Accessory clamping mechanism and power tool with same

A technology of clamping mechanism and power tool, which is applied in the direction of manufacturing tools and portable motorized devices, and can solve the problems of reducing the versatility of the accessory clamping mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

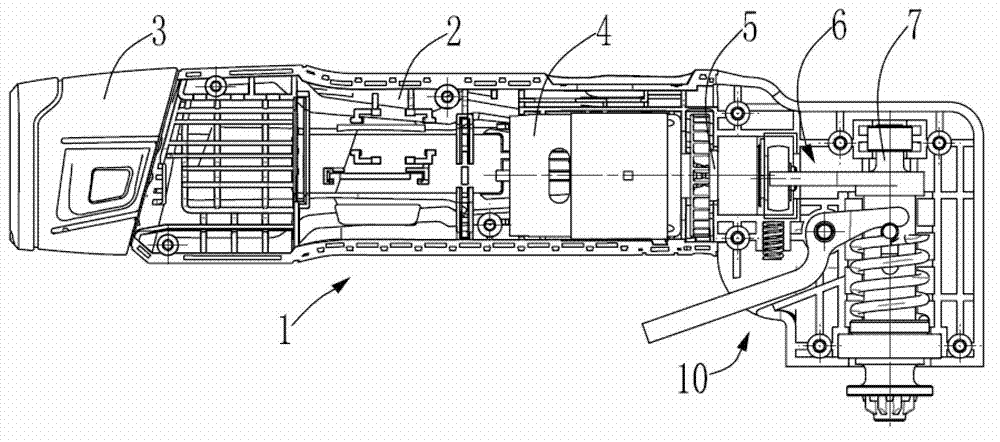

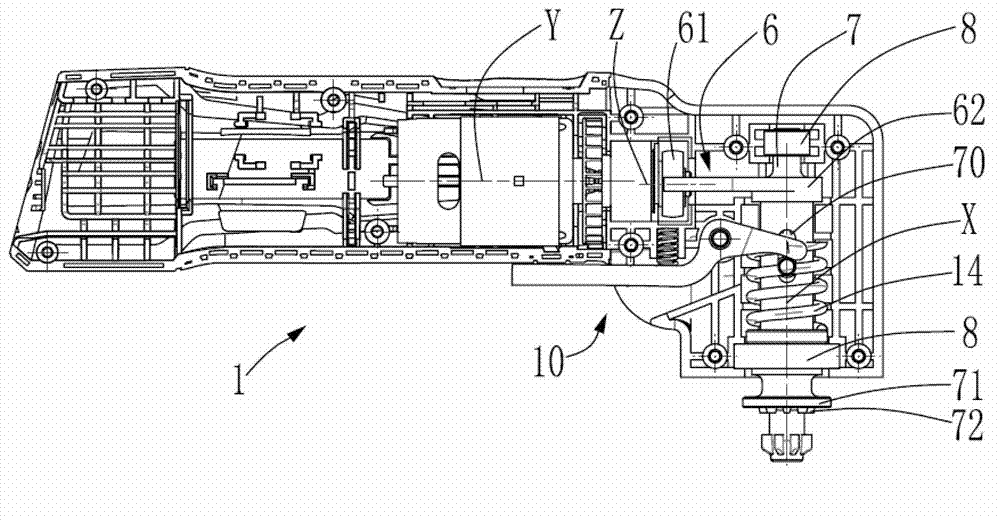

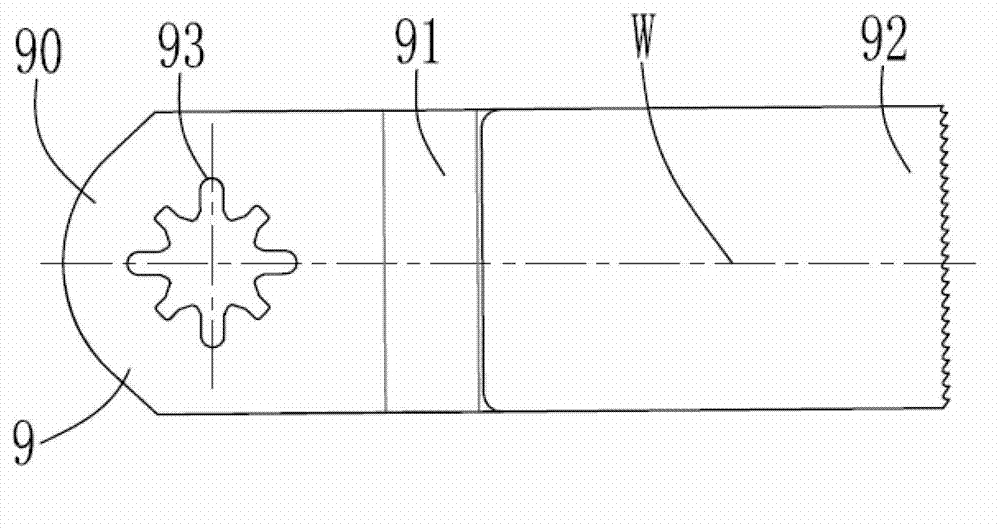

[0031] Such as Figure 1-2 As shown, a power tool 1 with an accessory clamping mechanism is disclosed in the first embodiment of the present invention. In this embodiment, an oscillating power tool is taken as an example for illustration. Those skilled in the art can understand that the accessory The clamping mechanism can also be used for other power tools such as angle grinders, sanders, and circular saws. The power tool 1 includes a housing 2 , a power source 3 connected to the housing 2 , a motor 4 and a drive shaft 5 accommodated in the housing 2 , a transmission mechanism 6 , a working spindle 7 and an accessory clamping mechanism 10 .

[0032]The power source 3 provides power to the motor 4. It can be understood that the power source 3 can be a power source known to those skilled in the art such as a battery pack, an AC power supply, an air compressor or a mobile power supply. The drive shaft 5 is driven by the motor 4 and is rotatable about its axis of rotation Y (sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com