Synchronous transmission mechanism for air inlet guide vanes of axial flow air compressor

A technology of axial flow compressor and synchronous transmission, which is applied in the direction of machines/engines, liquid fuel engines, and components of pumping devices for elastic fluids, etc. It can solve problems such as large size, complex structure, and small installation space, and achieve The effect of increased range of motion, simple clamping structure, and many rotating parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

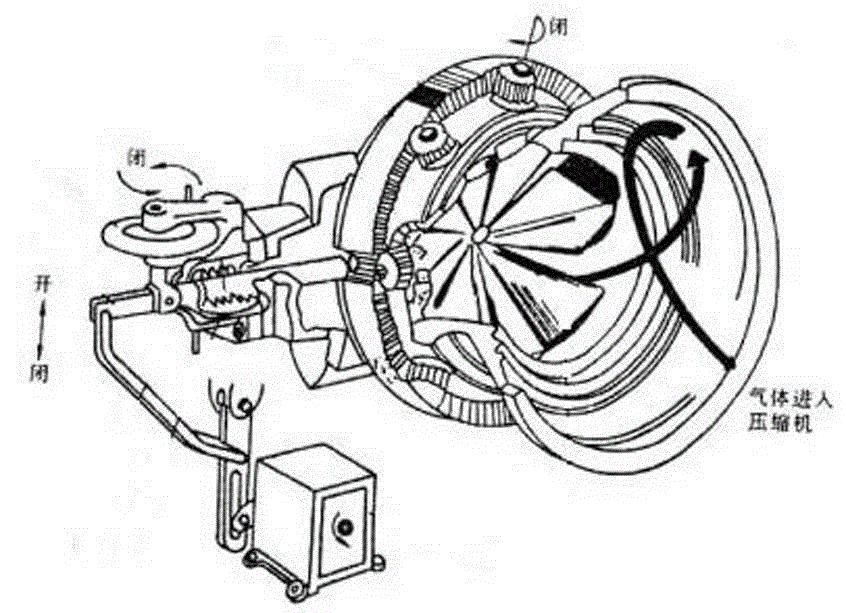

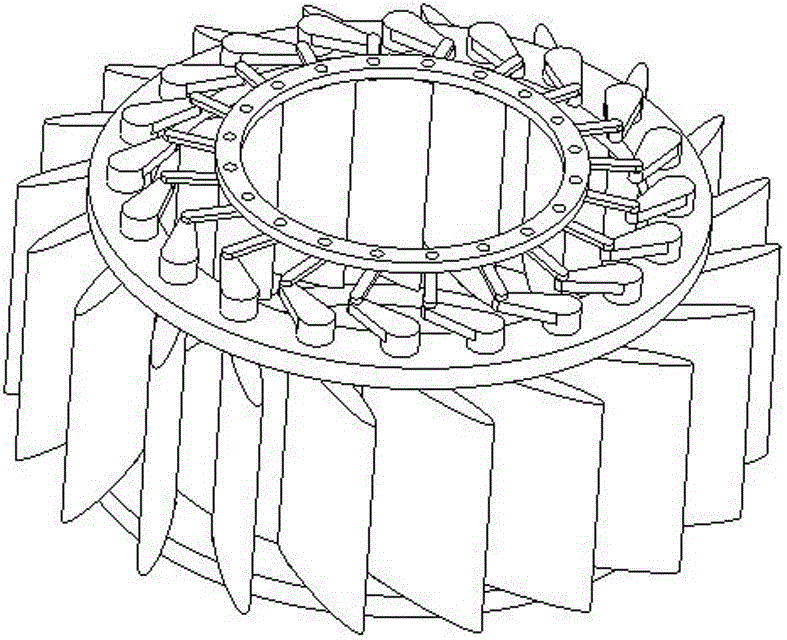

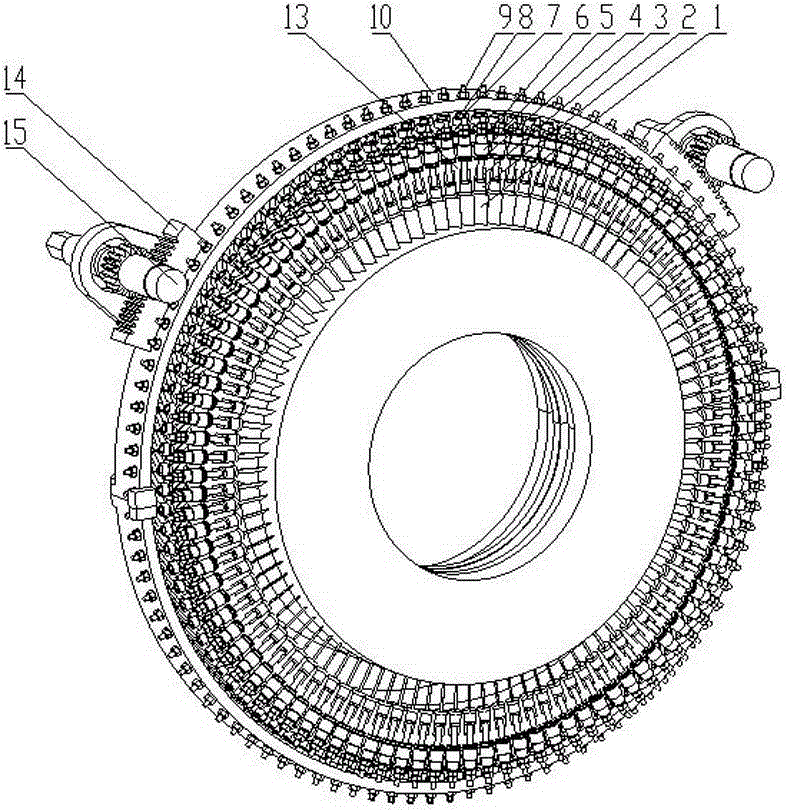

[0023] Such as Figure 3-6 As shown, the present invention is a synchronous transmission mechanism for the inlet guide vane of an axial flow compressor, and the inlet guide vane 1 of the axial flow compressor includes a working part and a rotating shaft part connected as one. Specifically: the working part of the intake guide vane 1 is in the shape of a blade, and is evenly distributed in the radial direction on the annular intake passage of the axial flow compressor; the number of intake guide vanes 1 on the cylinder block 13 of the axial flow compressor corresponds An installation hole for inserting the rotating shaft is provided, and the end of the rotating shaft protrudes from the outer peripheral surface of the cylinder 13 . Such design makes the installation position of the inlet guide vane 1 limited, but the rotating shaft part can rotate in the installation hole, and the rotating shaft part drives the working part to rotate, thereby changing the angle of the working pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com