Chuck

A collet and clamping technology, which is applied in the field of collets for clamping working heads, can solve problems such as inconsistent fit gaps between parts and working heads, deviations in shape and position tolerances, and vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

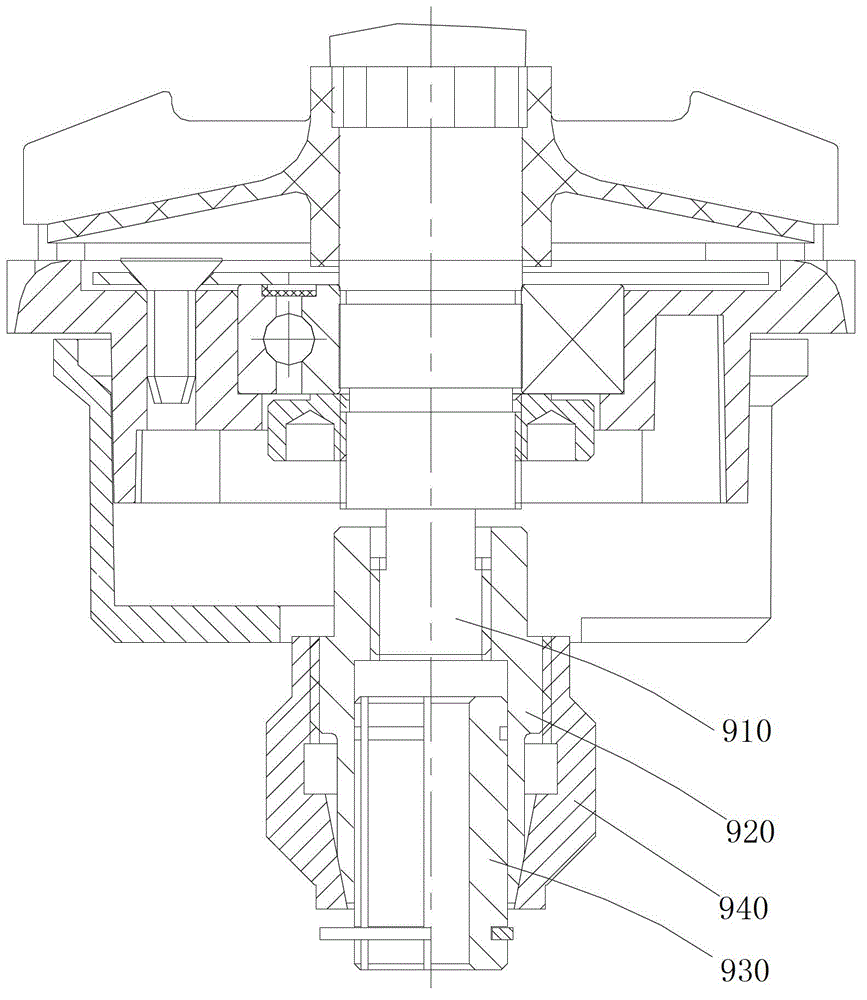

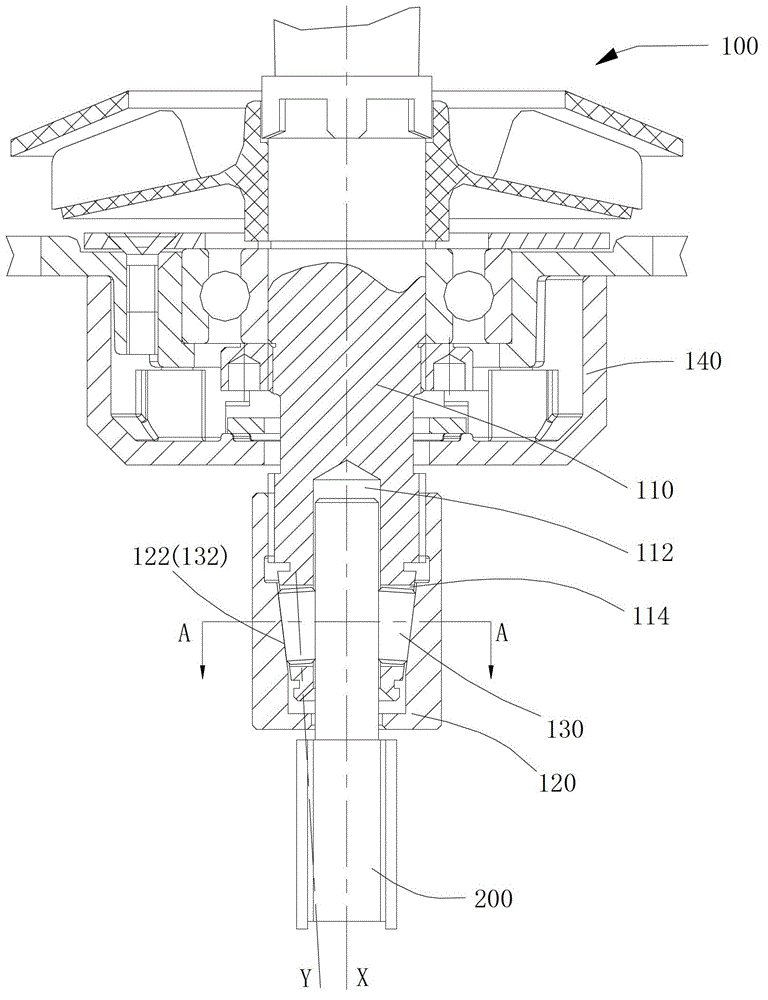

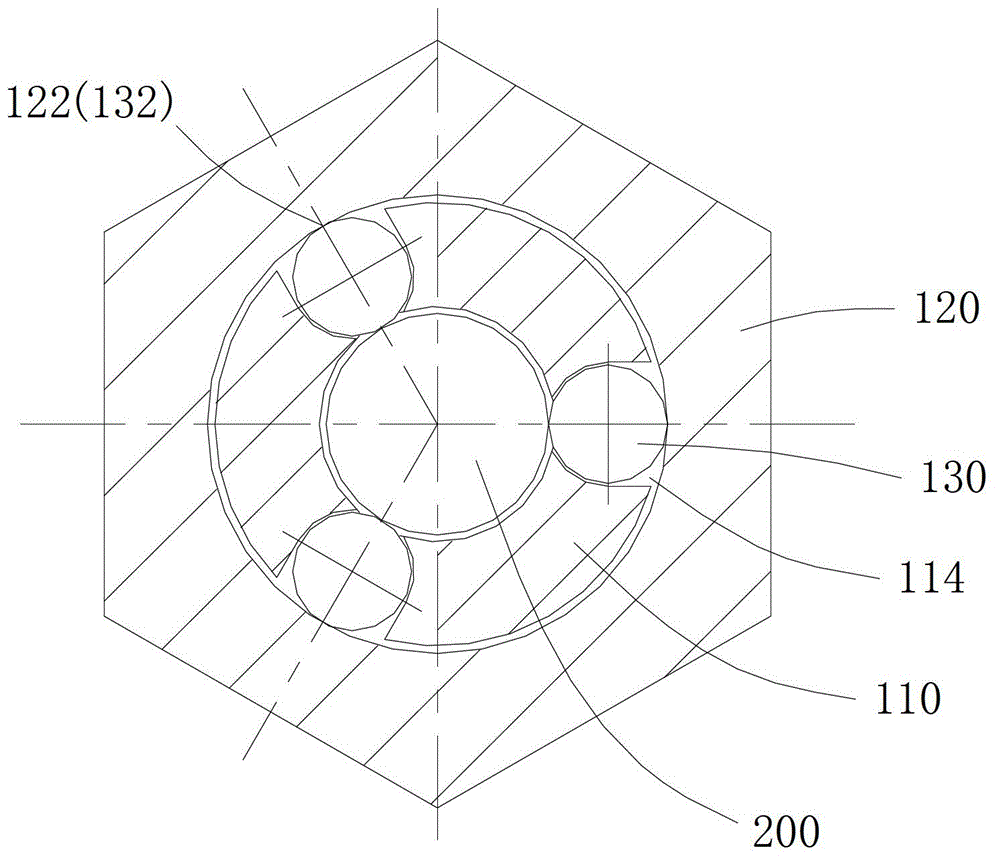

[0030] The preferred embodiment of the chuck will be described below in conjunction with the accompanying drawings.

[0031] Please refer to Figure 2 to Figure 5 , discloses a collet 100 for clamping and releasing a working head 200. The collet 100 can be applied to power tools, such as electric wood milling, wrench, drill and other power tools.

[0032] In one embodiment, the collet 100 includes a main shaft 110 , a lock nut 120 sleeved on the outside of the main shaft 110 , and a locking member 130 for locking the working head 200 . The main shaft 110 can be the output shaft of the motor, and can also be connected with the motor shaft, so that the main shaft 110 can realize rotation or impact motion. The collet 100 can clamp different types of working heads, so that the power tool can realize different functions, such as clamping a fastening head when realizing the function of an impact wrench, or clamping a milling cutter when realizing milling.

[0033] Please refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com