Printing press and method for operating the same

A technology for printing machine and running interruption, which is applied in the direction of printing machine, printing, general parts of printing machinery, etc., to achieve the effect of easy cleaning and simplified operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

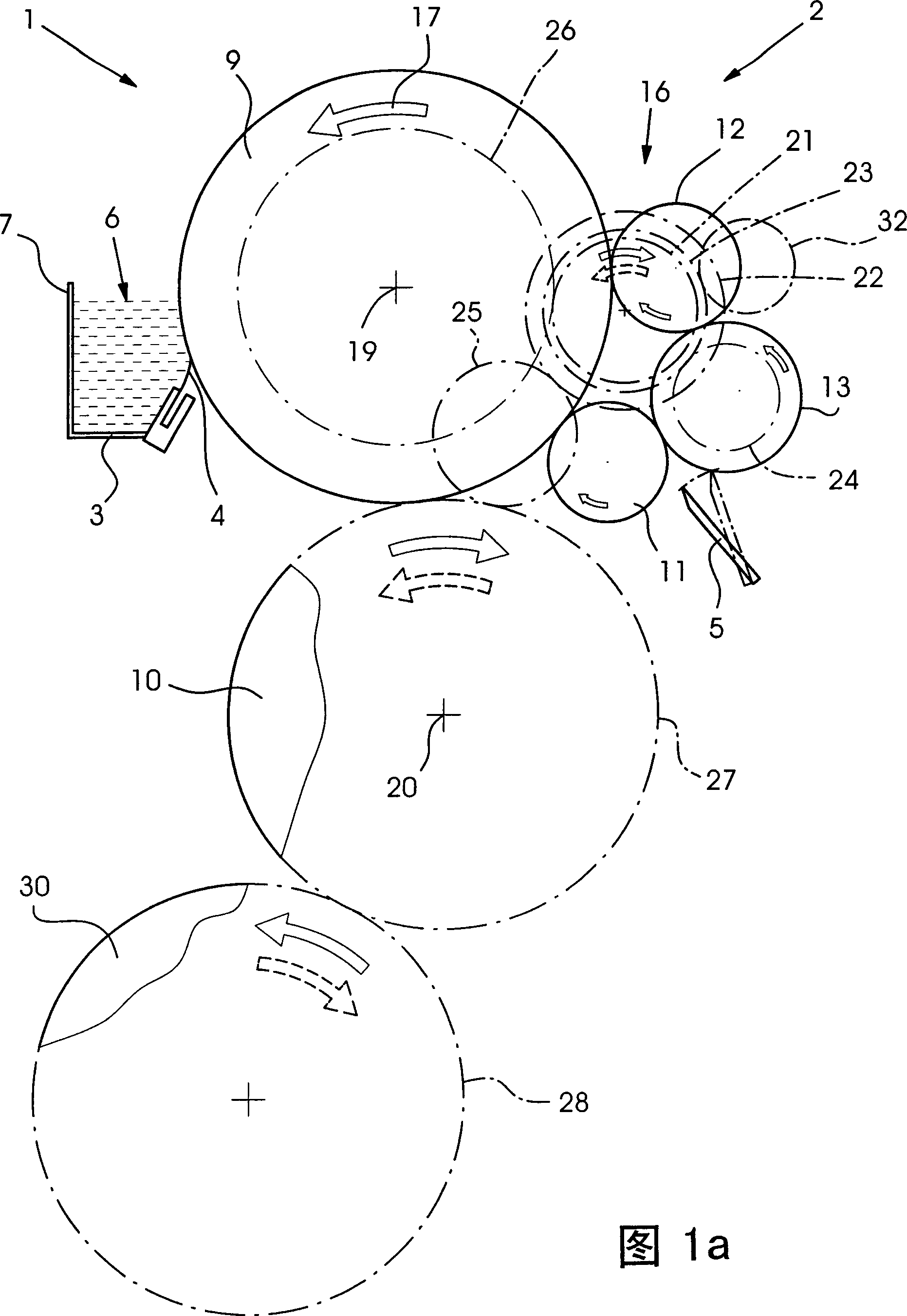

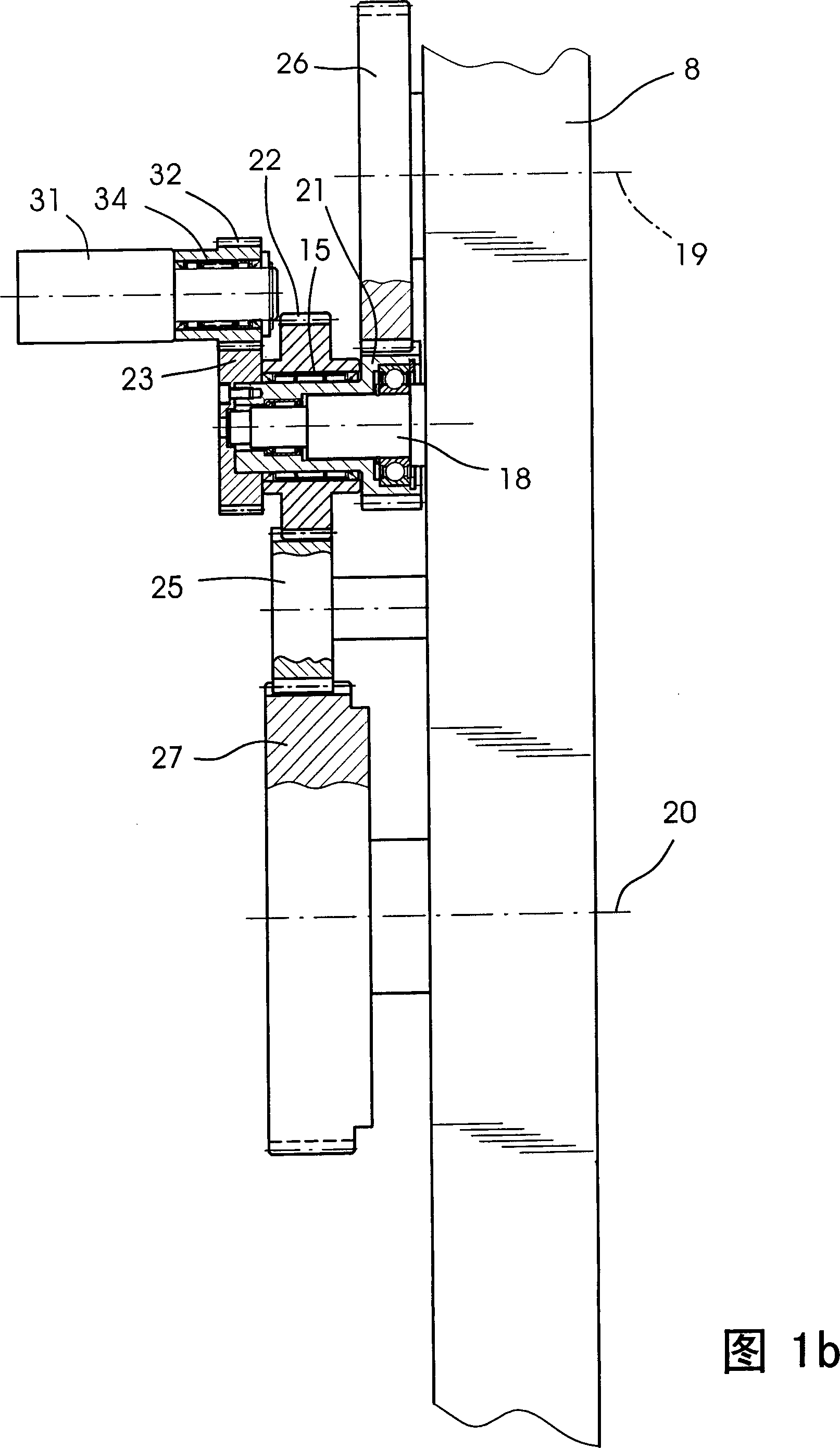

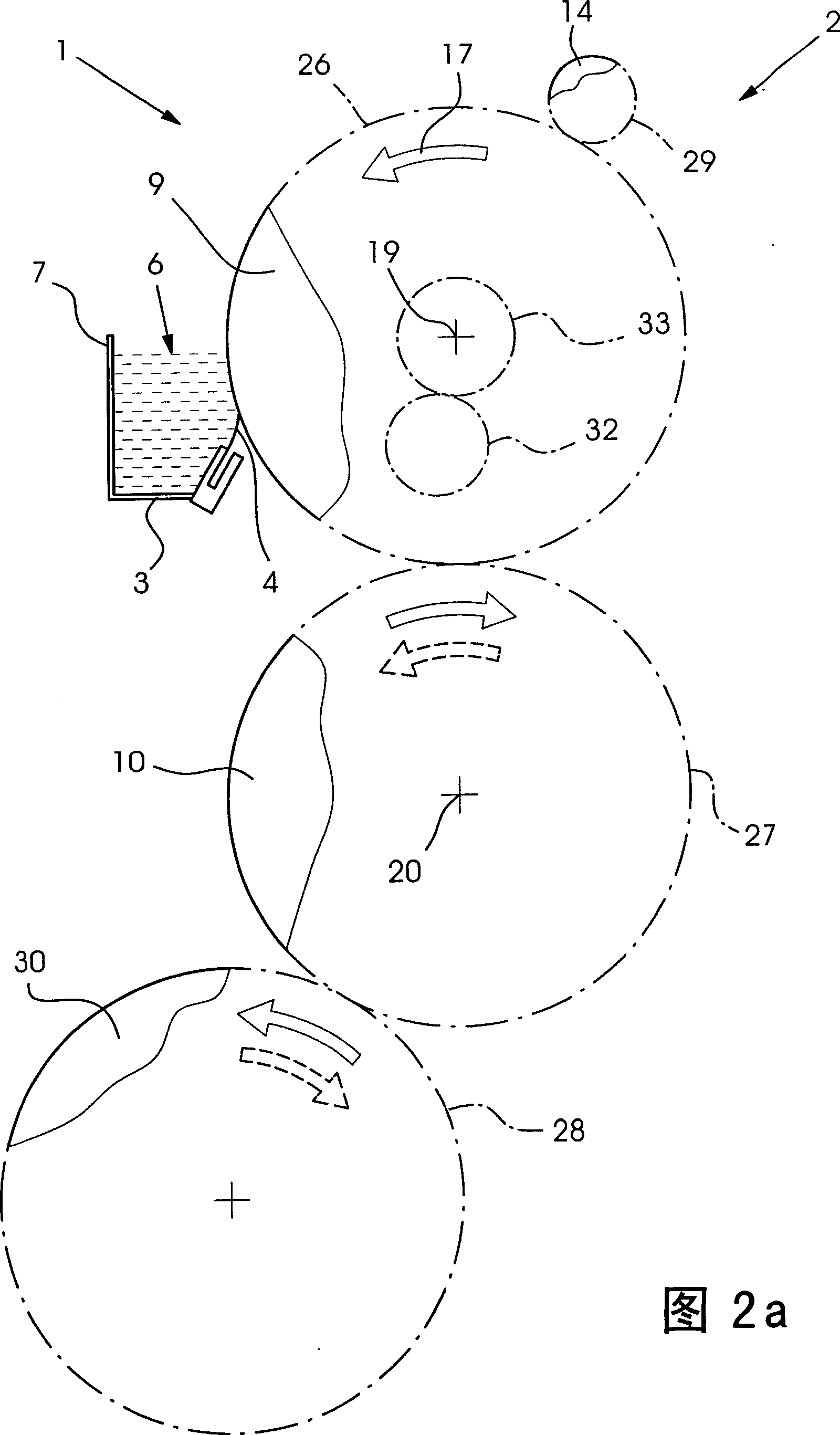

[0022] The first embodiment shown in FIGS. 1a and 1b and the second embodiment shown in FIGS. 2a and 2b respectively relate to a printing press 1 for offset offset printing. Each printing press 1 includes a printing plate cylinder 30 and an anilox inking device 2, the anilox inking device 2 includes an anilox roller 9 and an inking roller 10, the anilox roller 9 has a geometric The anilox roller has a rotation axis 19, and the ink form roller 10 has a geometrical ink form roller rotation axis 20. The inking roller 10 is in rolling contact with the anilox roller 9 and also in rolling contact with the plate cylinder 30 during printing operation.

[0023] On the anilox roller 9 rests an ink transfer device which is different from the chamber doctor blade. The ink transfer device includes an ink fountain 3 with a metering blade 4. The metering doctor blade 4 is the only doctor blade of the ink transfer device and rests on the anilox roller 9 in the opposite direction to the rotation d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com