Electric shockproof hammer convenient to install

An anti-vibration hammer and electric power technology, applied in the direction of mechanical vibration damping device, etc., can solve problems such as the risk of bolt installation process, and achieve the effect of simplifying the installation process and the connection structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

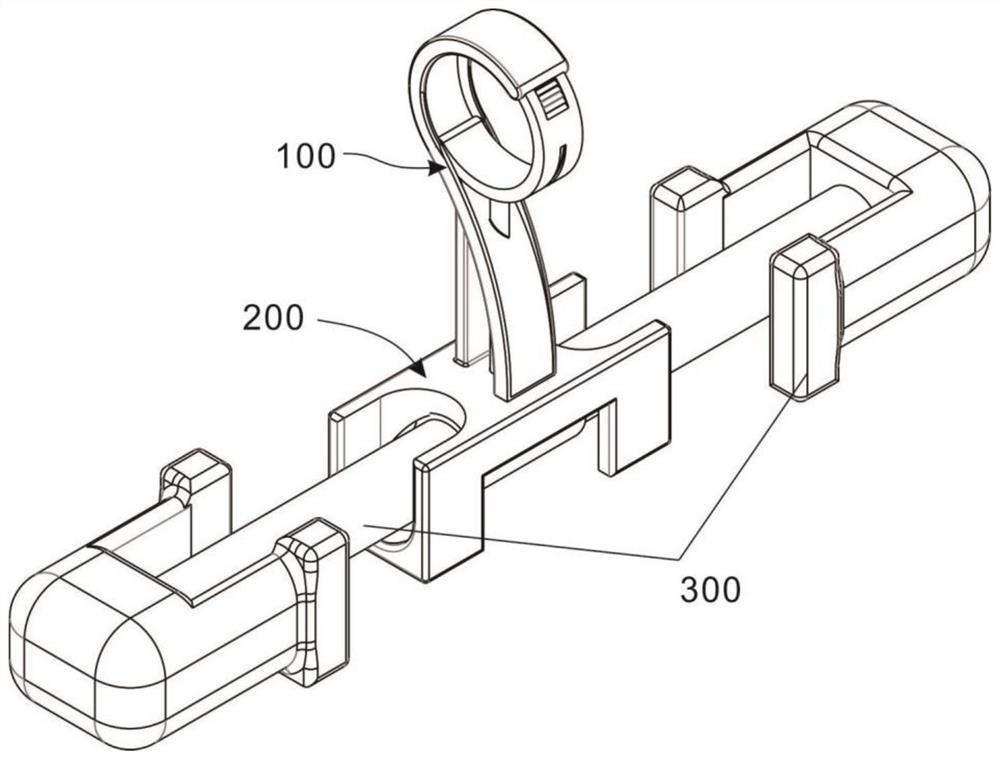

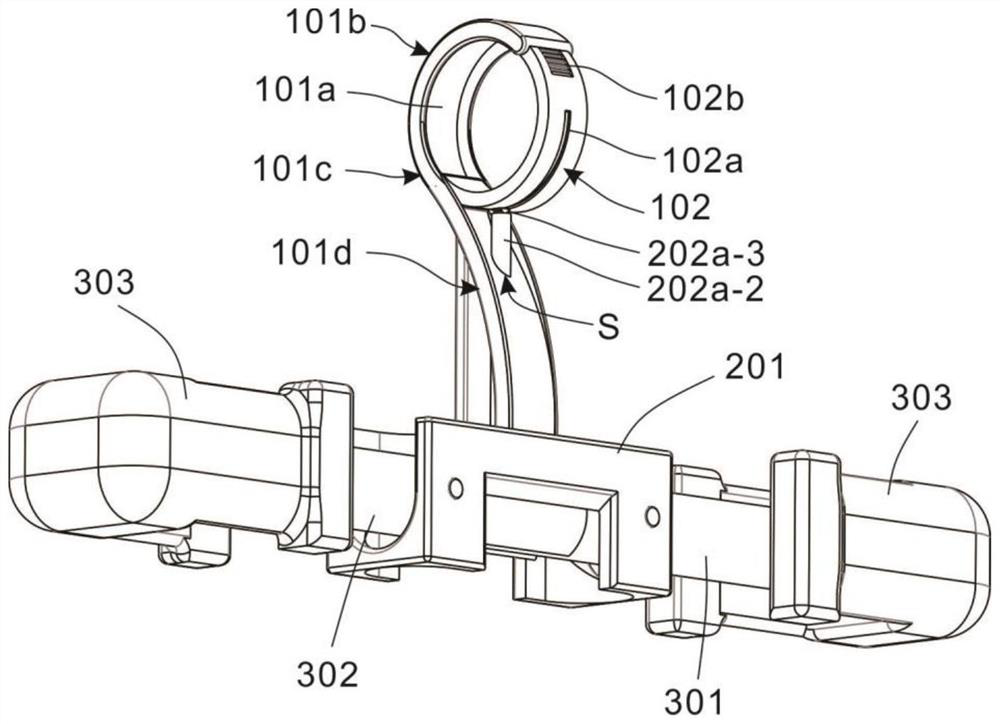

[0033] refer to figure 1 and 2 , as the first embodiment of the present invention, an electric anti-vibration hammer that is easy to install is provided, and the anti-vibration hammer includes a clamp unit 100 , a connection unit 200 and a hammer head unit 300 . Among them, the clamp unit 100 is the part of the anti-vibration hammer used to clamp the power cable, that is, the head of the anti-vibration hammer; the connection unit 200 is used to connect the clamp unit 100 and the hammer unit 300; the hammer unit 300 is a traditional anti-vibration hammer The hammer head style is used to reduce the vibration on the power cable. Further, the hammer head unit 300 is used to provide the driving force when the clamp unit 100 is clamped. The difference from the traditional anti-vibration hammer is that the hammer at both ends The head is a split structure.

[0034] Specifically, the wire clamp unit 100 includes a wire clamp hook 101 and an arc-shaped clamping plate 102 connected to...

Embodiment 2

[0038] refer to figure 1 , 2 , 4 and 6 are the second embodiment of the present invention. This embodiment is different from the first embodiment in that: the clamp hook 101 has a limiting groove 101a along its plate side wall, and the limiting groove 101a Distribute the side of the plate body of the wire clamp hook 101; the wire clamp hook 101 is divided into a bending part 101b, a neck 101c and a connecting part 101d from top to bottom as a whole, and the limiting groove 101a starts from the end of the bending part 101b and finally connects The bottom of the part 101d; the sidewall of the neck 101c is provided with a through hole S; the connecting part 101d is fixed on the top sidewall of the connecting shell 201 .

[0039] An assembly groove 101e is provided in the limit groove 101a at the end of the bending portion 101b, and the limit fastener 103 is installed in the assembly groove 101e; the assembly groove 101e is divided into a first end 101e-1 and a second end 101e-2,...

Embodiment 3

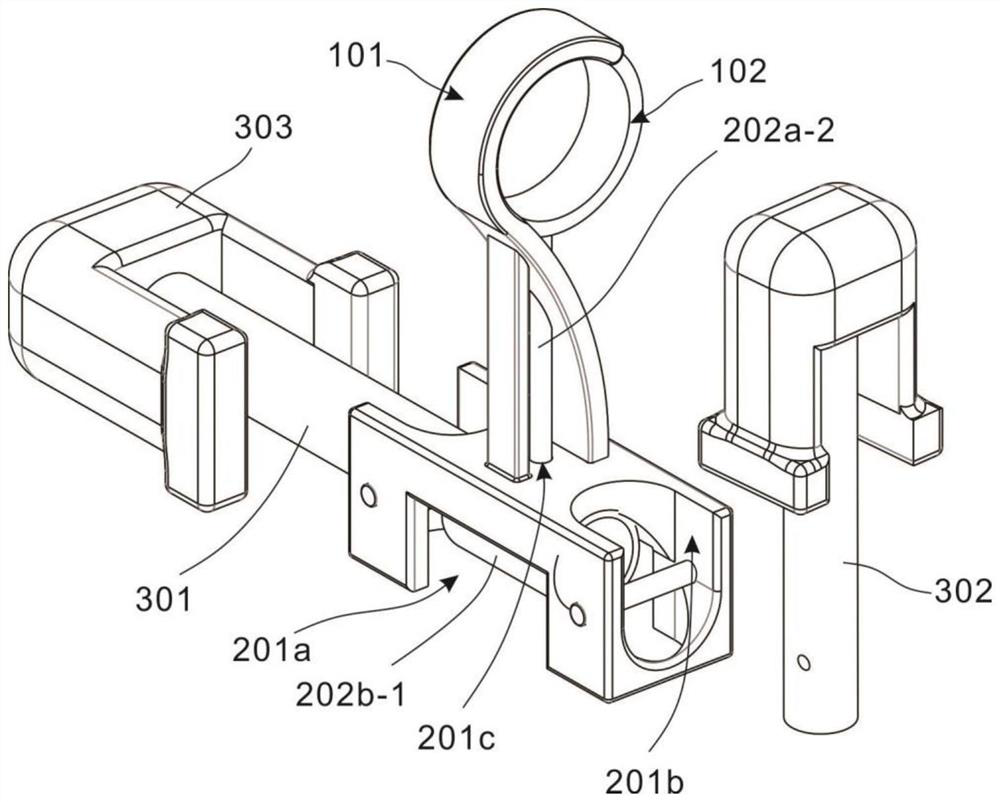

[0049] refer to Figure 1-7 , which is the third embodiment of the present invention. This embodiment is different from the second embodiment in that: a mounting groove 201a is opened in the side wall of the lower end of the connection housing 201, and limiting grooves 201b are symmetrically opened on the side walls of both ends. , and a connecting hole 201c is opened on the side wall of the middle part thereof.

[0050] The connection assembly 202 includes a driving part 202a and a connecting part 202b, both of which are mated and connected. One end of the driving part 202a is located in the installation groove 201a, the other end extends in the wire clip hook 101, and the connecting part 202b is arranged in the installation groove 201a.

[0051] The driver 202a includes an arc-shaped drive plate 202a-1 and a drive rod 202a-2 connected to the top side wall of the arc-shaped drive plate 202a-1, wherein the arc-shaped drive plate 202a-1 is located in the installation groove 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com