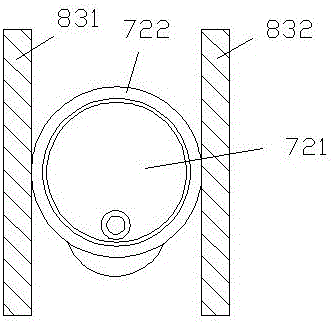

[0011] According to an embodiment, an energy-saving oriented material vibration equipment includes a frame 7, a vibrating material holding part 9 hinged to the upper part of the frame 7 through a hinge shaft 90, and a vibrating material holding part 9 that can be fixedly arranged on the frame The vibration-driven slider 8 that moves left and right on the roller walking track 71 at the bottom of 7, wherein the vibration-driven slider 8 includes a middle main body 83 and two inclined parts 81, 82 arranged symmetrically left and right, the two The inclined parts 81, 82 are used to respectively carry the sliding of the left supporting slider 812 and the right supporting slider 822, and the two ends of each of the two inclined parts 81, 82 are provided with a mounting block 15, and the mounting block 15 is fixed on A guide rod 16 parallel to the inclined surfaces 81, 82 is provided, and the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com