Curved prism, curved prism assembly and processing method thereof

A technology of curved prisms and components, applied in prisms, optical elements, installation, etc., can solve the problems of difficult phase adjustment of prisms, difficult installation and fixation of curved prisms, and achieve good implementability, high reliability, and simple clamping structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

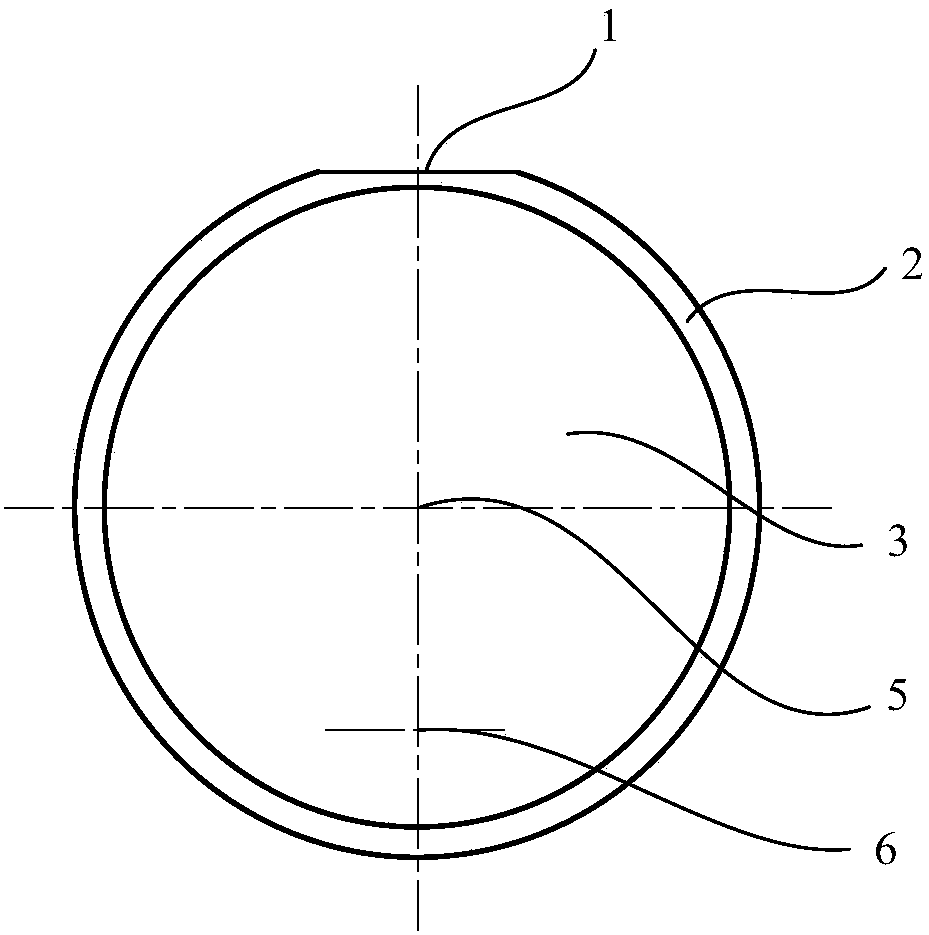

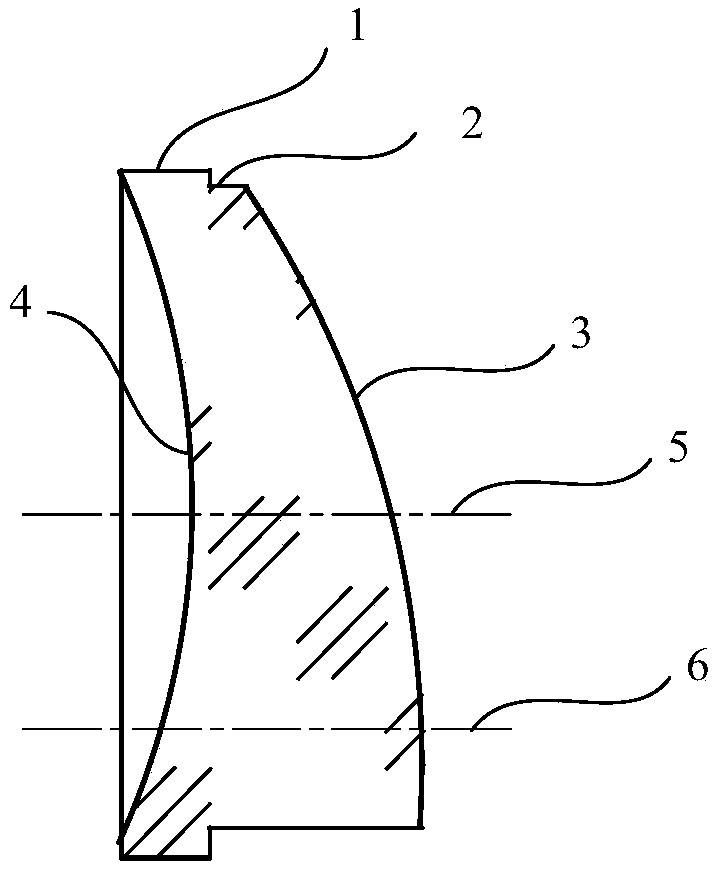

[0028] A curved prism, comprising a concave surface 4 and a convex surface 3, the outer surface of the curved prism is provided with a step chamfer 2, the step chamfer 2 divides the outer surface into a large-diameter side and a small-diameter side; the large-diameter side is a cylindrical truncated body On the outer side, the sectional surface of the cylindrical truncated body is the phase positioning flat end surface 1; the phase positioning flat end surface 1 is parallel to the optical axis 5 of the concave surface. The phase positioning flat end surface 1 is perpendicular to the main section of the optical axis defined by the optical axis 5 of the concave surface and the optical axis 6 of the convex surface. The stepped surface of the stepped chamfer 2 is perpendicular to the optical axis 5 of the concave surface.

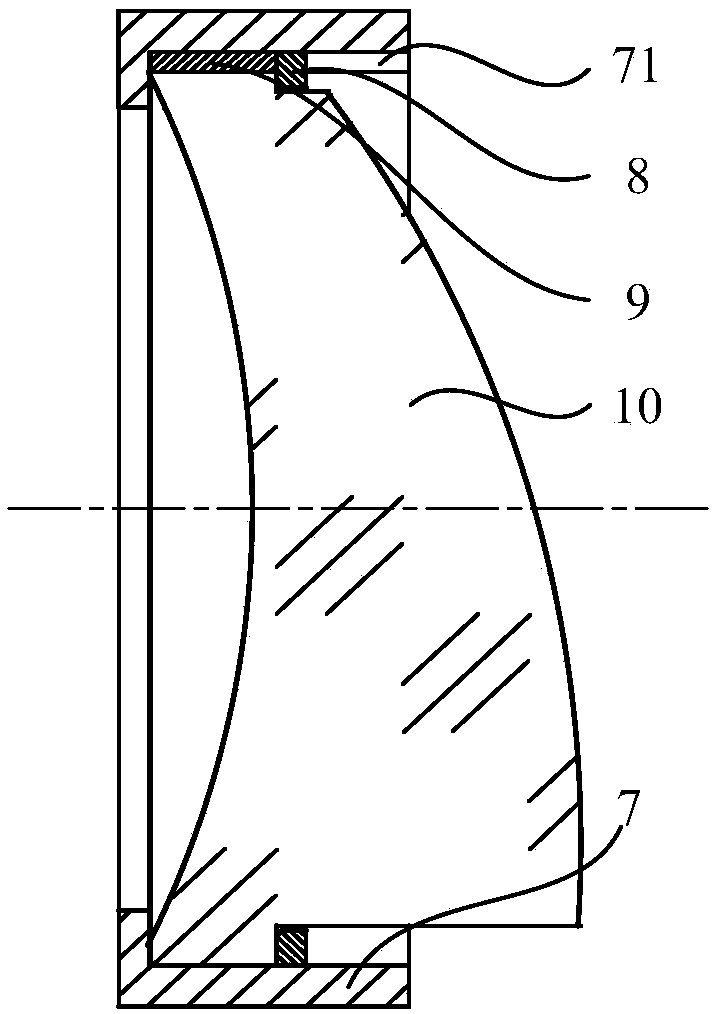

[0029] A curved prism assembly, comprising a curved prism, a picture frame 7, a threaded pressure ring 8 and a positioning block 9; the inner hole of the pictu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com