Municipal sludge energy treatment system

A technology for treating system and municipal sludge, applied in biological sludge treatment, waste fuel, etc., can solve problems such as failure of normal operation or outage of key equipment, failure to maintain a stable high organic load, and reduction of system processing efficiency, etc. Small land area, high organic load and organic matter removal rate, and the effect of improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

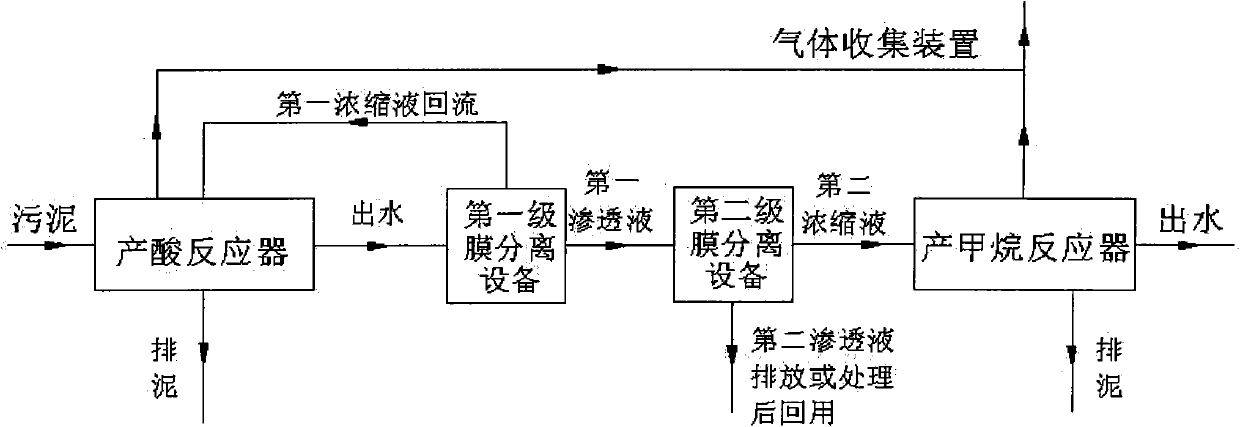

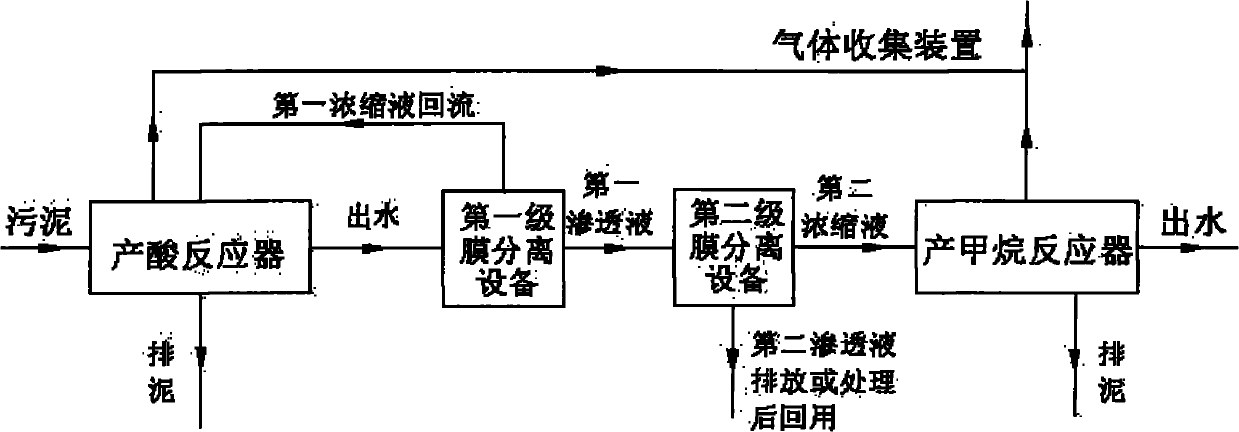

[0024] Equipment: Pilot scale, the diameter of the acid production reaction pool is 2.5m, the height is 2.1m, and the effective volume is about 10m 3 , the bottom inclination angle can be 20°; the methanogenic reaction pool adopts a rectangular shape, the length, width and height are 4m, 3m and 3m respectively, and the effective volume is 30m 3 . One end of the acid production reaction tank is connected to the sludge inlet, and the other end is the water outlet. The water outlet is connected to the first-stage membrane separation equipment (microfiltration vibrating membrane). The connecting pipe enters the second-stage membrane separation equipment (ultrafiltration vibrating membrane), the retentate end of the second-stage membrane separation equipment connects the pipe into the methane production reaction tank, and the permeation end connects the pipe to directly discharge water.

[0025] Both the acid production reaction tank and the methane production reaction tank are pr...

Embodiment 2

[0029] The equipment is as in Example Requirement 1, but the second-stage membrane separation equipment adopts nanofiltration membrane.

[0030]The source of sludge is the same as in Example 1. The sludge enters from one end of the acid production reaction tank, the HRT is set to 2.5 days, the temperature in the tank is 36°C, and then it is output from the other end and enters the first-stage membrane separation equipment, where the separation becomes the first The concentrated liquid and the first permeate at the permeate end, the first concentrated liquid is connected through pipelines and flows back into the acid-generating reaction tank to mix with the newly entered sludge to continue the hydrolysis reaction, prevent the loss of acid-generating bacteria, and maintain a high concentration in the acid-generating reactor. The hydrolyzed acid-producing bacteria; the first permeate enters the second-stage membrane separation equipment and is separated into the second concentrate...

Embodiment 3

[0033] The equipment is as required in Example 1, but the two-stage membrane separation equipment adopts tubular membrane, the first-stage membrane separation adopts ultrafiltration membrane, and the second-stage membrane separation adopts nanofiltration membrane. Under this device, the second permeate can be reused directly, the COD in the methanogenic phase can be maintained at 28000mg / L, the average organic matter decomposition rate of the system can be maintained at about 55%, and the biogas conversion rate of organic matter can be maintained at about 1.1L / g VS , the gas production rate is maintained at 14m 3 / m 3 For wet sludge, the volatile fatty acids in the effluent of the methanogenic phase are lower than 200mg / L. Compared with the vibrating membrane, the tubular membrane is less expensive, but the number of backwashing is more frequent than that of the vibrating membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com