Preparation method for oil-absorbing swelling rubber

An oil-absorbing expansion and rubber technology is applied in the field of oil-absorbing rubber to achieve the effect of low price, excellent performance and improving oil-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

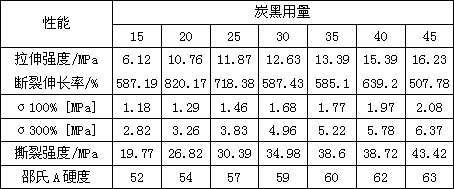

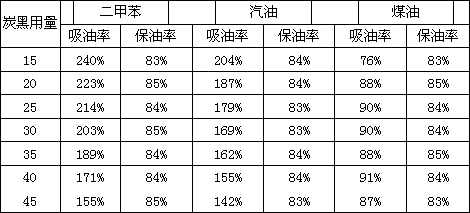

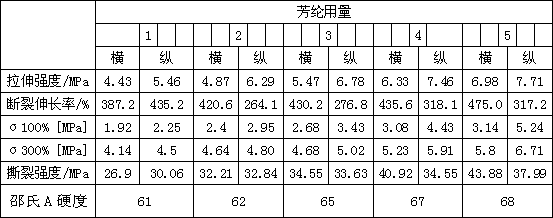

[0022] Example 1: Take 200 grams of styrene-butadiene rubber and 100 grams of carbon black and mix them evenly on a double-roll mill. The temperature of the double-rolls is set to 40 °C for the front roll and 30 °C for the rear roll. Add 100 grams of oil-absorbing resin in the process of mixing; add aramid fibers after mixing evenly, add vulcanization aid after further mixing evenly, zinc oxide 7.5 grams, stearic acid 3 grams, anti-aging agent 5 grams, accelerator TT0. 48 grams, 2.7 grams of sulfur, 2.1 grams of DM, 5.1 grams of M5.1 grams, 0.71 grams of D0.71 grams, and 2.25 grams of CZ continue to mix evenly, and then pass through the next sheet. The vulcanization time and vulcanization temperature are measured by a rotorless rubber vulcanizer. After vulcanization, the oil-absorbing swellable styrene-butadiene rubber blend is obtained. Appropriately extending the cold pressing time is conducive to the improvement of the performance of the blend:

[0023] Mechanical property...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com