Eccentric clamping fixture

An eccentric clamping and fixture technology, applied in the direction of clamping, manufacturing tools, support, etc., can solve the problem that the clamping jaw cannot guarantee the clamping accuracy, etc., and achieve the effect of convenient modification, tight fit and simple clamping structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

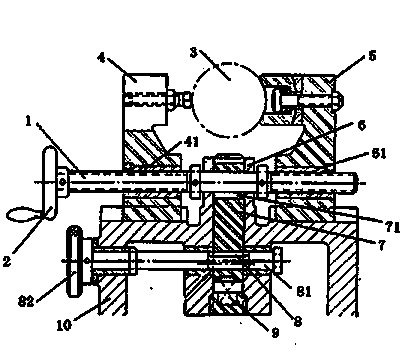

[0016] combined with figure 1 The shown eccentric clamping fixture includes a base 10 and a threaded column 1, wherein the end of the threaded column 1 is fixedly connected with a hand wheel 2, and left and right external thread sections of the same length are provided at both left and right ends of the threaded column 1 41 and right threaded section 42, threaded column 1 middle part has a section of blank section, left external threaded section 41 and right threaded section 42 have the opposite direction of thread rotation, left external threaded section 41 and right threaded section 42 are evenly connected with splints, left The splint 4, and the middle part of the right splint 5 are all provided with through holes, and the left threaded sleeve 41 and the right threaded sleeve 51 of the opposite direction of rotation are welded in the two through holes, and the left splint 4 and the right splint 5 are all connected to the base 10 The other end of the sliding connection is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com