Probe holder system, message for fixing a probe holder system and method for adjusting a probe

A technology of fixed parts and fixed distances, which is applied in the direction of measuring devices, instruments, measuring instrument components, etc., and can solve problems such as the limitation of adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

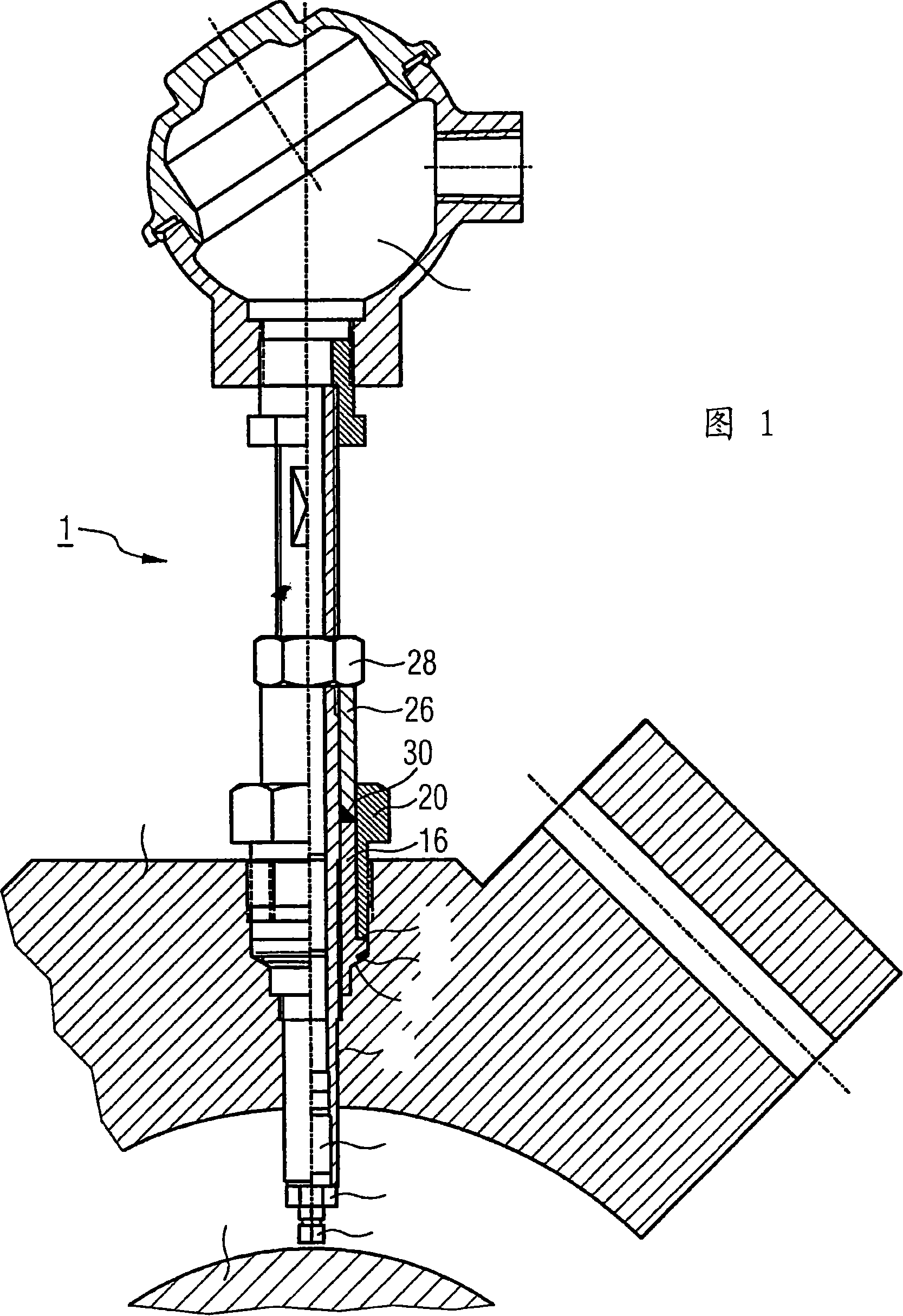

[0030] The probe holder system 1 according to FIG. 1 is provided for fastening a probe 2 on a housing 4 of a machine, not shown in detail. The probe 2 is used here for rotational speed measurement of a shaft 6 surrounded by a housing 4 , wherein the shaft 6 is mounted in oil O for friction reduction and cooling. The oil pressure prevailing inside the housing 4 exceeds the machine or ambient pressure outside the housing 4 . In order to achieve as high a measurement accuracy as possible during rotational speed measurement, the probe 2 is positioned at a relatively small radial distance of 1.5 mm from the axis 6, where the allowable tolerance is only ±0.1 mm.

[0031] The actual probe 2 or sensor is mounted at the end of a support rod 8 which is inserted from the outside into a corresponding hole 10 in the housing wall and can also be removed again for maintenance purposes. At the opposite end of the support rod 8 and the sensing head 12 there is a terminal 14 through which the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com