Patents

Literature

73results about How to "Simple clamping structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

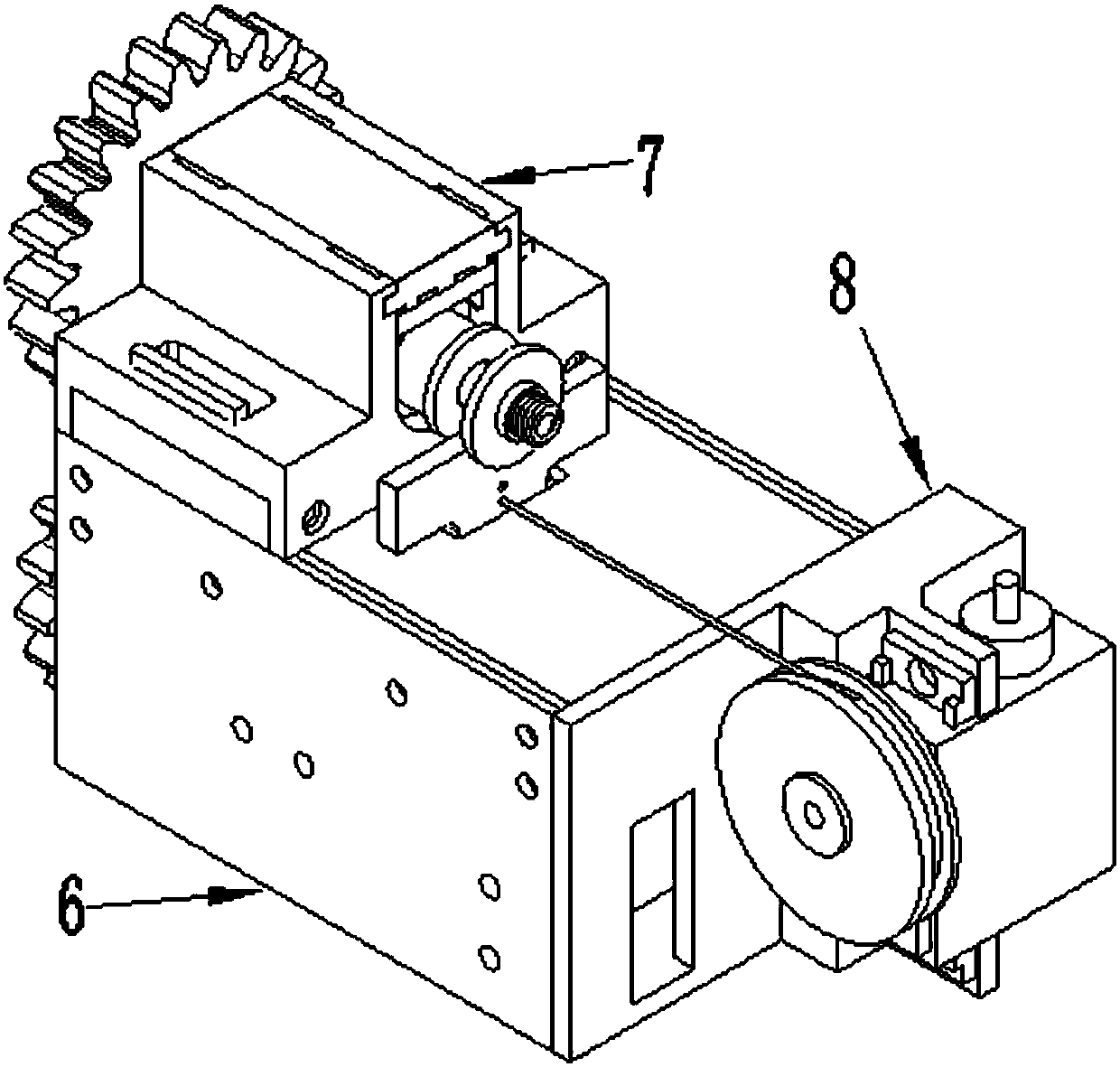

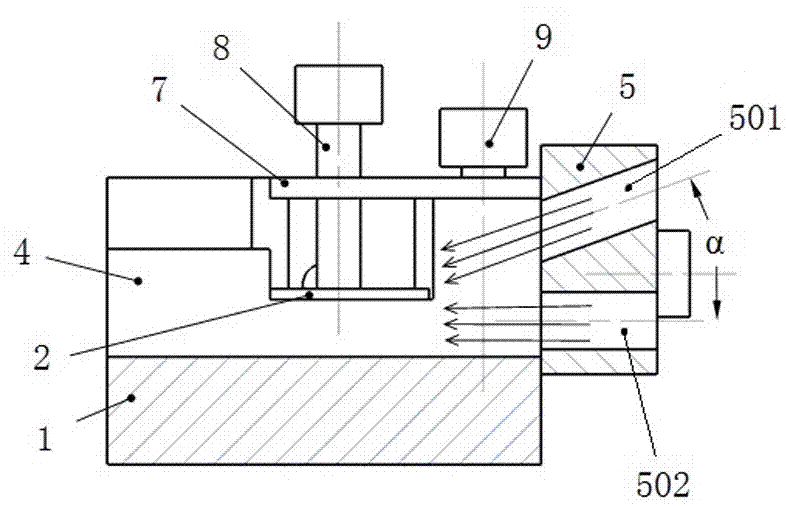

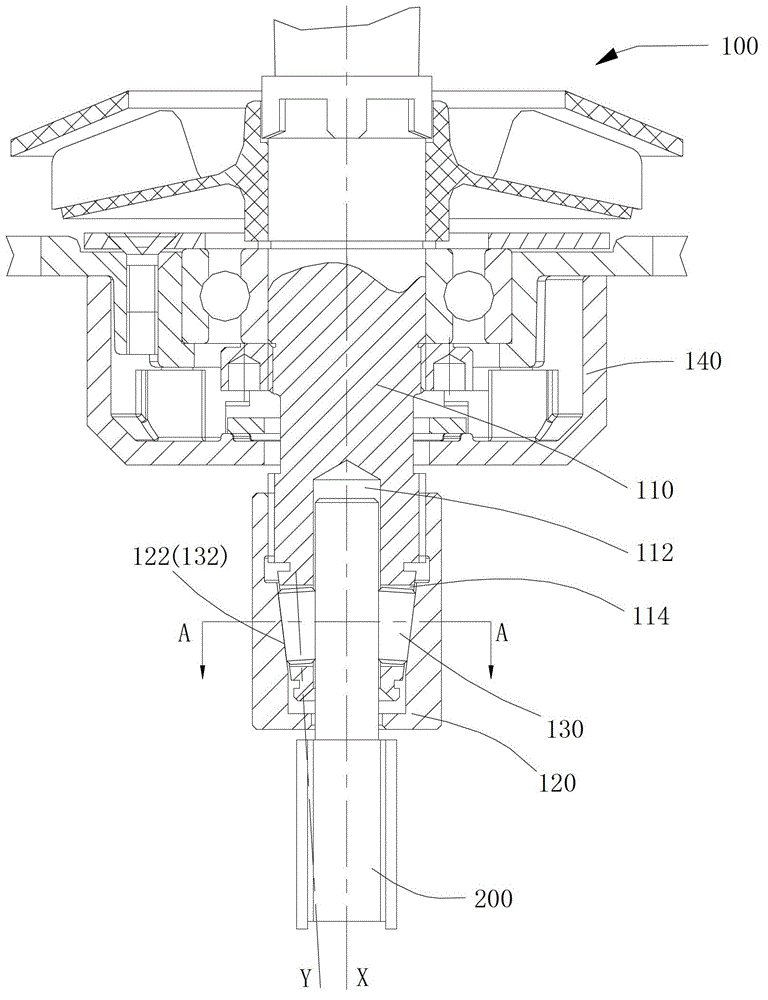

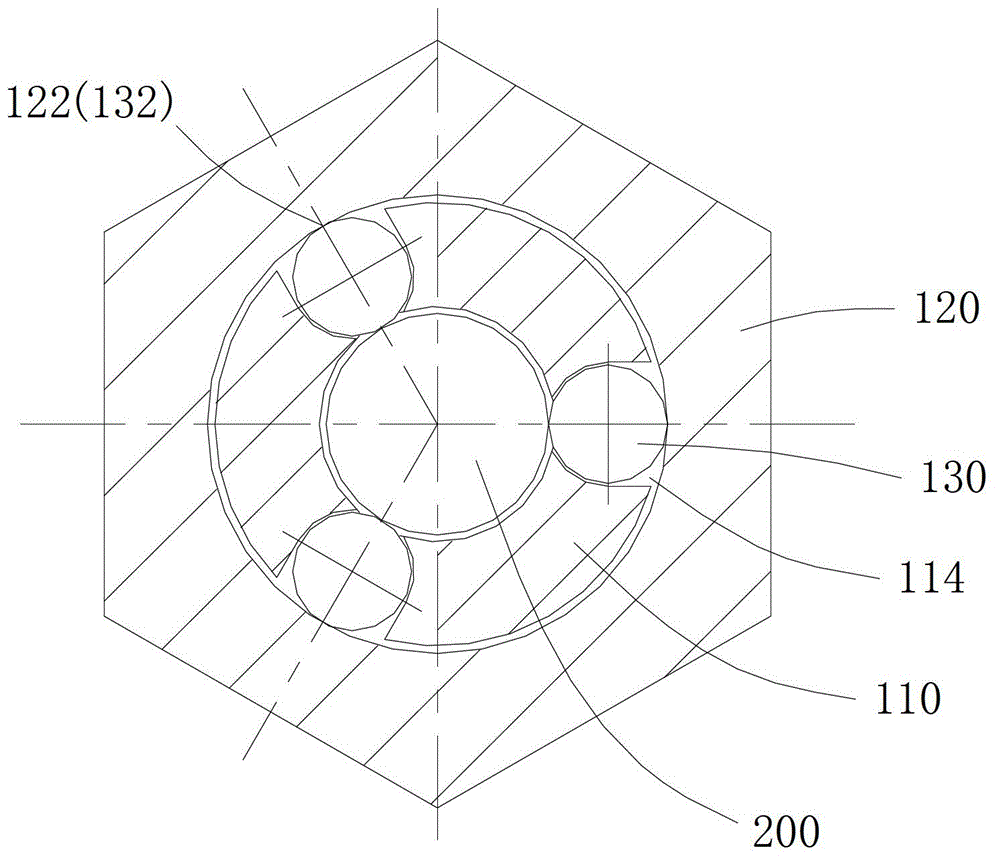

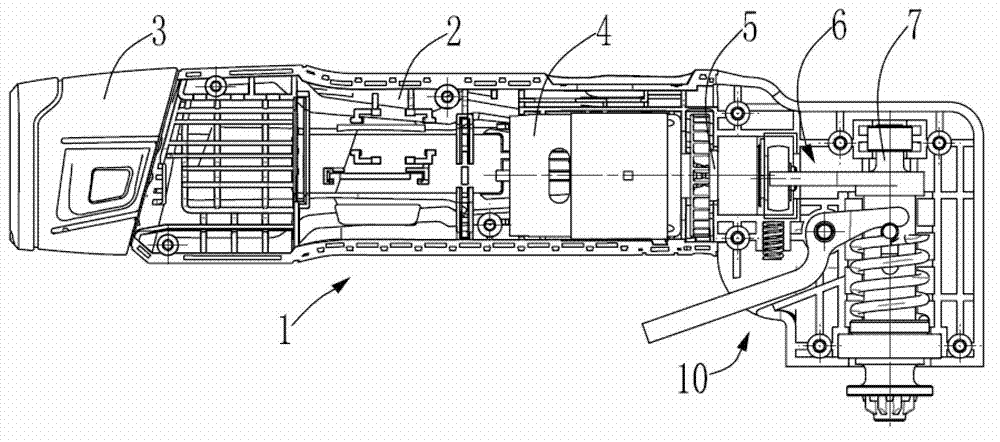

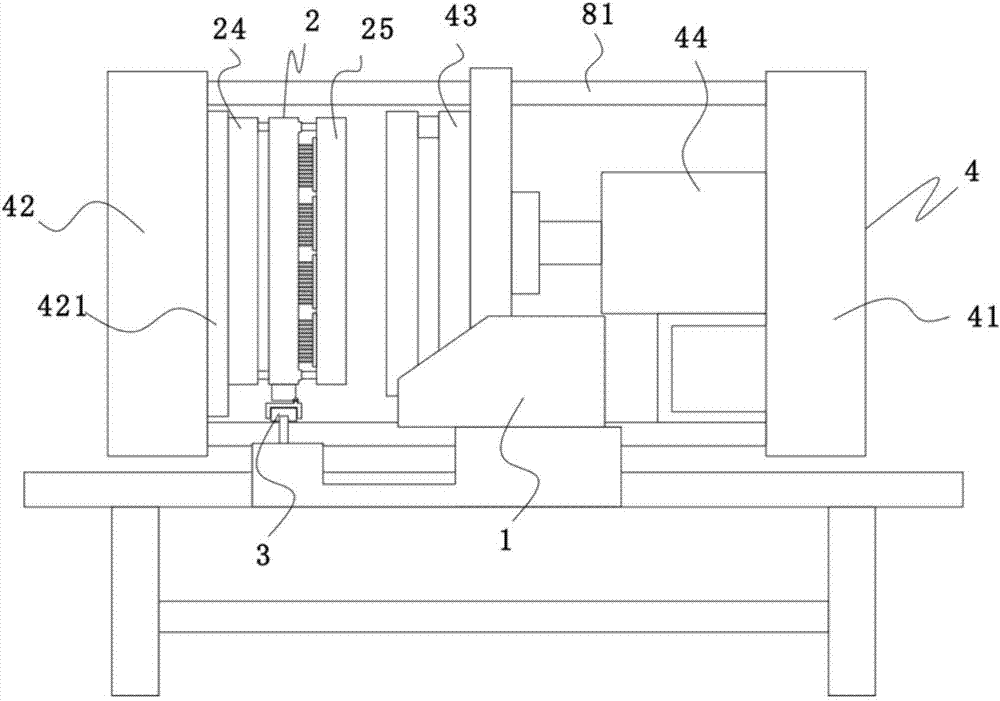

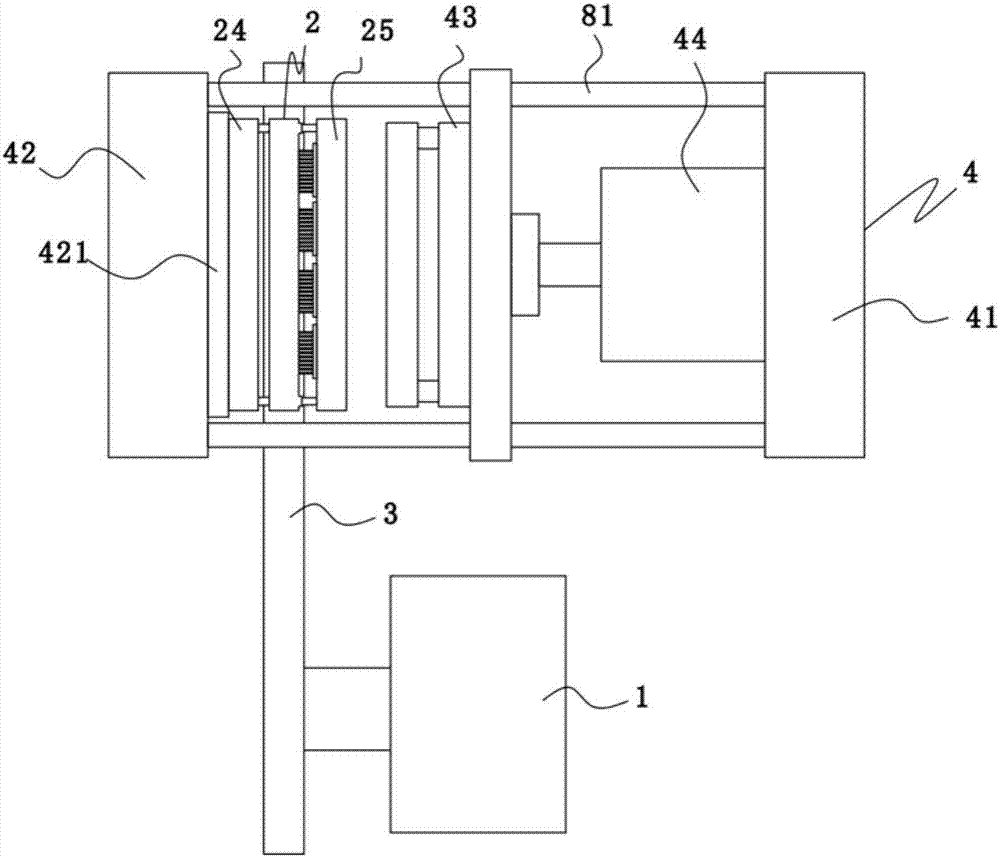

Catheter and guide wire control device for interventional operation and control method of catheter and guide wire control device

PendingCN107349514AEffective clampingAccurate clampingGuide wiresMedical devicesEngineeringGuide wires

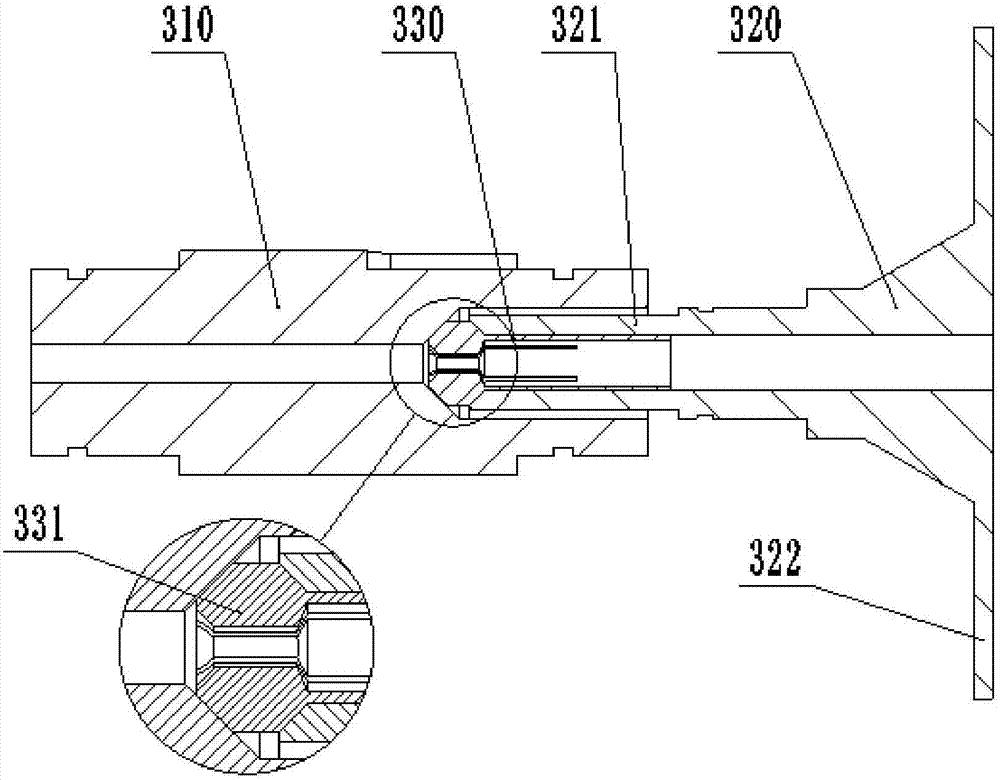

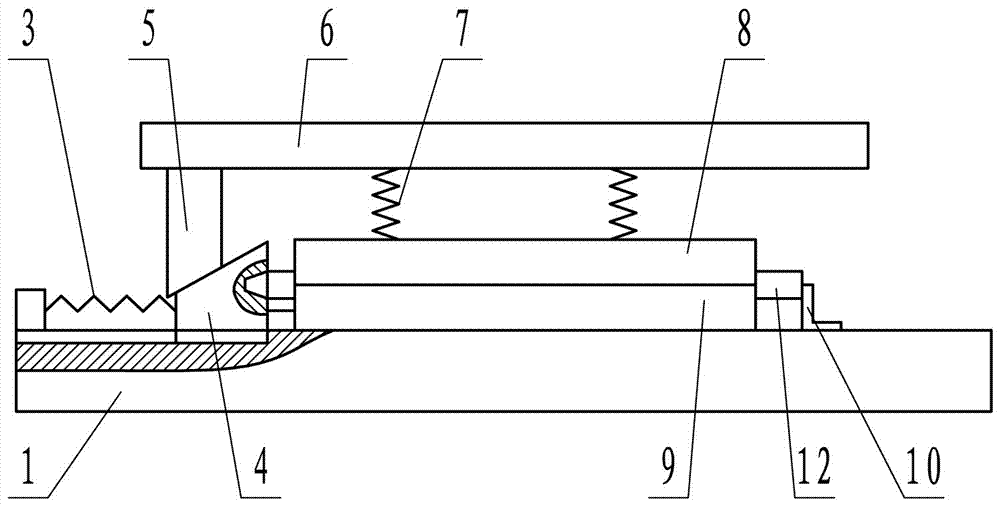

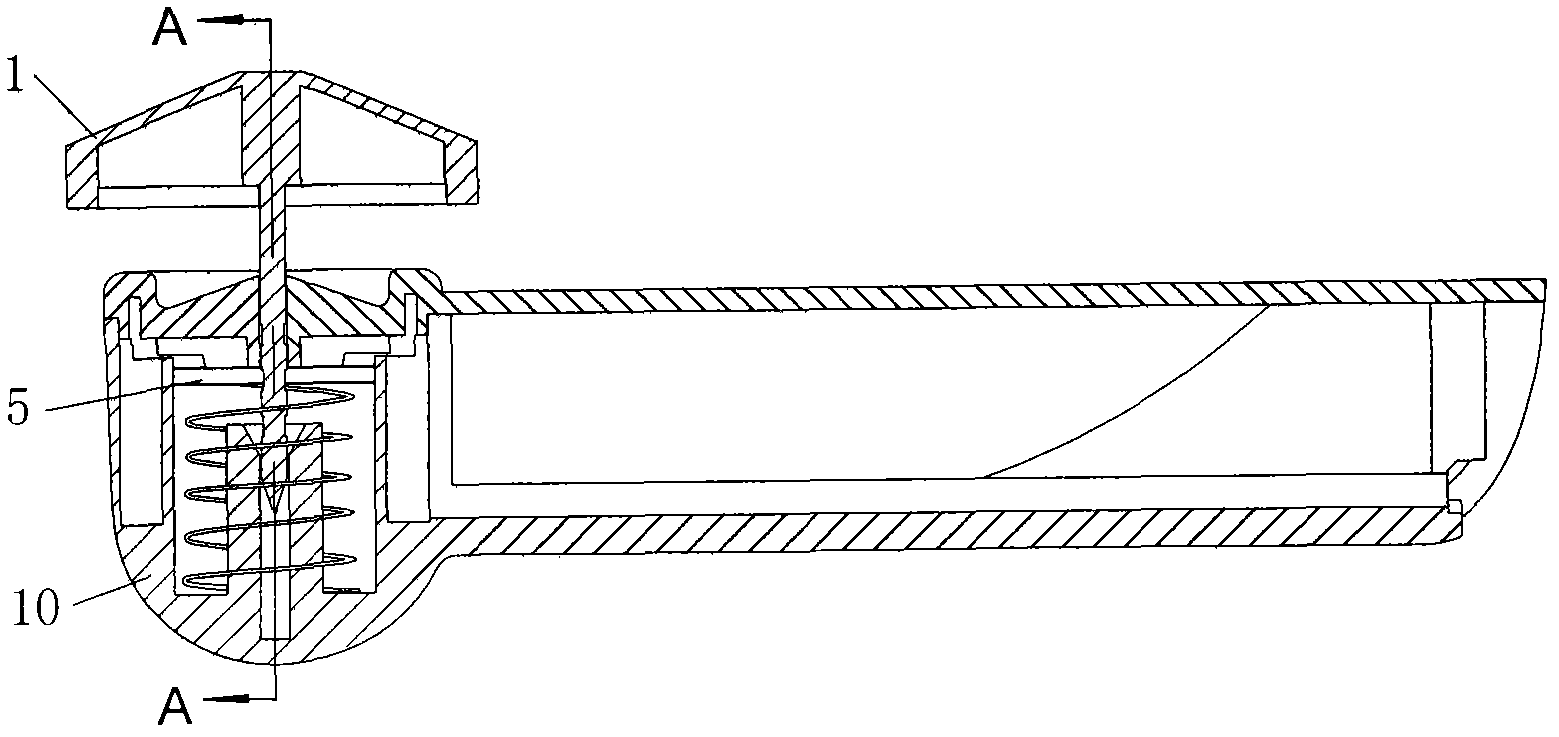

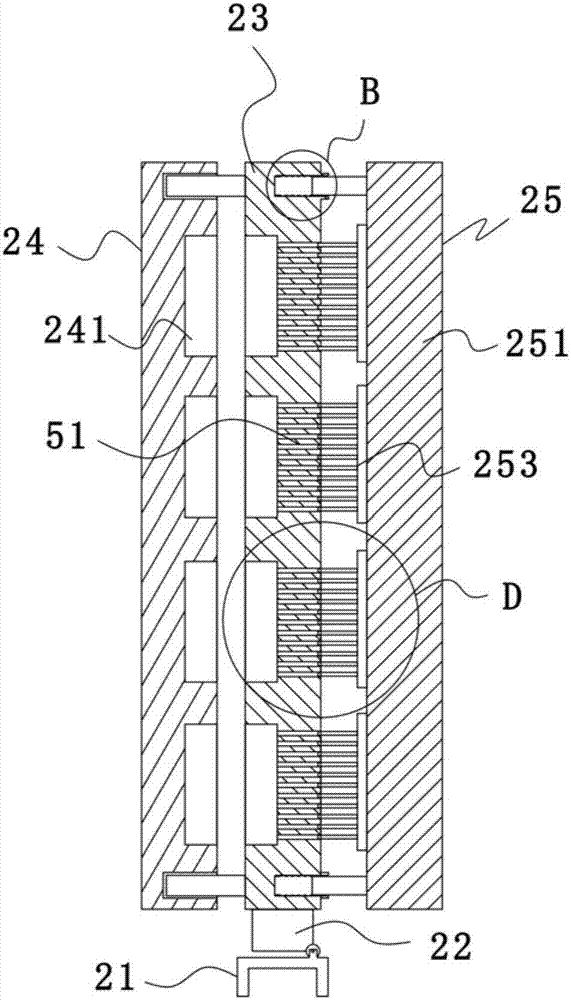

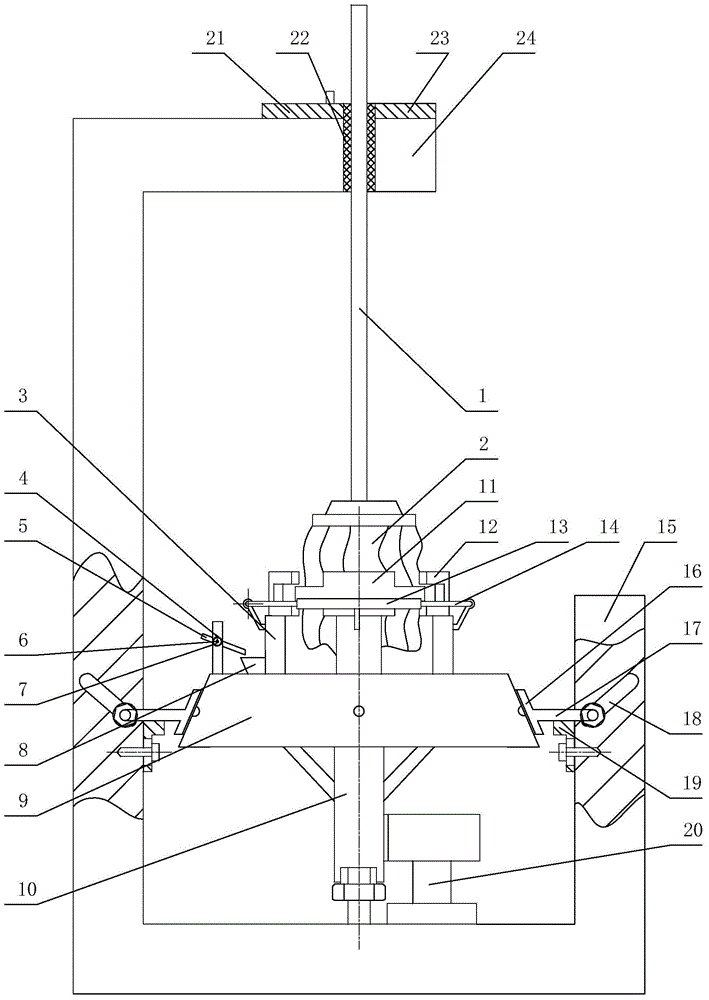

The invention discloses a catheter and guide wire control device for an interventional operation and a control method of the catheter and guide wire control device, belonging to the technical field of minimally invasive vascular interventional operations. The device comprises a clamping mechanism, a sleeve driving assembly and a brake braking assembly, wherein the clamping mechanism comprises a sleeve, a braking part and a clamping part, after the clamping part with a clamping end is mounted in the braking part, the braking part is in threaded connection with the sleeve, a notch is formed in one end, with the clamping end, of the clamping part, and the clamping end is in conical fit with the sleeve; the sleeve driving assembly is used for driving the sleeve to rotate; the brake braking assembly is used for clamping or loosening the braking part. With the method, a catheter or a guide wire can be clamped, pushed and twisted, and force measurement also can be realized; the efficient, accurate and nondestructive clamping and loosening for the guide wire and the catheter can be realized, and the catheter and the guide wire can be cooperatively operated.

Owner:SHENZHEN INST OF ADVANCED BIOMEDICAL ROBOT CO LTD

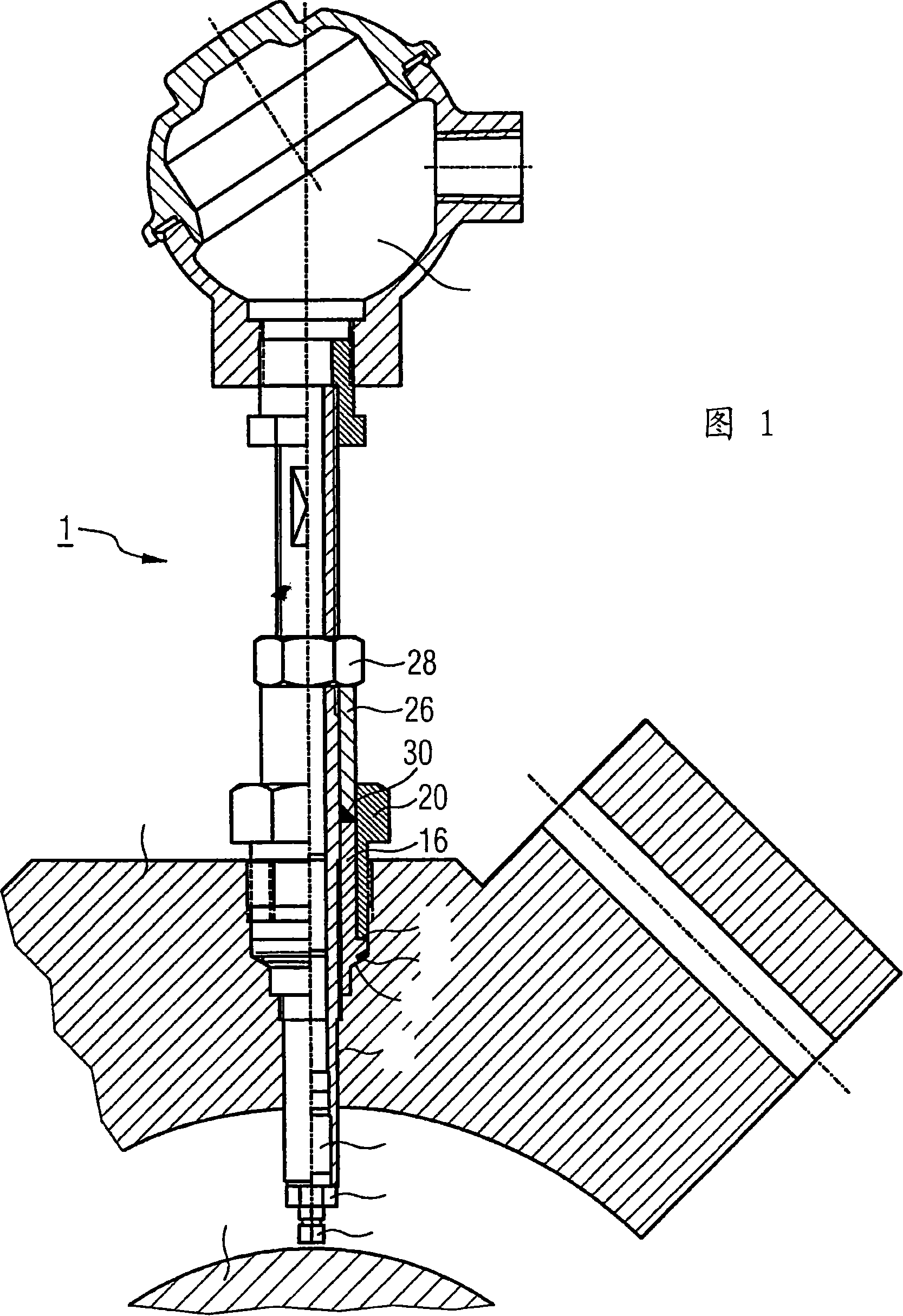

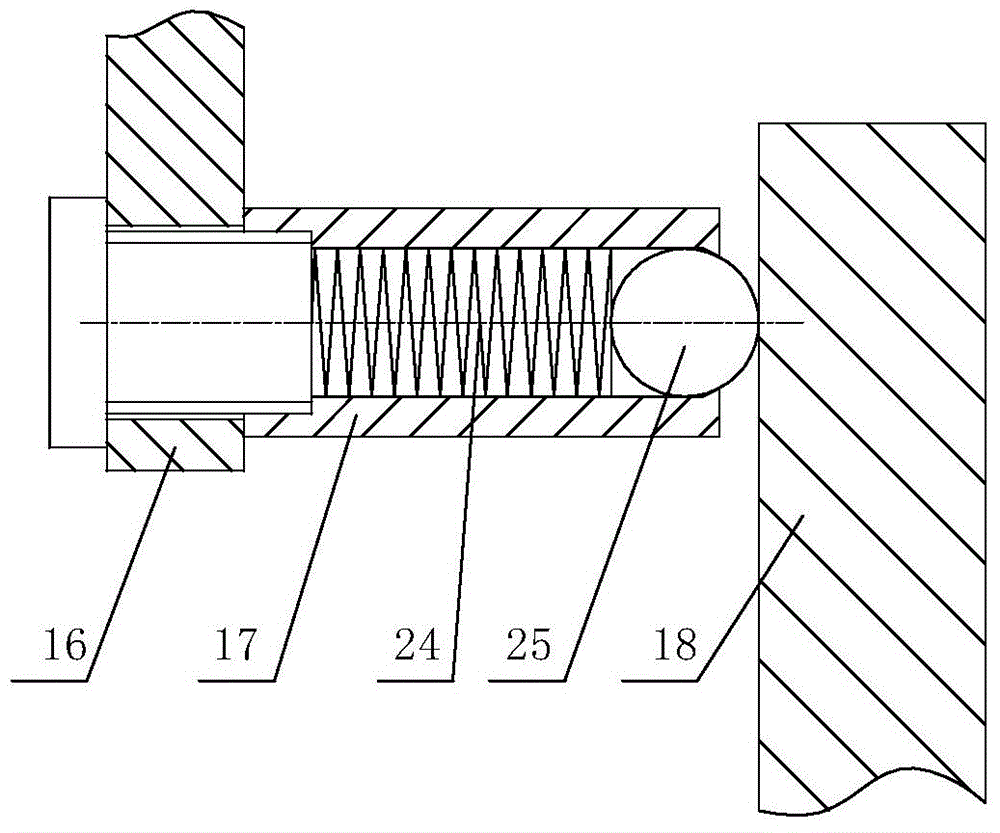

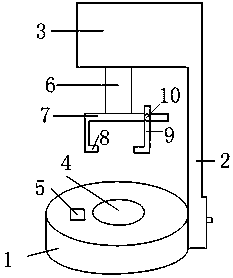

Probe holder system, message for fixing a probe holder system and method for adjusting a probe

InactiveCN101091104APrecise positioningReproduce original spacingMeasurement apparatus componentsBiomedical engineering

A probe holder system (1) for fixing a probe (2) to a housing (4), wherein it is possible to provide a simple structure and position the probe (2) as accurately and easily as possible in relation to a measuring object. According to the invention, a housing bushing (16) provided with an inner thread and a carrier rod (8) for the probe (2), which can screwed into the threaded bushing (16), are provided. The threaded bushing can be placed in a reference position in an associated recess (10) of the housing wall and can be arrested by means of a locking element.

Owner:SIEMENS AG

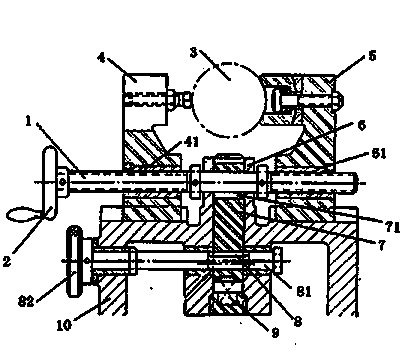

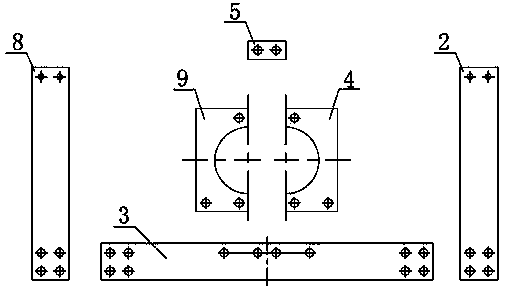

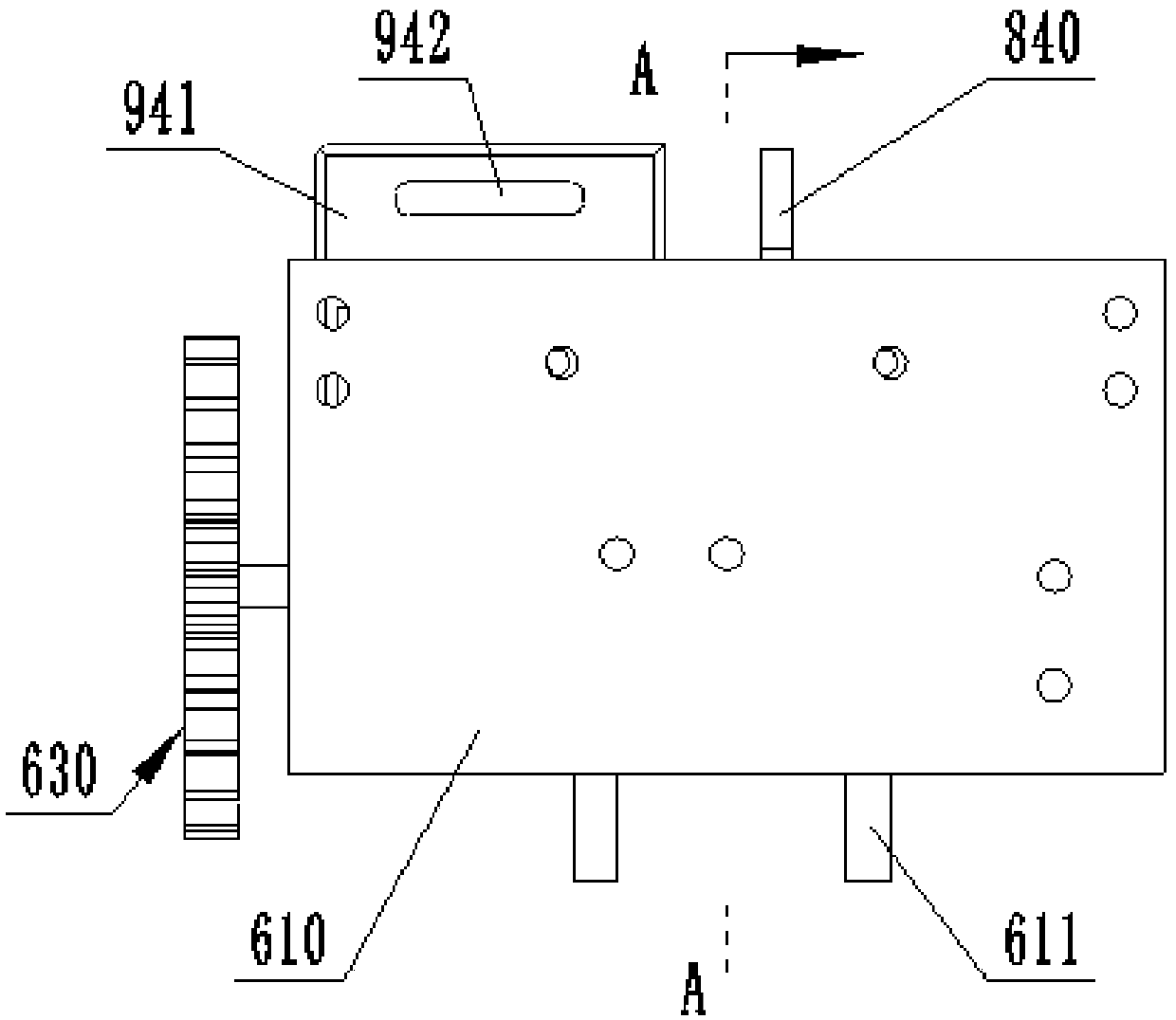

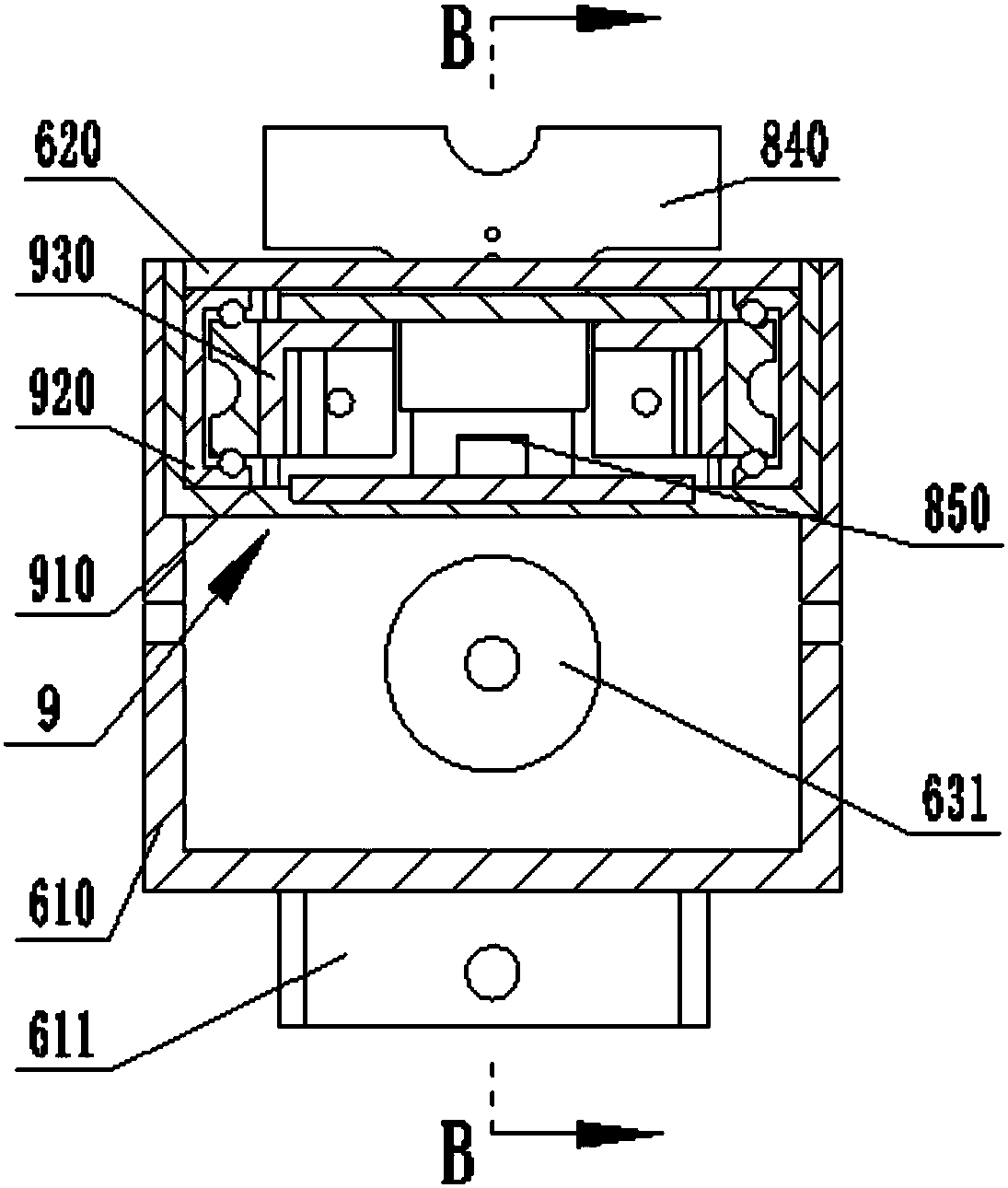

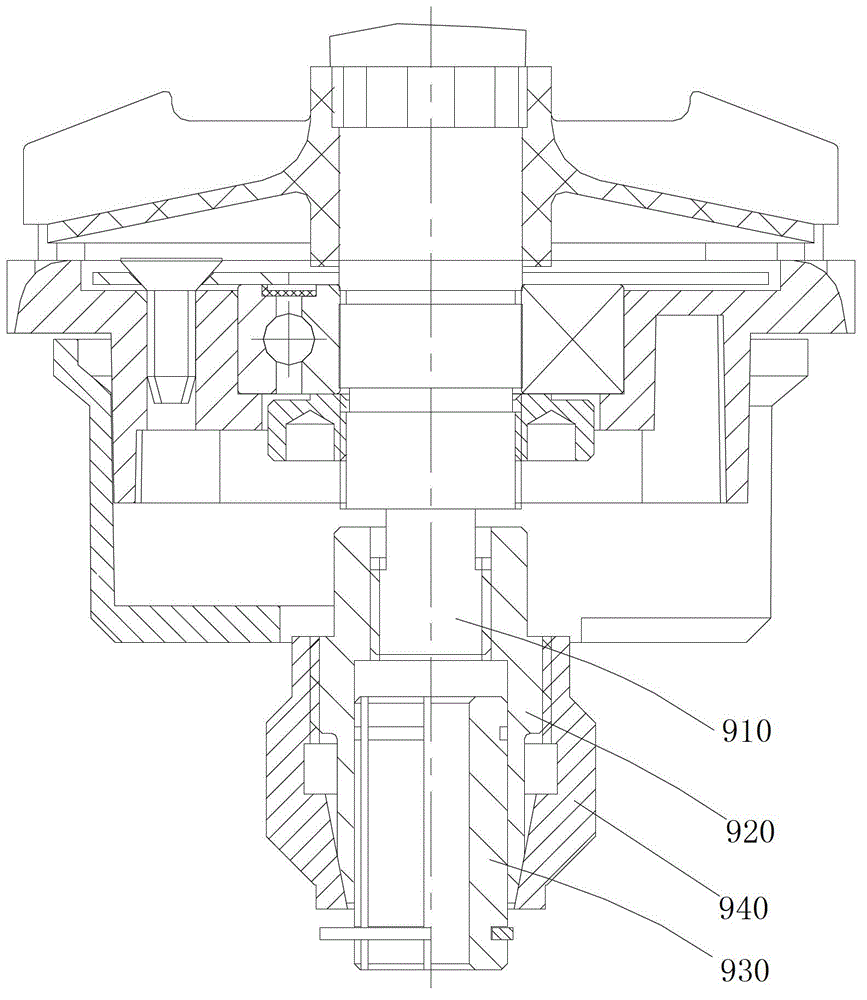

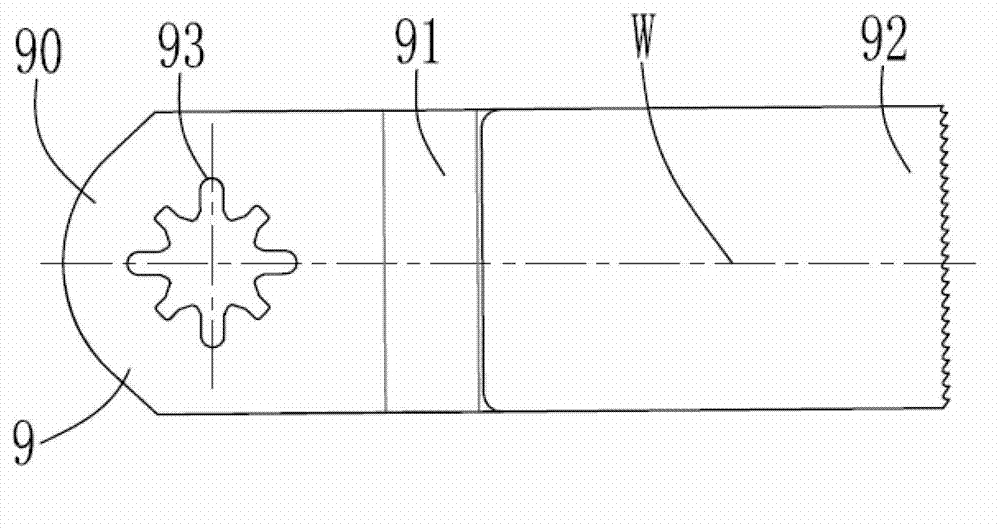

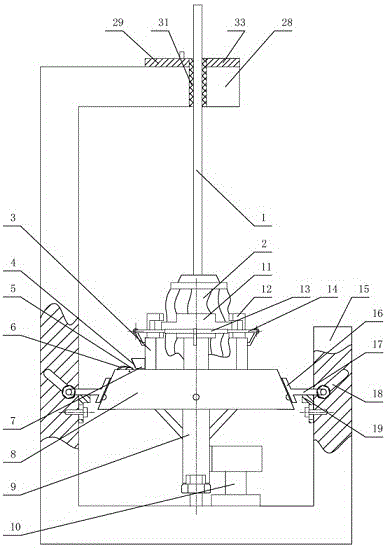

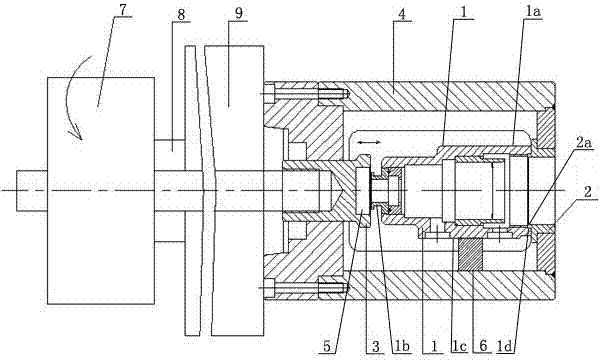

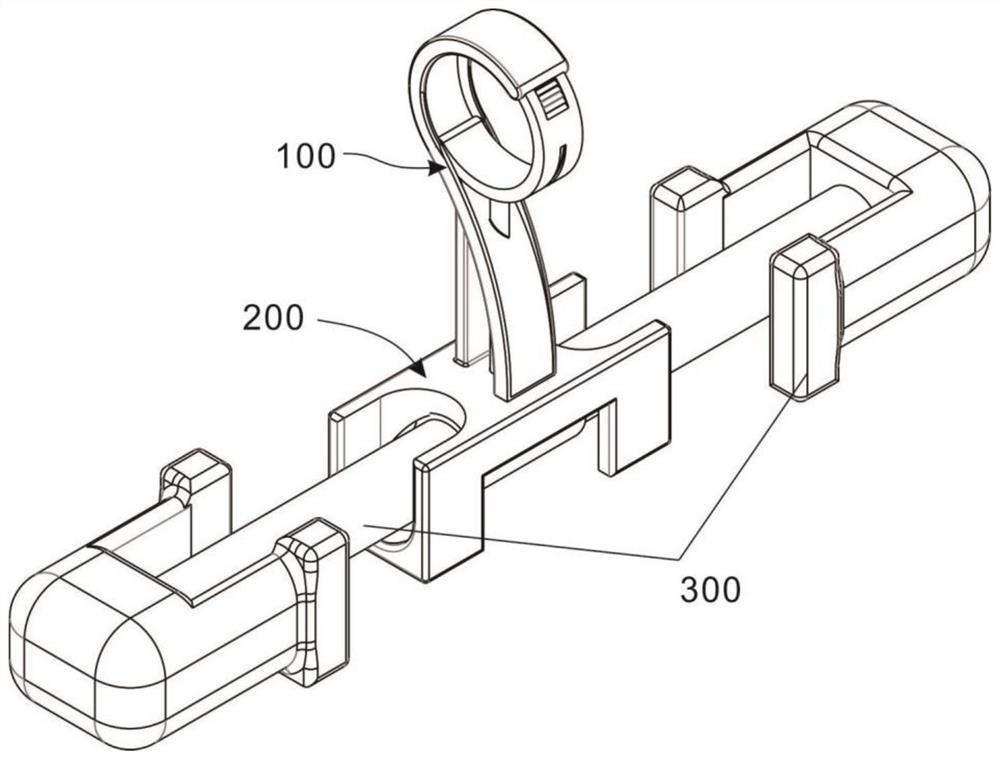

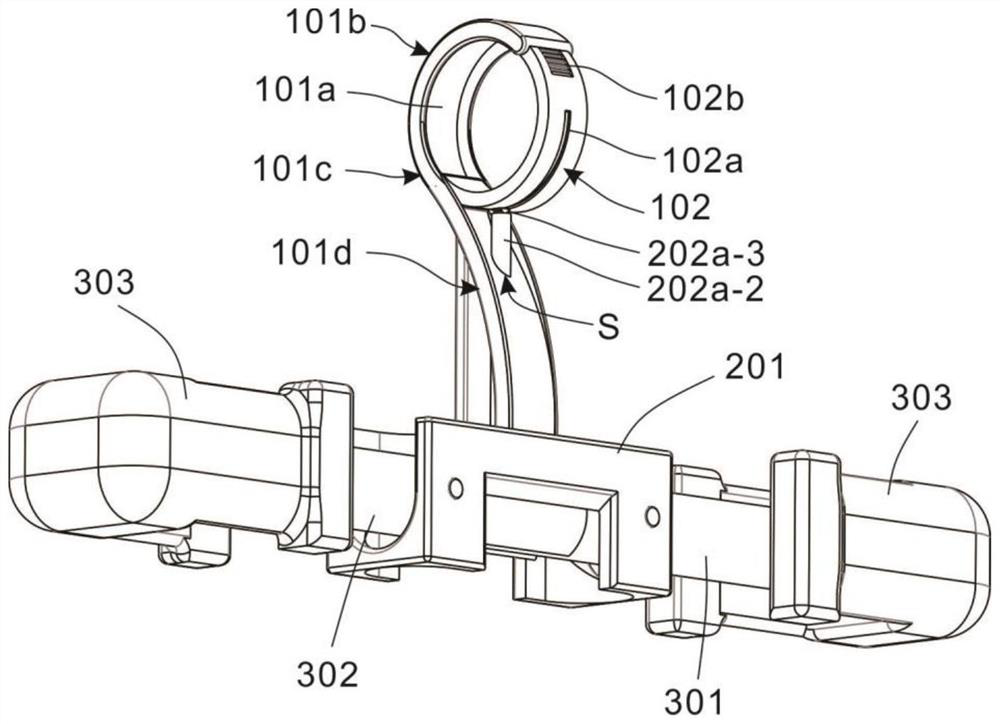

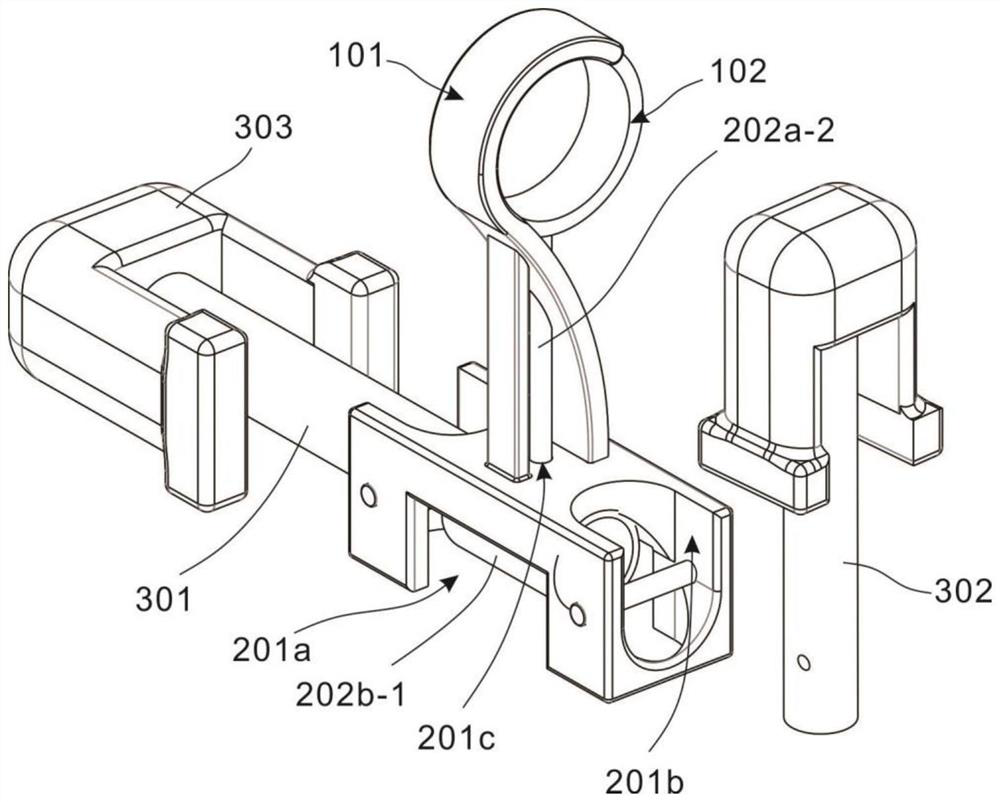

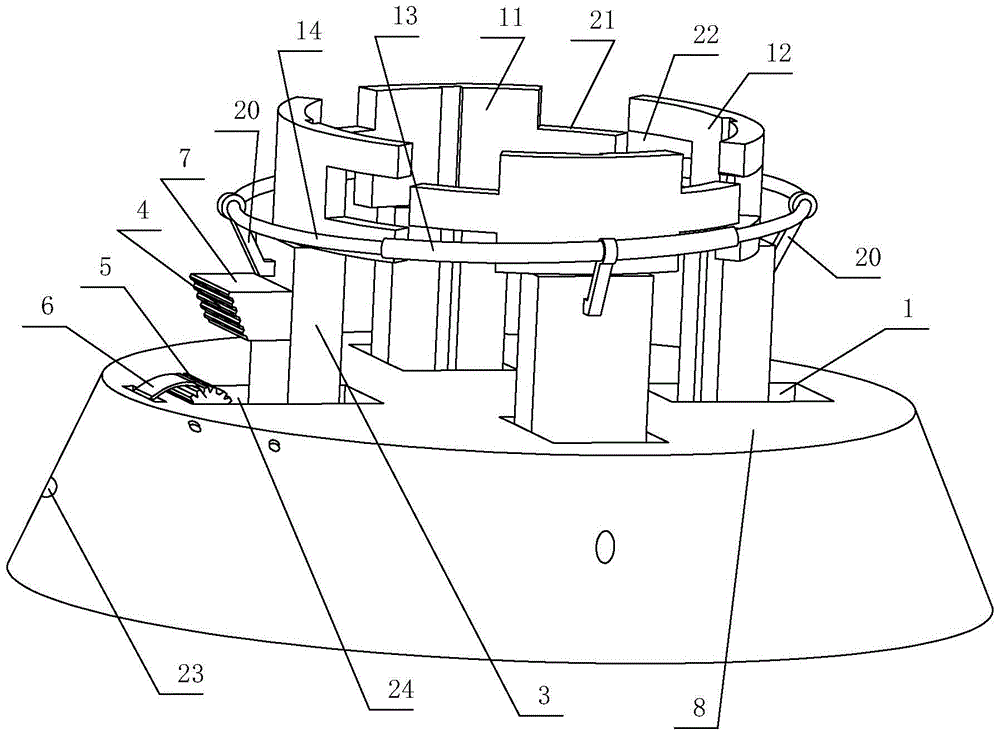

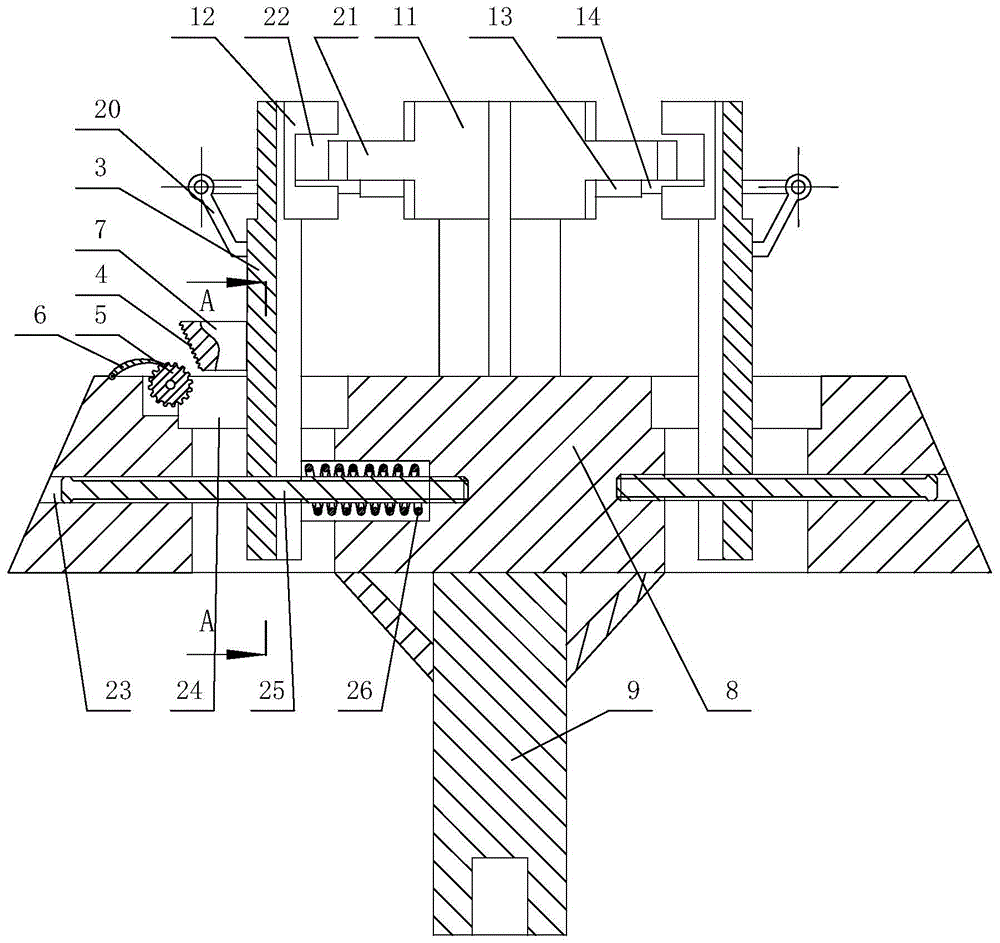

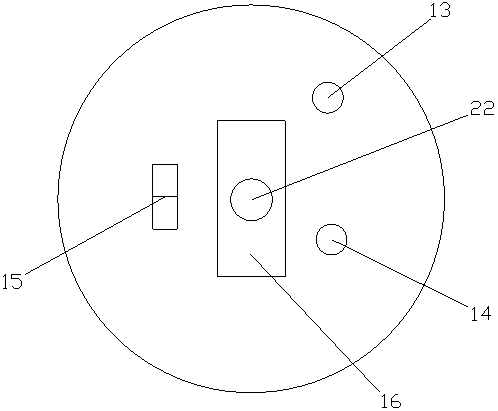

Guide wire controller and operation method thereof

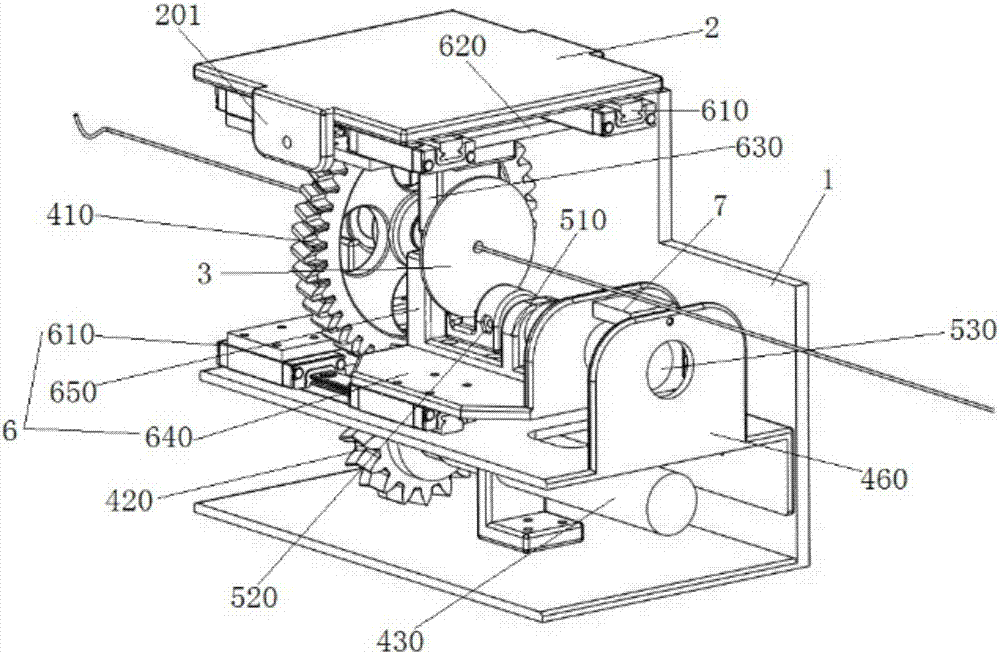

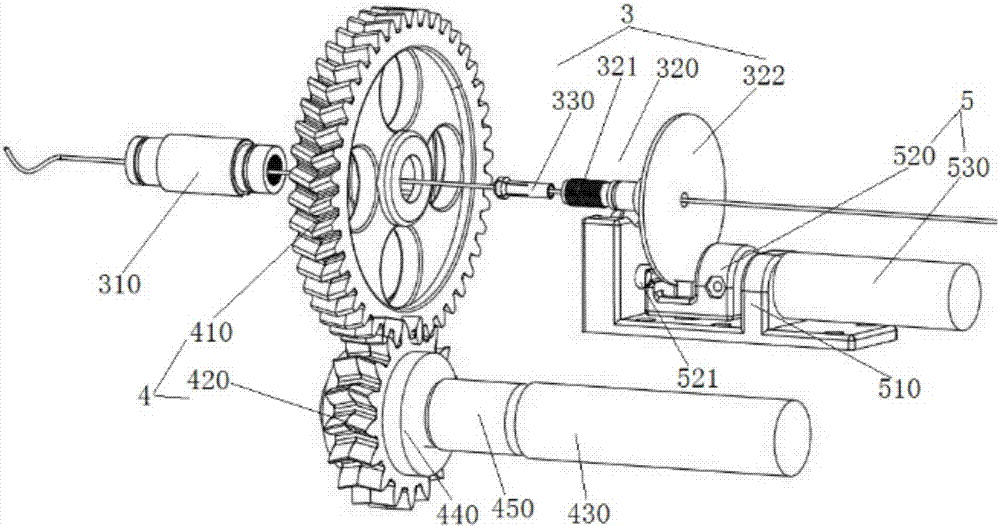

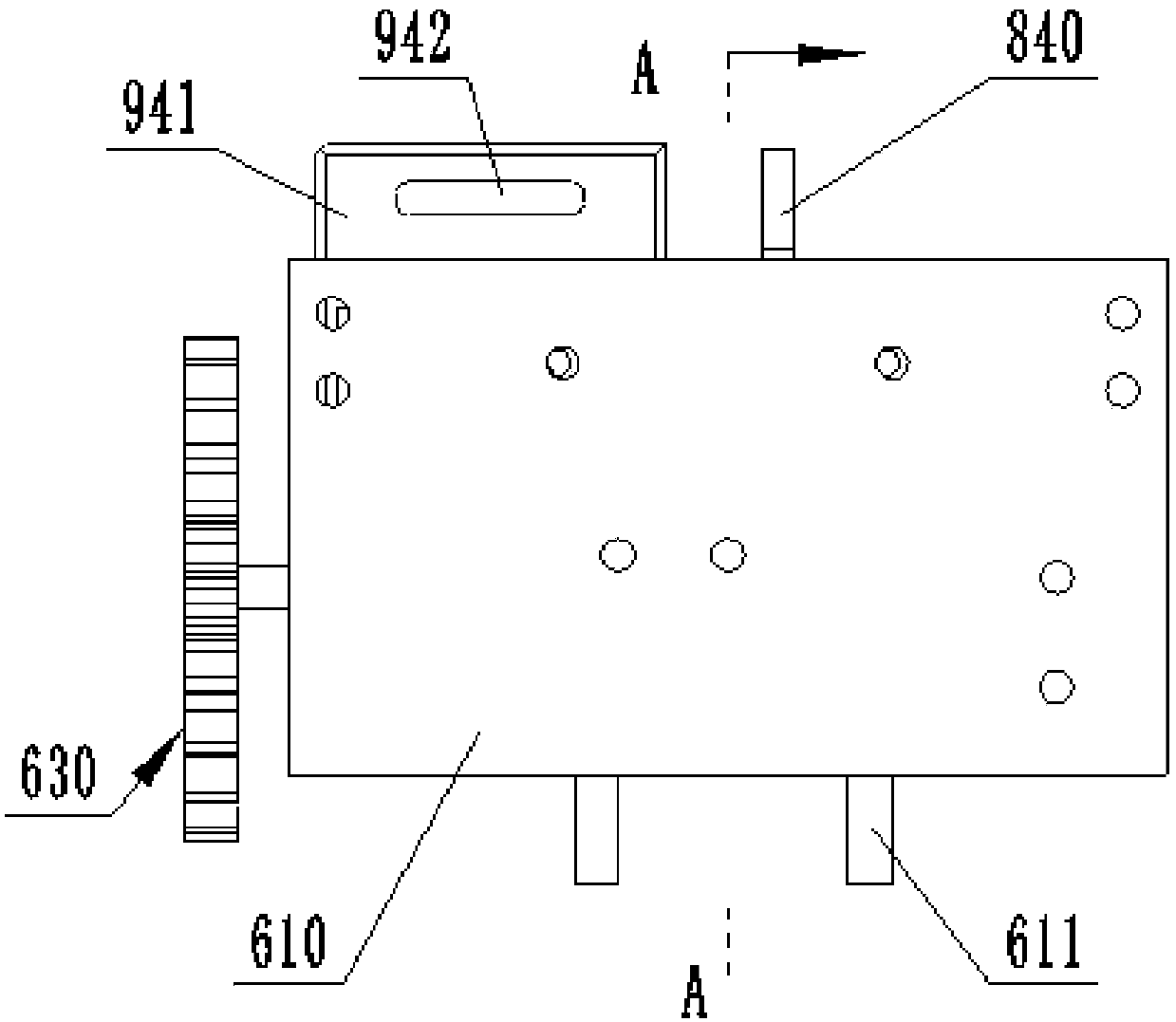

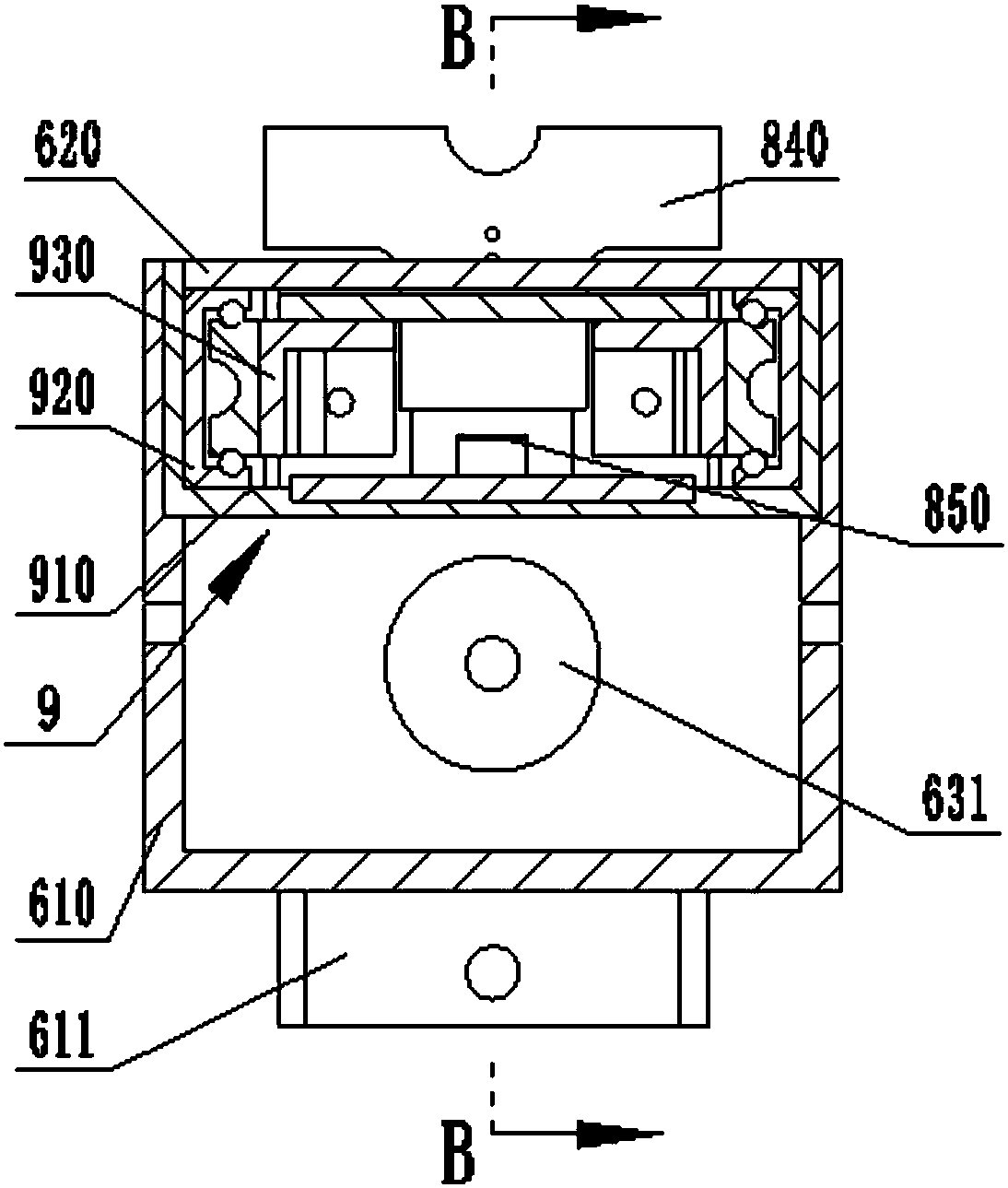

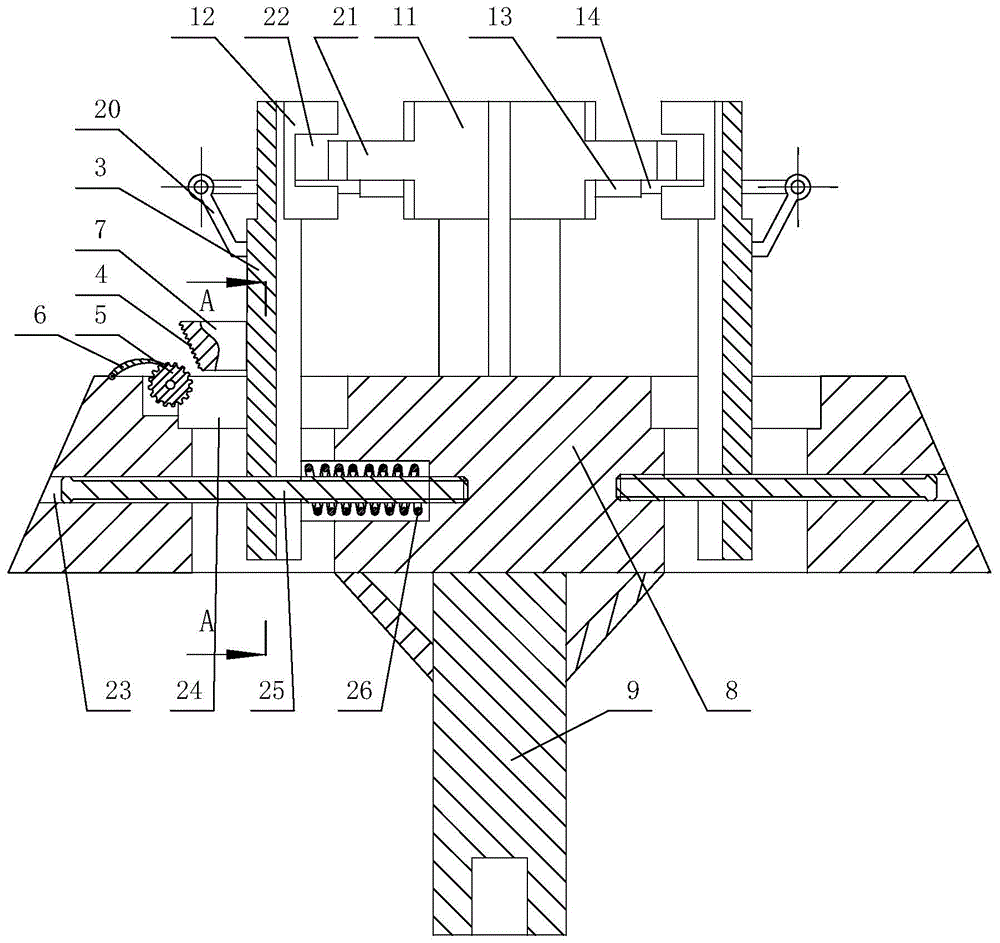

PendingCN107753107ASimple clamping structureSimple combinationGuide wiresSurgical manipulatorsSurgical robotModular design

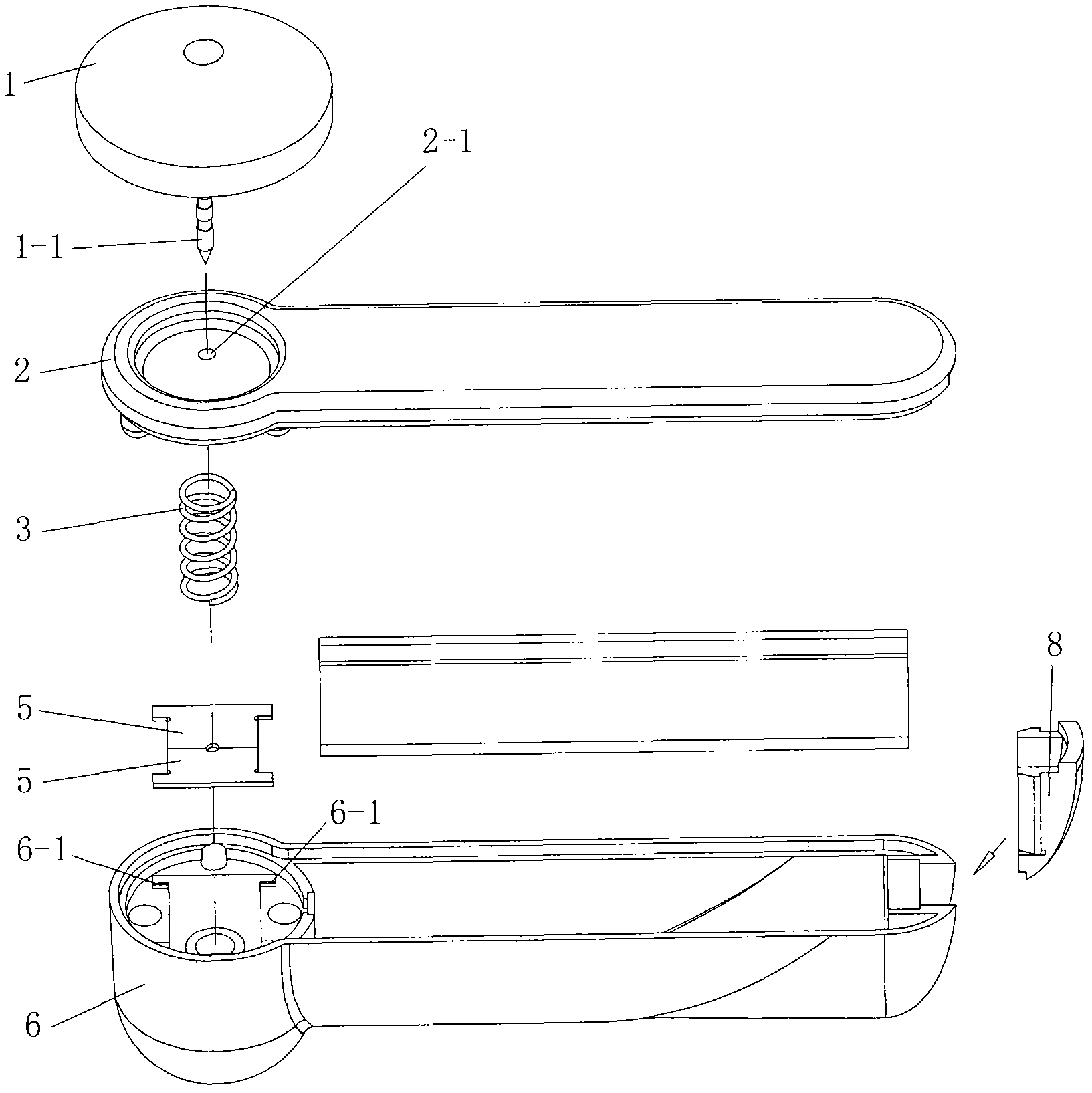

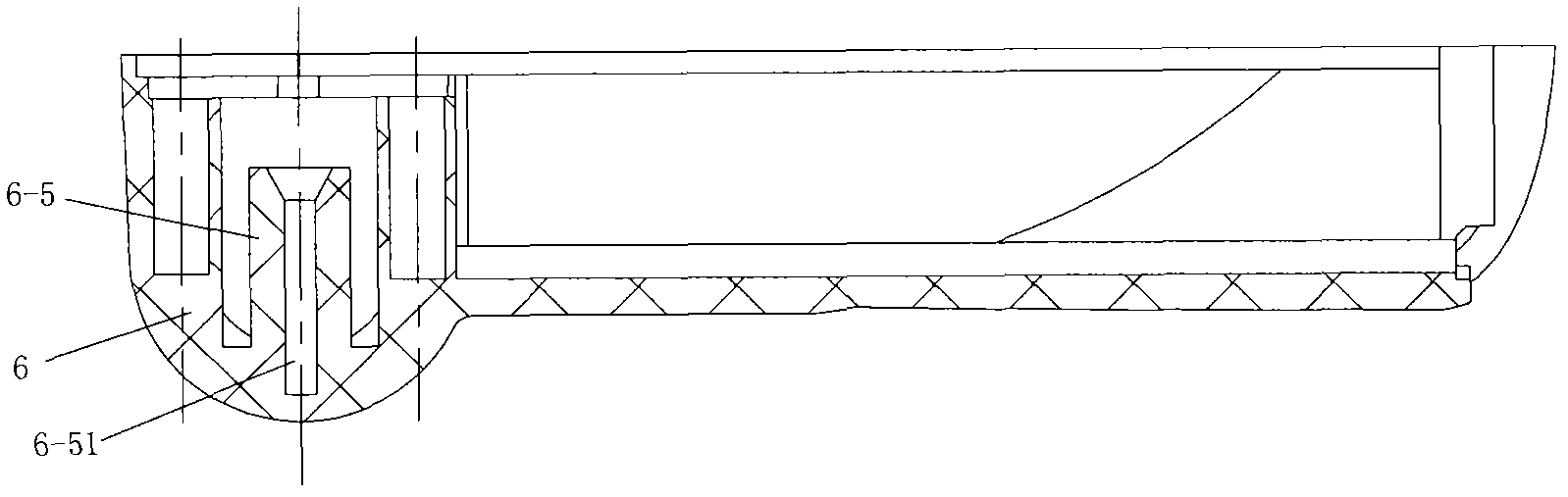

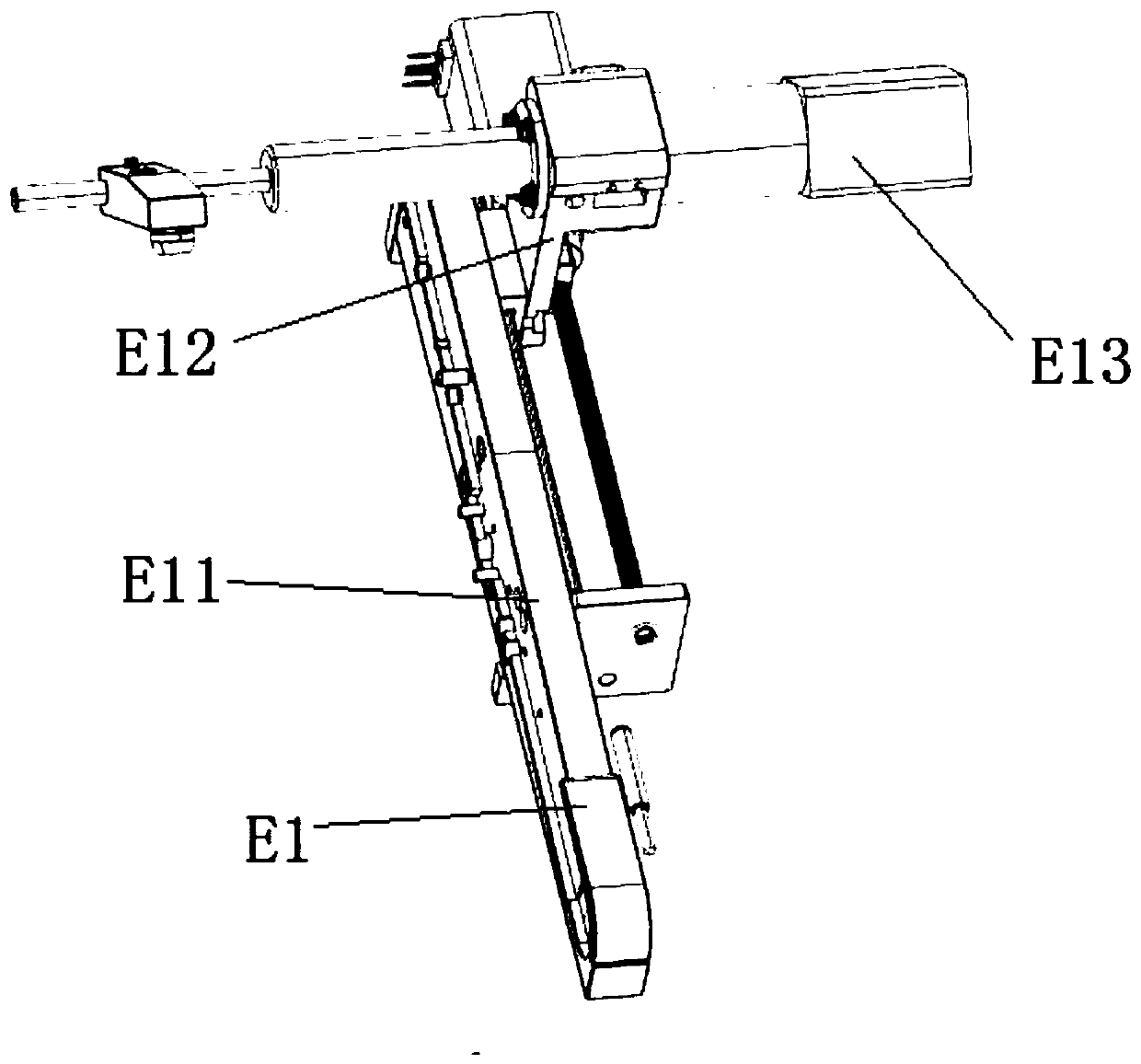

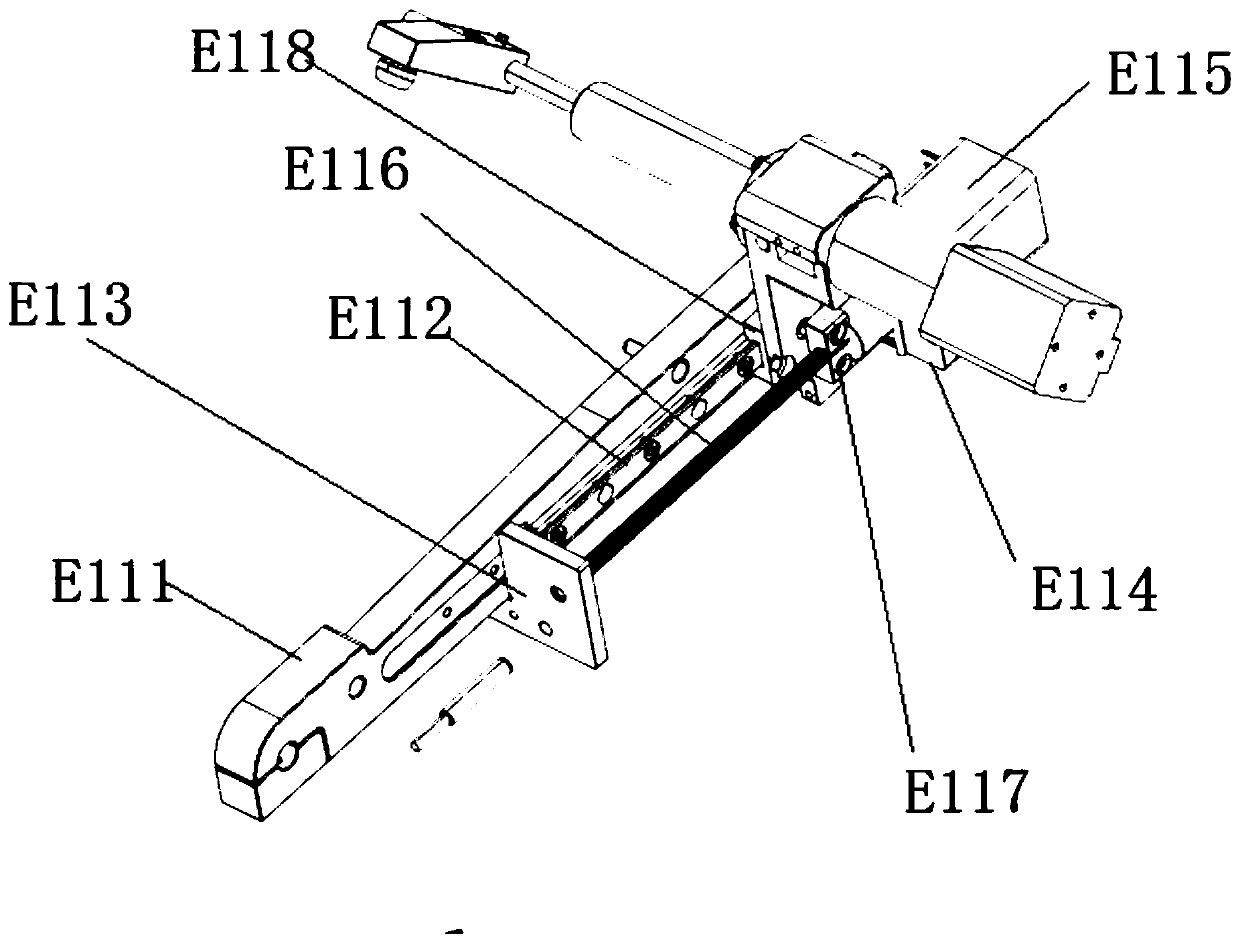

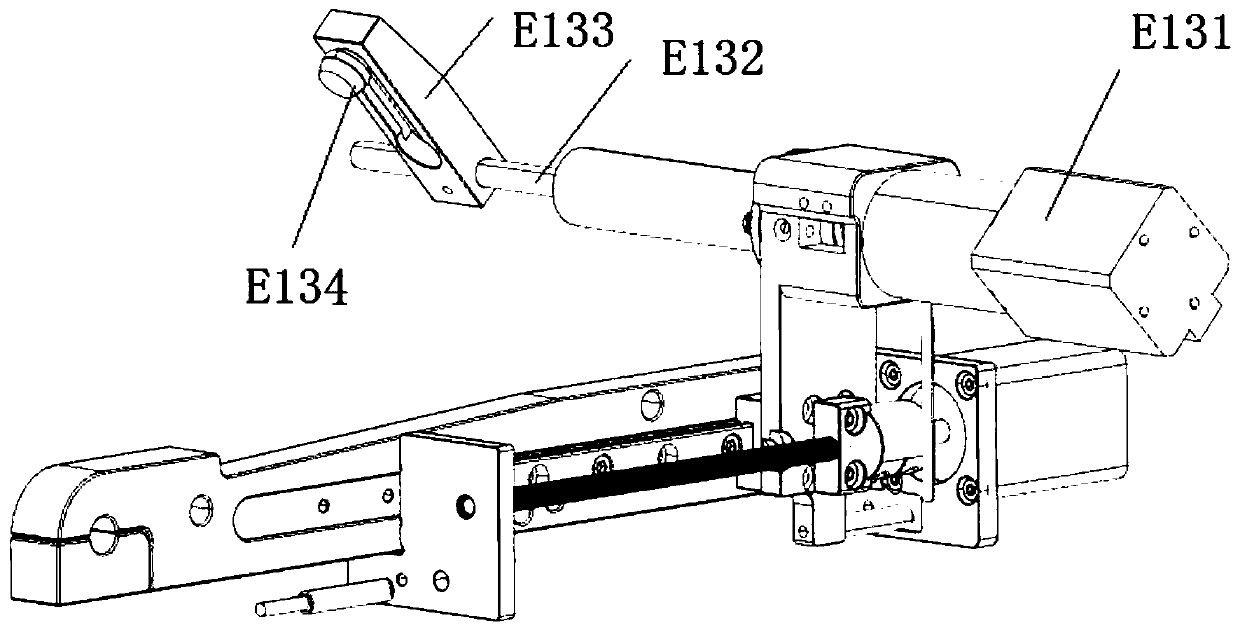

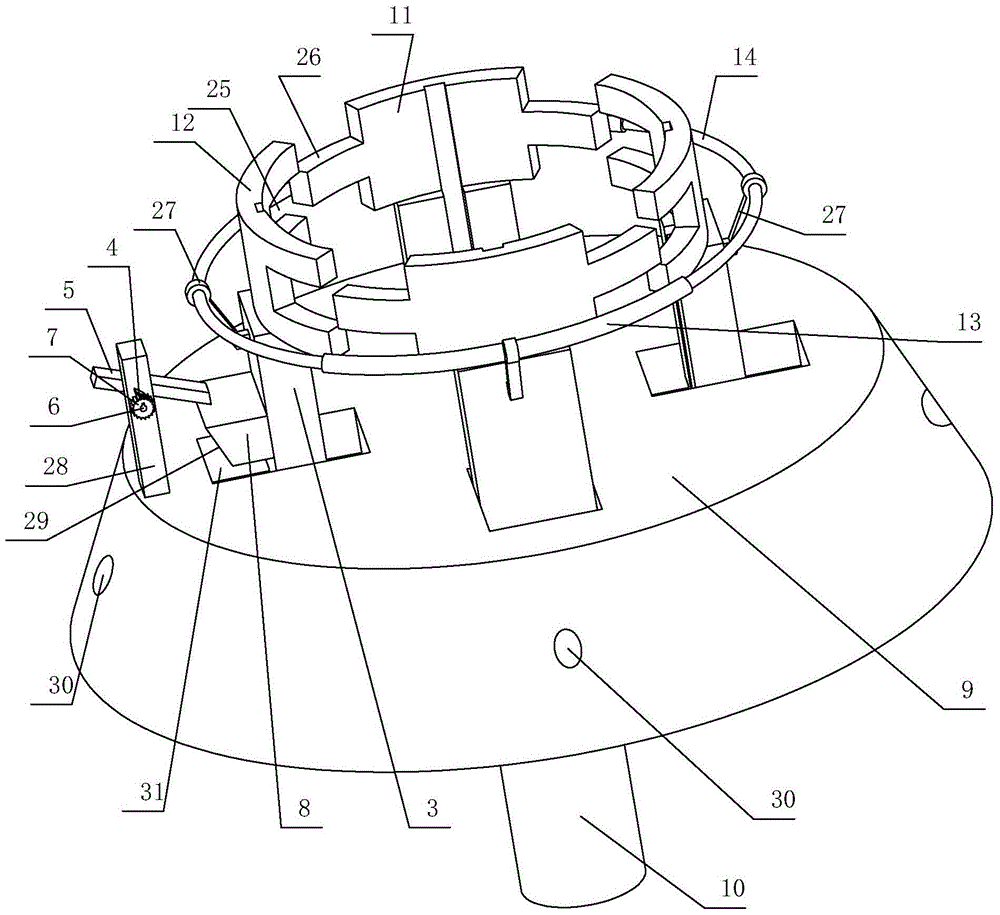

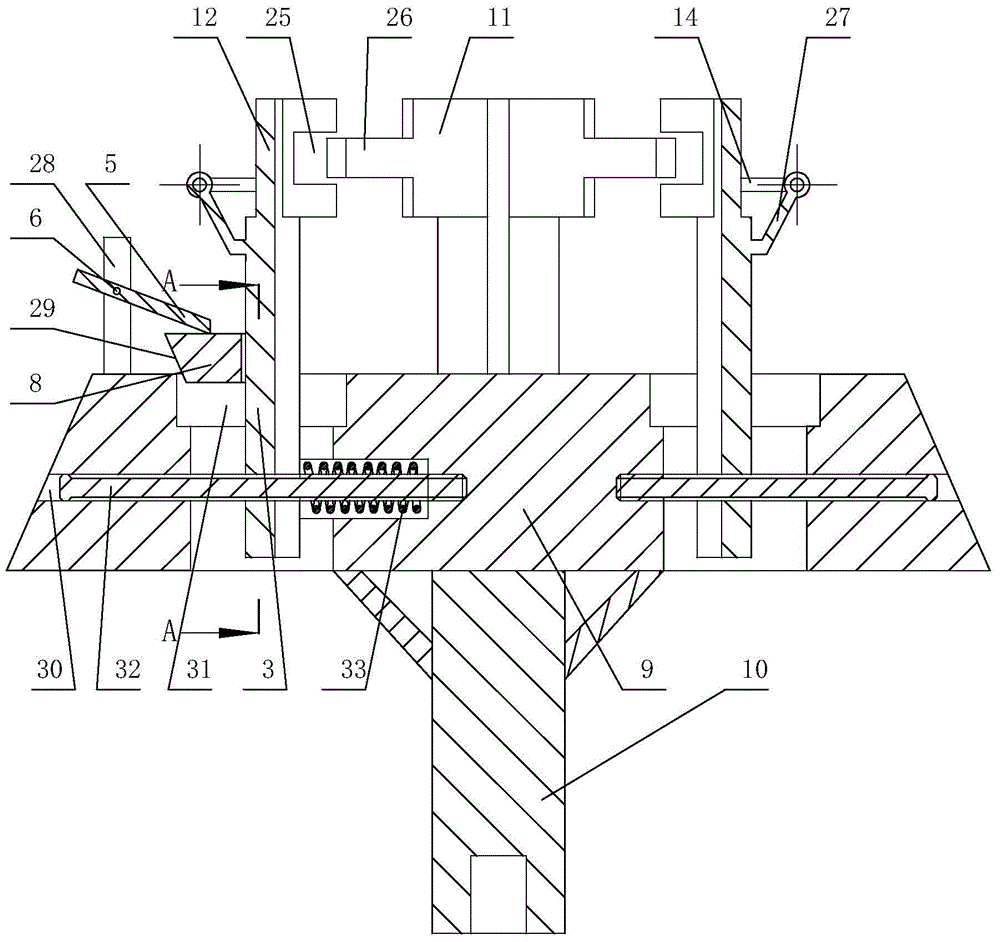

The invention discloses a guidewire controller in a slave device of an interventional surgery robot and a method for using the same, belonging to the technical field of minimally invasive blood vessel interventional surgery. The guide wire controller includes a guide wire controller base, a guide wire clamping device and a clamping switching mechanism installed on the guide wire controller base; the guide wire clamping device is used to clamp the guide wire, and the clamping switch The mechanism is used to drive the guide wire clamping device to loosen the clamp on the guide wire; the guide wire lock adopts a special cone surface and cone hole structure to realize the clamping of the guide wire. The pedestal is mounted on a height-adjustable base that also includes a guidewire torsion device and a force-measuring assembly. The present invention has a simple overall structure, adopts a modular structure design, is easy to disassemble and assemble, has a compact structure, is light in weight overall, and has low manufacturing cost.

Owner:BEIJING TIANTAN HOSPITAL AFFILIATED TO CAPITAL MEDICAL UNIV

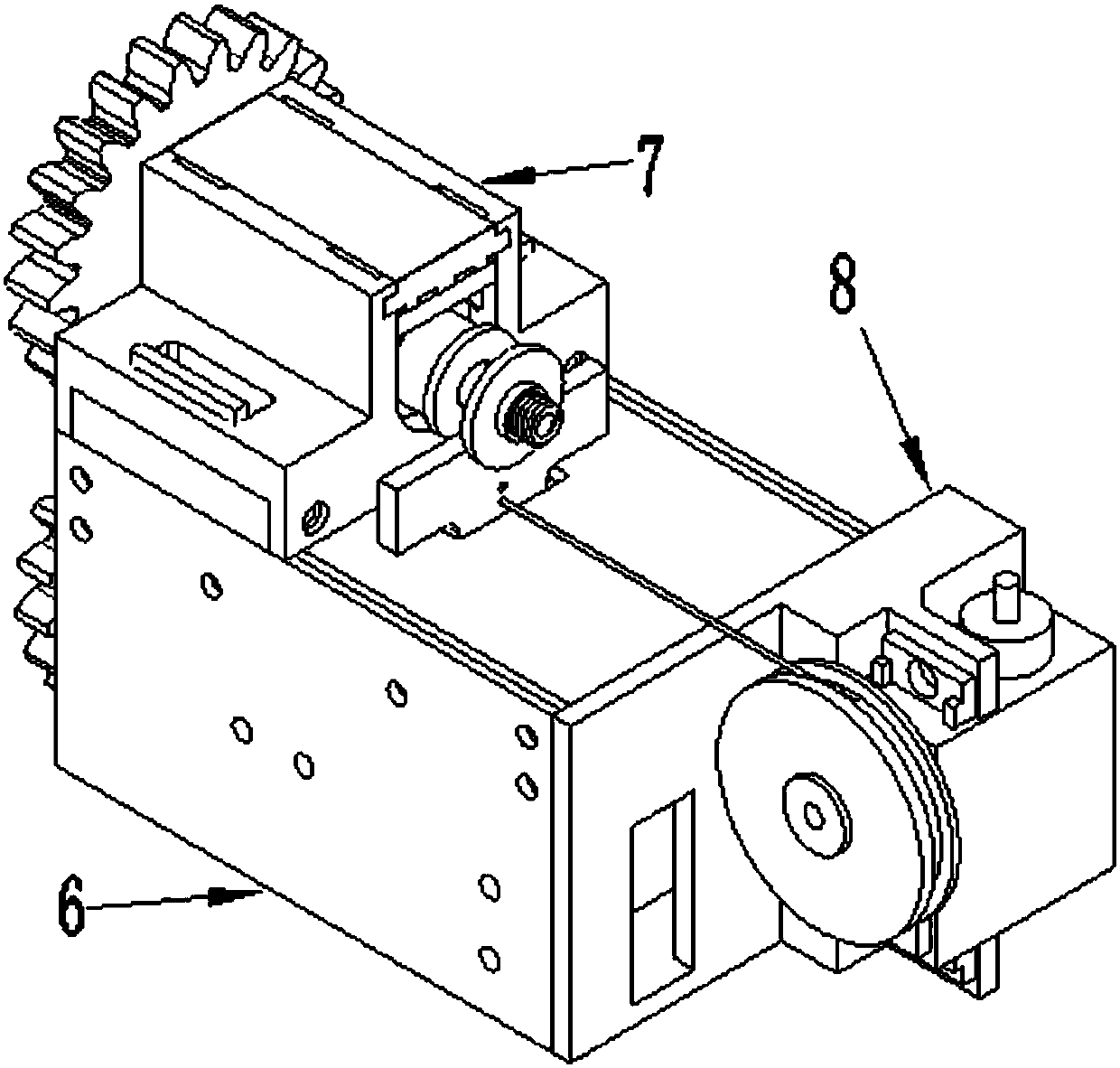

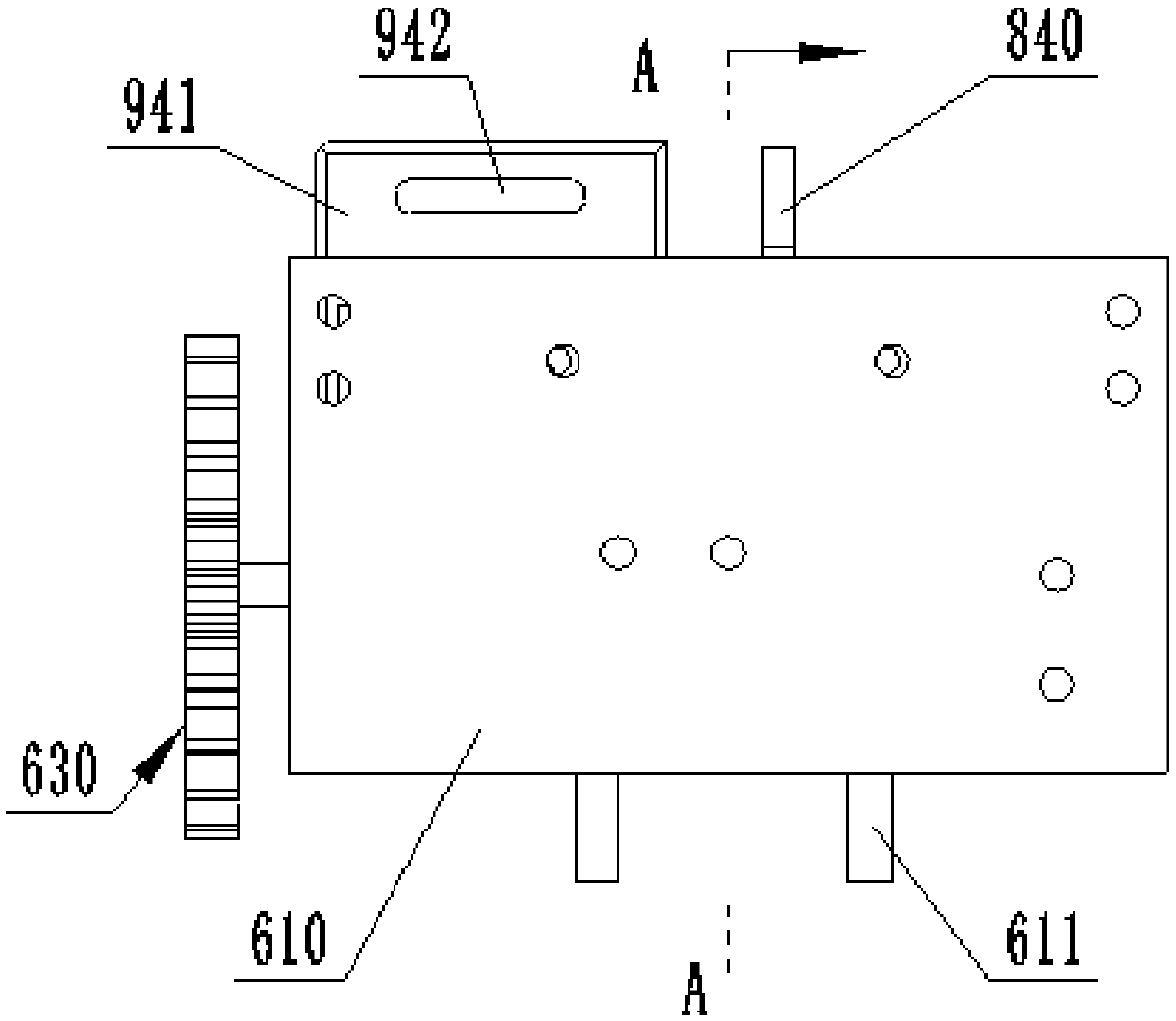

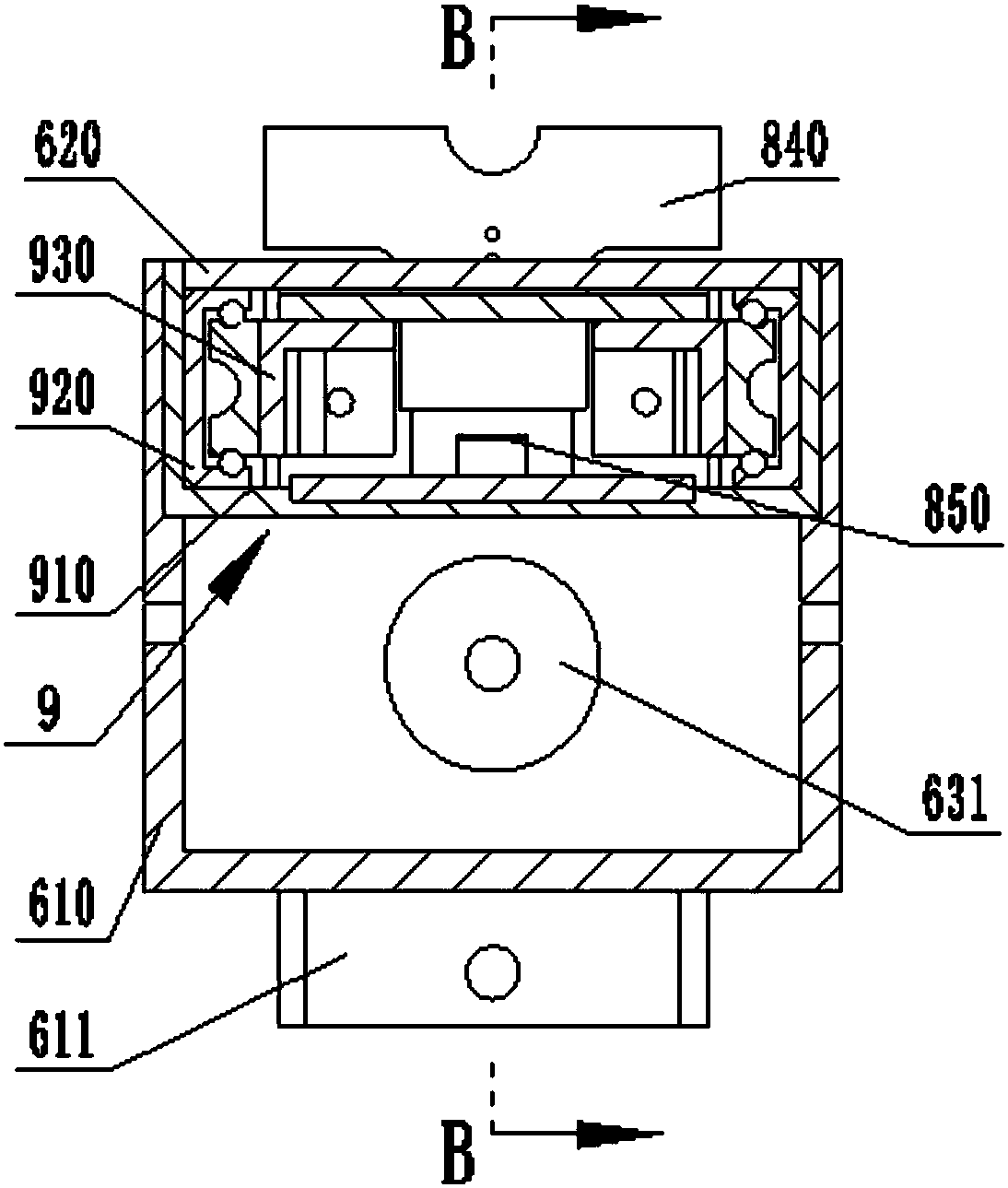

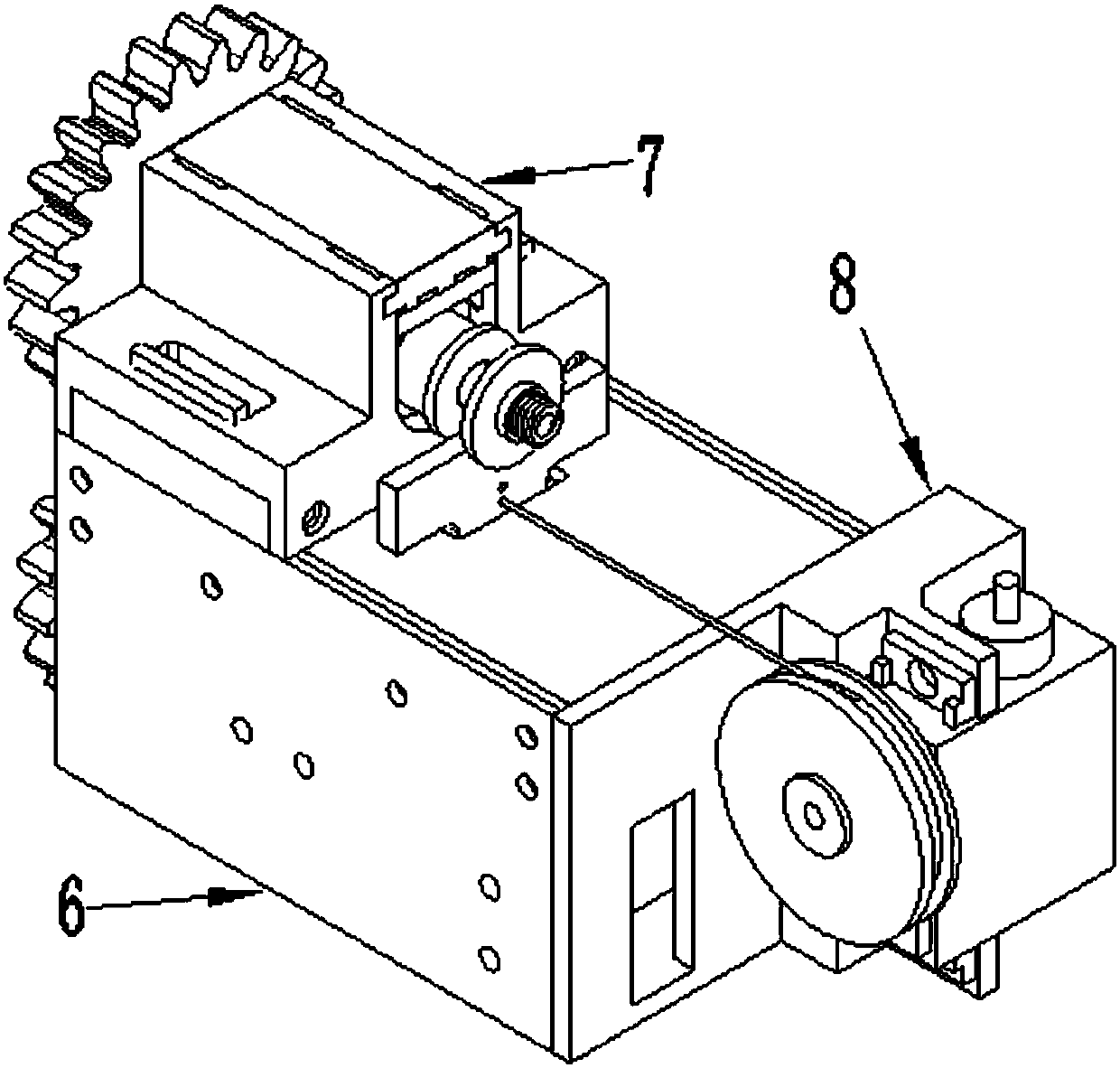

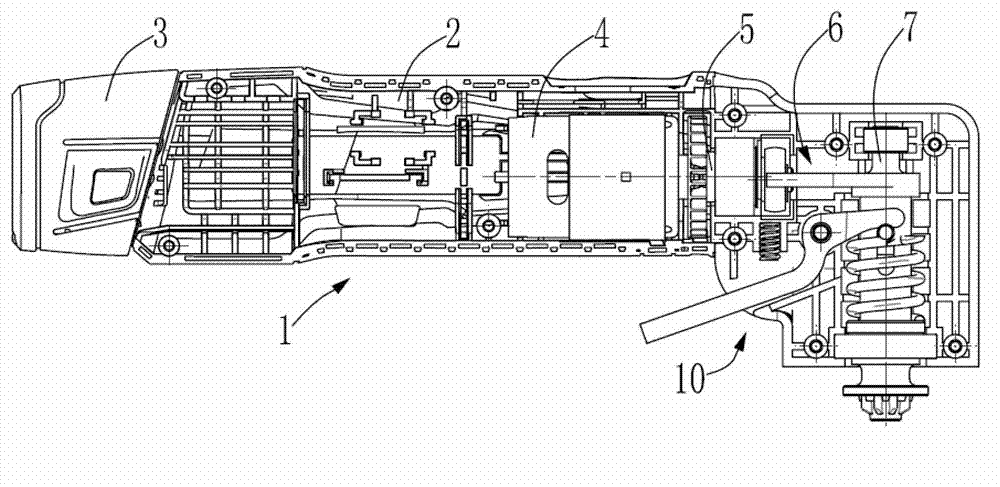

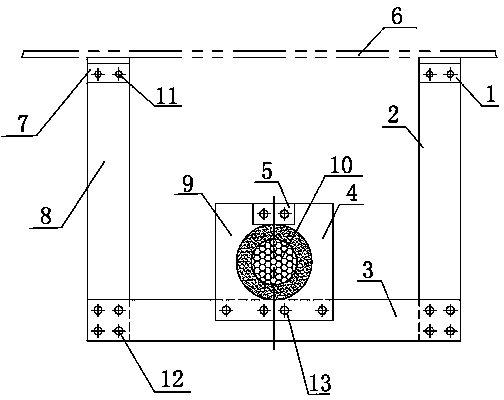

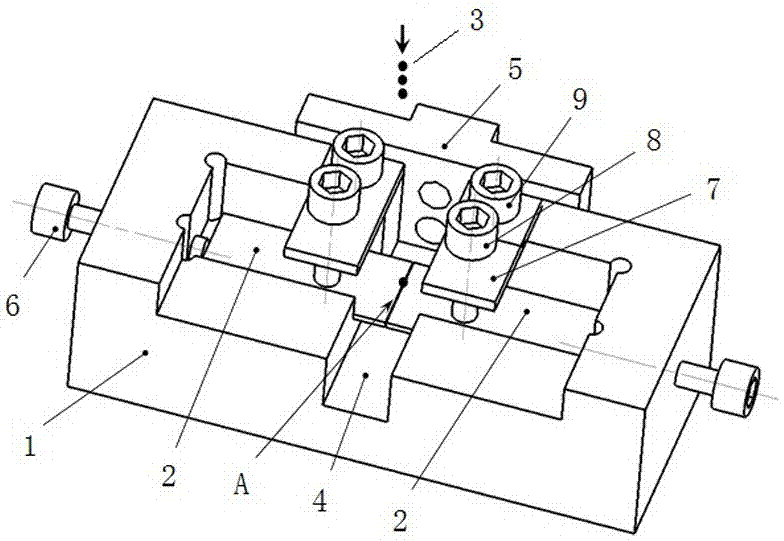

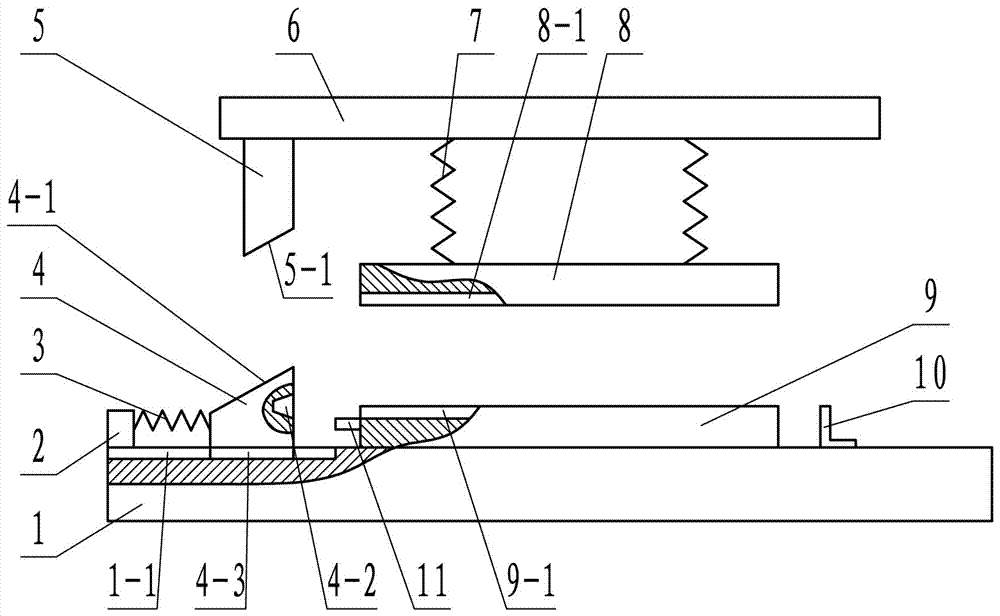

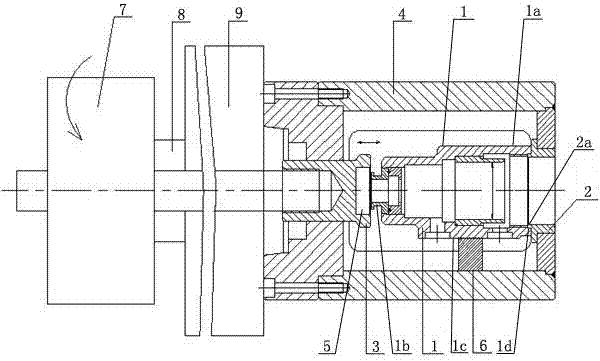

Guide wire controller and operation method thereof

PendingCN107754072ASimple clamping structureStructural design, simple combinationGuide wiresMedical devicesModular structureBiomedical engineering

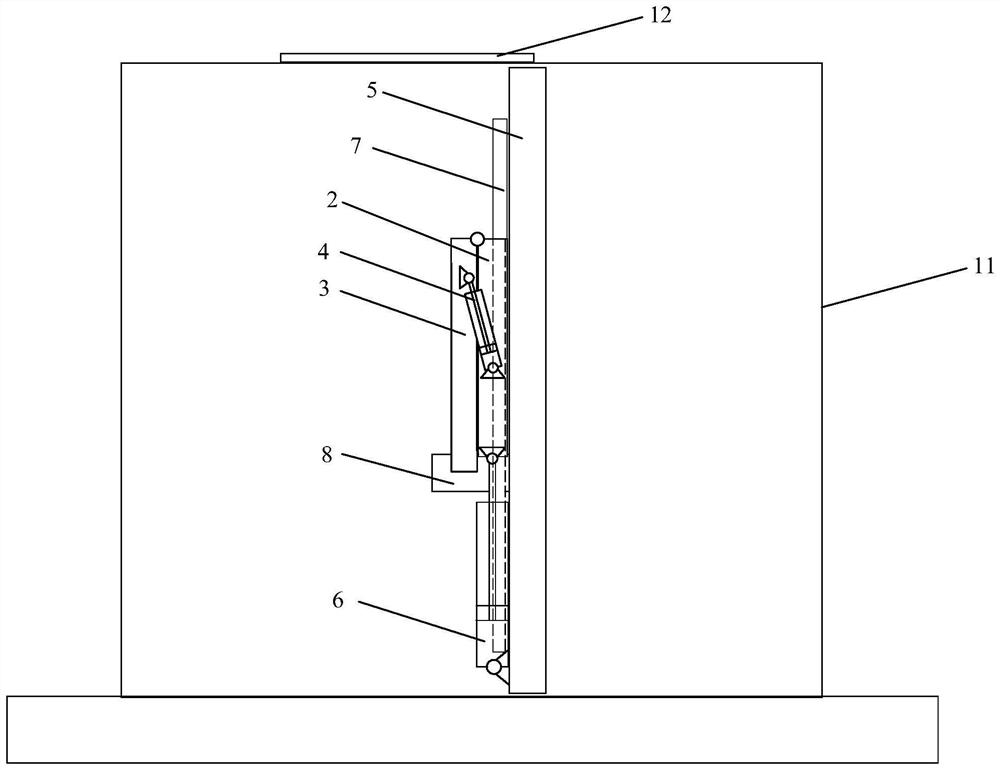

The invention discloses a guide wire controller in an interventional operation robot slave client device and a using method thereof, and belongs to the technical field of minimally invasive vascular interventional operation. The guide wire controller comprises a guide wire controller base, a guide wire clamping device and a clamping switching mechanism, wherein the guide wire clamping device and the clamping switching mechanism are installed on the guide wire controller base, the guide wire clamping device is used for clamping a guide wire, and the clamping switching mechanism is used for driving the guide wire clamping device to loosen the guide wire. Different from the mode of adopting one device to control clamping and loosening in the prior art, clamping and loosening of the guide wireare controlled separately by means of the guide wire controller, the guide wire clamping mechanism (7) clamps the guide wire all the time in a default state, when the guide wire needs to be loosened,the clamping switching mechanism (8) is used for switching to loosen the guide wire, and the structure is optimized greatly. The base is installed on a pedestal with adjustable height, and a guide wire twisting device and a force measurement assembly are arranged on the base. The guide wire controller is simple in overall structure, easy to disassemble and combine by means of the modular structural design, compact in structure, light in overall weight and low in manufacturing cost.

Owner:BEIJING TIANTAN HOSPITAL AFFILIATED TO CAPITAL MEDICAL UNIV

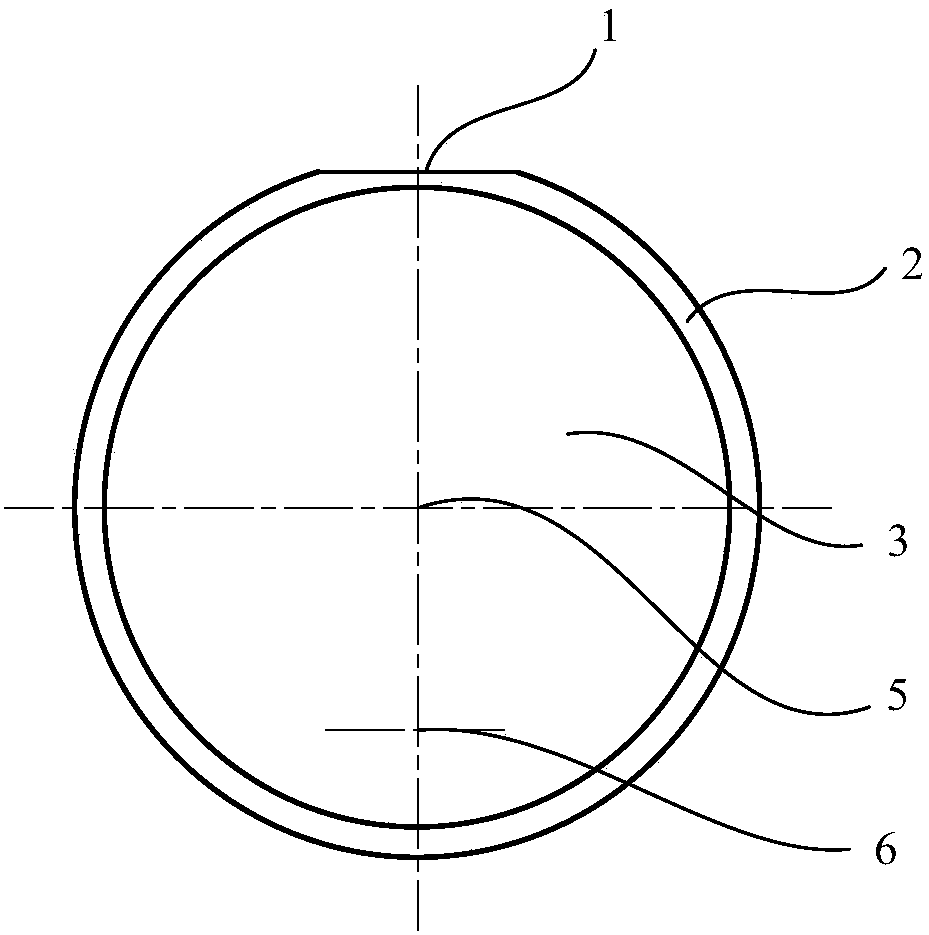

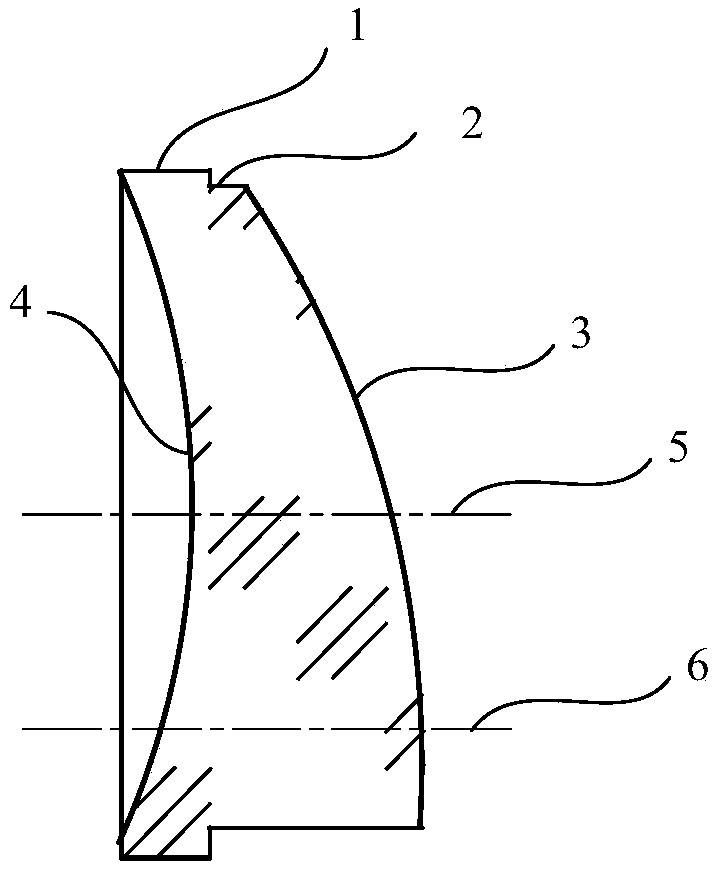

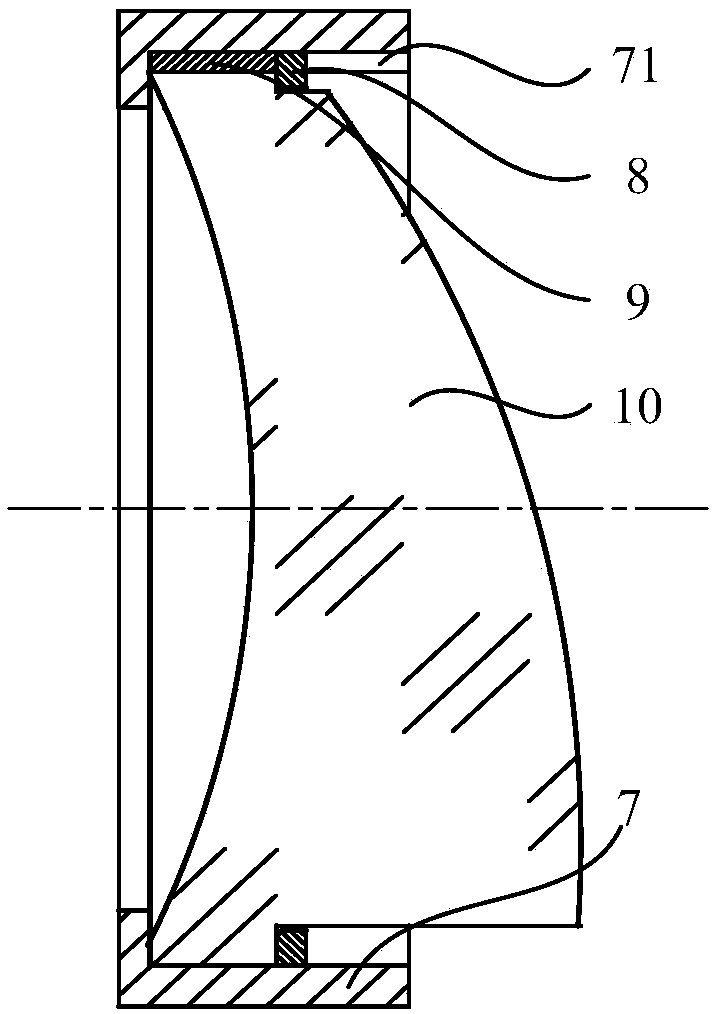

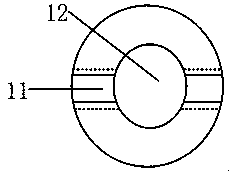

Curved prism, curved prism assembly and processing method thereof

The invention relates to a curved prism, a curved prism assembly and a processing method thereof. The problems that the curved prism is difficult to mount and fix and phase adjustment of the prism isdifficult are solved. The curved prism assembly comprises a curved prism, a mirror frame, a threaded ring and a positioning block. The curved prism assembly comprises a concave surface, a convex surface, a phase positioning level end face and a stepped chamfer; the phase positioning level end face is arranged on an outer side face of the prism; a positioning groove parallel to a light axis of theconcave surface is formed in an inner hole of the mirror frame; the positioning block is a cylindrical truncated body and is matched with a cylinder on which a large-diameter side face is positioned;ribs matched with the positioning groove are arranged on an arc surface on the outer side of the positioning block 9; and the threaded ring can be screwed into the inner hole of the mirror frame and is pressed on a stepped surface of the stepped chamfer. The curved prism disclosed by the invention is simple in clamping structure and excellent in applicability, the prism phase does not need to be adjusted in the mounting process, and the reliability is high.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Accessory clamping mechanism and power tool with same

ActiveCN103170956AImprove versatilityEliminate hidden dangersPortable power-driven toolsEngineeringPower tool

The invention provides an accessory clamping mechanism which is used for clamping an accessory on a working arbor flange of a power tool, and a working arbor is provided with a first longitudinal axis. The accessory clamping mechanism comprises at least one clamping piece, a push component, an elastic piece, a driving component and a motion conversion piece. The push component supports the clamping piece, and the push component and the clamping piece are driven by a driving piece to move along the first longitudinal axis. The push component is pressed towards a clamping position through the elastic piece. The driving component is used for enabling the push component and the clamping piece to move along the first longitudinal axis, the driving component comprises the driving piece, and the driving piece moves between a first position and a second position. On the first position, an accessory is arranged on the clamping position. On the second position, the accessory is arranged on a releasing position. The motion conversion piece drives the clamping piece to move along a direction different from the first longitudinal axis. The invention further provides a power tool with the accessory clamping mechanism.

Owner:NANJING CHERVON IND

Eccentric clamping fixture

InactiveCN104289929APrevent rotationMaster quicklyPositioning apparatusMetal-working holdersEngineeringCam

The invention relates to a machining fixture, in particular to an eccentric clamping fixture. The eccentric clamping fixture comprises a base and a threaded column, a hand wheel is fixedly connected at the end of the threaded column, the threaded column is divided into a left part and a right part, each of the two parts is provided with a thread, two sections of the threads are opposite in thread turning direction, each of the left part and the right part is in threaded connection with a clamping plate, ends of the clamping plates are slidably connected with the base while the other ends are used for clamping workpieces, a boss is arranged on the base and between two clamping jaws, the clamping jaws are slidably connected in the boss, a through hole is formed in a drive end of each clamping jaw, a cam matched with the corresponding through hole and capable of locking the corresponding clamping jaw is arranged in the through hole, and the each cam is provided with a handle; the threaded column penetrates driven ends of the clamping jaws, and clamping holes for penetrating of the threaded column are formed in the driven ends of the clamping jaws. By the machining fixture, machining precision under the condition that reacting force in clamping of the workpieces is guaranteed.

Owner:CHONGQING HAONENG XINGFU SYNCHRONIZER

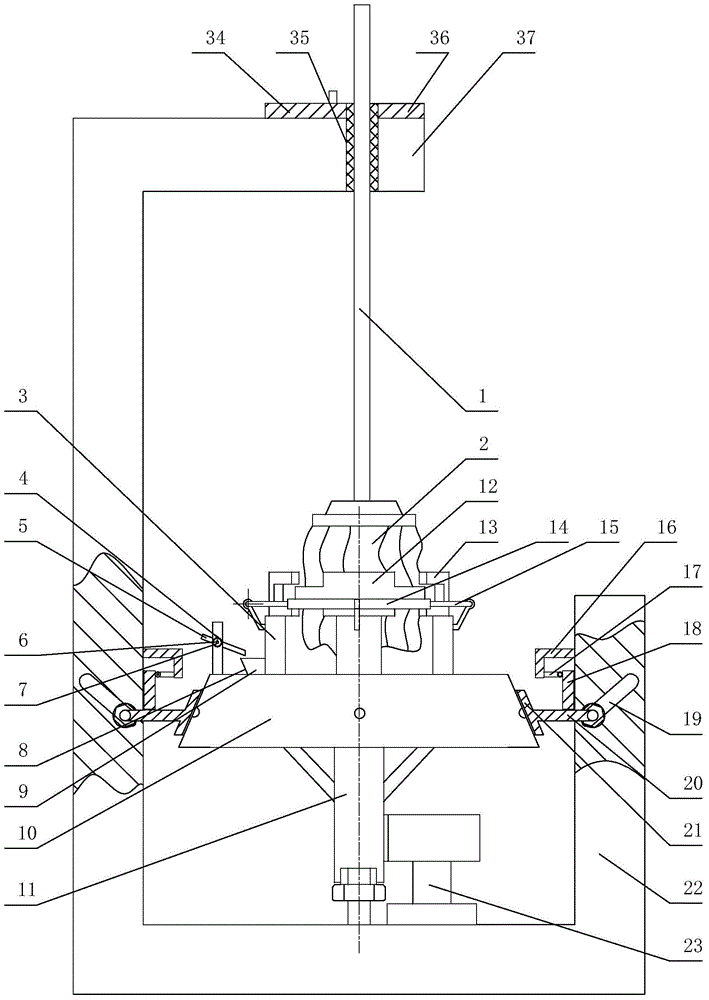

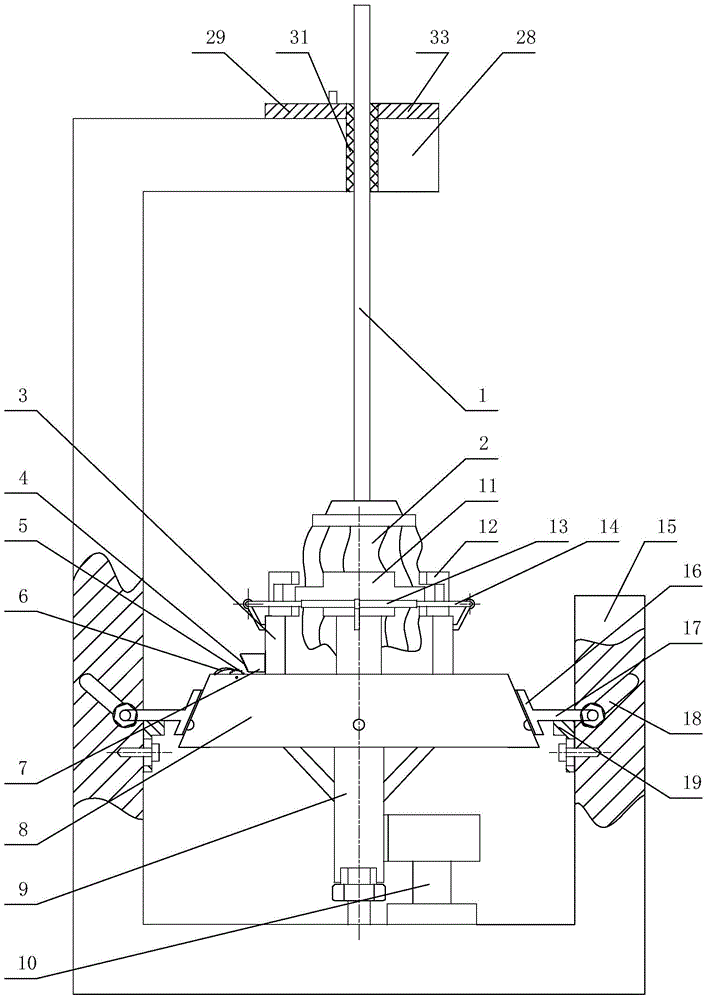

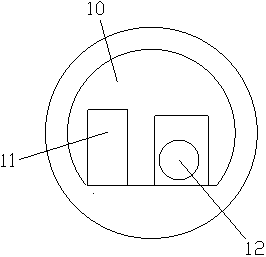

Mop dehydrator

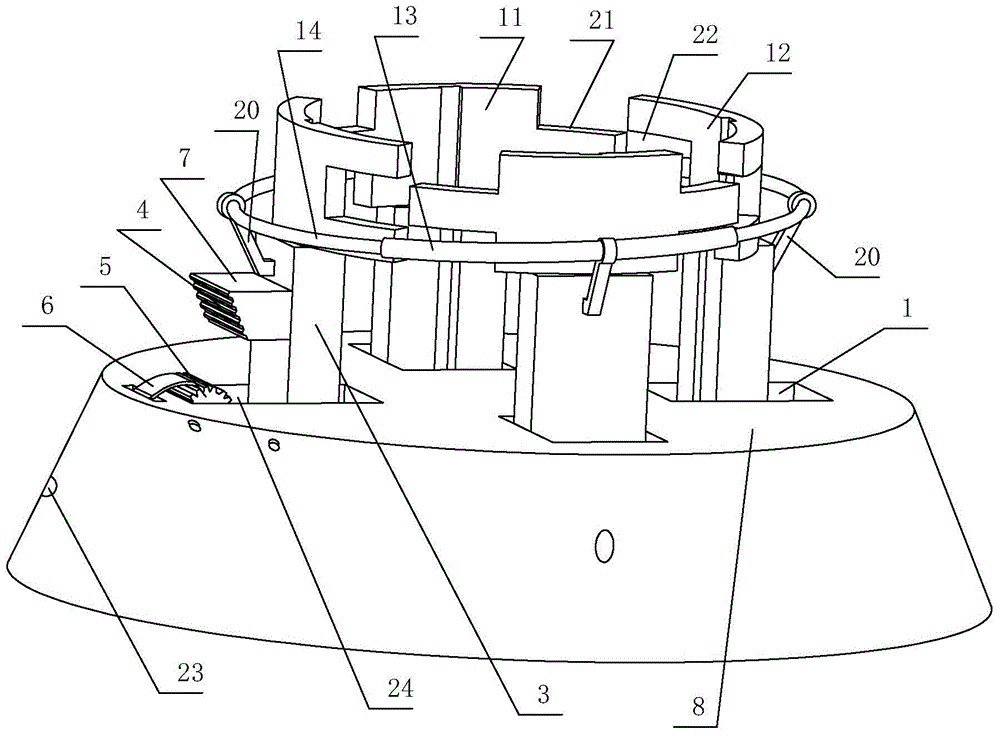

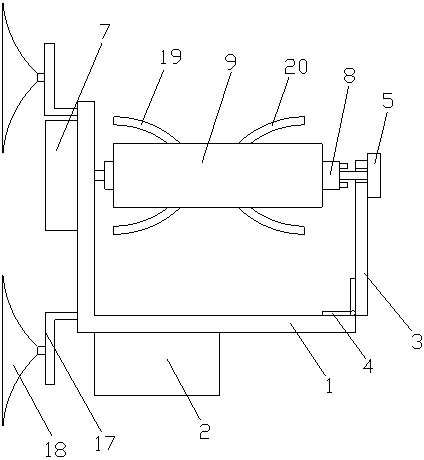

The invention discloses a mop dehydrator which comprises a motor (23), a round table (10), a mop rod clamping device, a mop head clamping device and a mop head clamp driving device, wherein the mop head clamp driving device comprises a pressing block (9), a pressing lever (5), a ratchet wheel (7) and a pawl (4); one end of the pressing block (9) is connected with the mop head clamping device in a sliding manner in the vertical direction and buckled with the mop head clamping device in the horizontal direction; one end of the pressing lever (5) is compressed to the upper end surface of the pressing block (9); the round table (10) is a frustum of which the upper end is smaller than the lower end in diameter; an adjustment device for keeping the round table (10) in a horizontal state is also arranged between the round table (10) and a support base (22). Through adoption of the mop dehydrator, the operation noise is reduced greatly, and the mop can be better to be wrung out, so as to be more conducive to floor cleaning; in addition, the mop head clamping device is simple in structure and convenient to operate.

Owner:黄山市黄山区五丰源种养专业合作社

Shell type transformer lead clamping structure and clamping method

ActiveCN103515063AGuaranteed electrical performanceStable structureTransformers/inductances coils/windings/connectionsTransformerTransverse plane

The invention relates to a shell type transformer lead clamping structure and clamping method, and belongs to the technical field of transformers. According to the technical scheme, a first fixing plate and a second fixing plate are welded to a box cover, one end of each first supporting plate and one end of each second supporting plate are fixedly connected with the first fixing plate and the second fixing plate respectively, the other end of each first supporting plate and the other end of each second supporting plate are fixedly connected with the two ends of transverse plates respectively, a lead passes through a circular hole formed by matching two semicircular holes which are formed in a first lead clamping plate and a second lead clamping plate, the first lead clamping plate and the second lead clamping plate are fixed to the middle of the transverse plates respectively, the other end of the first lead clamping plate and the other end of the second lead clamping plate are fixed together through a lead fixing plate, and the shell type transformer lead is clamped and fixed. According to the clamping structure and clamping method, the supporting plates and the transverse plates are connected vertically and horizontally, the lead is firmly fixed by the semicircular holes of the lead clamping plates, on the premise that shell type transformer lead meets the insulation distance, the clamping structure is simple in structure, reliable in fixation and convenient to operate, the lead is lengthened to electric creep distance of the box cover to the maximum extent, and performance of products is guaranteed.

Owner:BAODING BAOLING TRANSFORMER

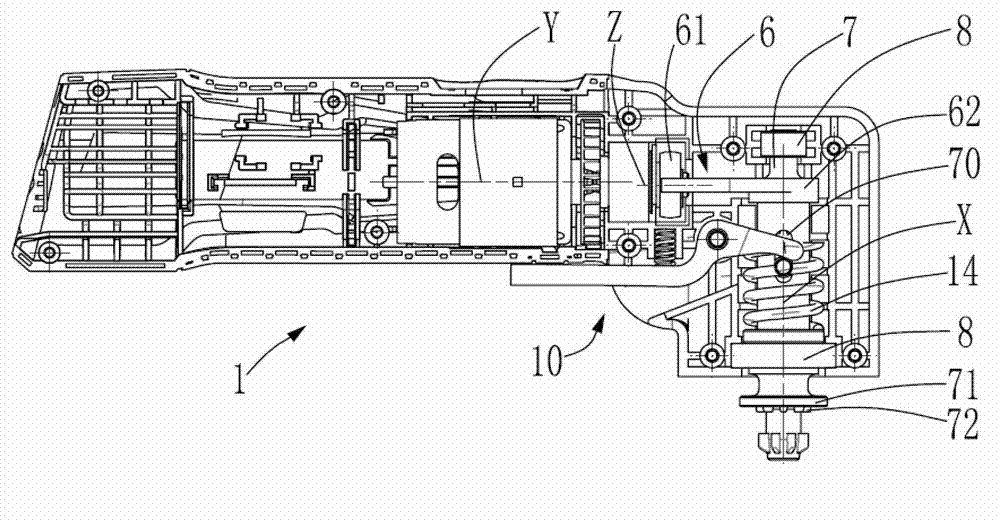

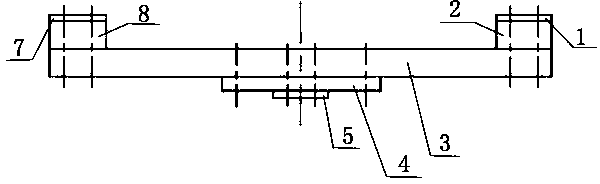

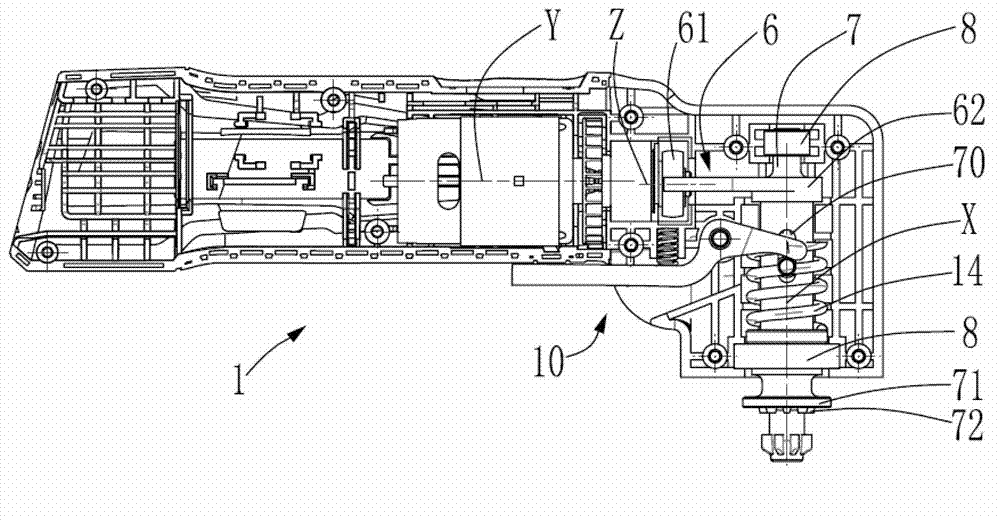

Guide wire controller for interventional operation robot and control method of interventional operation robot

ActiveCN107550570ASimple clamping structureSimple combinationDiagnosticsSurgical robotsEngineeringGuide wires

The invention discloses a guide wire controller for an interventional operation robot and a control method of the interventional operation robot, and belongs to the technical field of minimally invasive vascular interventional operations. The controller comprises a basal part as well as a guide wire clamping mechanism and a clamping switching mechanism which are arranged on the basal part, whereinthe guide wire clamping mechanism is used for clamping a guide wire; the clamping switching mechanism is used for driving the guide wire clamping mechanism to loosen clamping on the guide wire; the guide wire clamping mechanism comprises a guide wire locking sleeve, a guide wire locking rod and a guide wire locker; one end of the guide wire locking rod is provided with the guide wire locker and is arranged into the guide wire locking sleeve; and the guide wire locker, which is squeezed by virtue of the guide wire locking rod, can clamp the guide wire. The guide wire controller provided by theinvention is simple in overall structure, and the guide wire controller, which adopts modular structure design, is simple and convenient in dismounting and mounting combination, compact in structure,light in overall weight and relatively low in manufacturing cost.

Owner:SHENZHEN INST OF ADVANCED BIOMEDICAL ROBOT CO LTD

Double-sided gas-assisted device for pulse laser welding of metal sheets

InactiveCN106862761AAccelerate the cooling rate of high temperatureImproved surface oxidation qualityLaser beam welding apparatusSurface oxidationMetal sheet

The invention relates to a double-sided gas-assisted device for pulse laser welding of metal sheets. The double-sided gas-assisted device comprises a base. A cavity used for containing the at least two to-be-welded metal sheets in a flatly-lied manner is formed in the base. A pulse laser beam is arranged above the slicing seam of every two adjacent metal sheets. A through groove is formed below the slicing seam of every two adjacent metal sheets. A gas inlet insert is arranged on the portion, at one ends of the through grooves, of the base. An upper gas inlet hole facing the upper surfaces of the metal sheets and a lower gas inlet hole facing the lower surfaces of the metal sheets are formed in the gas inlet insert. The double-sided gas-assisted device is simple and reasonable in structural design, the problems that in the prior art, it is difficult to control the welding size precision of the metal sheets, surface oxidation is severe, the energy consumption is high, efficiency is low and safety is low are solved, and the defects in the prior art are overcome.

Owner:FUZHOU UNIV

Chuck

ActiveCN104149074ASimple clamping structureSimple force transfer structurePortable power-driven toolsEngineeringMechanical engineering

Owner:POSITEC MACHINERY ZHANGJIAGANG

Pipe fitting stamping-necking die

InactiveCN107511425AReduce the possibility of deformationSimple clamping structureShaping toolsMetal-working feeding devicesEngineeringPipe fitting

The invention discloses a punching die for pipe fittings, which relates to the technical field of stamping dies, and comprises an upper die base and a lower die base, a support block is fixed on the lower die base, and a lower groove is provided on the upper surface of the support block; There is a sliding die, and the sliding die is slidably matched with the lower die base. One end of the sliding die facing the support block is provided with a shrinking cavity, and the other end is fixed to the fixing plate on the lower die base through the first spring; There is a wedge, and the opposite surfaces of the wedge and the sliding die are respectively an upper inclined surface and a lower inclined surface for sliding fit; the upper template is connected with a pressing block through a second spring, and the lower surface of the pressing block is provided with an upper concave opposite to the lower groove. groove. The invention solves the problems that the pipe fittings are easily deformed and the pipe fittings have a complicated clamping structure existing in the existing pipe fitting necking mold.

Owner:柳州劲胜科技有限公司

Sheet steel type theftproof label

ActiveCN101986357AEasy to holdSimple clamping structureBurglar alarm electric actuationSheet steelEngineering

The invention relates to a theftproof label with the characteristics of good theftproof performance and simple structure. The technical scheme is as follows: the label comprises a nail head and a nail clamping seat matched with a nail rod by clamping, wherein the nail rod overhangs and protrudes from the cap of the nail head; a rod clamping mechanism and a circuit coil are arranged in the nail clamping seat; the top end of the shell of the nail clamping seat is provided with a hole; and the nail rod penetrates through the hole downwards to enter into the nail clamping seat to be clamped, pressed and fixed by the rod clamping mechanism. The label is characterized in that a plurality of circles of grooves surrounding the outer circumference surface are arranged on the nail rod; the grooves are separated by certain space; the rod clamping mechanism comprises two sheet steel which is arranged in the form of double doors and can respectively rotate; the sides of the seam crossing of the two sheet steel are provided with semi-circular nicks; a locating piece which limits the sheet steel in the horizontal folding states and allows the sheet steel to rotate below the horizontal plane is arranged above the sheet steel; and a spring which pushes the sheet steel upwards so as to fold the two sheet steel is arranged below the two sheet steel.

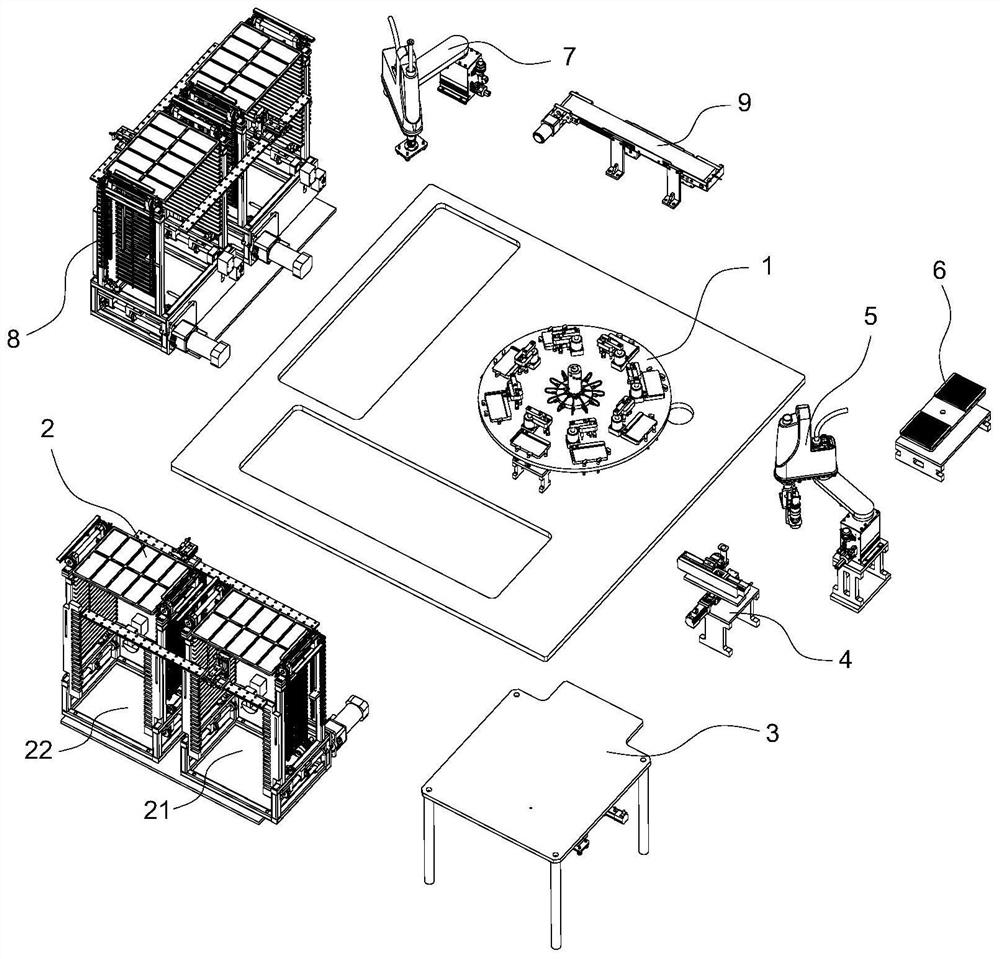

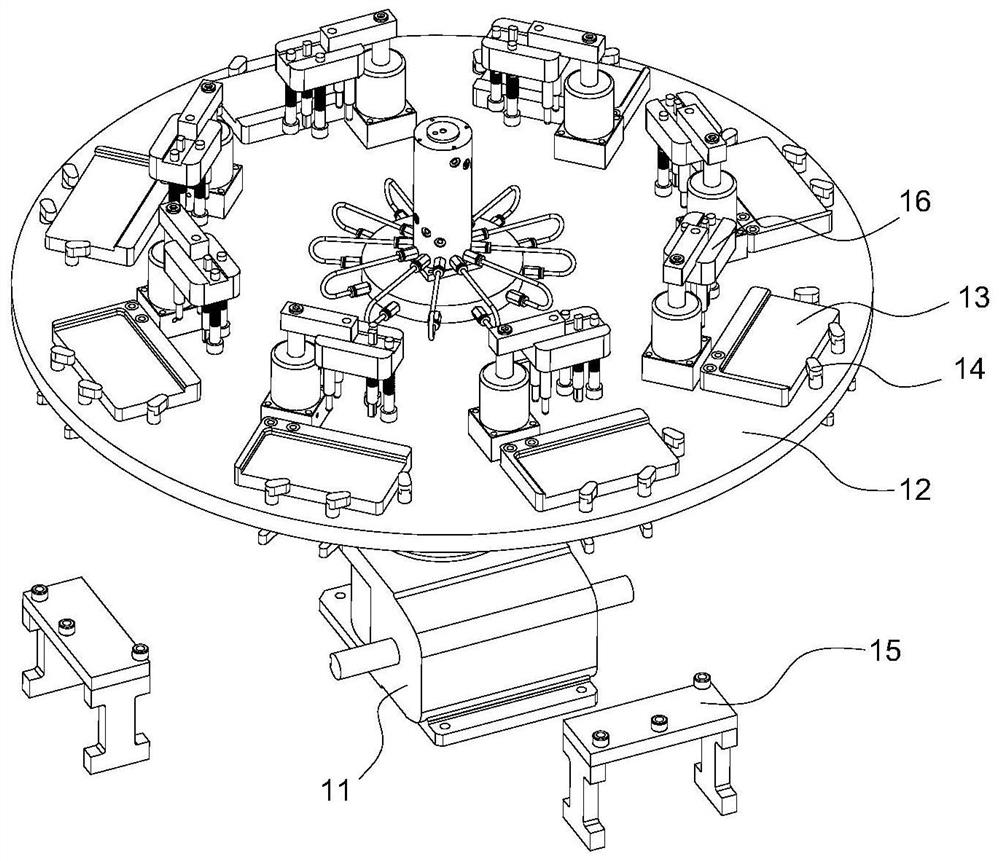

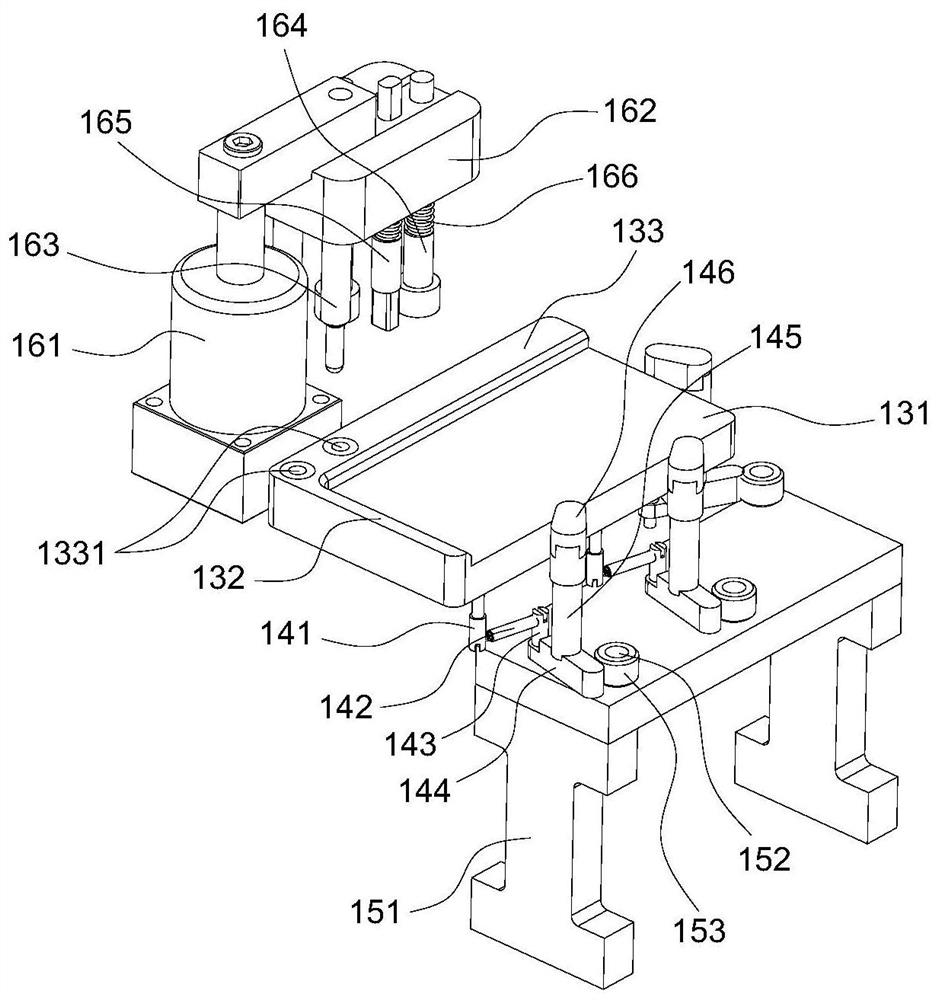

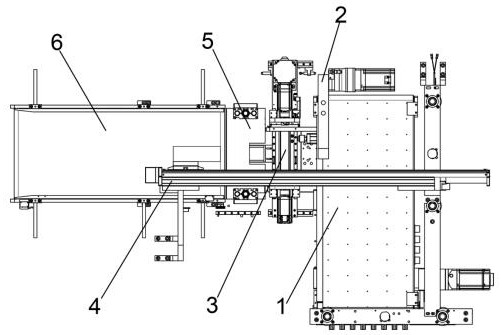

Camera module assembling equipment and assembling process thereof

ActiveCN112828589ARealize fully automatic assemblySave human effortAssembly machinesEngineeringCamera module

The invention relates to the field of automatic assembly, in particular to camera module assembly equipment and a process thereof, especially mobile phones, tablet personal computers, telephone watches and the like. The equipment comprises a rack as well as a turntable assembling device, a feeding bin, a transferring device, a dispensing device, a camera module feeding device, a robot grabbing and feeding device, a robot grabbing and discharging device, a qualified product bin and an unqualified product discharging device which are mounted on the rack, wherein a feeding station, a dispensing station, a camera module assembling station, a pressing station and a discharging station are sequentially arranged on the turntable assembling device; the upper part of the feeding bin is connected with the transferring device; the position of the transferring device is matched with the feeding station; the position of the dispensing device is matched with the dispensing station; the camera module feeding device is located on one side of the robot grabbing and feeding device; the position of the robot grabbing and feeding device is matched with the camera module assembling station; and the position of the robot grabbing and discharging device is matched with the discharging station. The camera module assembly equipment provided by the invention adopts a rotating disc type layout, so that the assembling efficiency is improved.

Owner:广西兴宇智能科技有限公司

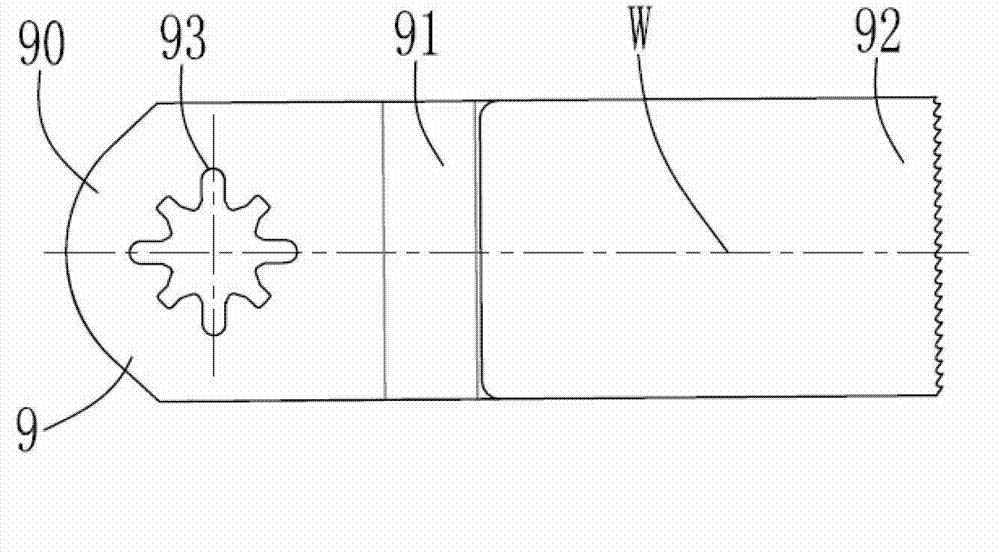

Accessory clamping mechanism and power tool with same

ActiveCN103170955AImprove versatilityEliminate hidden dangersPortable power-driven toolsPower toolFlange

The invention discloses an accessory clamping mechanism which is used for clamping an accessory on the flange of the working arbor of a power tool, and the working arbor is provided with a first longitudinal axis. The accessory clamping mechanism comprises a fastening flange, a driving component used for enabling the fastening flange to move between a releasing position and a clamping position, a push component connected with the fastening flange and a first elastic piece. The driving component comprises a pivot arranged on the shell body of the power tool and a driving piece pivoting between a first position and a second position around the pivot. On the first position, the fastening flange is arranged on the clamping position, and the accessory is clamped between a mandril flange and the fastening flange. On the second position, the fastening flange is arranged on the releasing position, and the accessory can be taken out between the mandril flange and the fastening flange. The fastening flange is pressed towards the clamping position through the first elastic piece, and the pivot is arranged between the user operating part of the driving piece and the first longitudinal axis. The invention further provides a power tool with the accessory clamping mechanism.

Owner:NANJING CHERVON IND

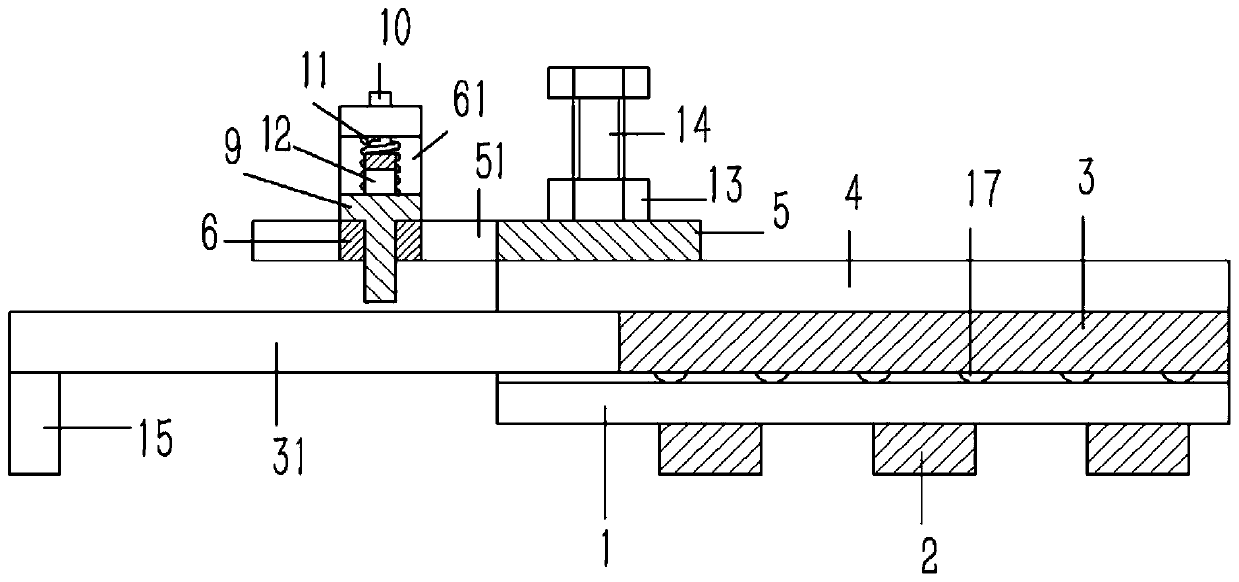

Automated wooden comb processing device

The invention discloses an automated wooden comb processing device. The automated wooden comb processing device comprises a workbench, a work station, a slide rail and a machine tool, wherein the machine tool is used for conducting punching operation on the work station. One end of the slide rail is connected with the machine tool, and the other end of the slide rail extends to the side of the workbench. The work station can move on the slide rail in a reciprocating manner. The work station comprises a slide sleeve, a connection portion, a locating plate body, a finished product collection plate body and a punching component, wherein the slide sleeve is matched with the slide rail; the connection portion is connected to the slide sleeve in an overturnable manner; the locating plate body is fixedly arranged on the connection portion; the finished product collection plate body is detachably connected to one side of the locating plate body; and the punching component is arranged at the other side of the locating plate body. By means of the automated wooden comb processing device, traditional manual assembling is abandoned; automated punching operation is adopted for assembling a comb; comb assembling efficiency is greatly improved; meanwhile, firmness of the comb is improved; and product performance is more stable.

Owner:浙江景宁华寅工艺品有限公司

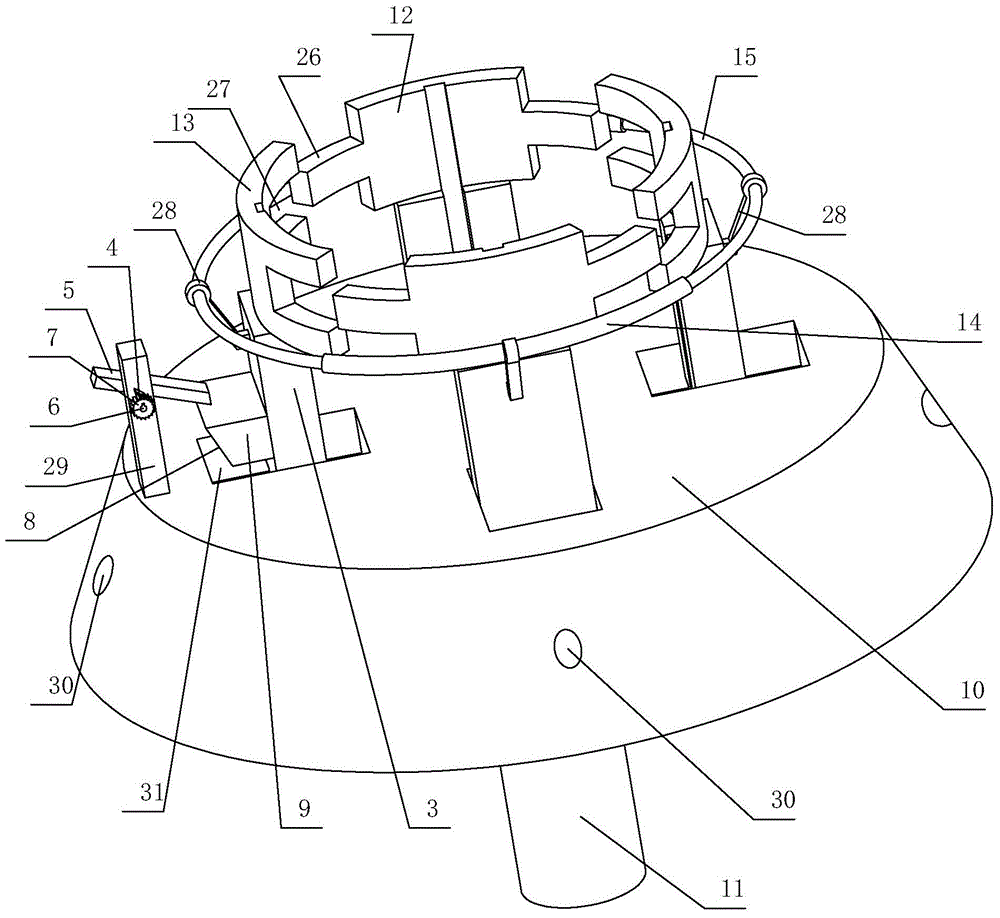

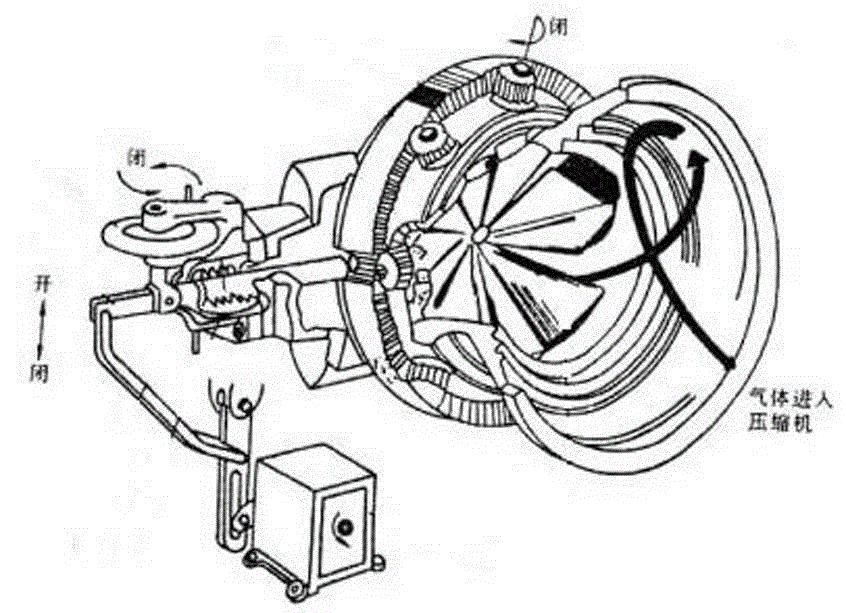

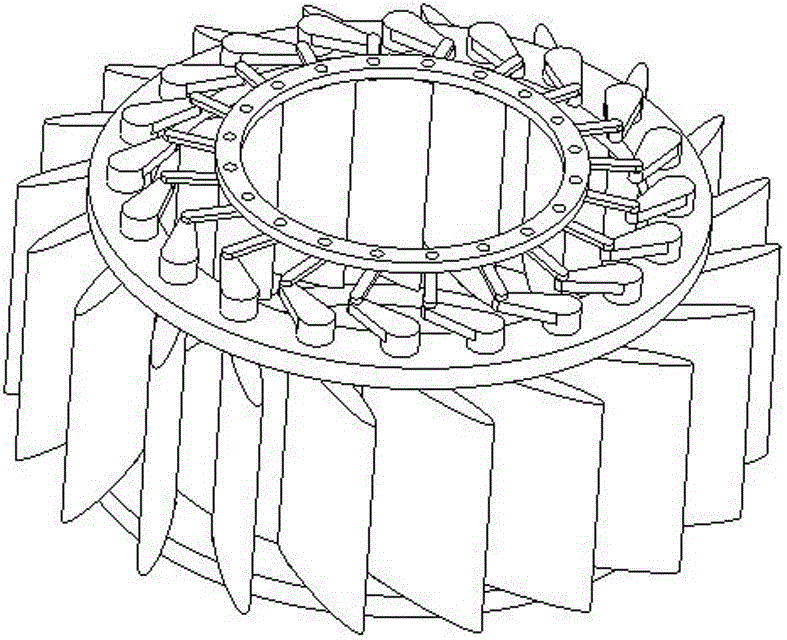

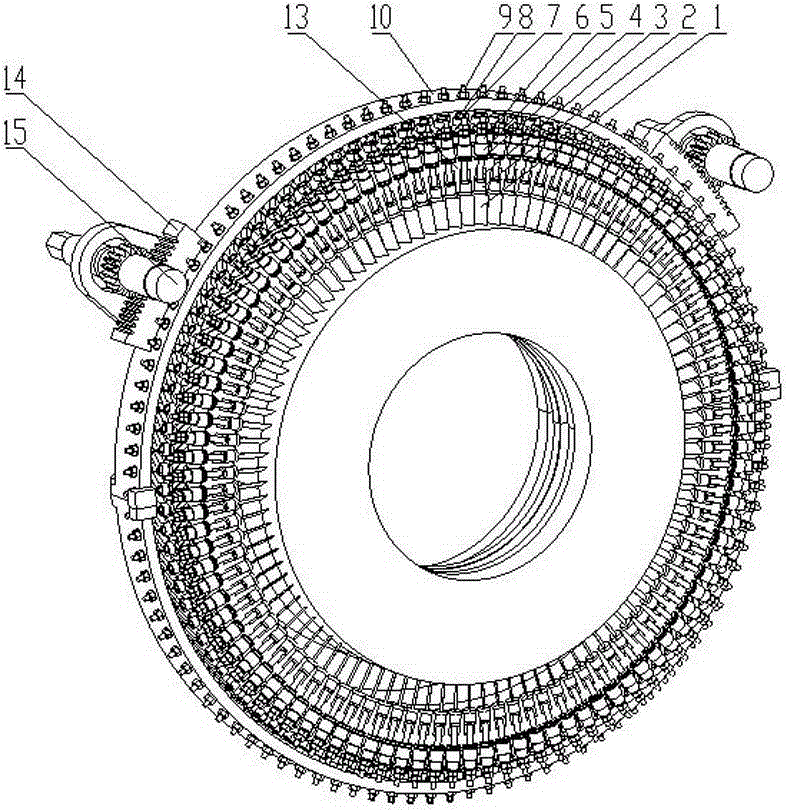

Synchronous transmission mechanism for air inlet guide vanes of axial flow air compressor

ActiveCN104632702AMany solutionsSolve space problemsPump componentsPumpsLocking mechanismEngineering

The invention provides a synchronous transmission mechanism for air inlet guide vanes of an axial flow air compressor. The synchronous transmission mechanism comprises a rotary disc, two stages of rotating rods and guide plates of the two stages of rotating rods. The section of the rotary disc is in an inverted-L shape, the bottom ring of the rotary disc is attached to and arranged on the periphery of a cylinder at the front ends of the air inlet guide vanes in a sleeving mode, and the tail end of a rotating ring is fixedly connected with the front end of the first stage of rotating rod. The tail end of the first stage of rotating rod is connected with the front end of the first stage of guide plate through a rotary pair, and the tail end of the first stage of guide plate is connected with the front end of the second stage of rotating rod through a rotary pair. The tail end of the second stage of rotating rod is connected with the front end of the second stage of guide plate, and the tail end of the second stage of guide plate is connected with the rotating shaft parts of the air inlet guide vanes through a rotary pair. The rotary disc is driven by a guide vane driving unit arranged in the axial flow air compressor to rotate. The synchronous transmission mechanism can be used for a structure small in installation space and large in number of guide vanes, and it is achieved that the whole circle of guide vanes synchronously rotate with high precision in a large range; the guide vanes are pretightened though an elastic pretightening device, the structure can be conveniently adjusted, and the precision of the mechanism can be further improved; a locking mechanism is simple in structure and relatively high in precision.

Owner:DONGFANG TURBINE CO LTD

Mop dewatering device

InactiveCN105996930AEasy clampingEasy to cleanCarpet cleanersFloor cleanersRound tableClamp connection

The invention discloses a mop dewatering device which comprises a motor (10), a supporting base (15), a connection support base (9), a round table (8), a mop rod clamping device, a mop head clamping device and a mop head clamping driving device. The mop head clamping driving device comprises a pressing block (7), a gear (5) and an elastic piece (6), one end of the pressing block (7) is fixedly connected with the mop head clamping device in the vertical direction, the side wall of the other end of the pressing block (7) is an inclined face (4), the gear (5) is rotationally connected to the round table (8), one end of the elastic piece (6) is hinged to the round table (8), the other end of the elastic piece (6) is in clamped connection with a gear groove of the gear (5), and the inclined face (4) is a gear face meshed with the gear (5). By the adoption of the structure, work noise is greatly lowered, a mop can be wrung drier, and the ground can be cleaned more conveniently. Besides, meshing transmission of the gear inclined face on the pressing block and the gear is adopted in the mop head clamping driving device, the structure is simple, and operation is convenient.

Owner:陈铭鸿

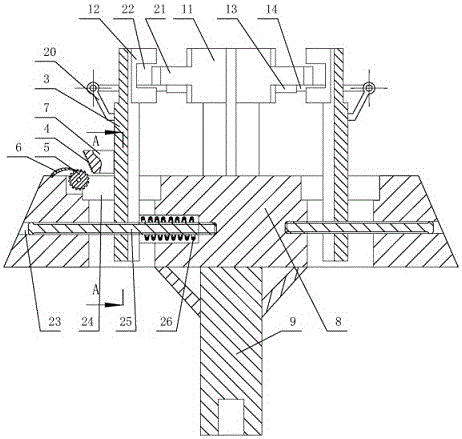

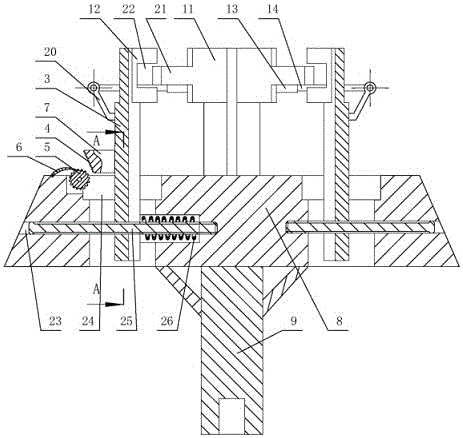

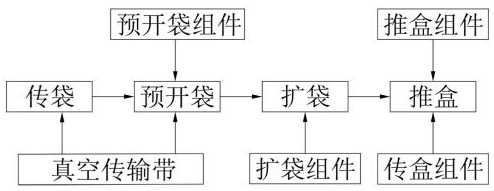

Novel bag expanding and box packaging process

InactiveCN111977081ASimple clamping structureAvoid displacementPackagingEngineeringMechanical engineering

The invention provides a novel bag expanding and box packaging process. The process comprises the steps that (1) a packaging bag is conveyed or placed on a vacuum conveying belt, and the packaging bagand the vacuum conveying belt are in synchronous transmission; (2) a bag pre-opening assembly opens a bag opening of the packaging bag to form an opening or a gap; (3) a bag expanding assembly entersthe pre-opening of the packaging bag to completely expand the bag opening of the packaging bag to be rectangular; and (4) a box pushing assembly pushes a packaging body into the packaging bag. The packaging bag is conveyed after being adsorbed and fixed through the vacuum conveying belt, the clamping structure of the packaging bag is simplified, and the packaging bag can be prevented from shifting in the conveying process; the packaging bag is pre-opened through the vacuum conveying belt and a bag pre-opening rotary arm, the step that a bag opening suction nozzle adsorbs the packaging bag isomitted, and the bag pre-opening rotary arm starts to reset while the bag is pre-opened; after a bag expanding piece stretches into the bag pre-opening, the packaging bag is expanded outwards, the bagclamping step of a bag opening film clamp is omitted, and the bag expanding procedure is simplified; and a box pushing mechanism is installed in a machine, the occupied space of the machine is reduced, and all structures in the machine are more compact.

Owner:深圳永创智能设备有限公司

Clamping platform on ceramic cutting machine

InactiveCN111168863ASimple clamping structureWorking accessoriesStone-like material working toolsScrew jointManufacturing engineering

The invention discloses a clamping platform on a ceramic cutting machine. The clamping platform comprises two sets of longitudinal L-shaped side brackets; the side brackets are composed of vertical parts and horizontal parts; a plurality of transverse bottom rods are fixedly connected to the lower end surface of each side bracket; a sliding platform is arranged between the side brackets, and is propped against the horizontal parts of the side brackets; limiting barrier strips are propped against the upper end surface of the sliding platform, and are fixed on the vertical parts of the corresponding side brackets; a transverse positioning plate is fixedly connected to the upper end surfaces of the rear ends of the side brackets; a plurality of clamping bolts are inserted into the positioningplate, and are in screw joint onto fixed nuts; and the fixed nuts are fixed on the positioning plate.

Owner:苏州哲思达智能设备科技有限公司

Structure of valve sleeve turning fixture

ActiveCN107984277AImprove processing qualityFor direct clampingPositioning apparatusMetal-working holdersStress pointEngineering

The invention discloses a structure of a valve sleeve turning fixture. The structure comprises a positioning sleeve, a clamping head and a clamping drive mechanism, wherein one end of the positioningsleeve is fixedly connected onto a clamp body, a bulge part is arranged axially at the other end of the positioning sleeve, the bulge part of the positioning sleeve is correspondingly matched with a step part of the end surface of a straight-port structure of the valve body, and a groove is formed in the end surface of a clamping head; when the valve body is clamped, the bulge part of the valve body is located in the groove, and the stress point of the clamping head for clamping the valve body is positioned on the valve body end surface on the periphery of the bulge part. According to structural design of the positioning sleeve and the clamping head which are located at two ends of the valve body, effective positioning is formed by the positioning sleeve and a straight port of the valve body, the groove in the end surface of the clamping head is used for preventing the bulge part at the end of the valve body from being damaged by clamping, two ends of the valve body are directly clamped by the positioning sleeve and the clamping head, and the clamping process is greatly simplified; moreover, the clamping structure is simple, positioning accuracy is high, and valve sleeve turning quality is effectively improved.

Owner:MEISHAN CRRC BRAKE SCI & TECH CO LTD

Mop dehydration device

The invention discloses a mop dehydration device which comprises a motor (10), a support base (15), a connecting support (9), a round table (8), a mop rod clamping device, a mop head clamping device and a mop head clamp driving device, wherein the mop head clamp driving device comprises a pressing block (7), a gear wheel (5) and a spring piece (6); one end of the pressing block (7) is fixedly connected to the mop head clamping device in the vertical direction; the side wall of the other end of the pressing block (7) is an inclined surface (4); the gear wheel (5) is rotationally connected onto the round table (8); one end of the spring piece (6)is hinged to the round table (8), and the other end of the spring piece (6) is buckled with a tooth groove of the gear wheel (5); the inclined surface (4) is a tooth surface meshed with the gear wheel (5). Through adoption of the mop dehydration device, the operation noise is reduced greatly, and the mop can be better to be wrung out, so as to be more conducive to floor cleaning; in addition, the mop head clamp driving device adopts a structure of meshed transmission between the inclined tooth surface on the pressing block and the gear wheel, so that the mop head clamp driving device is simple in structure and convenient to operate.

Owner:菏泽智慧新材料科技有限公司

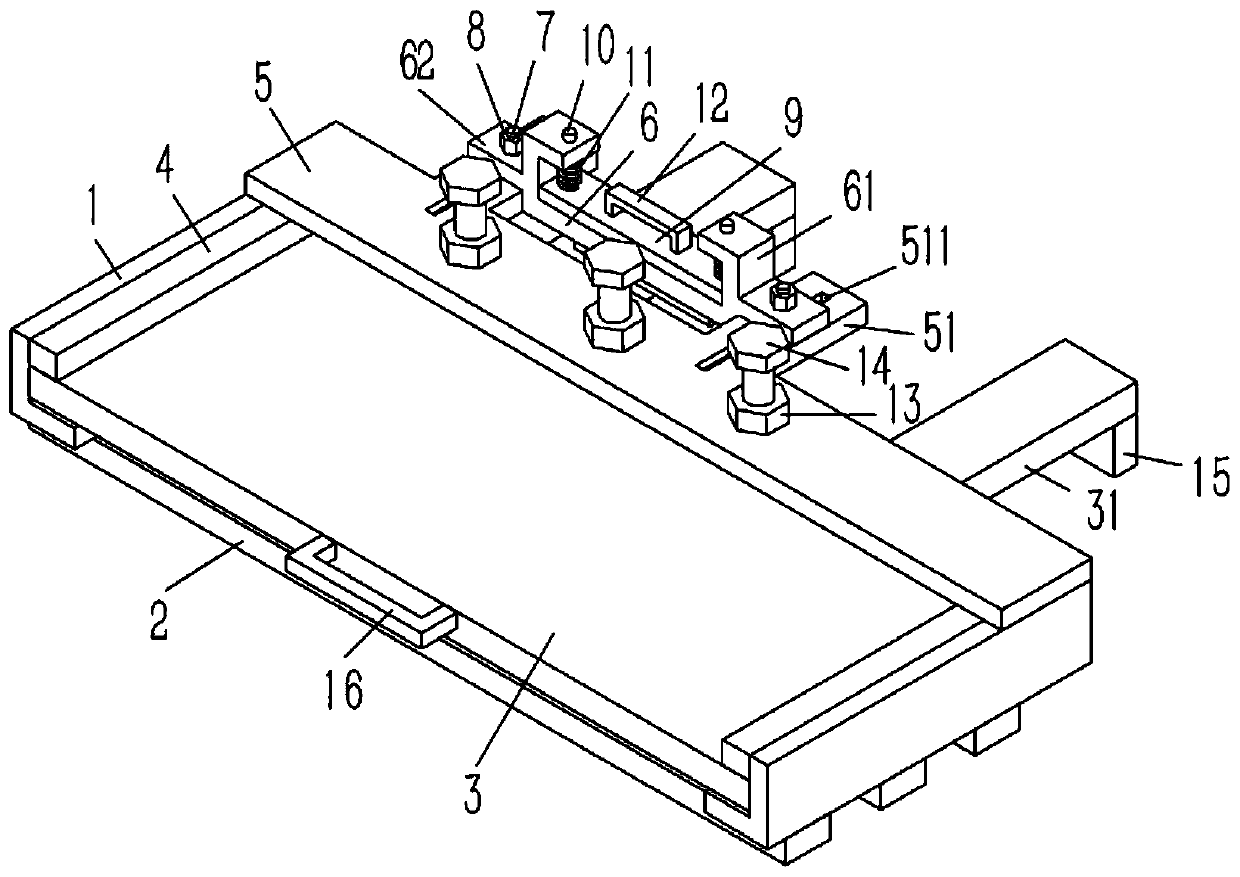

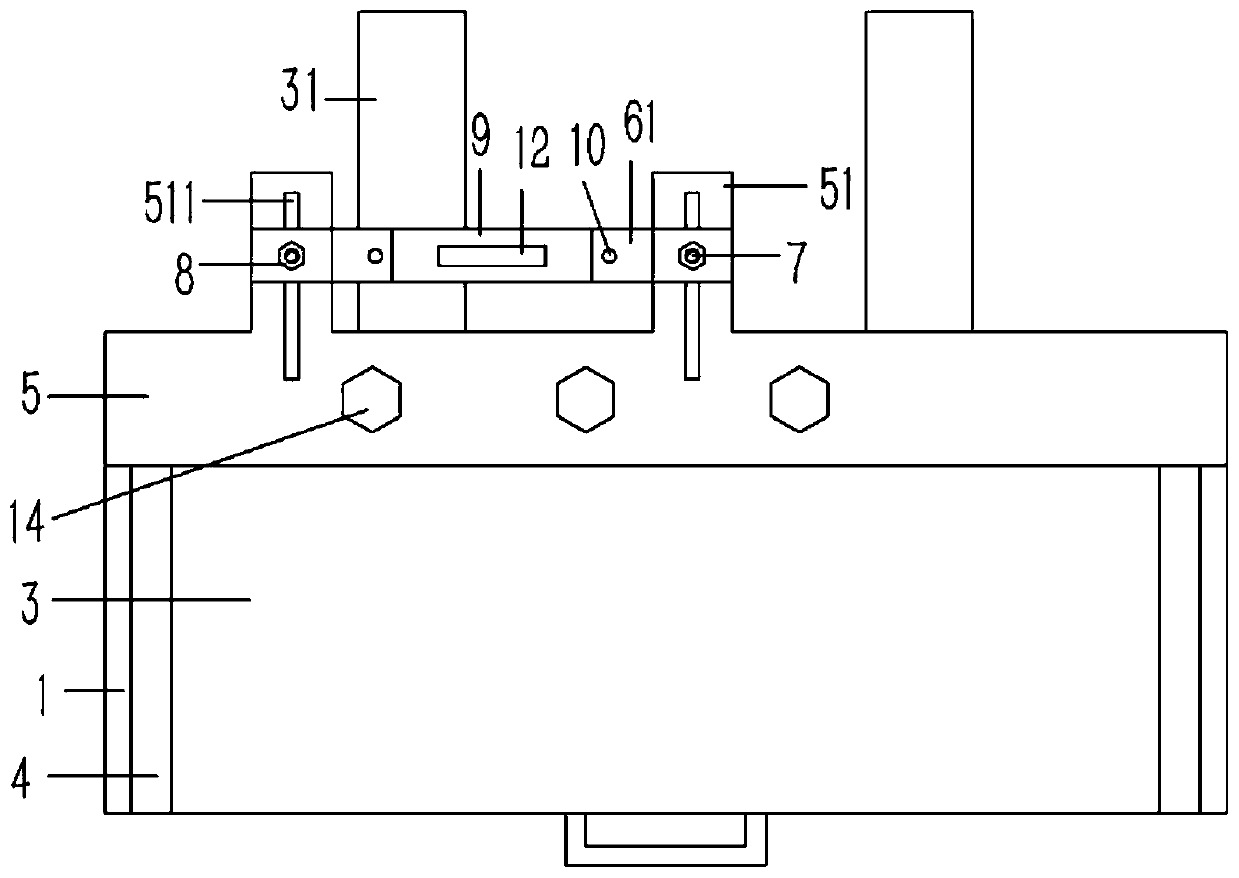

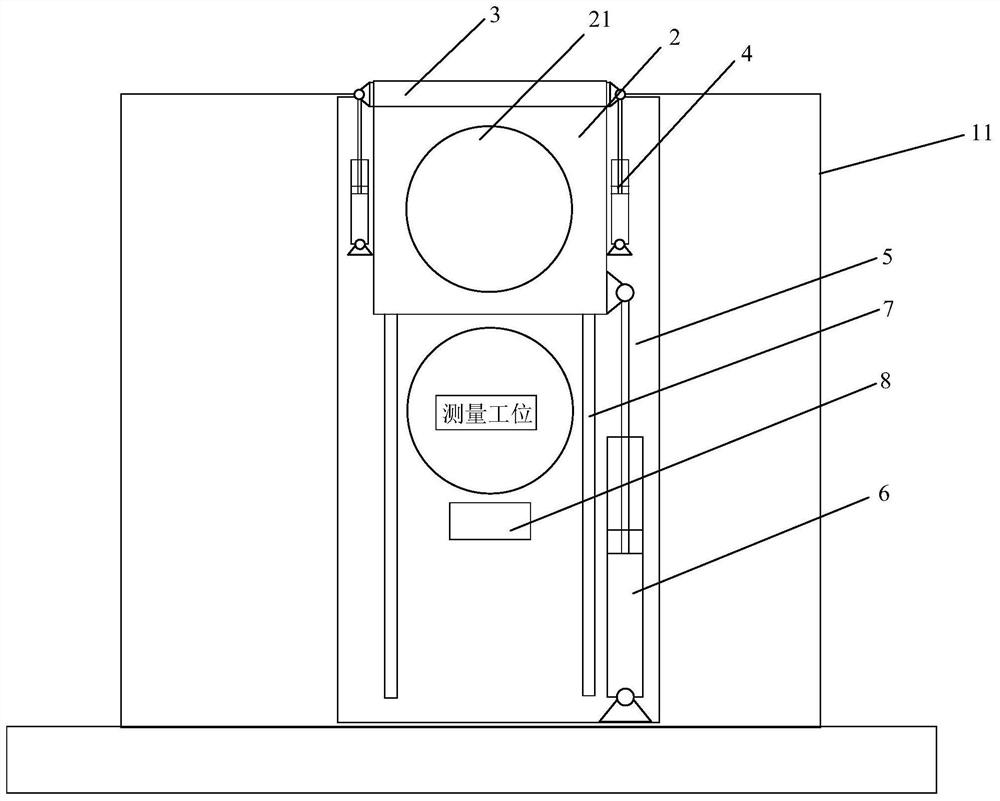

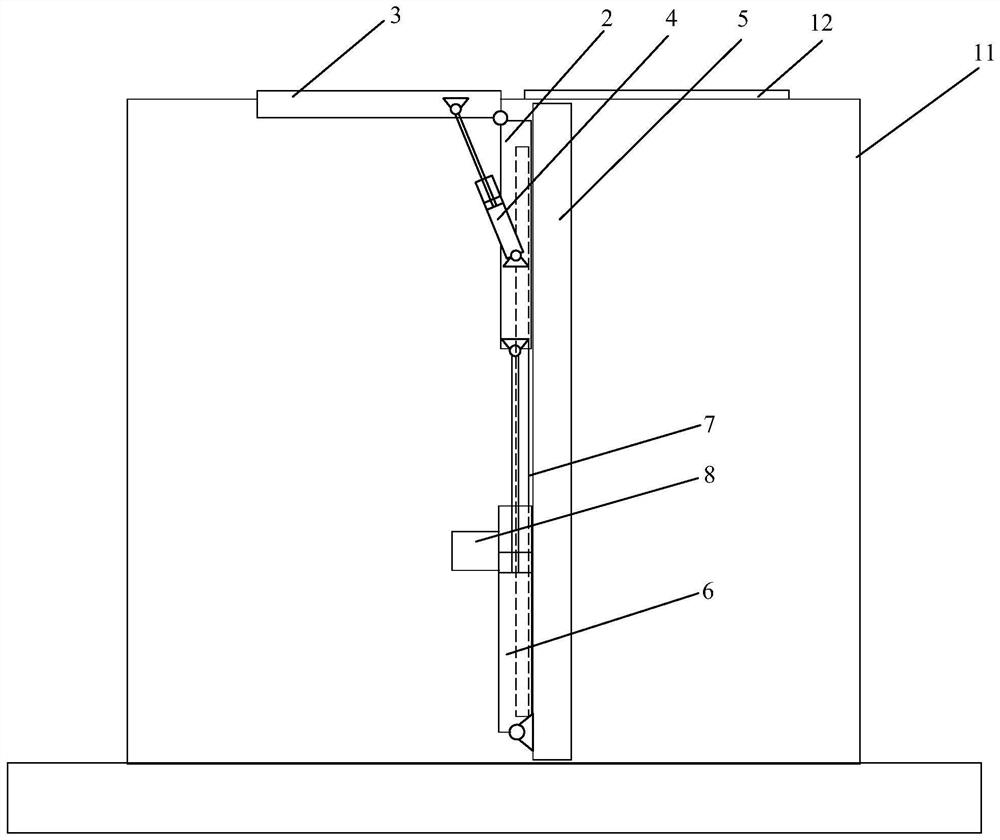

Substrate bearing device and detection device

PendingCN111816603ASimple clamping structureReduce the difficulty of positioningSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringManipulator

The invention relates to the technical field of substrate detection, and discloses a substrate bearing device and a detection device. The substrate bearing device comprises a cavity, a mounting plateand a carrying table, wherein an opening is formed in the top part of the cavity; the mounting plate is arranged in the cavity; the carrying table is used for clamping a substrate; the carrying tableis in running fit with the mounting plate; and the carrying table can be selectively overturned to a horizontal posture and at least partially protrudes out of the cavity from the opening, or overturned to a vertical posture and completely contained in the cavity. The substrate bearing device is simple in structure, can conveniently and accurately hand over the substrate to a manipulator, and canmeasure the vertical posture of the substrate. The detection device provided by the invention comprises the substrate bearing device, and can conveniently and accurately transfer the substrate to themanipulator through using the substrate bearing device.

Owner:SHANGHAI PRECISION MEASUREMENT SEMICON TECH INC

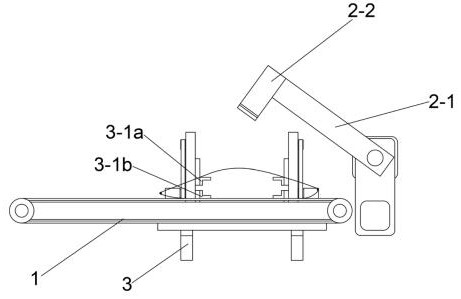

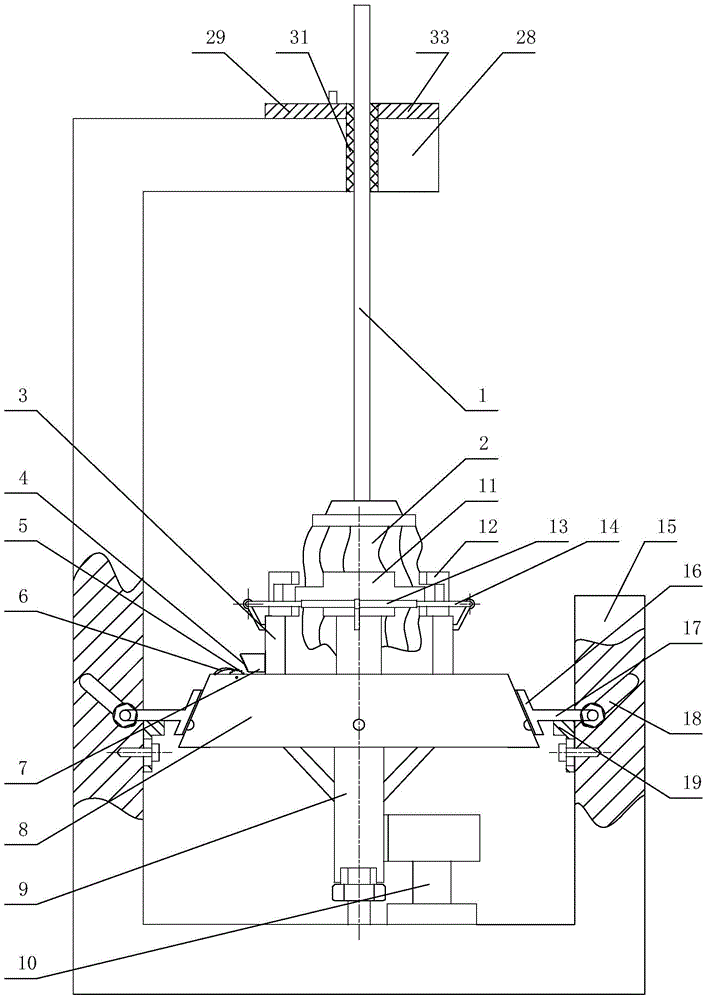

Automatic book scanner and control method

PendingCN111385432AAdjust the clamping angleAccurate rubbingPictoral communicationComputer hardwareComputer graphics (images)

The invention discloses an automatic book scanner and a control method. The automatic book scanner comprises a supporting assembly, a positioner, a page rubbing device, two pressing devices, a camera,an angle adjuster, a page turning device and a controller, wherein the controller is electrically connected with the angle adjuster, the positioner, the page rubbing device, the page turning device,the pressing devices and the camera.

Owner:广州鑫至简科技有限公司

Electric shockproof hammer convenient to install

ActiveCN113328403ASimplify the installation processSimple clamping structureDevices for damping mechanical oscillationsPower cableClassical mechanics

The invention discloses an electric stockbridge hammer convenient to install. The electric stockbridge hammer comprises: a wire clamp unit which comprises a wire clamp hook and an arc-shaped clamping plate cooperatively connected with the wire clamp hook, wherein the wire clamp hook is internally provided with a limiting fastener, and the limiting fastener is connected with the side wall of the arc-shaped clamping plate; a connecting unit arranged at the bottom of the wire clamp hook and comprising a connecting shell and a connecting assembly arranged in the connecting shell; and hammerhead units which are symmetrically arranged on the two sides of the connecting unit, wherein each hammerhead unit comprises a first connecting rod, a second connecting rod and hammerheads arranged at the ends of the two connecting rods. The wire clamp unit is of a movable clamping structure, a movable arc-shaped clamping plate of the wire clamp unit is driven by the connecting unit, and the driving force of the connecting unit comes from the deflection effect when the hammer head is placed; and when the hammerheads are placed from a vertical state to a horizontal state, the connecting rod bodies of the hammer heads push the driving rod to move upwards so as to push the arc-shaped clamping plate to be inserted into the wire clamp hook, and the arc-shaped clamping plate and the wire clamp hook are clamped on a power cable together, so that a stable clamping structure is formed.

Owner:GUIZHOU POWER GRID CO LTD

Anti-toppling wireless charging type simple stamping machine

The invention belongs to an anti-toppling wireless charging type simple stamping machine. A wireless charging module, a power storage module, a control module, a motor driving module and a photoelectric switch module are arranged in a base, and the bottom of the base is provided with a movable sucker; a cam mechanism is arranged on the upper portion of a support, and the lower end of a connectingrod is fixedly connected with an L-shaped fixing frame; and a sliding frame matched with the fixing frame and a fixing bolt form a simple and practical clamping structure. The wireless charging moduleand the cam structure are applied, the seal clamping structure is improved, so that the effects of reducing the size, being convenient to use and compact in clamping are achieved, and the stamping machine is prevented from being limited by a power socket; the purposes that the multi-occasion application is carried out and the cost is low are achieved, the structure is simple, and the operation iseasier; and the self structure has the function of preventing a seal from turning over, and the special design of the base can prevent the machine from toppling over when the machine works.

Owner:XIAN XINGUIXI INFORMATION TECH CO LTD

mop dehydrator

The invention discloses a mop dehydration device which comprises a motor (10), a support base (15), a connecting support (9), a round table (8), a mop rod clamping device, a mop head clamping device and a mop head clamp driving device, wherein the mop head clamp driving device comprises a pressing block (7), a gear wheel (5) and a spring piece (6); one end of the pressing block (7) is fixedly connected to the mop head clamping device in the vertical direction; the side wall of the other end of the pressing block (7) is an inclined surface (4); the gear wheel (5) is rotationally connected onto the round table (8); one end of the spring piece (6)is hinged to the round table (8), and the other end of the spring piece (6) is buckled with a tooth groove of the gear wheel (5); the inclined surface (4) is a tooth surface meshed with the gear wheel (5). Through adoption of the mop dehydration device, the operation noise is reduced greatly, and the mop can be better to be wrung out, so as to be more conducive to floor cleaning; in addition, the mop head clamp driving device adopts a structure of meshed transmission between the inclined tooth surface on the pressing block and the gear wheel, so that the mop head clamp driving device is simple in structure and convenient to operate.

Owner:菏泽智慧新材料科技有限公司

Mop to water device

The invention discloses a mop dehydration device which comprises a motor (20), a support base (15), a connecting support (10), a round table (9), a mop rod clamping device, a mop head clamping device and a mop head clamp driving device, wherein the mop head clamp driving device comprises a pressing block (8), a pressing lever (5), a ratchet wheel (7) and a pawl (4); the pressing block (8) is connected with the mop head clamping device in a sliding manner in the vertical direction and buckled with the mop head clamping device in the horizontal direction; one end of the pressing lever (5) is compressed to the upper end surface of the pressing block (8); the ratchet wheel (7) is fixedly connected onto a pin shaft (6); one end of the pawl (4) is hinged to a vertical column (28), and the other end of the pawl (4) is buckled with the ratchet wheel (7). Through adoption of the mop dehydration device, the operation noise is reduced greatly, and the mop can be better to be wrung out, so as to be more conducive to floor cleaning; in addition, the mop head clamping device is simple in structure and convenient to operate.

Owner:南通东湖国际商务服务有限公司

Device and method for producing roll paper

The invention discloses a device for producing roll paper. The device comprises a connecting frame and a control device. A movable plate is arranged at an end of the L-shaped connecting frame, a hingeis arranged between the movable plate and the connecting frame, the movable plate and the connecting frame are fixedly connected with two hinge plates of the hinge, the movable plate and the connecting frame are hinged and connected to each other by the hinge, an encoder is arranged on a side surface of the movable plate, a groove which is matched with an input shaft of the encoder is formed in the movable plate, a semicircular connector is arranged at the tail end of the input shaft of the encoder, a disc type motor is arranged on a side surface of the connecting frame, a through hole whichis matched with an output shaft of the disc type motor is formed in the side surface of the connecting frame, the disc type motor is fixedly connected with the connecting frame, the tail end of the output shaft of the disc type motor penetrates the through hole, a rotary shaft is connected with the tail end of the output shaft of the disc type motor, and the disc type motor is in linkage with therotary shaft. The device for producing the roll paper has the advantage of small volume.

Owner:DONGGUAN BAITIANE PAPER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com