Steel-making production process intelligent scheduling method

An intelligent scheduling and production process technology, applied in the energy industry, program control, electrical program control, etc., can solve the problems of lack of intelligent scheduling methods and systems for the whole process of steelmaking, backward production management technology and means, and lagging information level. , to achieve the effect of reducing energy consumption, compact operation and optimized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

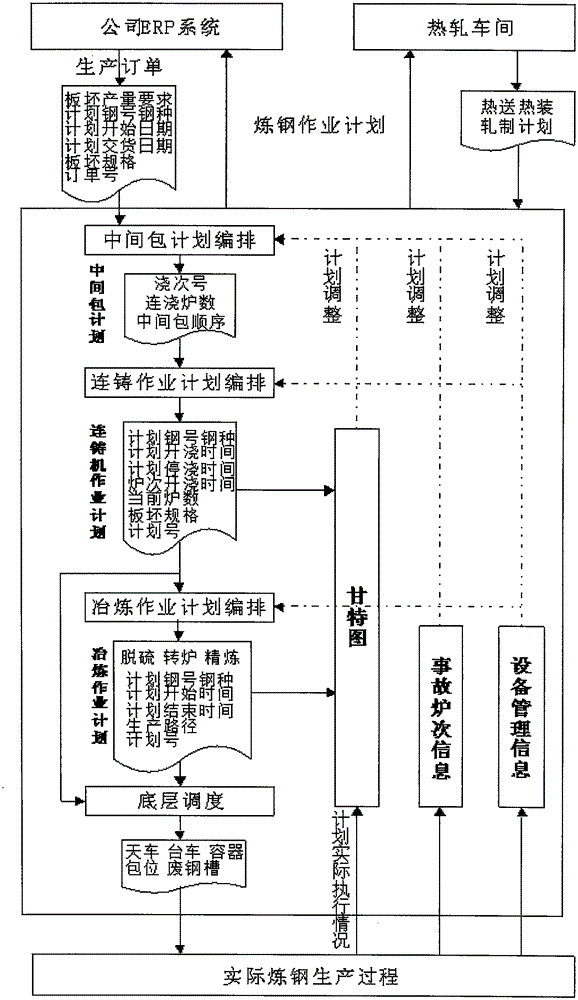

[0035] Such as figure 1 As shown, a steelmaking production process intelligent scheduling method, the scheduling method mainly includes the following steps:

[0036] 1) Obtain a production order, which includes the order number; the length, height, thickness, density and weight requirements of the slab specification; the steel type and steel grade to be produced; the planned start time and the planned delivery time;

[0037] 2) Pre-process the order according to the slab output, specification, delivery date, steel grade and steel type;

[0038] 3) Arrange the tundish plan, determine the tundish sequence, the number of continuous pouring furnaces and pouring number and other information;

[0039] 4) Arranging the operation plan of the continuous casting machine, and determining the planned starting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com