Hydraulic cooling device

A cooling device and hydraulic technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the assembly and maintenance/repair difficulties of hydraulic oil cooling device, the reduction of system volume efficiency, and the lack of compactness of the system. and other problems, to achieve the effect of compact structure, sufficient cooling air volume and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

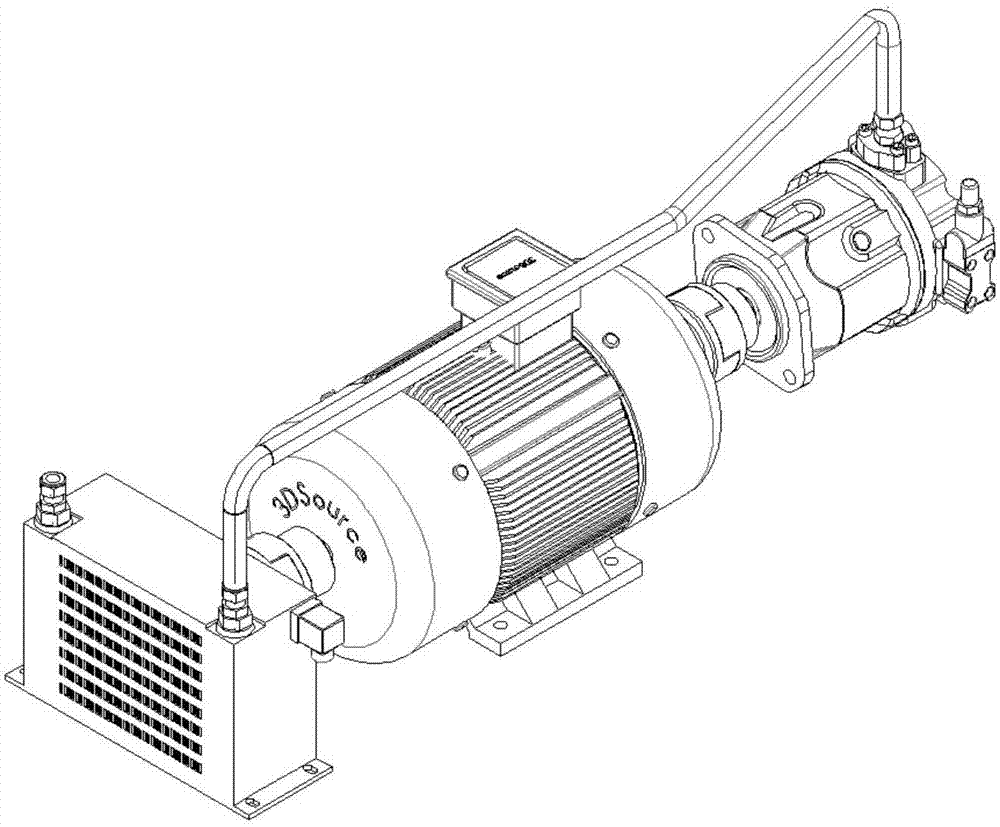

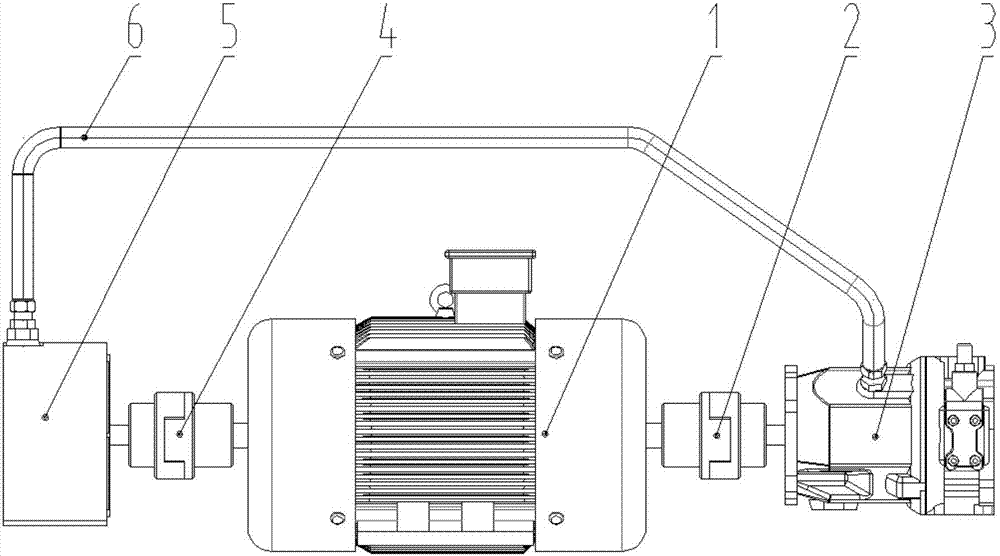

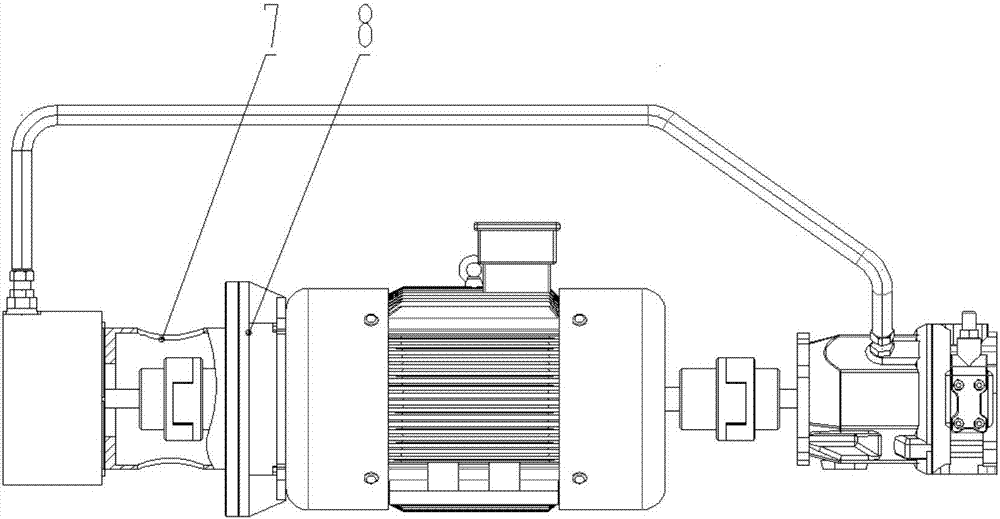

[0030] Such as Figure 1-3 The shown hydraulic cooling device includes a double-head motor 1, one end of the double-head motor 1 is connected to the hydraulic pump 3 through the first coupling 2, and the other end is connected to the air cooler 5 through the second coupling 4, so The air cooler 5 is connected to one end of the oil delivery pipeline 6 , and the other end of the oil delivery pipeline 6 is connected to the hydraulic pump 3 .

[0031] Such as Figure 4-7 As shown, the air cooler 5 includes a housing 51 and a bottom plate 54, the two sides of the top of the housing 51 are provided with an oil inlet 56 and an oil outlet 57, and the inside of the housing 51 is connected to the oil inlet 56 and the outlet. The vertical direction of the oil port 57 communication position is provided with several layers of parallel heat dissipation hollow plates 52; the inside of the air cooler 5 is provided with a fan device 55 adjacent to the heat dissipation hollow plate 52, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com