Steelmaking production plan intelligent scheduling method based on big data rule self-learning

A technology of rules and plans, applied in the direction of data processing applications, computing, energy industry, etc., can solve problems such as the failure to execute plans smoothly, and achieve the effects of reducing energy consumption, saving production costs, and compact operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

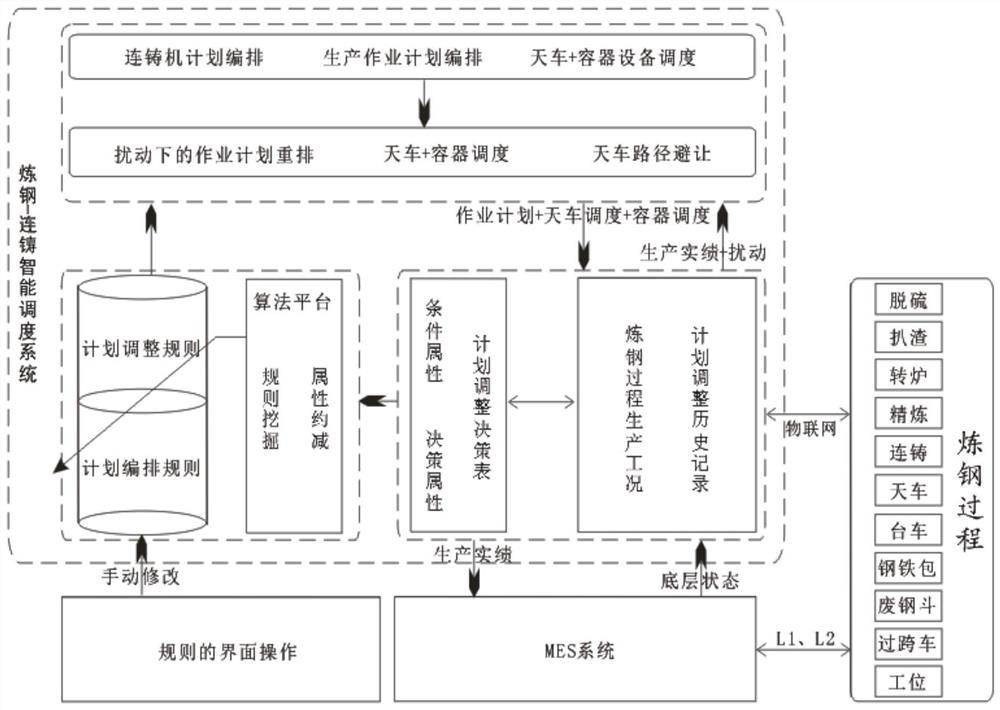

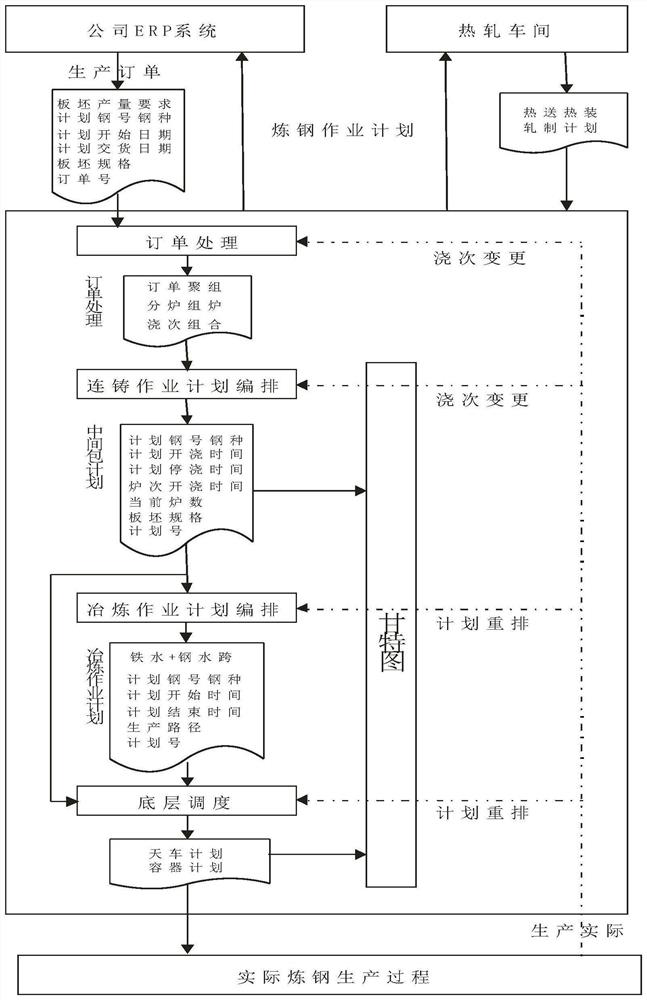

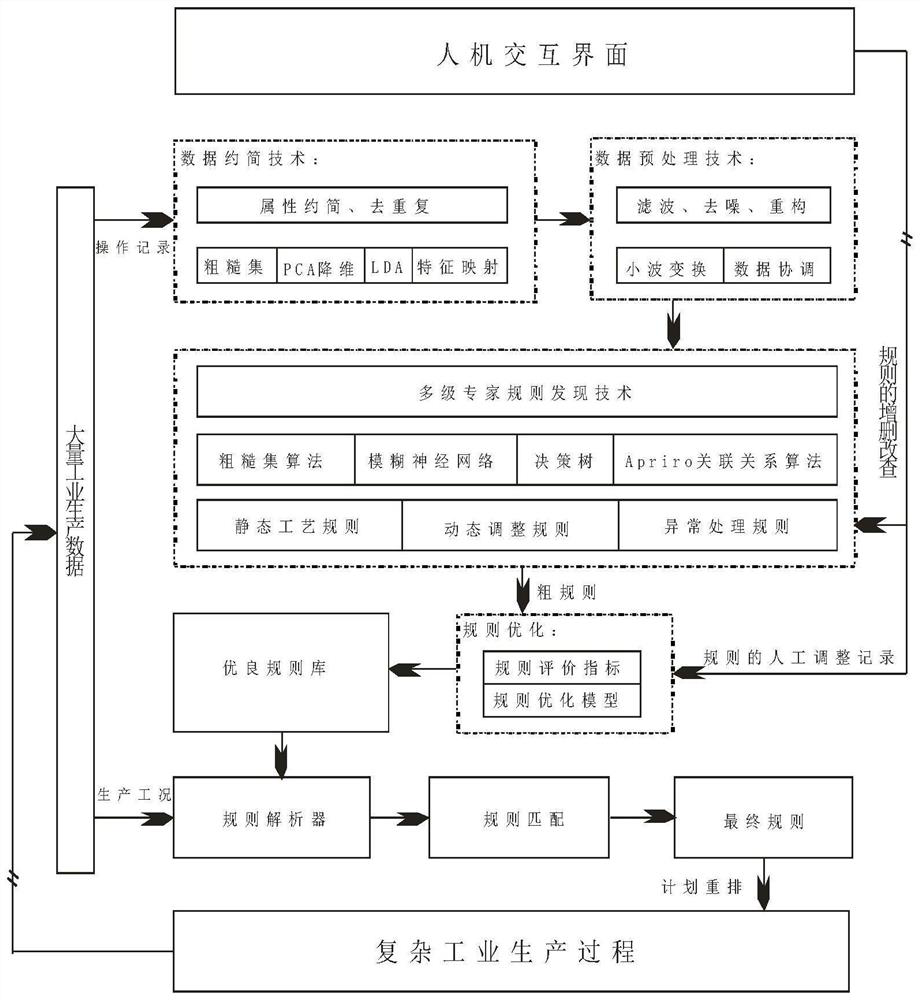

[0029] figure 1 It is a frame diagram of the scheme of the present invention, and the technical scheme of the present invention mainly includes five contents: 1) production planning; 2) static operation planning arrangement; 3) execution equipment arrangement; 4) dynamic rearrangement of plan interference; 5) Gantt chart display. The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] 1) Obtain production information, the production information includes production order information and slab rolling plan; the production order information includes slab specification requirements such as order number, length, height, thickness, density and weight, and the planned production steel Type and steel grade; planned start time and planned delivery time; the slab rolling plan is generated according to the hot delivery and hot charging production plan given by the hot rolling workshop.

[0031] 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com