Camera module assembling equipment and assembling process thereof

A camera module and assembly equipment technology, which is applied in the field of telephone watches, tablets, camera module assembly equipment and its technology, and mobile phones, can solve problems such as low assembly efficiency, low clamping efficiency, and complex clamping structure, and achieve improved The effect of assembly efficiency, simple clamping structure and fast clamping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

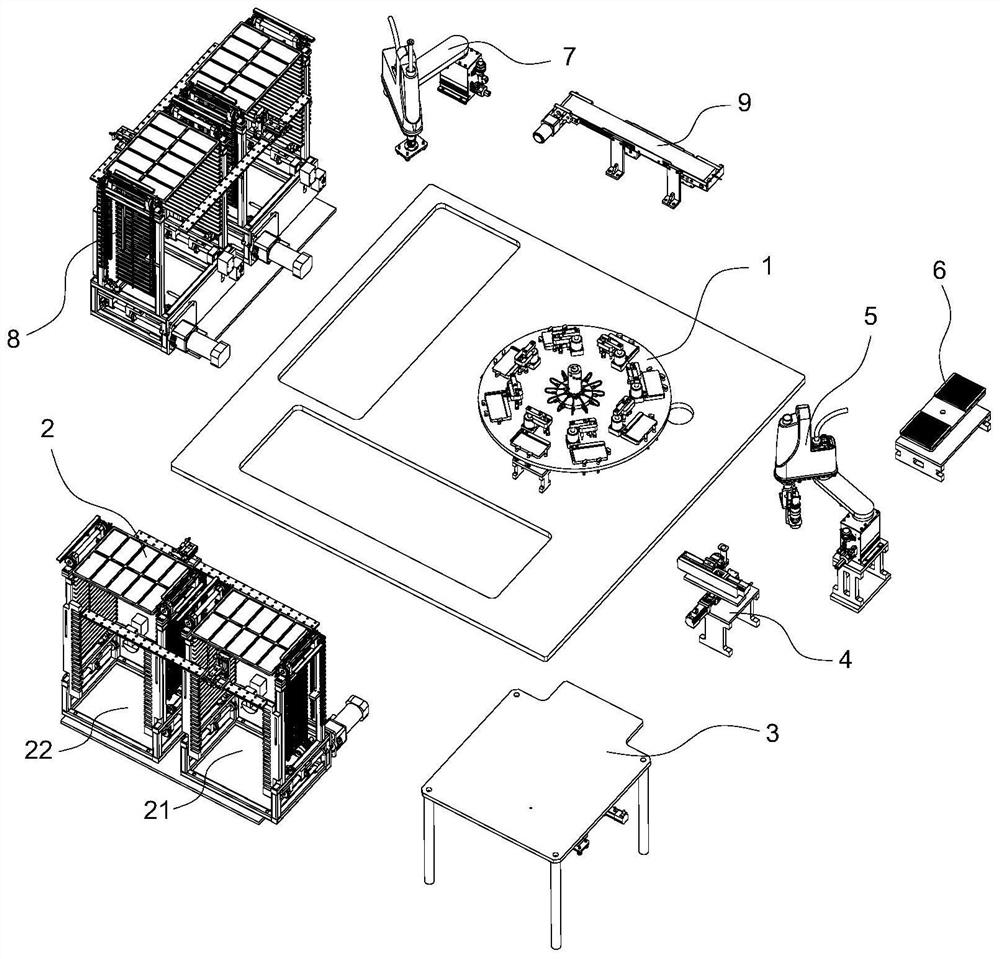

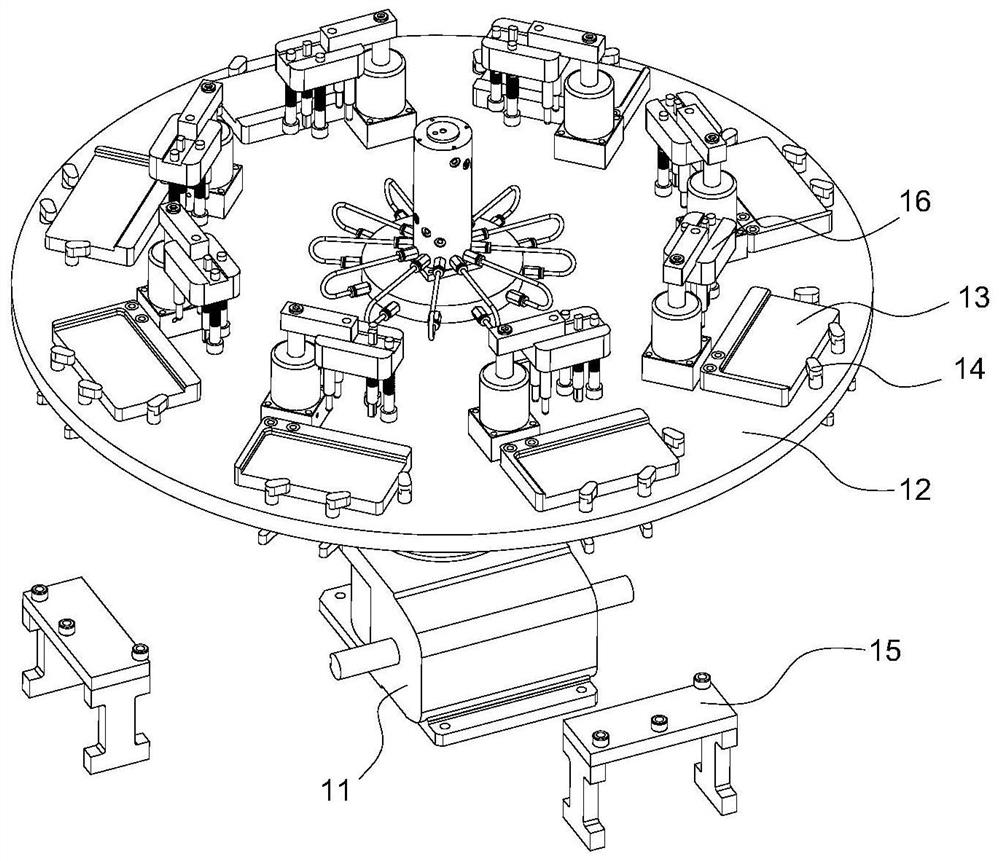

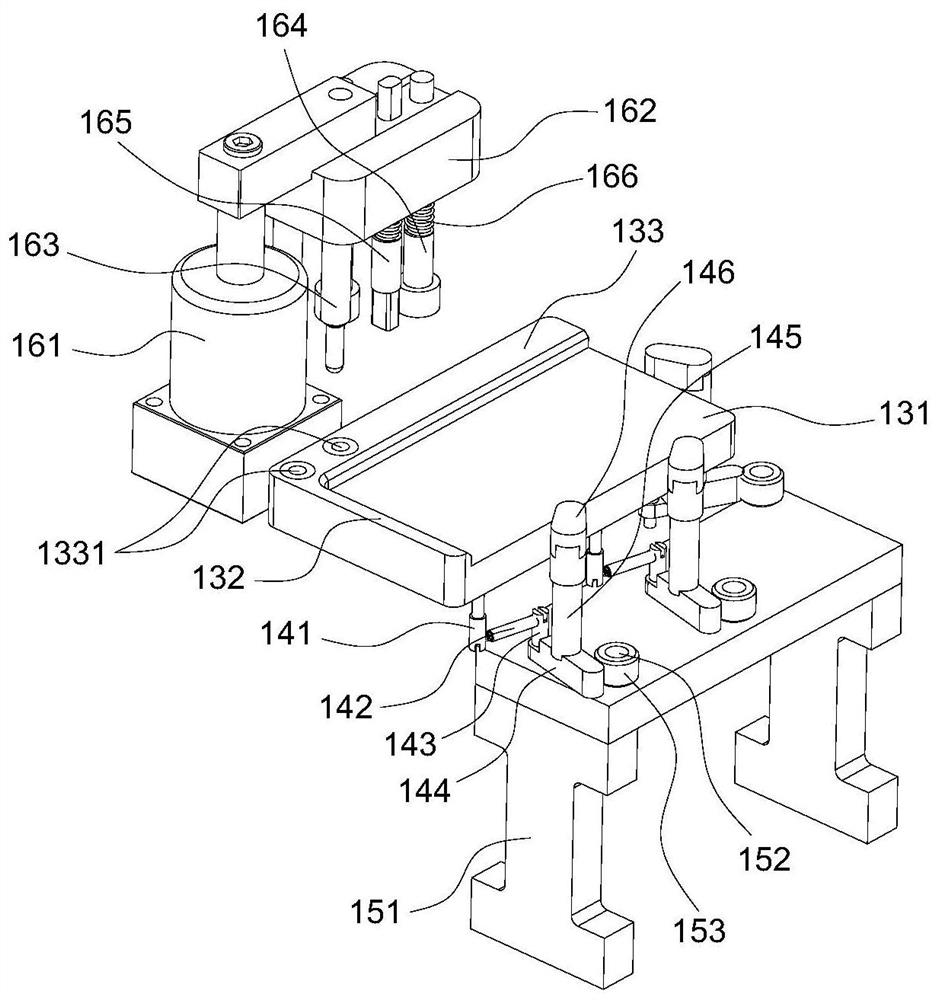

[0032] Such as figure 1As shown, a camera module assembly equipment, the equipment includes a frame and a turntable assembly device 1 installed on the frame, a feeding bin 2, a transfer device 3, a dispensing device 4, a camera module feeding device 6, The robot grabs the feeding device 5 , the robot grabs the unloading device 7 , the qualified product bin 8 and the unqualified product discharging device 9 . The turntable assembly device 1 is sequentially provided with a feeding station, a glue dispensing station, a camera module assembly station, a pressing station and a discharging station. The top of the feeding bin 2 is connected with the transfer device 3 . The position of the transfer device 3 matches the feeding station. The position of the dispensing device 4 matches the dispensing station. The camera module feeding device 6 is located on one side of the robot grabbing feeding device 5 . The position where the robot grabs the feeding device 5 matches the assembly s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com