Rotary shaft type steel bar splitting machine

A steel separating machine and rotating shaft technology, used in metal rolling, manufacturing tools, metal processing equipment, etc., can solve the problem that the steel pushing step distance cannot be accurately controlled, the contact distance between the pushing steel machine and the hot billet is close, and it is not easy to achieve. Automatic control and other issues, to achieve the effect of simple structure, light overall weight and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

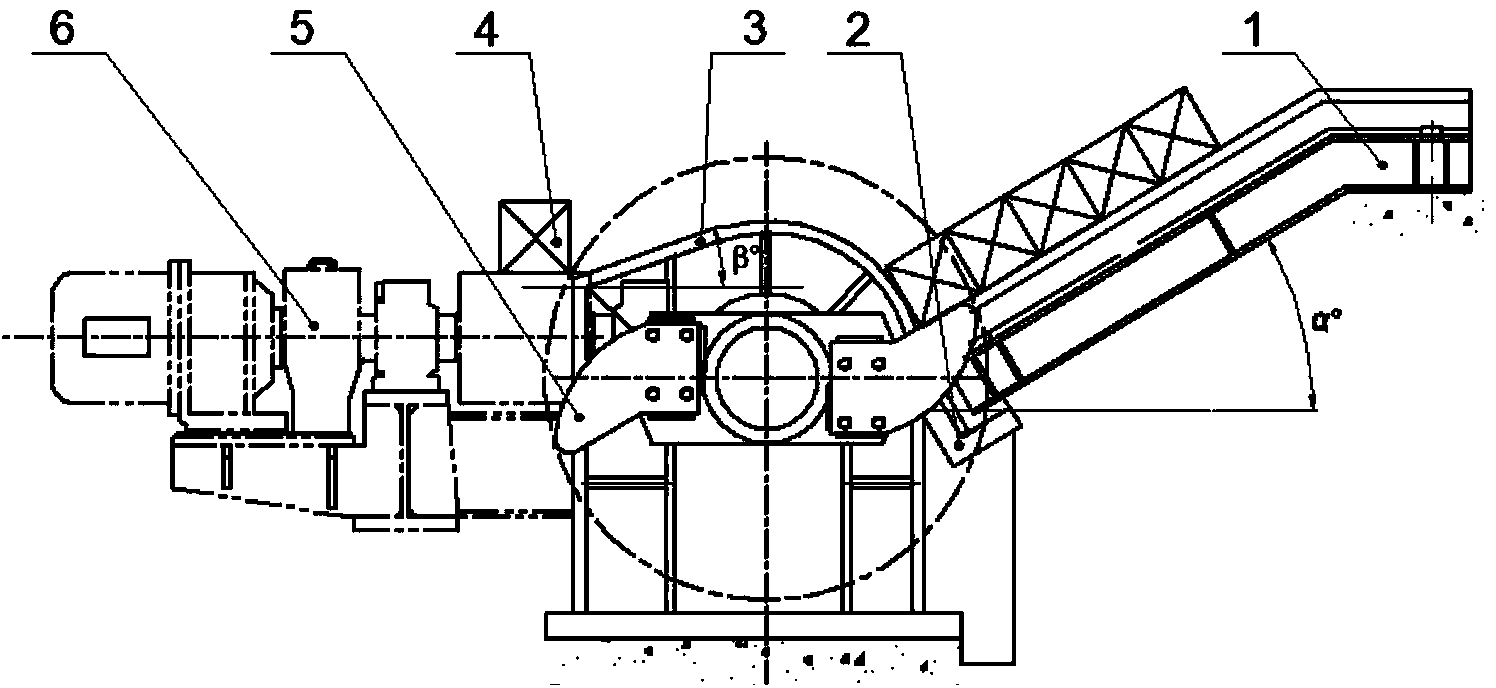

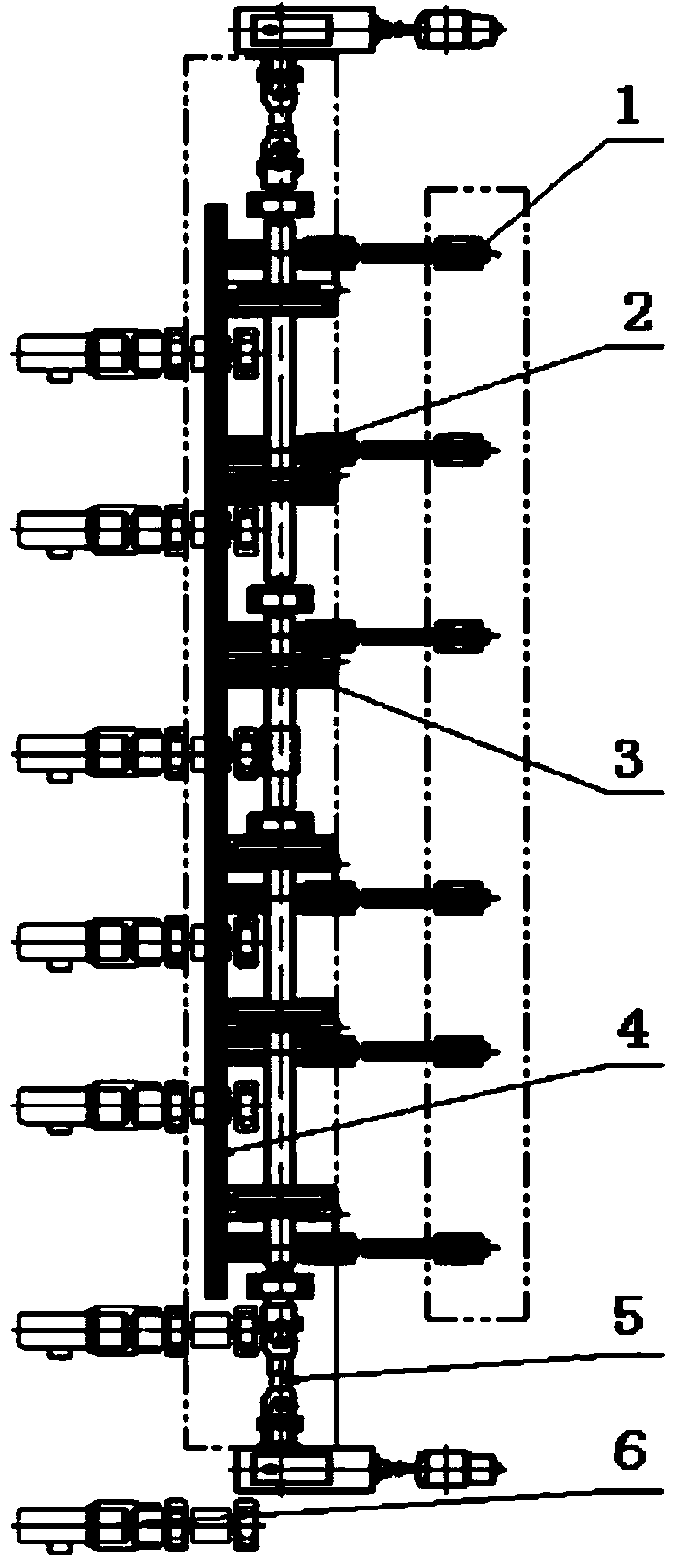

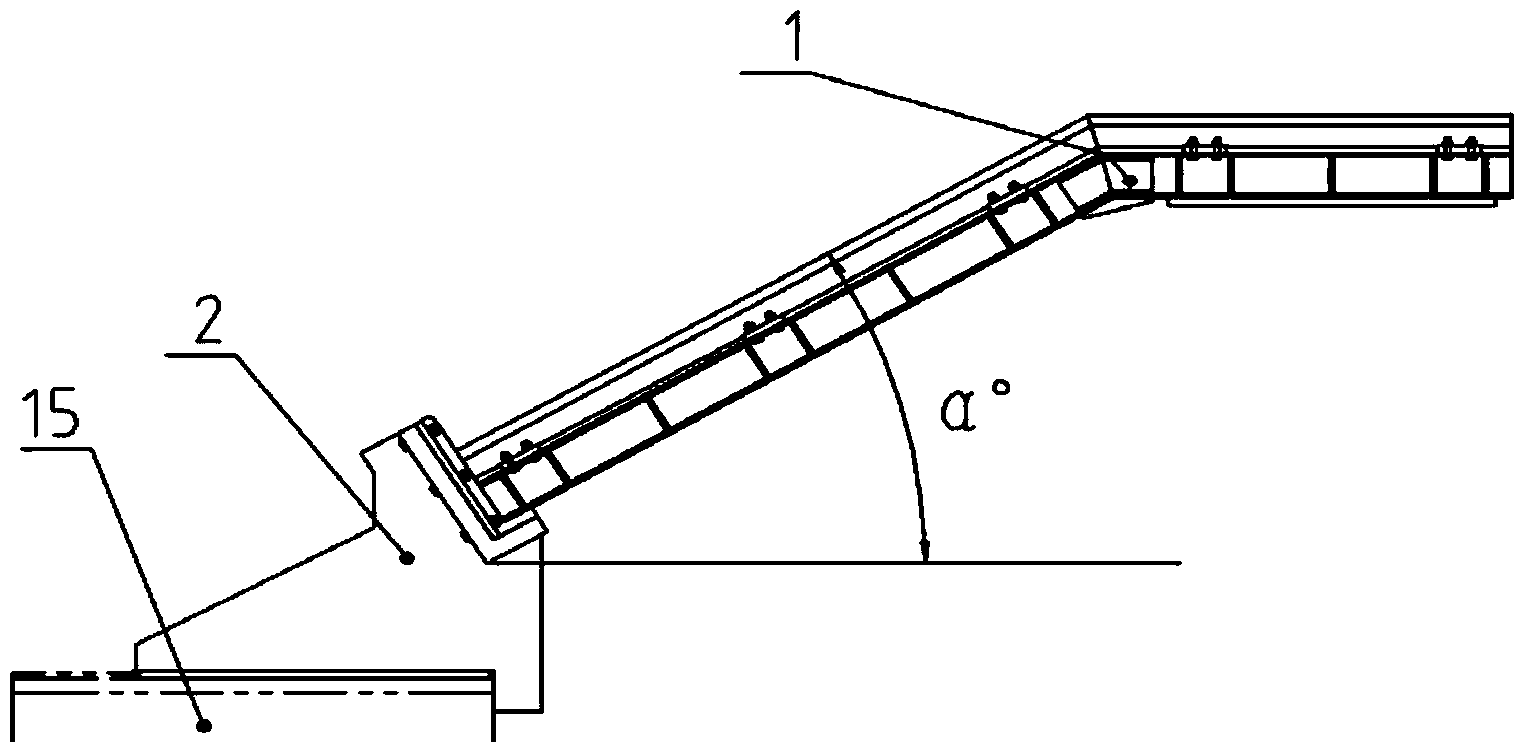

[0019] Embodiment of the present invention will be described in further detail below in conjunction with accompanying drawing: figure 1 , figure 2 A kind of rotating shaft type steel splitting machine shown, is made up of slide rail steel bench 1, steel bench seat 2, guide rail frame 3, steel splitter body 5; as image 3 Shown is a schematic diagram of the position connection of the steel frame 1, the frame seat 2, and the base 15. The steel frame 1 adopts a welded steel structure, and the standard light rail is fixed on the steel structure with bolts and pressure plates. Above, the steel platform base 2 is a welded steel structure, one end is fixed on the base 15 by bolts, and the other end is connected with the slide rail steel platform 1 through bolts, and the steel platform base 2 is designed with a detachable stopper , the welded steel structure base 15 is fixed on the foundation by anchor bolts, the inclination angle α of the slide rail connected to the steel platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com