Driving wheel suspension damping mechanism for AGV, chassis and AGV

A technology of suspension shock absorption and drive wheel, which is applied in the direction of suspension, motor vehicle, elastic suspension, etc. It can solve the problems of unsmooth operation, large space occupation, poor stability of trolley, etc., and achieves simple and compact structure and good shock absorption effect , the effect of strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

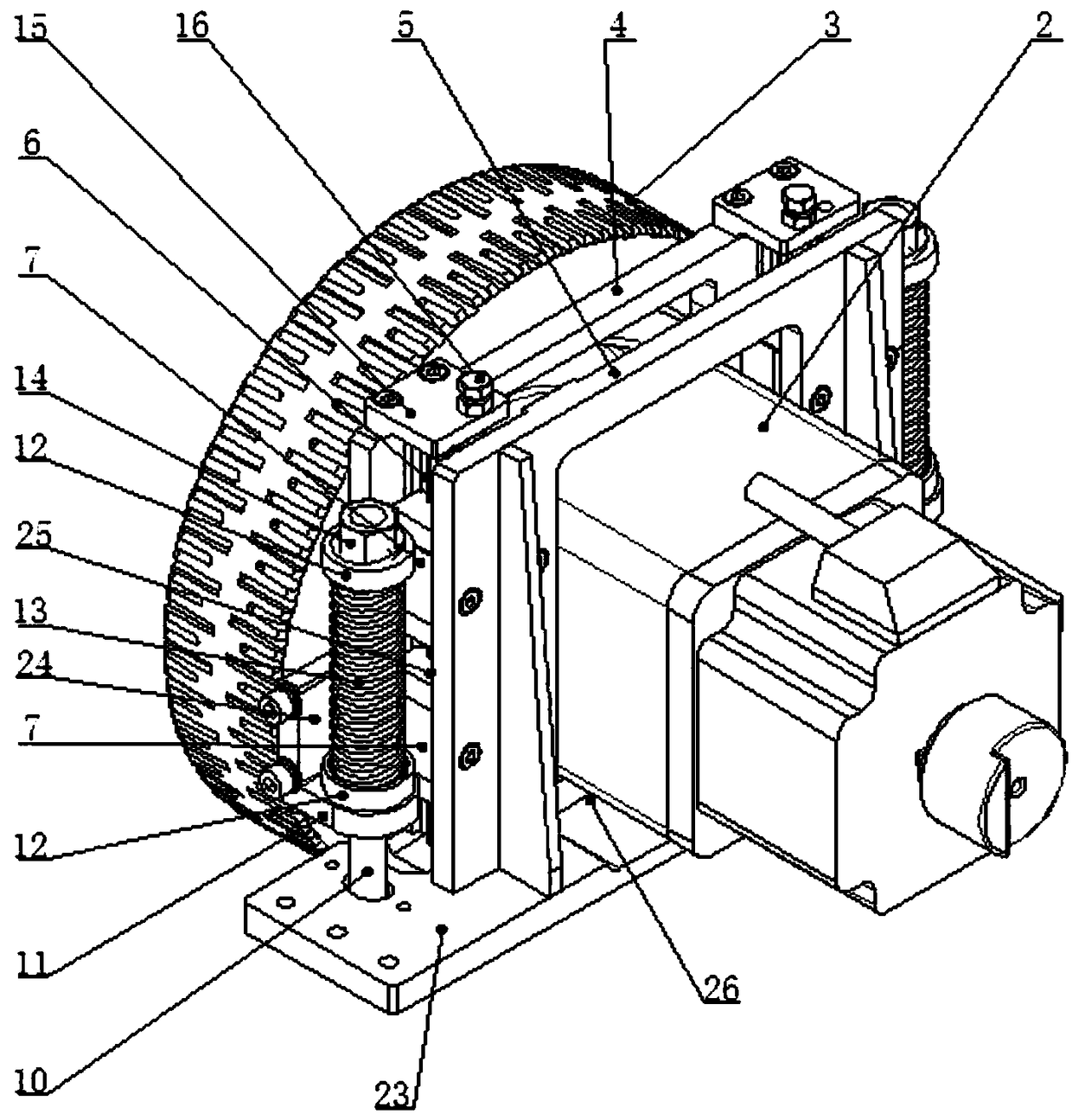

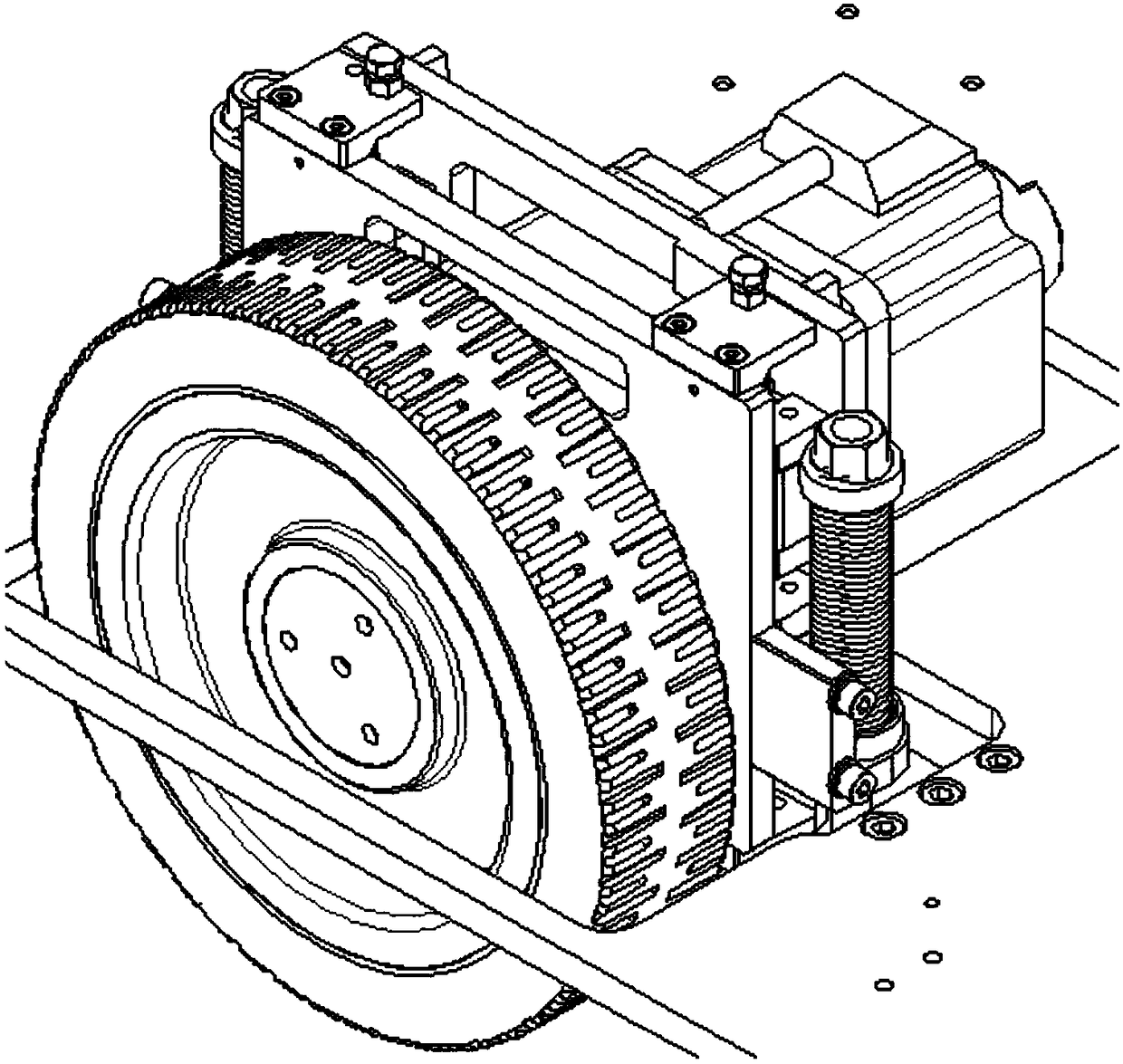

[0027] This embodiment provides a driving wheel suspension damping mechanism 1 for an AGV, see the attached Figure 1-7 , the suspension damping mechanism 1 includes, guide rail fixing plate 4, slider fixing plate 5, linear guide rail 6, slider 7, slider limit mechanism, guide rod 10, guide rod fixing mechanism, spring, spring fixing device, Spring limit device.

[0028] The guide rail fixing plate 4 is arranged on the chassis P, and it includes two vertical guide rail fixing part plates and a first connecting part plate connecting the two guide rail fixing part plates, and the two guide rail fixing part plates are connected with the first guide rail fixing part plates. The connecting part board is vertical, and the linear guide rail 6 is arranged on the guide rail fixing part board on the guide rail fixing board 4 along the vertical direction; the slider fixing board 5 is arranged on the chassis P, which includes two vertical The slider fixed part plate is connected with the...

no. 2 example

[0040] This embodiment provides a driving wheel suspension damping mechanism for an AGV trolley. On the basis of the first embodiment, the side of the slider fixing plate 5 of the suspension damping mechanism 1 near the spring 13 is equipped with multiple Sensor 25, a plurality of sensors 25 are arranged along the vertical direction, and are used to detect the compression and / or elongation of rectangular spring 13, the relative displacement of linear guide rail 6 and slide block 7, the vibration damping mounting plate 23 and the servo motor 2. One / multiple sensors 26 are arranged on the groove surface of the opposite side. The sensors 26 are used to detect the relative position of the servo motor 2 and the suspension damping mounting plate 23, and compare it with the preset value, so as to judge the suspension damping The state of the mechanism, such as whether there is an error, whether there is a fault, whether it is damaged, etc.

[0041] It also includes a controller, whic...

no. 3 example

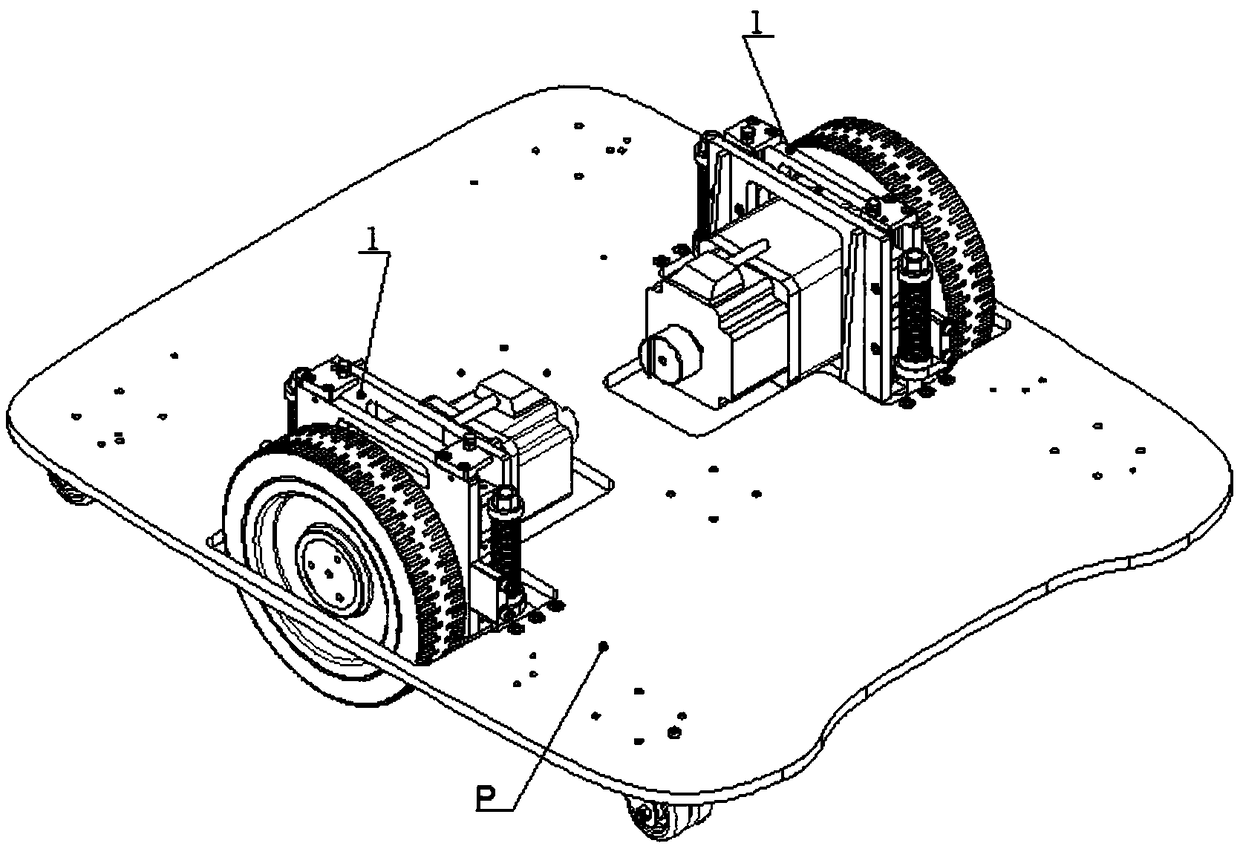

[0043] This embodiment provides a kind of AGV chassis, refer to figure 1 , which includes the driving wheel suspension damping mechanism for the AGV trolley described in any one of the first embodiment and the second embodiment.

[0044] Specifically, there is an installation notch on the chassis P of the AGV trolley, which is used for installing the suspension and damping mechanism 1, and can be set as a "convex"-shaped notch.

[0045] Moreover, at least two of the driving wheel suspension and damping mechanisms 1 are arranged on the chassis P of the AGV trolley.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com