Double-sided gas-assisted device for pulse laser welding of metal sheets

A thin metal plate and pulse laser technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult control of welding dimensional accuracy, lack of multi-directional positioning and fixing, affecting appearance and surface quality, etc., to achieve surface Improved oxidation quality, reasonable structural design, and improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

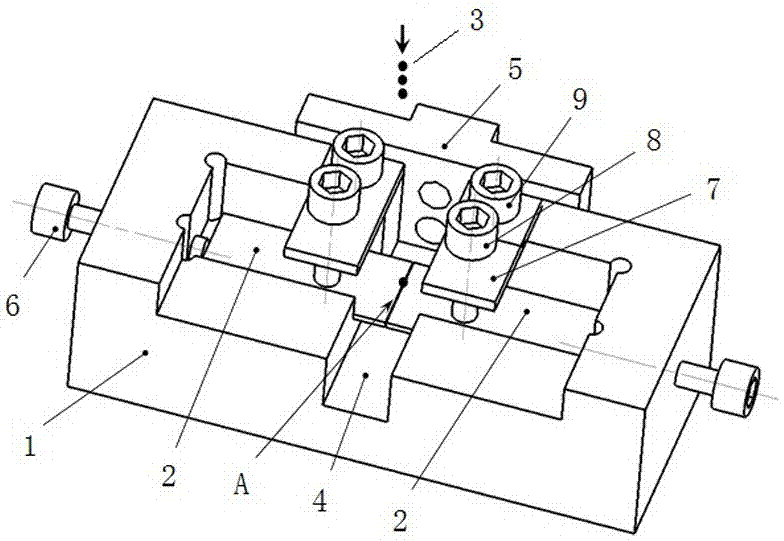

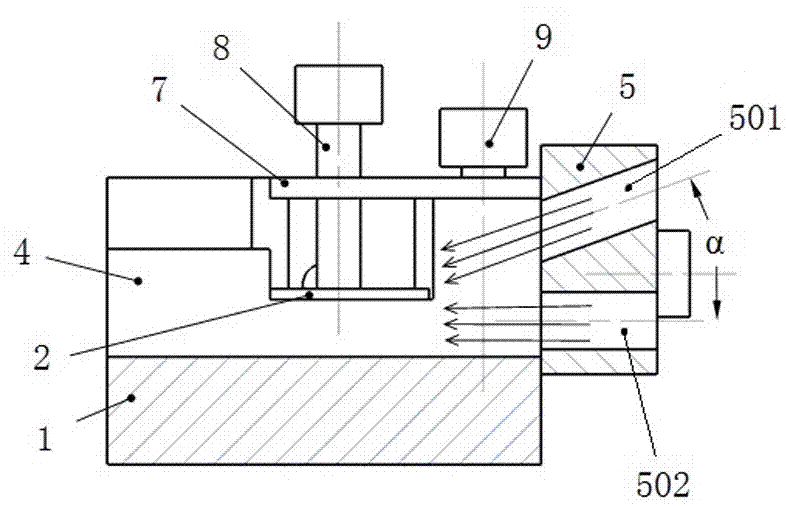

[0029] Such as Figure 1~2 As shown, a double-sided gas-assisted device for pulsed laser welding of thin metal plates includes a base 1, and the base 1 is provided with a concave cavity for placing at least two thin metal plates 2 to be welded, and all the thin metal plates 2 are arranged side by side. Setting, a pulsed laser beam 3 is arranged above the seam A of any two adjacent metal sheets 2, and a through groove 4 is provided below the seam A of any two adjacent metal sheets 2, so The base 1 is provided with an air intake insert 5 at one end of the through groove 4, and the air intake insert 5 is provided with an upper air intake hole 501 facing the upper surface of the metal sheet 2 and a lower air intake hole facing the lower surface of the metal sheet 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com